When it comes to maintaining and optimizing the functionality of your lawn care equipment, having a clear overview of its internal structure is essential. A well-organized representation of each component can significantly simplify the repair and maintenance process, allowing users to identify specific elements quickly.

Whether you are a seasoned professional or a weekend warrior, familiarizing yourself with the intricate arrangement of various mechanisms can lead to improved performance. Knowledge of the configuration not only enhances the efficiency of your machine but also extends its lifespan, ensuring that it remains in top condition for years to come.

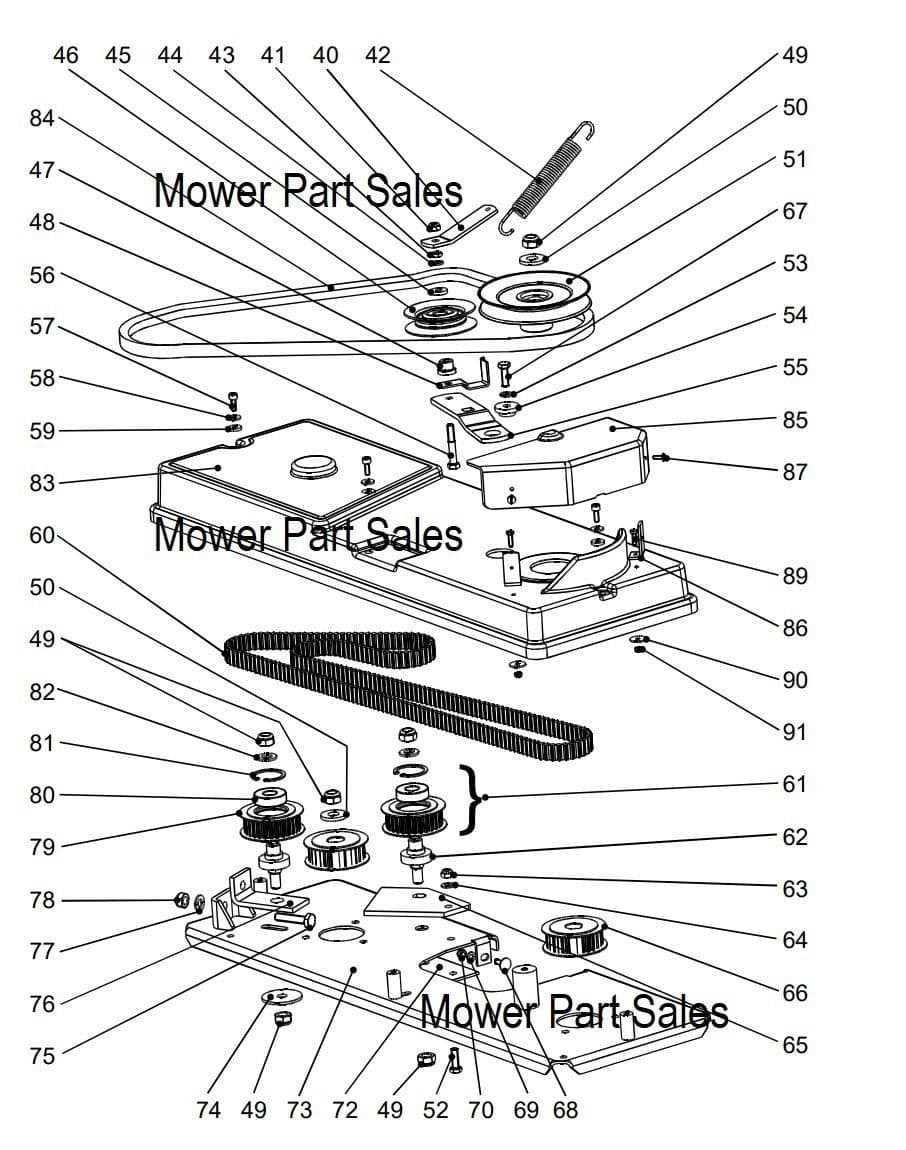

In this section, we will explore the layout and relationships of different elements within the equipment. By understanding how these parts interact, you can make informed decisions regarding upgrades, replacements, and general upkeep, ultimately maximizing the effectiveness of your gardening tasks.

