The efficient operation of machinery often depends on the precise interplay of individual elements. Knowing how these components work together is essential for anyone looking to maintain or enhance performance. By exploring detailed visual guides, you can gain a clearer understanding of how each piece fits within the overall system, ensuring smooth operation and preventing issues before they arise.

In complex equipment, every element has a specific role. Whether it’s for maintenance, troubleshooting, or upgrading, having a visual representation of the components is invaluable. This guide provides insight into the relationships between various sections, helping you to better grasp their functionality and how they contribute to the seamless operation of the whole system.

Whether you’re a seasoned technician or a curious enthusiast, familiarizing yourself with the internal structure and arrangement of key elements can enhance both your understanding and ability to handle future tasks. This knowledge allows for quicker solutions and more informed decision-making when working with intricate machinery.

Essential Components of Husqvarna 460 Rancher

The structure of a reliable cutting tool includes various crucial elements, each playing a vital role in ensuring smooth operation and long-term durability. These components are carefully engineered to work in harmony, providing efficiency, safety, and ease of use for users of all experience levels. Understanding the importance of these elements can enhance performance and help with effective maintenance.

Engine Unit: The heart of the machine, responsible for powering all operations. This section is designed to generate the necessary force, ensuring efficient cutting under different conditions. Proper care of this unit is essential for consistent performance.

Cutting Mechanism: This part includes the blade and related systems that interact to provide sharp and accurate cutting. Regular upkeep of the sharp edge ensures precision and extends the life of the tool.

Fuel System: This mechanism ensures the engine receives the necessary fuel mixture for proper combustion. Maintaining a clean and efficient system is key to avoiding operational issues and ensuring optimal energy output.

Vibration Control: This feature reduces strain on the operator during prolonged use, making the tool more comfortable to handle. I

Guide to Chain and Bar Maintenance

Proper upkeep of the cutting chain and guide bar is essential for efficient operation and longevity. Regular care ensures smooth performance and prevents excessive wear, which can lead to decreased cutting power and increased strain on the machine. Here, we’ll outline key maintenance practices to help you keep these components in optimal condition.

- Cleaning the bar and chain: After each use, remove debris and sawdust buildup from both the chain and guide bar. This helps maintain smooth movement and reduces friction.

- Lubrication: Ensure consistent oiling of the chain and bar. This reduces wear and overheating during operation. Check the oil reservoir regularly and top it off as needed.

- Chain tension: Maintain proper chain tension to avoid excessive wear on both the chain and bar. A loose chain can jump off or cause damage, while an overly tight chain can strain the motor.

- Sharpening the chain: Dull teeth on the chain reduce cutting efficiency and increase the risk of accidents. Regular sharpening ensures a clean cut and reduces

Understanding the Engine Assembly Layout

The engine assembly consists of several interconnected components, each playing a crucial role in ensuring efficient operation. By familiarizing yourself with the overall structure, you can better understand how the various elements work together to power the machine. This section provides a clear overview of the engine’s primary parts and their organization.

Main Components of the Engine Block

- Cylinder: The core of the engine where combustion occurs, producing the energy needed for movement.

- Piston: Moves within the cylinder, converting energy from combustion into mechanical power.

- Crankshaft: Transforms the piston’s linear motion into rotational motion, driving other engine parts.

- Cooling System: Maintains optimal temperature by dissipating excess heat generated during operation.

Connecting Components and Systems

Various systems link to the engine block to support its function. Below are key elements involved in connecting and controlling the engine:

- Fuel System:

