The intricate workings of an engine require a thorough understanding of its various components and their interrelations. A comprehensive visual representation can significantly aid in grasping the complex assembly and functionality of these mechanical parts. Such illustrations serve as invaluable resources for both enthusiasts and professionals seeking to enhance their knowledge and maintenance skills.

In exploring these schematics, one can appreciate the importance of each element within the system. From the core components that generate power to the supporting features that ensure smooth operation, every piece plays a crucial role. Delving into this visual guide allows for better troubleshooting, repairs, and upgrades, leading to improved performance and longevity.

Whether you’re a seasoned mechanic or a curious hobbyist, having access to detailed outlines can facilitate a deeper understanding of how to optimize engine performance. By familiarizing yourself with the layout and relationships of the various elements, you can make informed decisions that contribute to the overall efficiency and reliability of the machinery in question.

Understanding Kohler CH740 Components

This section delves into the various elements that contribute to the functionality of a specific engine model. Each component plays a vital role in ensuring the optimal performance and longevity of the engine. By familiarizing yourself with these key parts, you can better appreciate how they work together to drive efficiency and reliability in operation.

The main sections of this engine encompass critical mechanisms, from power generation to fuel management. Understanding the interplay between these components is essential for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Cylinder Head | Encloses the combustion chamber, facilitating the intake and exhaust processes. |

| Piston | Converts the force from combustion into mechanical energy, driving the crankshaft. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion to power the engine. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber for efficient burning. |

| Ignition System | Initiates combustion by providing the necessary spark to ignite the fuel-air mixture. |

| Cooling System | Maintains optimal operating temperature by dissipating excess heat from the engine. |

Key Features of the CH740 Engine

The engine under discussion is designed to deliver robust performance and reliability in a variety of applications. It incorporates advanced engineering principles, ensuring efficiency and durability, making it a preferred choice for both professional and personal use.

Power and Efficiency

This model stands out with its impressive power output, enabling it to handle demanding tasks with ease. The innovative design optimizes fuel consumption, allowing for longer operational periods without frequent refueling, which is essential for extensive projects.

Durability and Maintenance

Constructed with high-quality materials, this engine boasts exceptional resilience against wear and tear. Its user-friendly maintenance features simplify upkeep, ensuring that users can perform routine checks and repairs with minimal effort. Reliability is a hallmark of this engine, providing peace of mind during operation.

Parts Identification for Maintenance

Understanding the various components of your engine is crucial for effective upkeep and performance optimization. Accurate identification of each element ensures that maintenance tasks are carried out efficiently, leading to prolonged functionality and reliability. This section provides a comprehensive overview of key elements to be aware of when performing service checks.

| Component | Description | Importance |

|---|---|---|

| Cylinder Head | Houses valves and provides the necessary sealing for combustion. | Essential for maintaining engine pressure and efficiency. |

| Piston | Moves within the cylinder to compress air-fuel mixture and generate power. | Critical for converting combustion energy into mechanical work. |

| Crankshaft | Transforms linear motion from the piston into rotational energy. | Vital for engine movement and overall performance. |

| Fuel System | Delivers the necessary fuel mixture to the engine for combustion. | Directly impacts power output and efficiency. |

| Ignition System | Initiates the combustion process by igniting the fuel-air mixture. | Crucial for starting and maintaining engine operation. |

By familiarizing yourself with these critical components, you can ensure that your maintenance practices are both effective and timely, ultimately extending the lifespan of your engine.

Common Repairs and Solutions

When dealing with small engines, it’s essential to understand the most frequent issues that may arise and how to address them effectively. This section highlights typical problems that users encounter, along with practical solutions to ensure smooth operation and longevity of the equipment.

1. Fuel System Troubles: Clogs in the fuel line or a dirty carburetor can lead to poor engine performance. To remedy this, regularly check and clean the fuel system components. Replacing fuel filters and ensuring the fuel is fresh can greatly improve functionality.

2. Ignition Difficulties: If the engine fails to start, the ignition system may be at fault. Inspect the spark plug for wear and replace it if necessary. Additionally, ensuring all electrical connections are secure can prevent intermittent issues.

3. Oil Leaks: Oil leaks can stem from worn gaskets or seals. Inspect the engine carefully and replace any damaged components to prevent loss of lubrication, which could result in serious damage.

4. Overheating: Engines can overheat due to blockages in the cooling system or low coolant levels. Regularly check the cooling system for debris and ensure that coolant levels are adequate to maintain optimal operating temperatures.