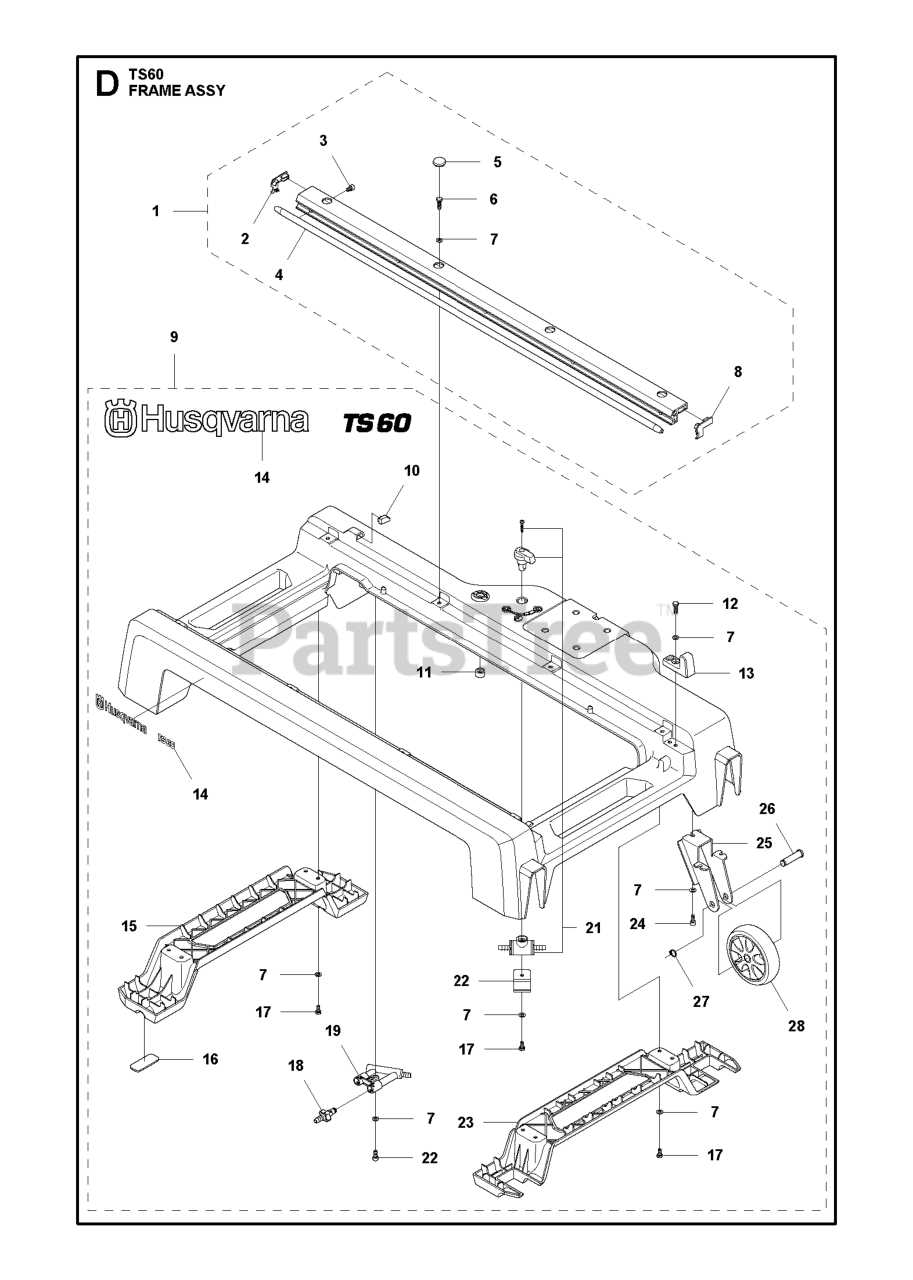

This section aims to provide a comprehensive overview of the essential elements that make up the mower model. By breaking down the various components, readers will gain insights into the functionality and maintenance of their equipment. Understanding these parts not only enhances the knowledge of the machine’s operation but also facilitates better care and troubleshooting.

