When it comes to maintaining your outdoor machinery, having a clear understanding of its individual components is essential. Each piece plays a critical role in ensuring optimal performance and longevity. Whether you are performing routine maintenance or troubleshooting issues, familiarity with these elements can save time and enhance efficiency.

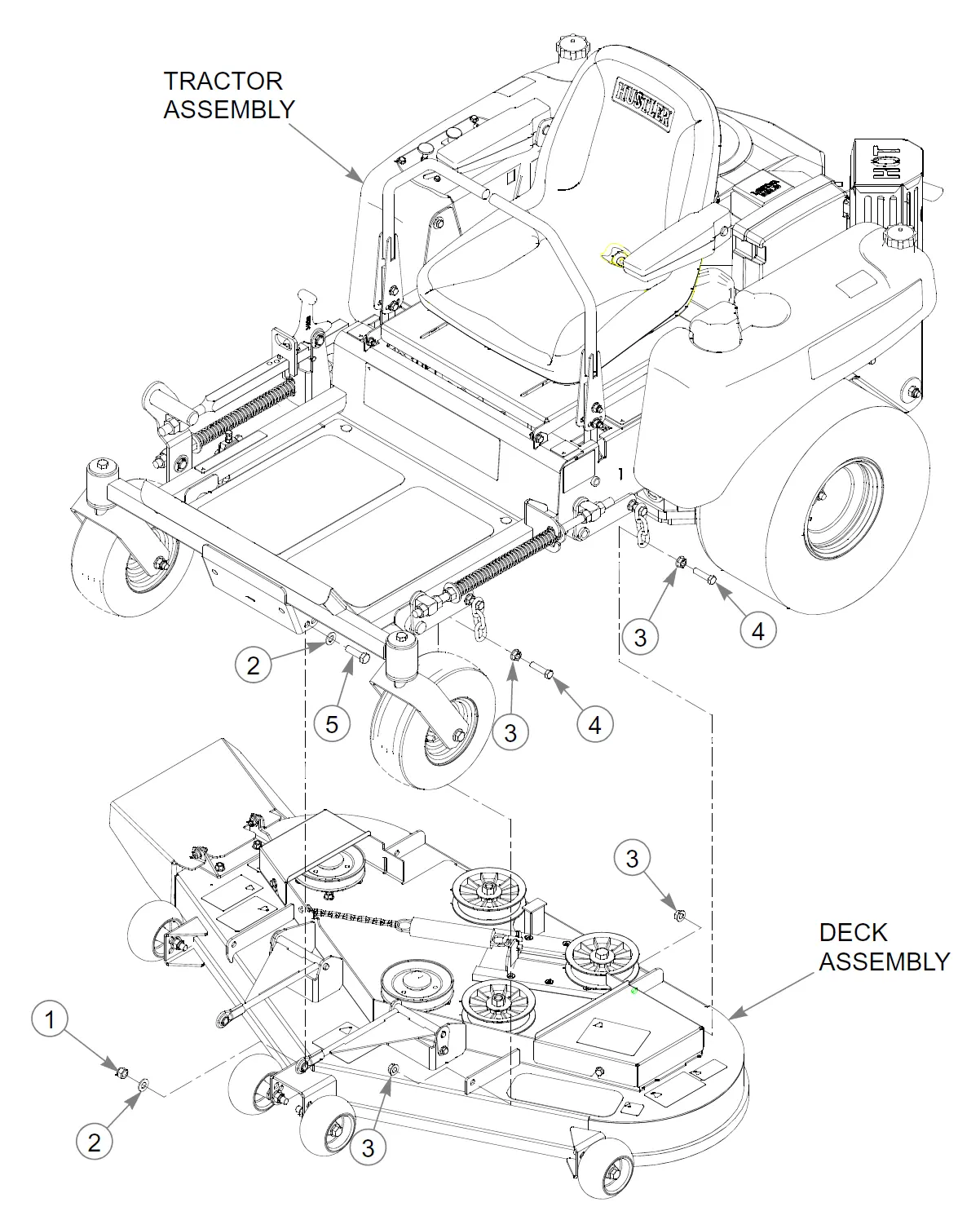

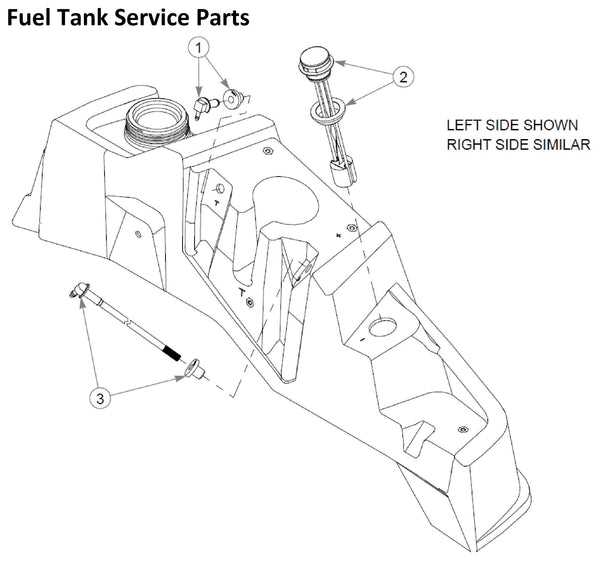

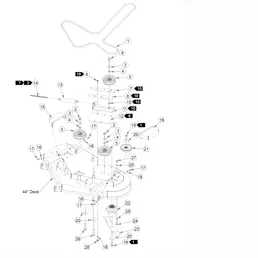

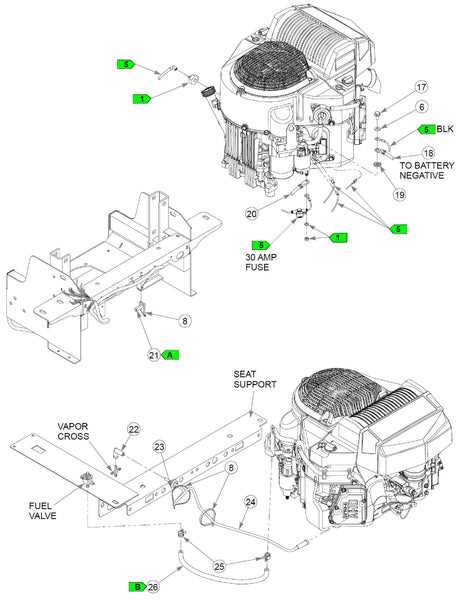

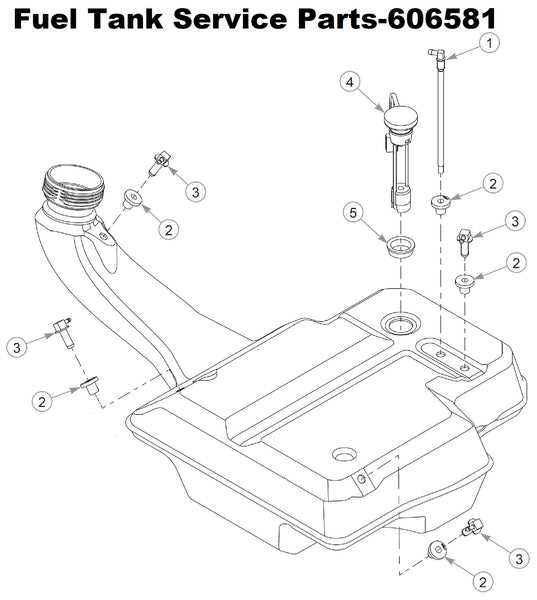

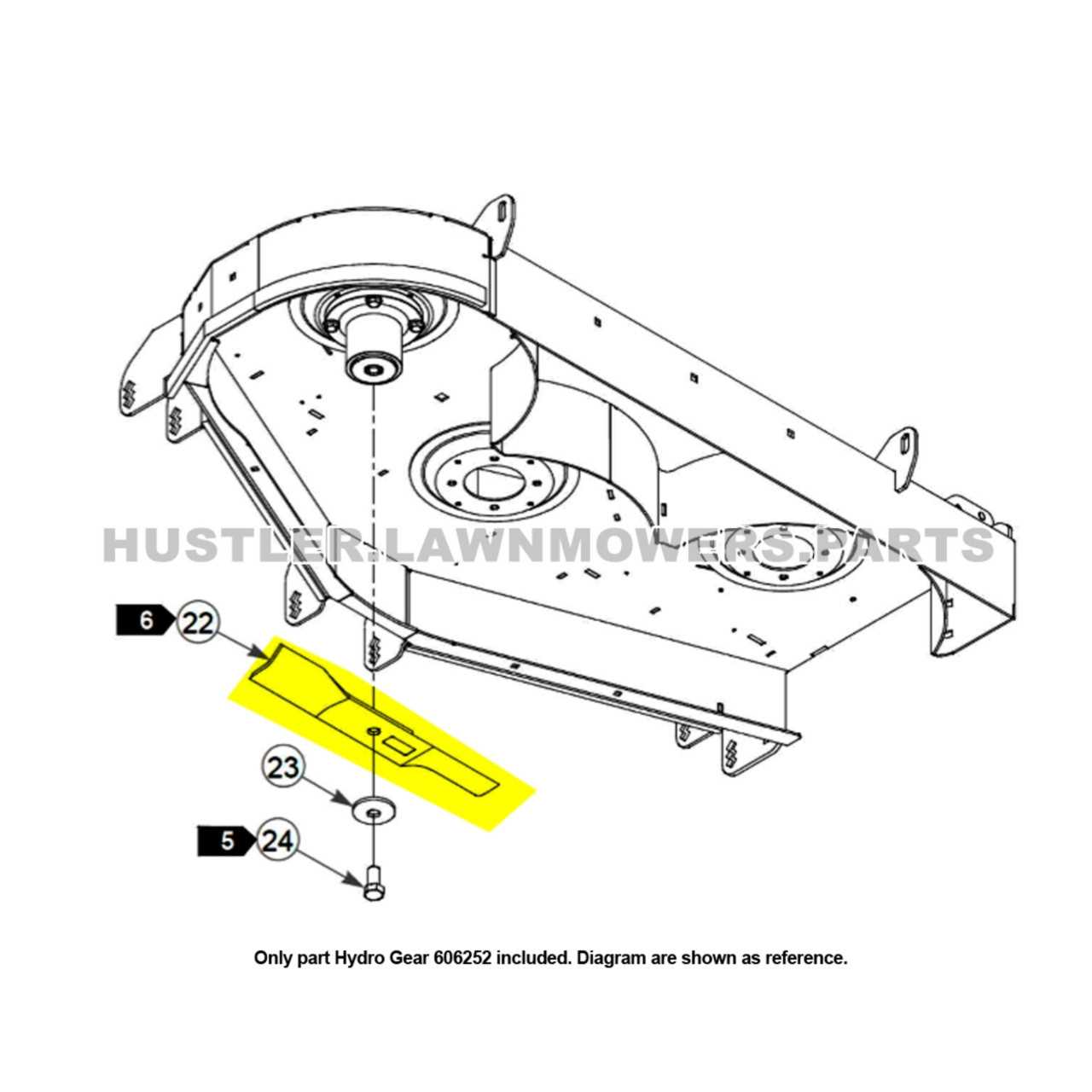

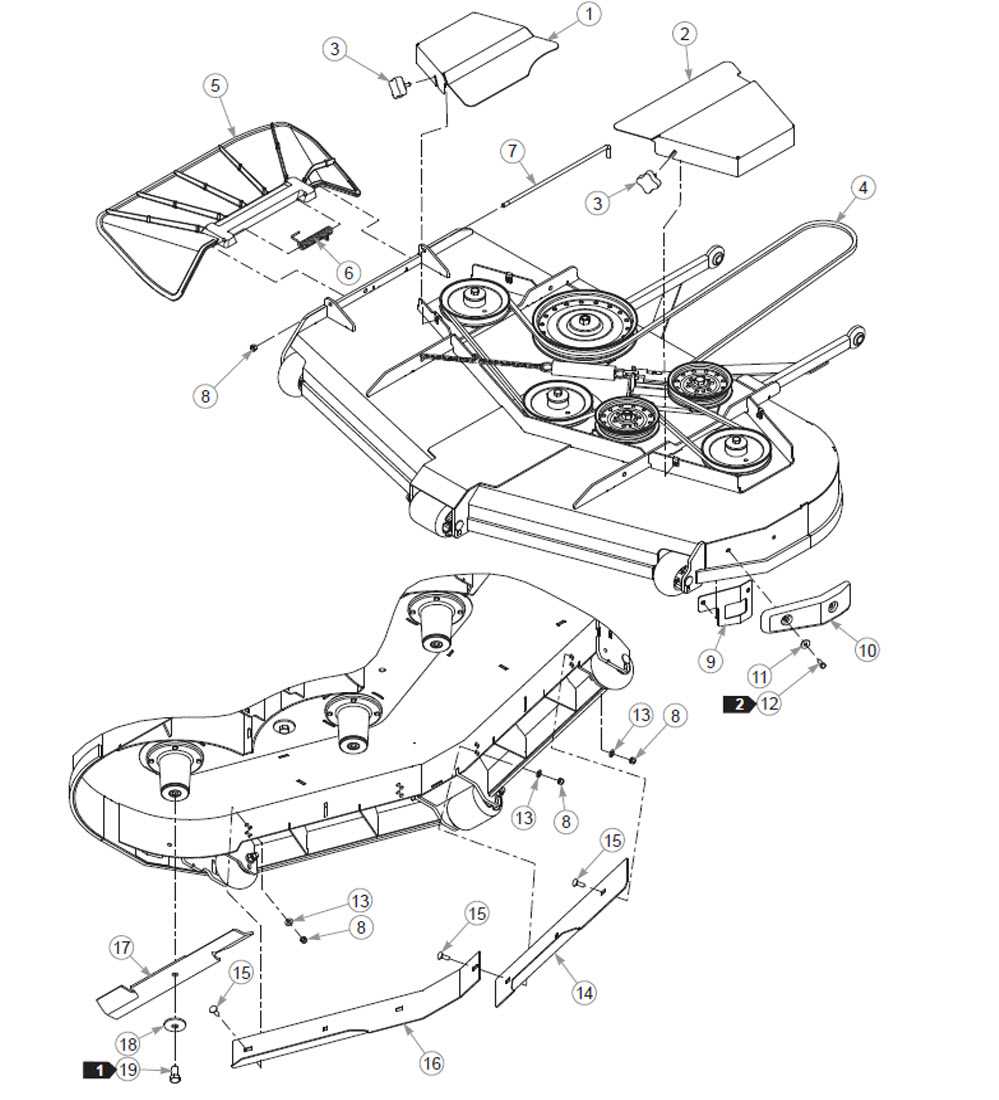

Visual representations of machinery parts can serve as invaluable references for both novices and seasoned users. These illustrations help users identify various elements quickly, facilitating easier repairs and replacements. A well-structured guide enables owners to navigate the complexities of their equipment with confidence.

In this exploration, we will delve into the intricate relationships between different segments of your lawn care apparatus. By breaking down the various elements, we aim to equip you with the knowledge necessary to keep your equipment running smoothly and effectively.

Understanding Hustler Fastrak Components