5. Vibration and Noise: Excessive vibration or unusual noises may indicate misalignment or loose parts. Tightening bolts and inspecting mounts can help resolve these issues, ensuring a quieter and smoother operation.

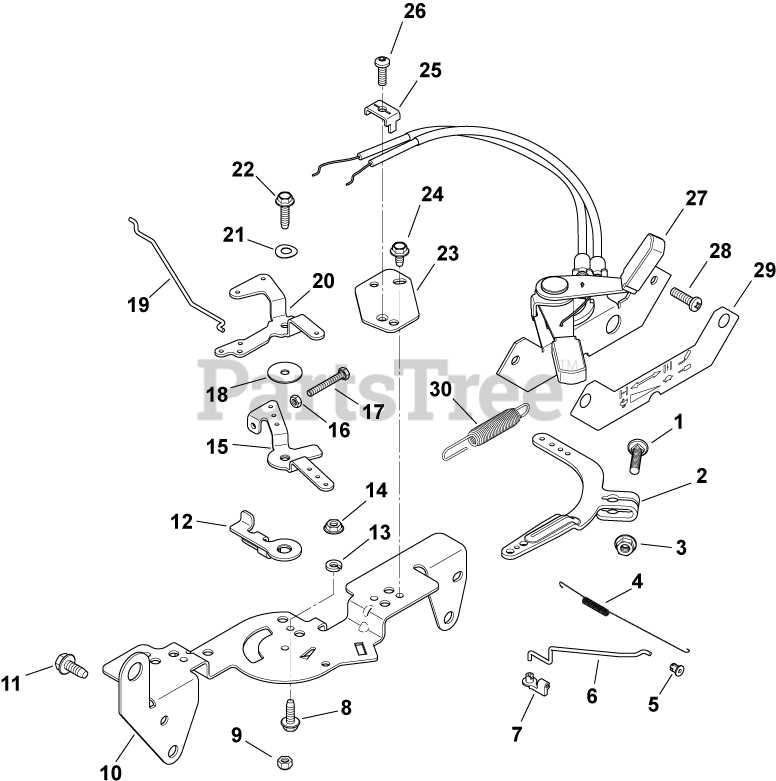

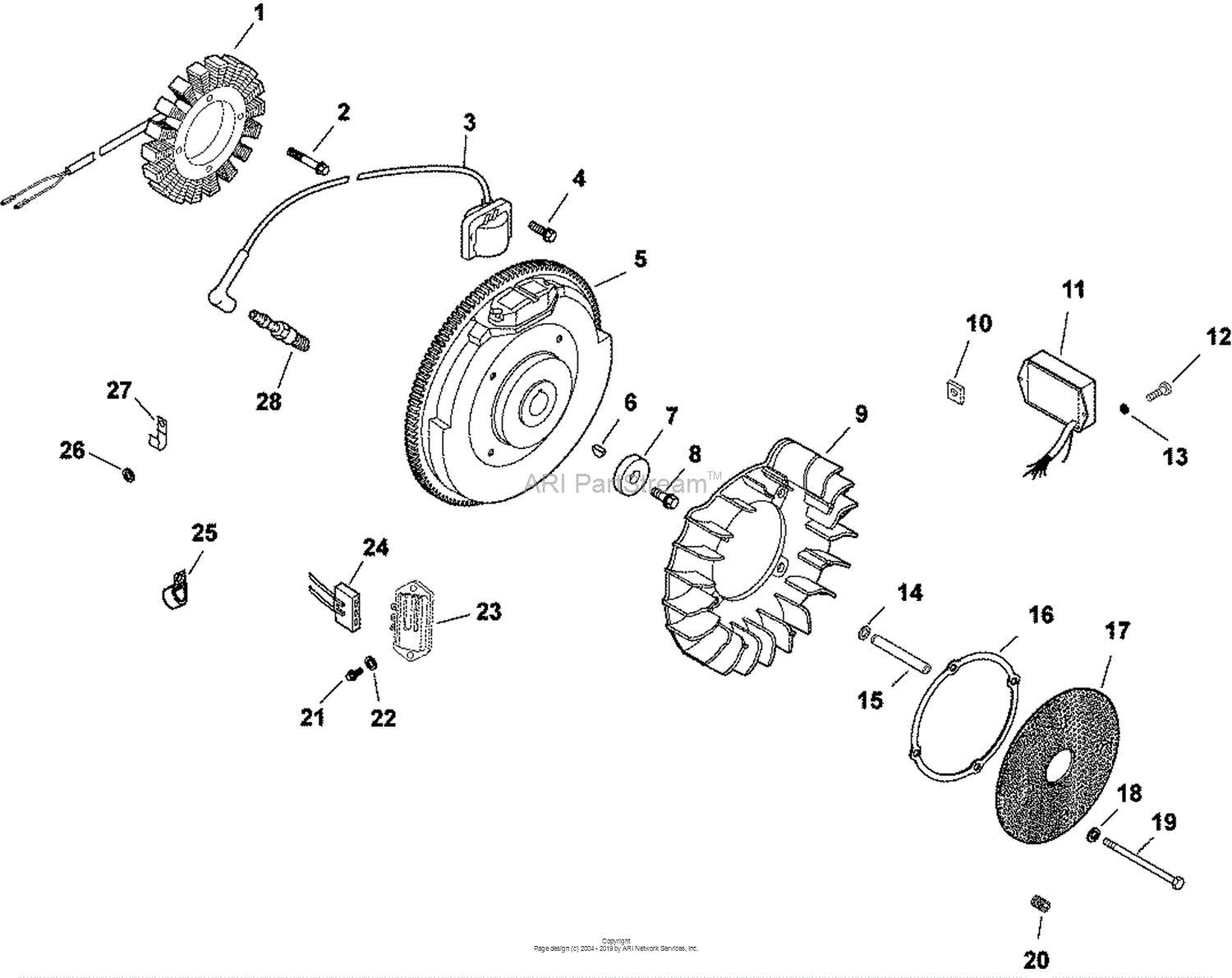

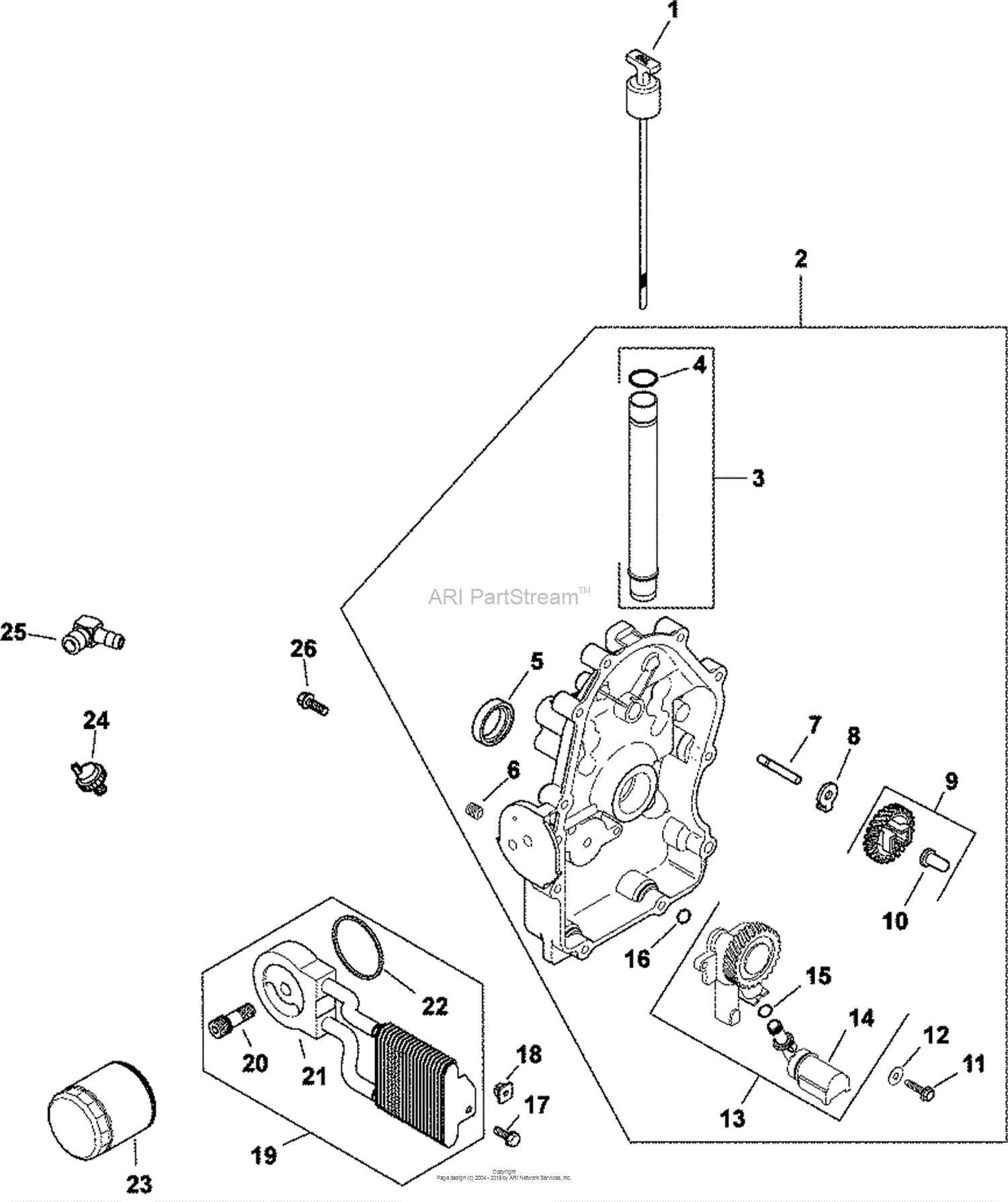

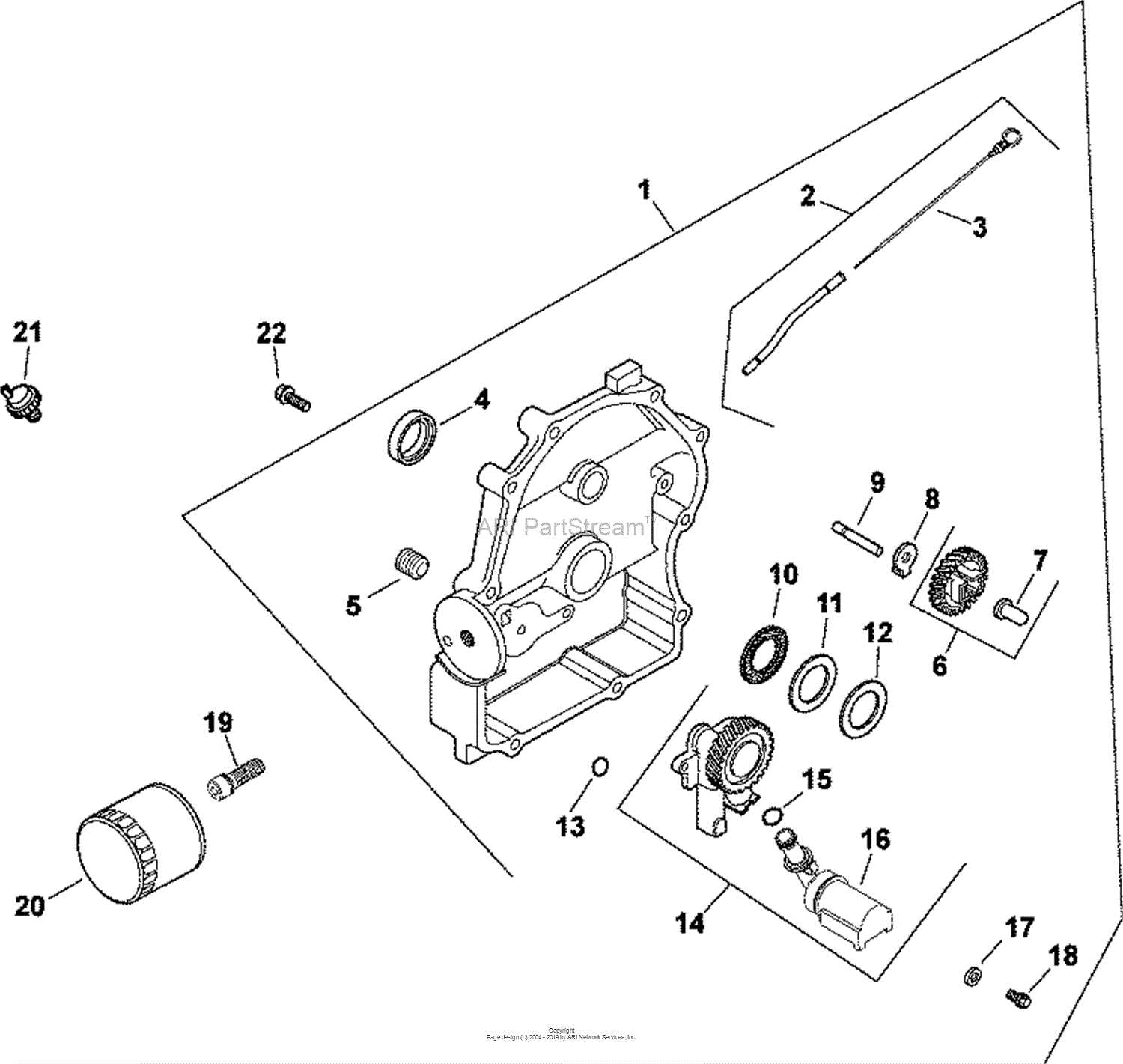

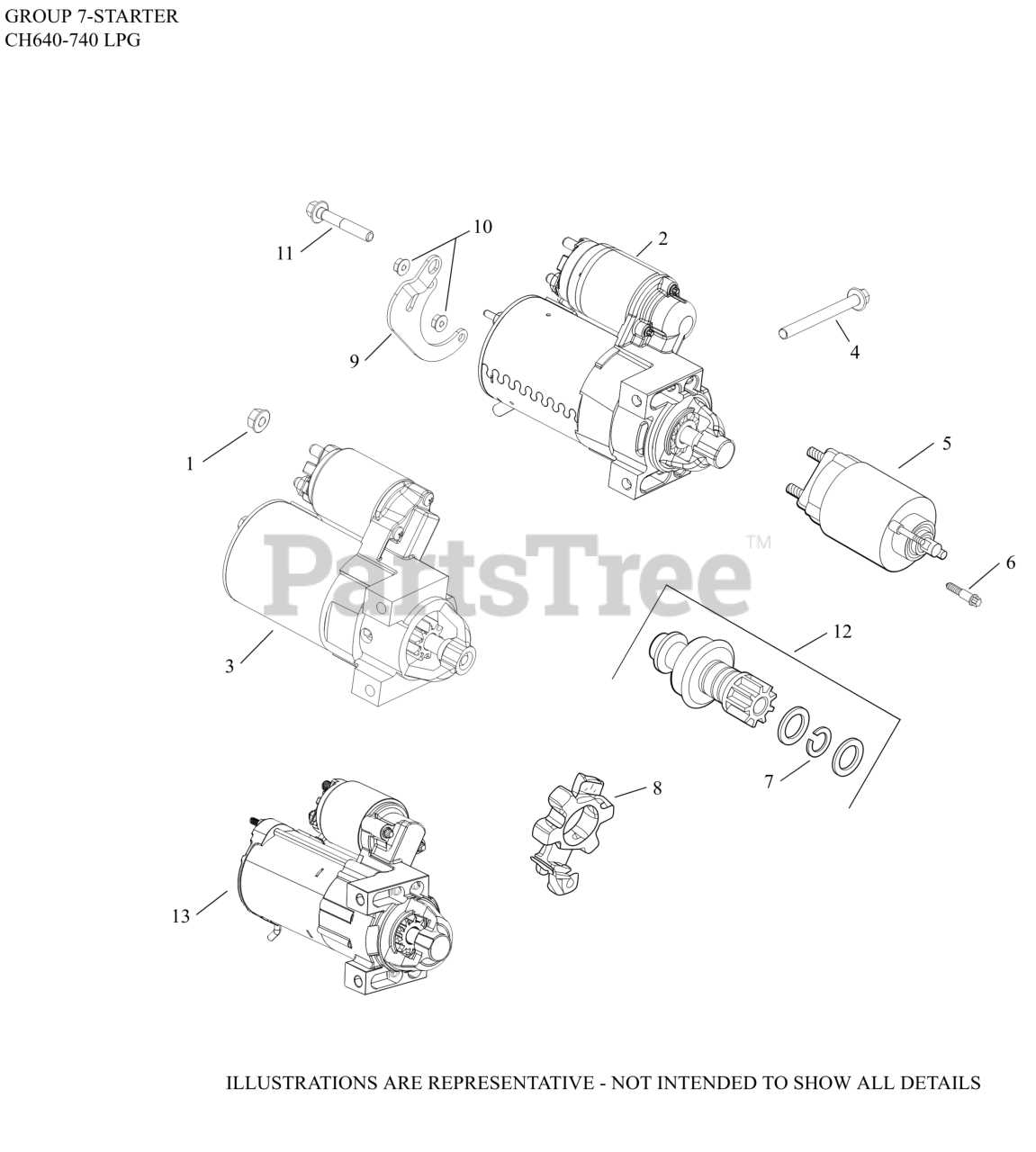

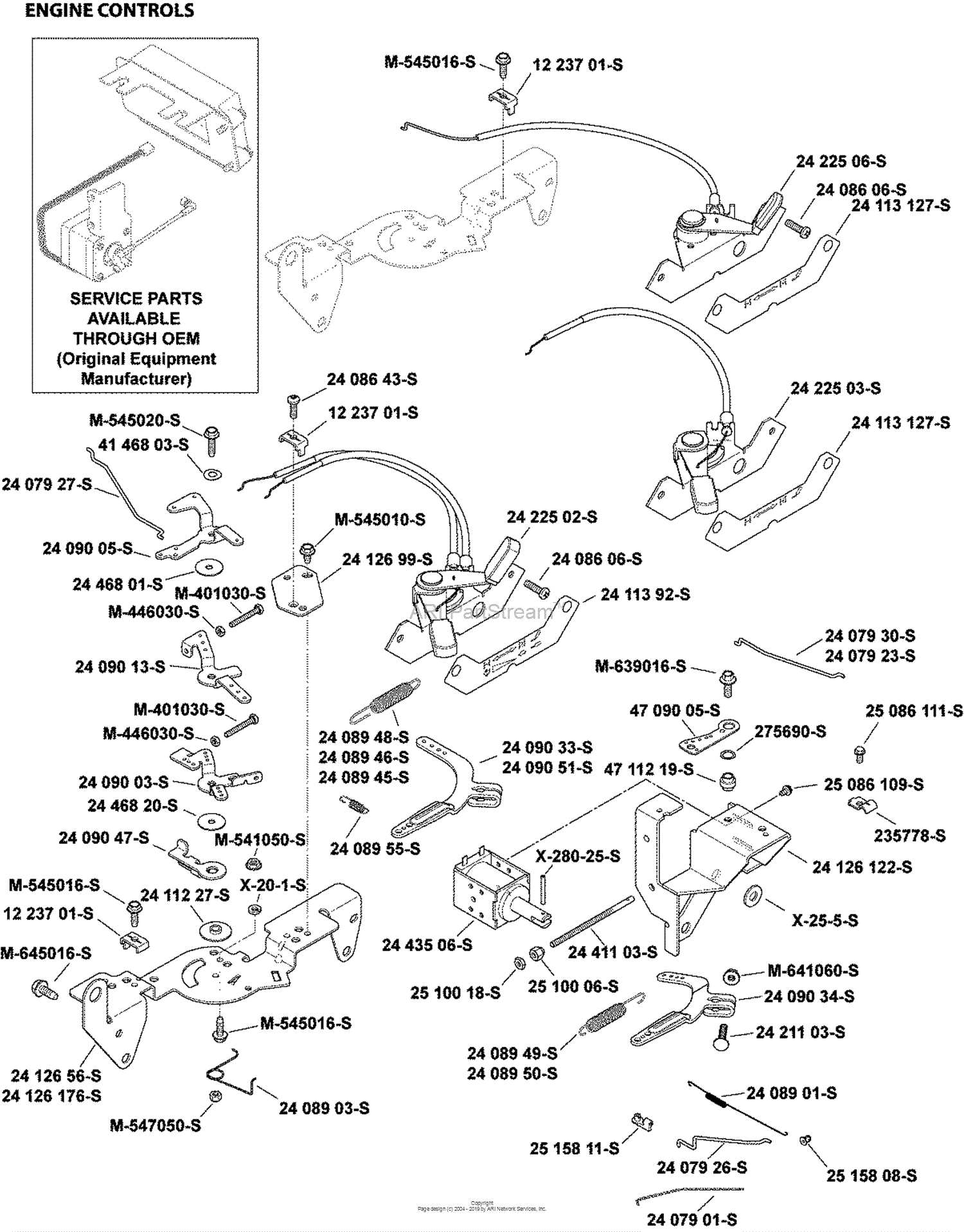

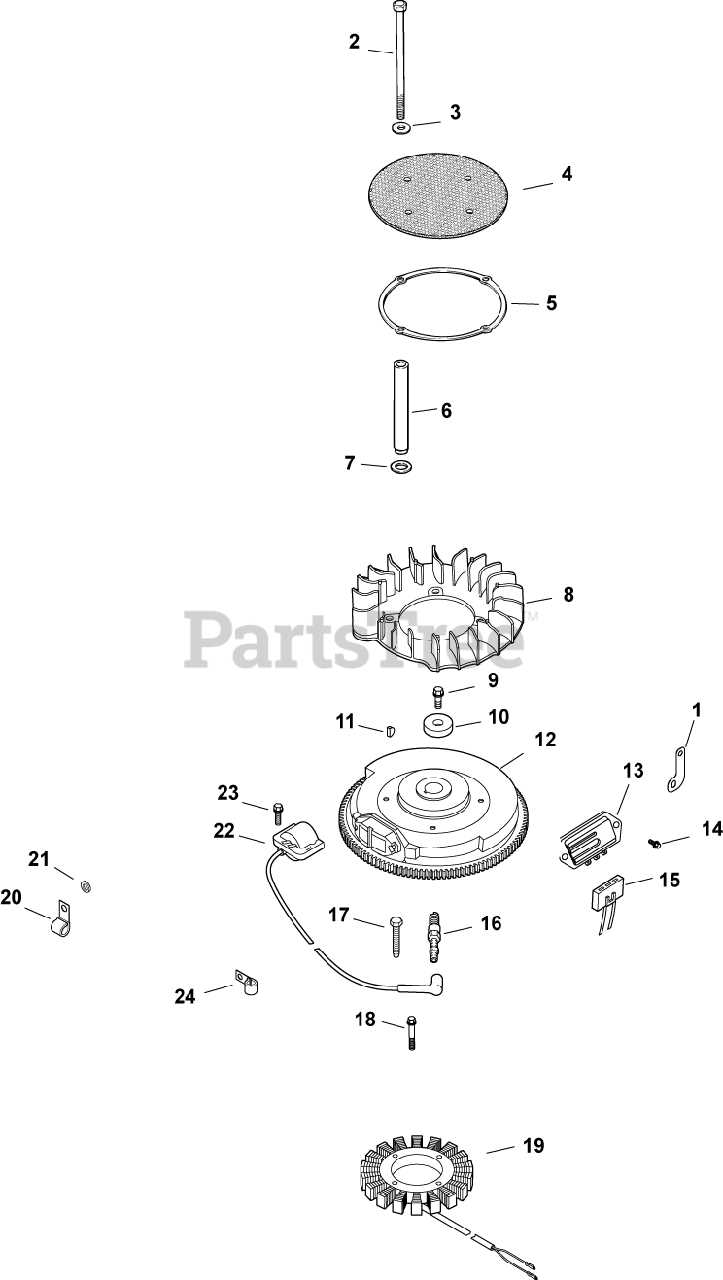

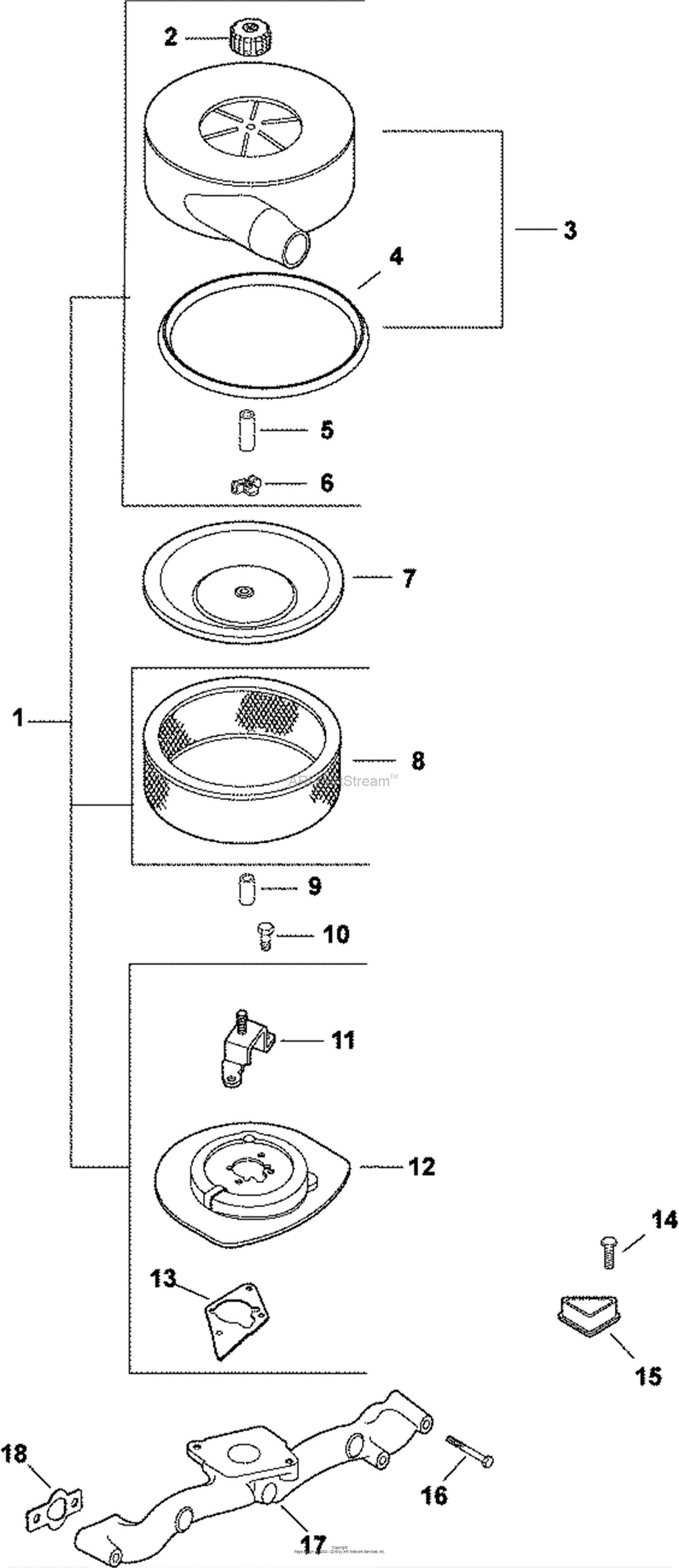

Exploring the Parts Diagram

Understanding the intricate components of a machine is crucial for effective maintenance and repair. By examining a detailed schematic representation, users can gain insight into how various elements interact, ensuring optimal performance and longevity of the equipment. This section delves into the key features of such a visual guide.