Key Components Overview

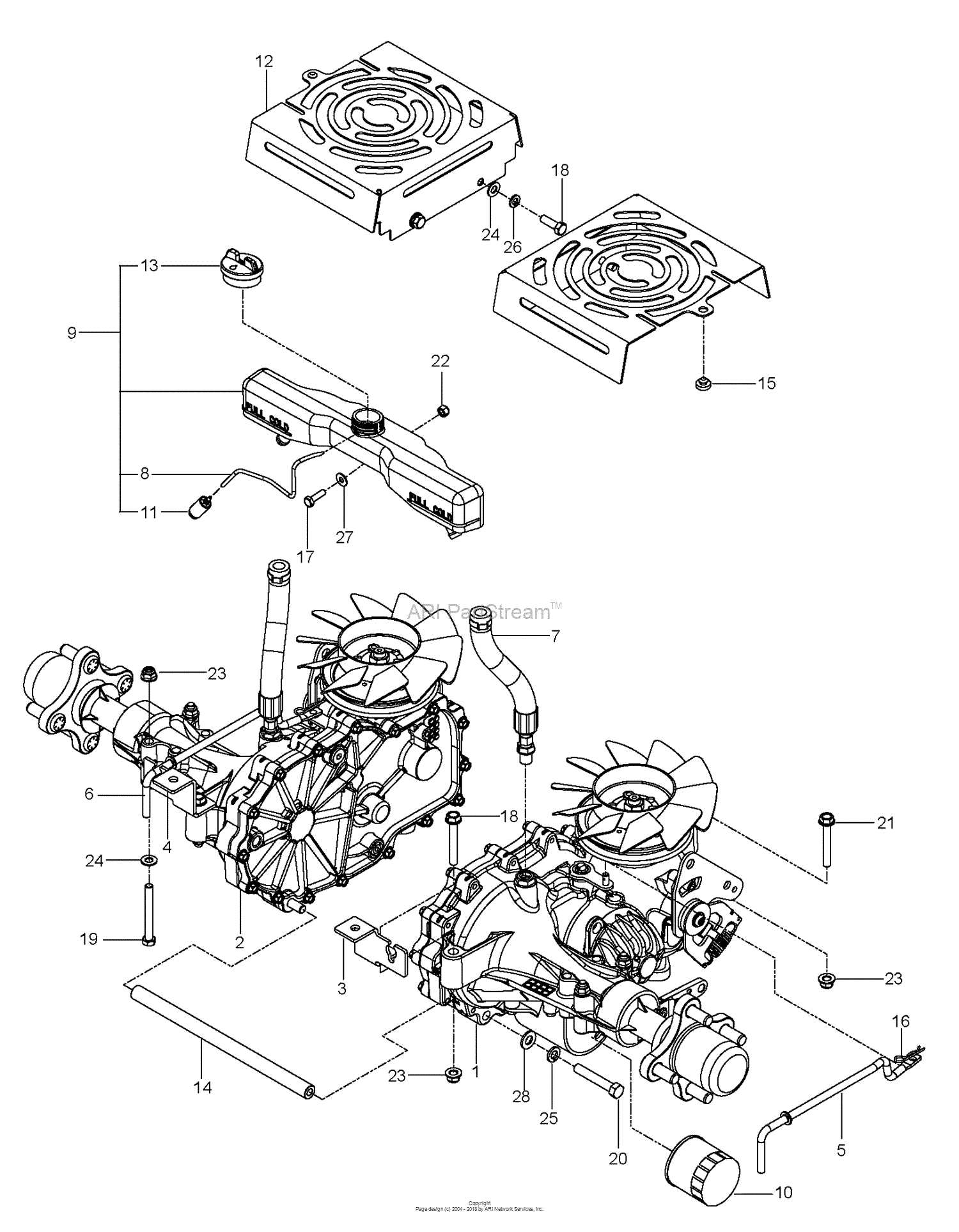

- Engine Assembly

- Transmission System

- Deck Structure

- Wheels and Tires

- Steering Mechanism

- Control Panel

Maintenance and Replacement Parts

- Regular Checks:

- Oil Level and Quality

- Air Filter Condition

- Commonly Replaced Items:

- Blades

- Batteries

- Belt Systems

Overview of Key Replacement Parts

When maintaining a lawn care machine, understanding the essential components that may require replacement is crucial for optimal performance. These elements play a vital role in ensuring the equipment operates smoothly and efficiently, allowing for consistent results in lawn maintenance tasks. This section provides an overview of the primary components that users should consider when looking for suitable substitutes.

Engine Components

The engine serves as the heart of the machinery, and its efficiency is paramount. Key components such as filters, spark plugs, and belts often need replacing to maintain peak performance. Regular checks on these items can prevent larger issues and ensure longevity in usage.