Gaining insight into the various elements of a high-performance mowing machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal functionality and longevity of the equipment. Familiarity with these elements can enhance user experience and aid in troubleshooting common issues.

Key Elements

- Engine: The powerhouse that drives the entire system, responsible for delivering the necessary torque and speed.

- Transmission: Facilitates smooth movement and speed control, allowing for efficient maneuverability.

- Chassis: The sturdy framework that supports all other components, ensuring stability and durability.

Maintenance Considerations

- Regular inspections of the engine and transmission are essential for identifying wear and tear.

- Keeping the chassis free from debris ensures optimal performance and reduces the risk of damage.

- Understanding the functionality of each component aids in diagnosing issues more effectively.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for maintenance and repair tasks. These illustrations serve as essential guides, allowing users to identify, locate, and understand the various elements involved in machinery. A detailed representation simplifies complex processes, ensuring efficiency and accuracy in operations.

Benefits of Clear Visual Guides

- Facilitates quick identification of components.

- Reduces the risk of assembly errors.

- Enhances troubleshooting capabilities.

- Saves time during maintenance procedures.

Conclusion

In the end, well-crafted visual aids contribute significantly to the ultimate effectiveness of any repair or maintenance effort. Accurate representations not only enhance understanding but also promote a smoother workflow, ultimately leading to better performance.

Common Issues with Fastrak Machines

Machines designed for efficient ground maintenance often encounter a range of operational challenges. Understanding these common issues can help users maintain their equipment effectively and ensure longevity in performance.

Performance Problems

One frequent concern involves reduced power and efficiency during operation. This can be attributed to factors such as fuel quality, air filter blockages, or worn-out components. Regularly checking and replacing filters and fluids is essential for optimal functionality.

Mechanical Failures

Mechanical breakdowns can disrupt the workflow significantly. Common signs include unusual noises, vibrations, or failure to start. Inspecting the drive belts and pulleys can prevent these issues from escalating. Additionally, ensuring that all connections are secure will help mitigate the risk of malfunction.

Where to Find Official Diagrams

Locating authoritative illustrations for your equipment can greatly enhance your understanding and maintenance capabilities. These resources provide clear visual guidance, ensuring that users can effectively manage repairs and replacements with confidence.

Several reliable sources are available for accessing these essential visuals:

| Source | Description | Link |

|---|---|---|

| Manufacturer’s Website | The official site often has a dedicated section for documentation, including technical illustrations and user manuals. | Visit here |

| Authorized Dealers | Many certified retailers provide access to technical resources, including detailed visuals for various models. | Visit here |

| Online Forums | Community-driven platforms can be valuable for sharing illustrations and insights among users with similar equipment. | Visit here |

| Repair Manuals | Specialized publications often include comprehensive illustrations alongside maintenance instructions. | Visit here |

Utilizing these resources can lead to more effective maintenance practices and a deeper understanding of your equipment’s workings.

