Understanding how various elements are arranged within machinery can greatly enhance maintenance and repair efforts. A clear view of the internal structure allows enthusiasts and professionals to easily identify connections and configurations. It helps to make complex equipment more accessible and comprehensible, offering a deeper understanding of its workings.

Whether for routine upkeep or addressing technical challenges, having a detailed look into the internal arrangements proves invaluable. With this information, one can ensure smoother operation and greater efficiency over time. Proper insights into these layouts also assist in identifying any signs of wear or potential issues before they become major problems.

In addition, this approach provides a solid foundation for selecting compatible components, ensuring that every replacement or adjustment aligns perfectly. It supports precision in handling various adjustments, fostering a seamless experience for those involved in equipment care.

Jx75 Parts Diagram Overview

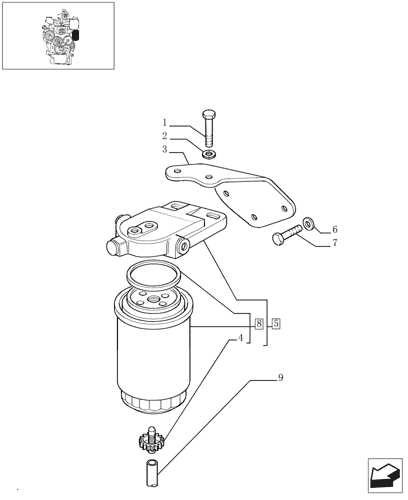

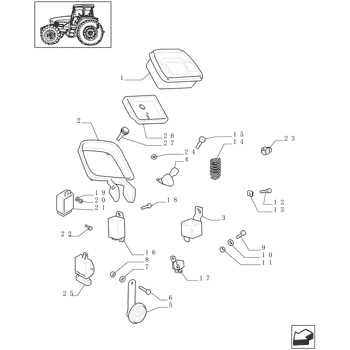

This section explores the arrangement and structure of various components in a mechanical system, providing insights into how different elements are connected and function together. Understanding this layout is essential for maintenance, repairs, and optimizing performance. Each element is organized in a way that ensures smooth operation, emphasizing the importance of proper positioning and alignment.

Detailed illustrations assist in visualizing the connections between elements, making it easier to identify specific segments and their roles within the entire setup. This approach simplifies troubleshooting and helps users maintain the equipment efficiently, ensuring its longevity and effective performance.

Understanding Key Components Layout

In any mechanical structure, knowing how individual elements are arranged is crucial for smooth operation and maintenance. The positioning of these elements impacts the functionality and accessibility, allowing for a more efficient and reliable system. By examining the overall structure, one can gain insight into how different segments interact with each other.

Each element in the system has a specific role, contributing to the seamless operation of the whole mechanism. Recognizing their arrangement helps in identifying where adjustments might be needed and how to optimize their interaction. This understanding is essential for effective troubleshooting and upkeep.

By exploring the placement of each component, users can better navigate the structure and ensure all elements are in their intended positions. This awareness not only facilitates quick adjustments but also enhances the longevity and reliability of the equipment.

Identifying Essential Parts and Functions

Understanding the fundamental elements and their roles is crucial for maintaining and operating various mechanical equipment. Each component has a specific purpose that contributes to the overall efficiency and performance of the machine. Recognizing how these elements work together ensures smooth operation and helps in diagnosing potential issues.

Core Mechanical Components

Several primary elements ensure the proper functioning of mechanical devices. Here is a list of some of the most critical components:

- Drive Mechanism: This system enables the movement and power transfer, ensuring the machine operates effectively.

- Cutting Assembly: A crucial element that ensures precision in trimming or cutting, depending on the machine’s design.

- Control System: Allows users to manage speed, direction, and other operational aspects for optimal performance.

Operational Role of Each Element

Each of these components has a distinct function that contributes to the overall effectiveness:

- The drive mechanism connects the power source to the moving parts, ensuring consistent motion.

- The cutting assembly, precisely calibrated, ensures clean and accurate results during operation.

- The control system offers users the flexibility to adjust settings, ensuring that the equipment meets the specific needs of different tasks.