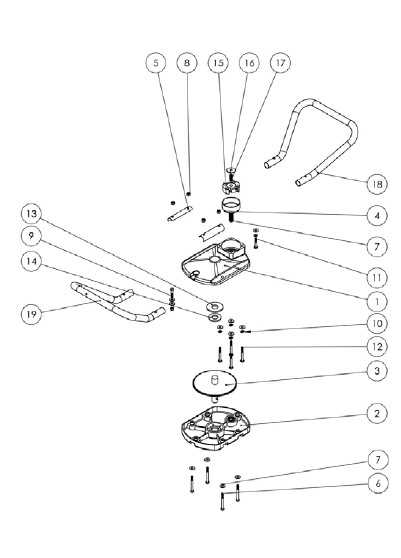

Cutting Mechanism

The cutting assembly is integral for achieving a clean and even cut. Essential elements like blades, spindles, and drive belts should be inspected regularly and replaced when worn. Keeping these components in top condition enhances cutting efficiency and improves overall results.

Assembly and Disassembly Procedures

This section provides essential guidelines for the systematic assembly and disassembly of the equipment. Understanding these procedures is vital for maintenance and repair tasks, ensuring that all components are handled properly and reassembled correctly for optimal functionality.

Preparation Steps

- Gather all necessary tools and equipment before starting the process.

- Refer to the technical manual for specific instructions and safety precautions.

- Work in a clean, organized environment to prevent losing small components.

Disassembly Process

- Begin by disconnecting the power source to ensure safety.

- Remove any coverings or protective parts as specified in the manual.

- Carefully detach the main components, starting from the outer sections and moving inward.

- Label each part and keep them organized for easier reassembly.

Assembly Process

- Ensure all components are clean and free of debris before starting.

- Begin reassembly by following the reverse order of disassembly.

- Secure each part tightly to avoid any loose connections.

- Reattach coverings and protective components as per the guidelines.

- Reconnect the power source and perform a thorough inspection to verify functionality.

Common Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention. By implementing simple maintenance practices, you can significantly extend the lifespan and performance of your machinery. This section outlines key strategies to promote longevity and reliability in your operations.

Regular Inspections

Conducting routine evaluations is essential for identifying potential issues before they escalate. Check for signs of wear, loose components, or leaks. Regular inspections allow you to address minor problems early, preventing costly repairs down the line.

Proper Cleaning

Keeping your equipment clean enhances performance and reduces the risk of damage. Remove debris and dirt from critical areas, ensuring that ventilation systems remain unobstructed. A clean machine operates more efficiently, which contributes to its longevity.

Remember: Regular maintenance not only boosts performance but also ensures safety and reliability in the long run. Make these practices a routine part of your operations for optimal results.

Troubleshooting Common Issues

Identifying and resolving frequent problems can significantly enhance the performance and longevity of your lawn care equipment. This section will guide you through typical challenges users encounter, offering practical solutions to restore functionality.

Engine Performance Problems

When the engine fails to start or runs poorly, it may indicate underlying issues. Consider the following troubleshooting steps:

- Check the fuel level and ensure it is fresh and free from contaminants.

- Inspect the air filter for dirt and blockages; replace if necessary.

- Examine the spark plug for wear or damage; cleaning or replacing it can improve ignition.

Mowing Issues

Uneven cutting or failure to mow effectively can be frustrating. To address these issues, follow these guidelines:

- Verify that the cutting blades are sharp and properly adjusted.

- Inspect the mower deck for debris or obstructions that may hinder performance.

- Ensure the tire pressure is consistent, as uneven tires can affect cutting height.

Recommended Tools for Repairs

When undertaking maintenance or fixing issues with outdoor machinery, having the right equipment is crucial for efficiency and effectiveness. Proper tools not only facilitate the repair process but also help in achieving a professional finish. Below are essential implements that can enhance your repair experience.

Essential Hand Tools

Wrenches and screwdrivers are fundamental for various tasks, enabling users to tighten or loosen fasteners with ease. A complete set should include different sizes and types to accommodate various components. Additionally, a socket set is invaluable for accessing hard-to-reach bolts.