Among the most valuable aspects of this illustration are:

- Identification of Components: Each segment is clearly marked, facilitating easy recognition of individual elements.

- Functional Relationships: The layout reveals how different parts collaborate, providing a holistic view of the machinery.

- Maintenance Tips: Notations within the visual aid often highlight maintenance intervals and common issues, aiding in proactive care.

- Assembly Guidance: Step-by-step references help in reassembling parts after repairs, minimizing the risk of errors.

Utilizing such a schematic not only enhances comprehension but also empowers users to undertake repairs confidently. Familiarity with this visual resource ultimately leads to more informed decision-making when addressing operational concerns.

Ordering Genuine Kohler Parts

When it comes to maintaining the performance and longevity of your equipment, sourcing authentic components is essential. Using original pieces ensures compatibility and reliability, which ultimately enhances the overall functionality of your machinery. In this section, we will explore the process of acquiring these vital elements for optimal operation.

Researching Authorized Suppliers is the first step in your journey to obtaining authentic components. Look for reputable dealers who specialize in genuine items and have a proven track record of customer satisfaction. Reading reviews and checking ratings can help you identify trustworthy sources.

Once you’ve found reliable suppliers, understanding the ordering process is crucial. Most suppliers offer online catalogs where you can browse available items and check their specifications. Be sure to gather all relevant information, such as model numbers and descriptions, to ensure you select the correct components.

Finally, placing your order should be straightforward. Many vendors provide user-friendly platforms for making purchases, allowing you to choose your desired items and proceed to checkout seamlessly. Pay attention to shipping options and return policies, ensuring a smooth transaction and peace of mind.

Assembly and Disassembly Guide

This section provides essential instructions for assembling and disassembling the equipment effectively. Whether you are performing maintenance or replacing components, understanding the correct procedures is crucial to ensure proper functionality and longevity.