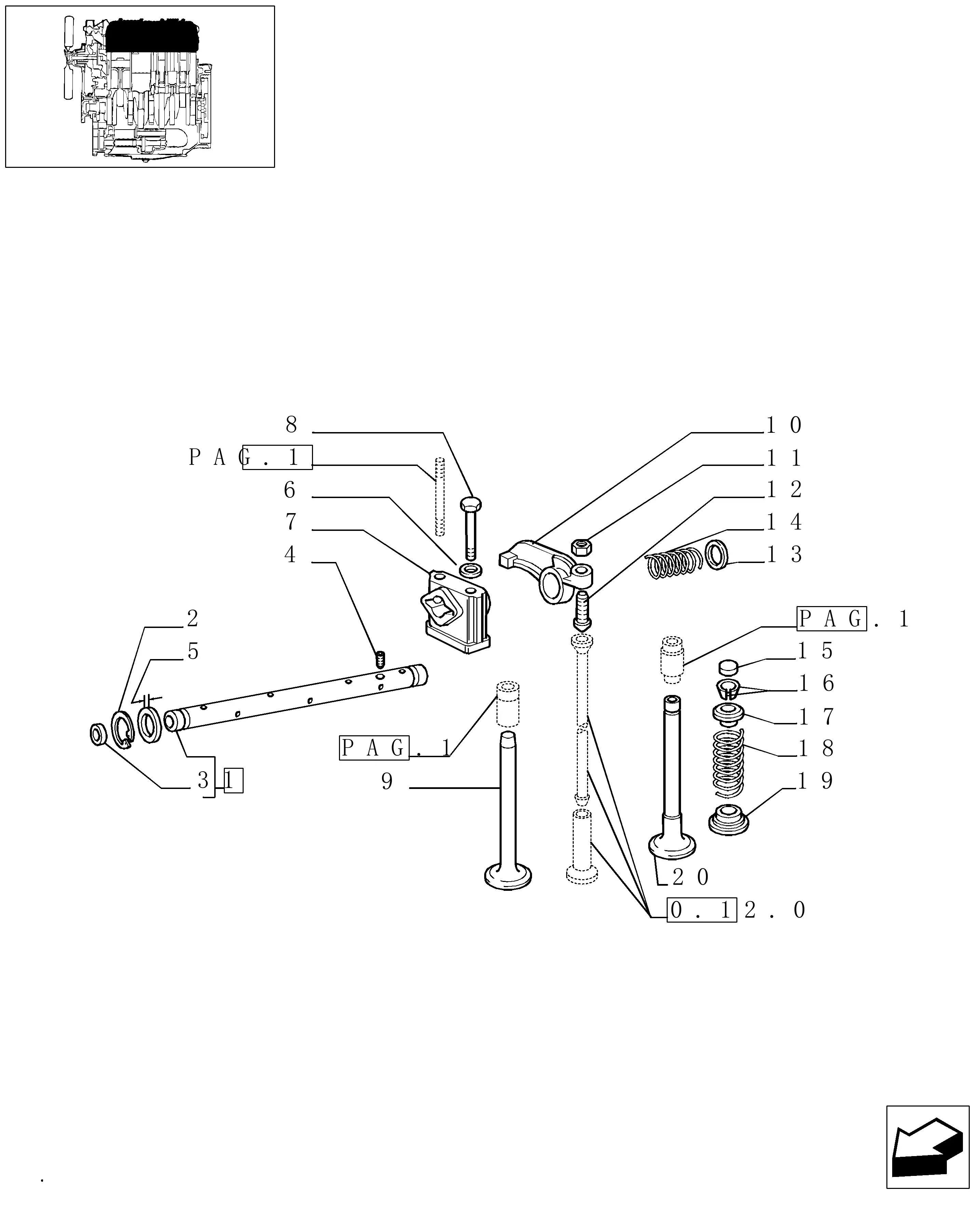

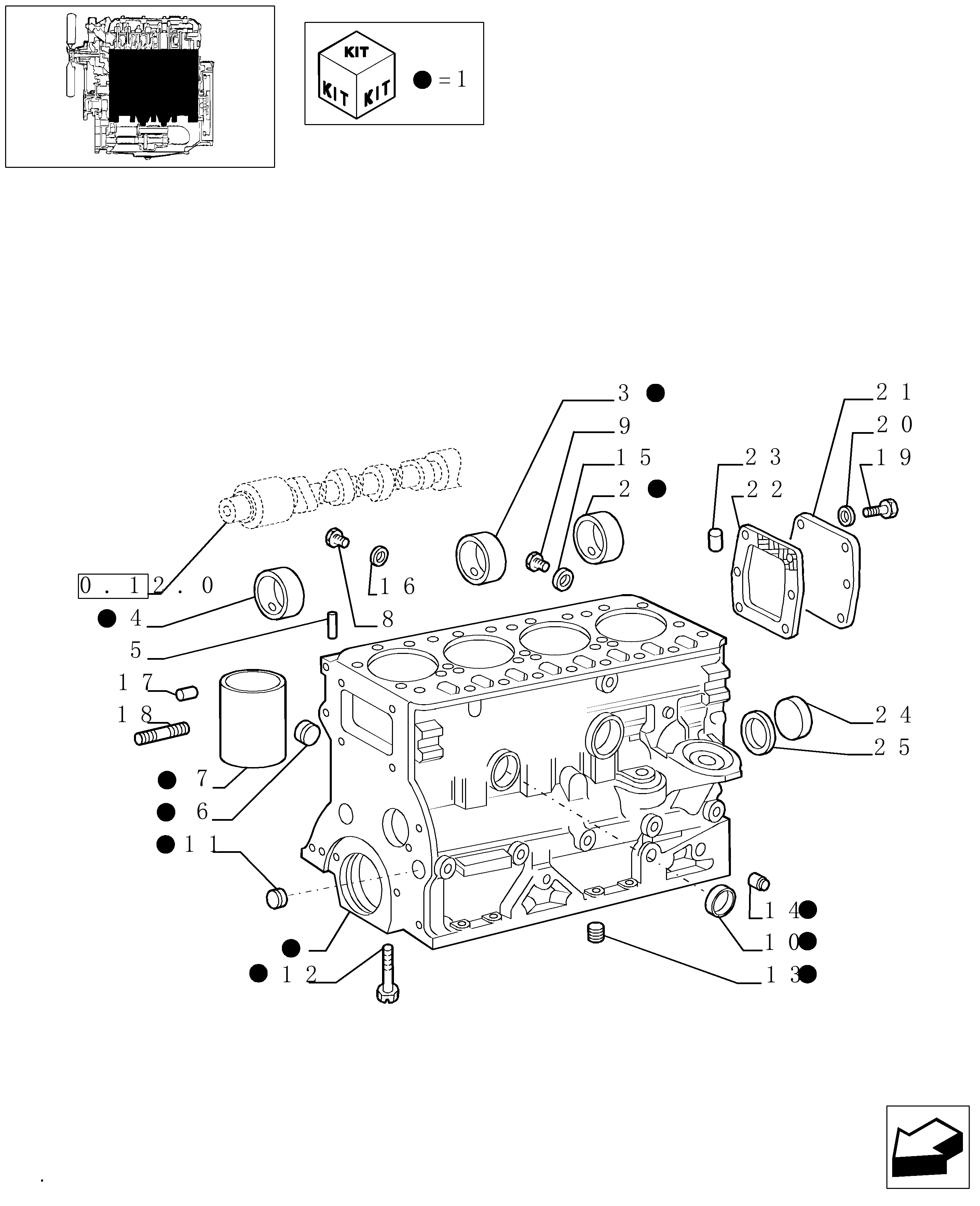

Detailed Guide to Engine Components

The following section provides a comprehensive overview of the various elements that make up an internal combustion system. Understanding the function and interaction of each element is crucial for ensuring smooth and efficient operation. This guide will cover the essential mechanical elements, focusing on their roles and how they contribute to the overall performance of the machinery.

Core Mechanical Elements

One of the fundamental parts of the system is the cylinder, where the combustion process occurs, transforming fuel into mechanical energy. Another vital element is the piston, which moves within the cylinder, converting the energy generated into motion. These components work together to create the necessary force to drive the machinery forward.