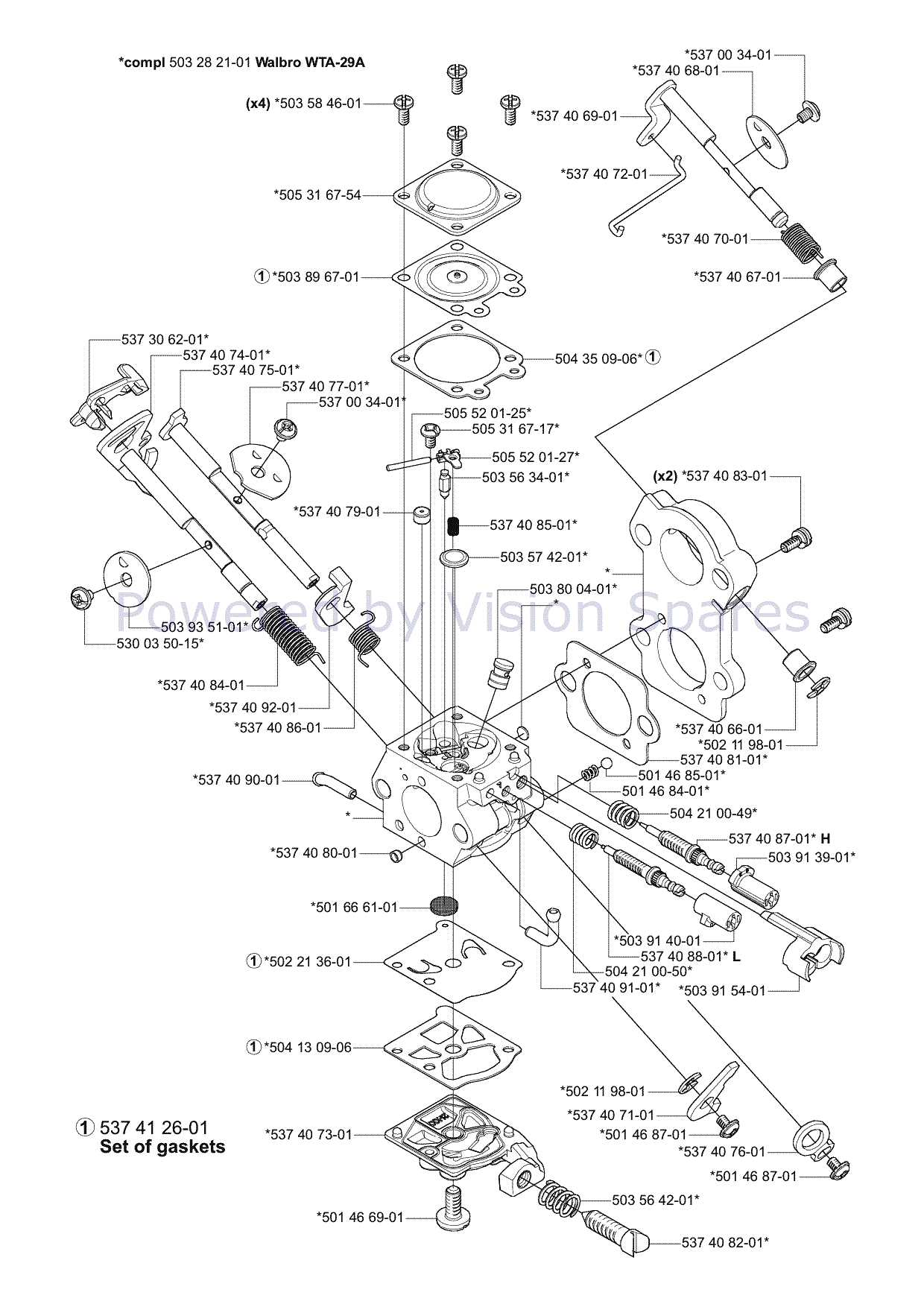

Fuel System Parts Overview

The fuel system is essential for ensuring that the machine operates smoothly and efficiently. Understanding its components allows for better maintenance and ensures consistent performance. Below is a summary of the key elements that make up this system, each contributing to the smooth transfer of fuel and optimal engine function.

Key Components

The system involves several critical elements, all designed to ensure a steady flow of fuel to the engine. These include devices that help regulate fuel delivery and components that ensure proper fuel mixture and filtration.

Component Function Fuel Tank Stores fuel for the engine, providing the necessary supply for operation. Fuel Line Transports fuel from the tank to the carburetor, ensuring a steady flow. Carburetor Mixes fuel with air to create a combustible mixture for the engine. Fuel Filter Starter Mechanism Breakdown