Before starting, gather the necessary tools and ensure a clean workspace to facilitate a smooth process. Follow these steps for optimal results:

- Turn off the power supply and disconnect any energy sources to avoid accidents.

- Carefully remove any covers or protective elements to access the inner components.

- Identify the components that need to be disassembled. Take note of their arrangement for easy reassembly.

During disassembly, handle all parts with care to prevent damage. Use appropriate tools to avoid stripping screws or harming sensitive areas. Once the components are removed, organize them systematically:

- Group similar items together.

- Label parts if necessary for clarity.

For reassembly, reverse the steps taken during disassembly:

- Ensure all components are clean and free of debris.

- Align parts correctly according to the notes taken earlier.

- Secure all fasteners and replace covers, ensuring everything is tightly fitted.

Once assembly is complete, perform a thorough inspection to confirm that all components are correctly positioned. Finally, reconnect the power supply and test the equipment to verify proper operation.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves a series of essential practices aimed at preserving its functionality and performance. By adhering to a consistent maintenance routine, users can avoid unnecessary breakdowns and costly repairs, thereby enhancing the overall efficiency of their machines.

Regular Inspections

Conducting periodic assessments is crucial for identifying potential issues before they escalate. Consider the following points:

- Check for signs of wear or damage on critical components.

- Inspect fluid levels and ensure they are within the recommended range.

- Look for any leaks or irregularities that may affect performance.

Routine Cleaning

Keeping the machinery clean helps prevent debris buildup that can hinder operation. Here are some steps to follow:

- Remove dirt and grime from the exterior surfaces.

- Clear any obstructions from air intake and exhaust areas.

- Regularly clean filters to maintain optimal airflow.

By implementing these maintenance tips, you can significantly enhance the durability and reliability of your equipment, ensuring it remains in excellent working condition for years to come.