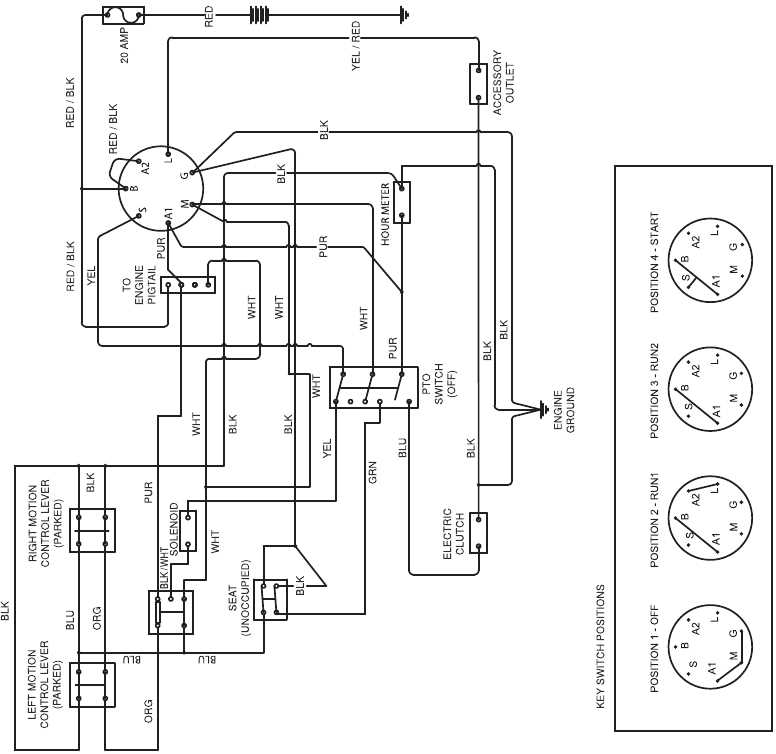

Power Equipment

For more complex repairs, consider utilizing a drill for driving screws and making holes. An impact wrench can significantly reduce effort when dealing with stubborn bolts. Furthermore, a reliable multimeter is essential for diagnosing electrical issues, ensuring that every aspect of the machinery functions correctly.

Finding Authentic Replacement Parts

Locating genuine components for your equipment is essential for maintaining optimal performance and longevity. Authentic replacements ensure that your machine operates efficiently and effectively, reducing the risk of damage and costly repairs. In this section, we will explore strategies to identify and procure high-quality substitutes, ensuring you keep your equipment in top condition.

Benefits of Genuine Components

Using original equipment ensures compatibility and reliability. Genuine components are specifically designed for your machinery, providing peace of mind that they will function as intended. Here are some advantages of selecting authentic components:

| Advantage | Description |

|---|---|

| Quality Assurance | Original components are manufactured to meet strict quality standards, ensuring optimal performance. |

| Longevity | Authentic parts typically last longer, reducing the frequency of replacements. |

| Warranty Protection | Using original components often keeps warranties intact, safeguarding your investment. |

| Enhanced Performance | Genuine parts work seamlessly with your equipment, maximizing efficiency and functionality. |

Where to Find Authentic Components

To secure genuine components, consider the following sources:

- Authorized dealerships that specialize in your equipment brand.

- Reputable online retailers known for selling original equipment.

- Manufacturer websites offering direct sales or information on authorized distributors.

By focusing on these reliable sources, you can ensure that you obtain the correct replacements for your machinery, preserving its performance and extending its lifespan.

Comparative Analysis of Aftermarket Options

The availability of alternative components for lawn care machinery can significantly impact performance and maintenance costs. This section explores various aftermarket solutions, emphasizing their benefits and potential drawbacks in comparison to original equipment offerings.

One of the primary advantages of opting for third-party components is the potential for cost savings. Aftermarket options often come at a lower price point, which can make repairs and upgrades more accessible for budget-conscious users. However, it’s crucial to consider the quality and durability of these alternatives. While some brands offer products that match or exceed the performance of original components, others may fall short, leading to frequent replacements and additional expenses.

Furthermore, compatibility is a significant factor to examine. Not all aftermarket solutions are designed to fit perfectly with every machine model. Conducting thorough research and consulting customer reviews can help users make informed decisions about which options will work best with their specific equipment.

In conclusion, while exploring alternative components can lead to substantial savings, careful consideration of quality, compatibility, and performance is essential. By weighing these factors, users can ensure that their choices align with their maintenance goals and operational needs.