How to Read Parts Diagrams Effectively

Understanding visual representations of components is essential for maintenance and repairs. Mastering this skill can significantly enhance your efficiency and accuracy when working with machinery.

Here are some tips to help you interpret these illustrations:

- Familiarize Yourself with Symbols: Learn the common symbols used to represent various elements.

- Identify Key Sections: Break down the image into manageable sections for easier comprehension.

- Refer to the Legend: Use the accompanying legend to decode any unfamiliar notations.

By applying these strategies, you can delve deeper into the technical aspects of your equipment and achieve the ultimate understanding needed for effective repairs.

Comparing Fastrak Models and Parts

When evaluating various models within a particular line of equipment, it’s essential to recognize the distinct characteristics and components that differentiate them. Each variant serves specific needs, catering to diverse preferences and operational requirements. Understanding these nuances enables users to make informed choices tailored to their landscaping tasks.

Key Features of Each Variant

Different models showcase unique functionalities that enhance efficiency. For instance, some versions may include advanced cutting mechanisms, while others focus on maneuverability in tight spaces. Assessing these features allows potential users to determine which variant aligns best with their operational goals.

Component Compatibility and Upgrades

Another crucial aspect involves the compatibility of various elements across models. Identifying interchangeable components can significantly streamline maintenance and repair processes. Users should consider upgrade options that enhance performance, ensuring longevity and reliability in their equipment.

Tips for Ordering Replacement Parts

When it comes to maintaining your machinery, acquiring the right components is crucial for ensuring optimal performance and longevity. Navigating the process of sourcing these items can be challenging, but with a few strategic approaches, you can streamline your experience and make informed decisions.

Know Your Model and Specifications

Before placing an order, familiarize yourself with the specific model of your equipment and its requirements. Consult the user manual or manufacturer’s website to gather essential details regarding dimensions, compatibility, and any unique features. This knowledge will help you avoid mistakes and ensure that you select the appropriate components for your needs.

Choose Reputable Suppliers

Quality is paramount when it comes to replacements. Research and select trustworthy vendors that specialize in the items you require. Reading reviews and seeking recommendations can guide you towards suppliers known for reliability and excellent customer service. Additionally, ensure that the provider offers a return policy, giving you peace of mind should the component not meet your expectations.

By taking these steps, you can effectively manage the process of acquiring necessary components, ultimately contributing to the smooth operation of your machinery.

Maintenance Best Practices for Longevity

Ensuring the durability and optimal performance of your equipment involves a proactive approach to upkeep. Regular maintenance not only enhances functionality but also extends the lifespan of essential components.

Routine Inspections: Conducting frequent evaluations can help identify potential issues before they escalate. Look for signs of wear and tear, and address them promptly.

Cleaning: Keeping surfaces free from debris and buildup is crucial. Regular cleaning prevents corrosion and keeps parts functioning smoothly.

Lubrication: Applying the right lubricants to moving parts minimizes friction and reduces the risk of damage. Follow manufacturer guidelines for the appropriate products.

Storage: Properly storing equipment when not in use protects it from environmental factors. Use covers and choose a suitable location to avoid exposure to moisture and extreme temperatures.

Periodic Servicing: Engaging a professional for thorough check-ups can provide insights that regular inspections might miss. Schedule services according to usage patterns.

By adhering to these strategies, you can significantly enhance the longevity and reliability of your machinery, ensuring it remains in peak condition for years to come.

Resources for DIY Repairs and Upgrades

Engaging in do-it-yourself maintenance and enhancements can be a rewarding endeavor. Accessing the right information and tools not only saves money but also empowers individuals to take control of their equipment. This section provides valuable resources that can assist both novice and experienced enthusiasts in achieving their repair and upgrade goals effectively.

Online Communities and Forums

Participating in online forums dedicated to equipment repair and improvement can be incredibly beneficial. These platforms allow users to share experiences, troubleshoot issues, and exchange tips. Joining a community provides access to a wealth of knowledge from fellow enthusiasts who have faced similar challenges.

Instructional Videos and Tutorials

Visual learning can enhance understanding and skill acquisition. Numerous websites offer video tutorials that guide users through various repair processes step-by-step. These resources often cover everything from basic maintenance tasks to more complex modifications, making them invaluable for DIY projects.

| Resource Type | Description | Examples |

|---|---|---|

| Online Forums | Discussion platforms where users can ask questions and share knowledge. | Reddit, LawnSite |

| Video Tutorials | Visual guides demonstrating repair techniques and upgrades. | YouTube, DIY Network |

| Repair Manuals | Comprehensive guides detailing specifications and procedures. | eBay, Manufacturer Websites |