Supporting Elements for Efficiency

Additionally, the crankshaft is responsible for translating the linear movement of the piston into rotational energy, which is then used to power the system. The valves play a key role in regulating the flow of air and fuel, as well as the exhaust gases, ensuring optimal efficiency during operation. Proper synchronization of these parts ensures a balanced and effective performance.

Exploring the Transmission Assembly

The transmission assembly plays a crucial role in ensuring smooth power transfer and efficient movement. This component consists of various interconnected elements that work together to optimize motion and control within the machinery. Understanding the function and interaction of these elements can help in maintaining and troubleshooting the overall system.

| Component | Function | Notes |

|---|---|---|

| Gear Set | Regulates speed and torque between the engine and wheels, providing multiple speed options. | Essential for adjusting to different terrains and operational demands. |

| Clutch Mechanism | Allows for the engagement and disengagement of power flow to enable seamless shifting. | Key for avoiding wear and tear during operation. |

| Control Levers | Enable the user to select different speed ranges and control direction. | Provides manual control over the transmission process. |

| Drive Belt | Transfers rotational force between various components, maintaining synchronized motion. | Re

Common Replacement Parts for MaintenanceRegular upkeep is essential for the longevity and efficient performance of any machinery. To ensure optimal functionality, certain components may require periodic substitution. Identifying these key elements can help maintain smooth operation and prevent unexpected breakdowns. Filters play a crucial role in keeping systems clean and free from contaminants. It is advisable to check and replace them at regular intervals to avoid performance issues. Belts are vital for transferring power between various moving parts. Over time, these can wear out, leading to reduced efficiency or even failure. Monitoring their condition and replacing them as needed is critical. Seals and Gaskets help prevent leaks and ensure a tight fit between components. Regular inspection and timely replacement can prevent costly repairs and maintain optimal performance. Lubrication Points often require attention. Regularly replenishing lubricant in designated areas can reduce friction and prolong the life of mechanical parts. Being proactive about replacing these common components can greatly enhance the reliability and efficiency of machinery, leading to better overall performance. How to Read Parts Diagrams EffectivelyUnderstanding visual representations of components is essential for efficient assembly and maintenance. These illustrations provide a clear layout of various elements, helping users identify and locate each section with ease. Mastering this skill can significantly enhance comprehension and facilitate troubleshooting tasks. Identifying Key ElementsBegin by familiarizing yourself with the essential features of the visual representation. Look for labels that indicate different sections, as well as any accompanying notes or legends that explain symbols used within the illustration. This will aid in quick recognition of crucial parts. Utilizing Reference GuidesSupplement your understanding with reference materials that offer detailed explanations of the components illustrated. Cross-referencing these guides with the visual representation can deepen your insight, allowing for better interpretation of complex layouts. Employing this method enhances overall accuracy and efficiency. Troubleshooting Issues Using Diagrams

Visual representations can greatly assist in diagnosing problems within complex systems. By examining these illustrations, users can identify potential faults and understand the layout of various components, facilitating effective resolution strategies. Here are some common advantages of utilizing visual aids for troubleshooting:

When encountering an issue, consider the following steps:

Utilizing these visual tools enhances the troubleshooting process, enabling more efficient identification and rectification of issues. Where to Find Jx75 Parts ReferencesLocating reliable resources for components and their specifications is crucial for ensuring optimal functionality and maintenance of your equipment. Various platforms offer valuable information, from manufacturer websites to specialized online forums. By exploring these sources, you can access comprehensive guides, illustrations, and detailed lists that will aid in identifying the required elements for your machinery. One effective approach is to visit the official website of the equipment manufacturer. They often provide extensive documentation, including technical manuals and reference guides that outline necessary components. Additionally, online marketplaces may have user-friendly catalogs where specific items can be easily searched and purchased. Engaging with online communities can also be beneficial. Forums and discussion groups dedicated to similar machinery allow users to share insights, recommendations, and experiences. These interactions often lead to discovering niche suppliers or alternative resources that may not be widely advertised. Lastly, consider consulting repair shops or professionals who specialize in the maintenance of similar equipment. Their expertise can direct you to trusted sources and save time in your search for the right components. |