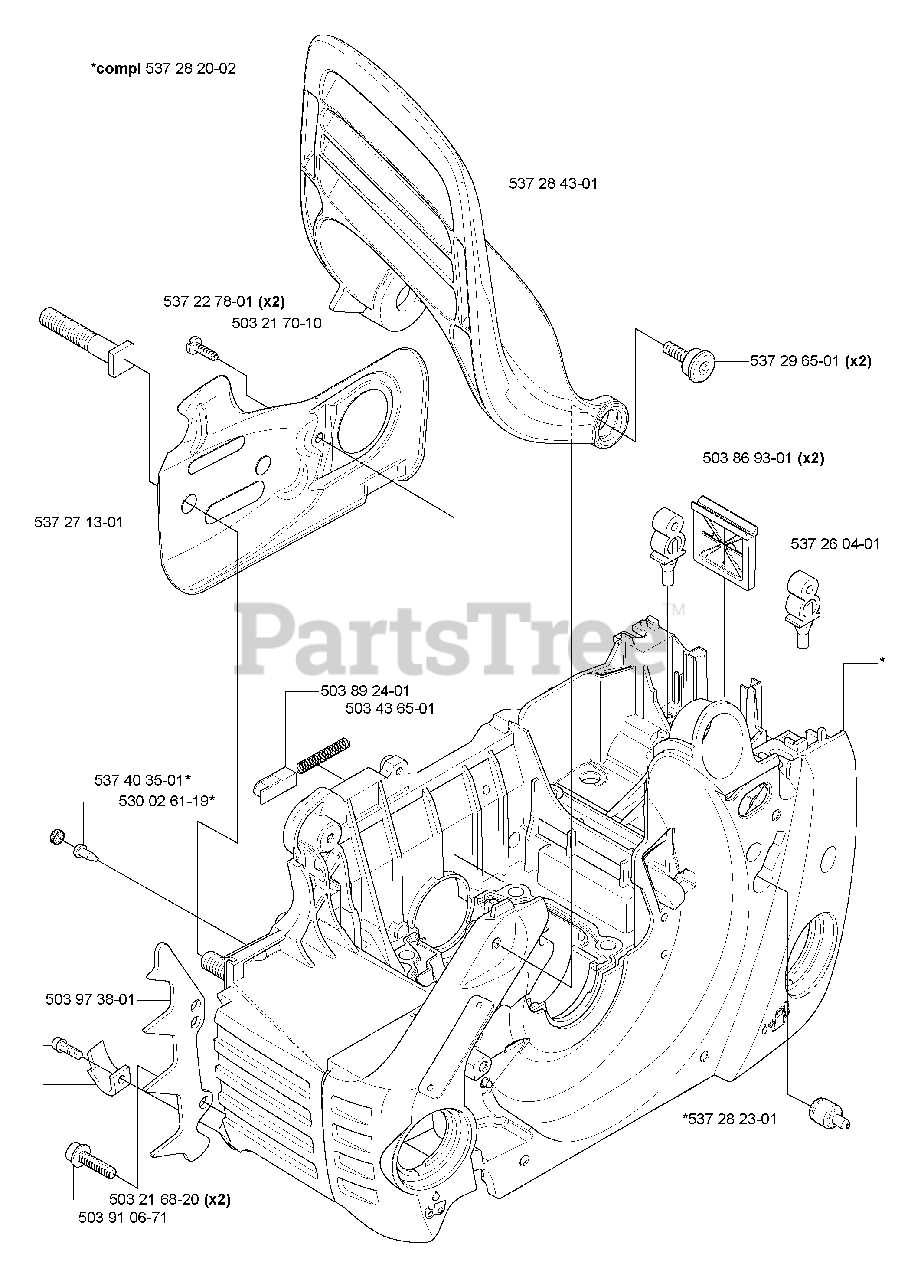

The starter system is a crucial component designed to initiate the operation of an engine. It allows the user to engage the internal components efficiently, ensuring a smooth start with minimal effort. Understanding its structure and how it functions can help maintain optimal performance and prevent potential issues.

- Handle and Cord: The handle is where the user pulls to activate the system, and the cord connects it to internal gears. A durable cord ensures long-term use and reliability.

- Recoil Spring: This spring is responsible for rewinding the cord after each pull. A malfunction here could result in the cord not retracting properly.

- Pulley System: The pulley houses the cord and provides the rotational movement necessary to engage the internal mechanism.

- Engagement Gear: When the cord is pulled, this gear meshes with the engine’s flywheel, initiating the ignition process. Proper alignment is essential for a smooth start.

Oil Pump and Lubrication System

The lubrication mechanism is crucial for the optimal functioning of any mechanical device. It ensures that moving parts operate smoothly, reducing friction and wear. This section delves into the intricacies of the oil delivery system, emphasizing its significance in maintaining equipment longevity and performance.

Functionality of the Oil Pump

The oil pump is responsible for circulating lubricant throughout the engine, ensuring all vital components receive adequate protection. Its design typically incorporates several key elements:

- Flow Control: Regulates the amount of oil supplied to various parts.

- Pressure Regulation: Maintains optimal pressure to prevent leaks and inefficiencies.

- Self-Priming Capability: Enables the pump to start functioning effectively even after periods of inactivity.

Lubrication Techniques

Effective lubrication can be achieved through various methods, each tailored to specific operational requirements. Common techniques include:

- Wet Sump: Utilizes a reservoir where oil is stored and pumped through the system.

- Dry Sump: Employs a separate tank for the lubricant, allowing for better oil management and cooling.

- Auto-Feed Systems: Automatically supply oil at regulated intervals, ensuring continuous protection.

Understanding the oil delivery system and its components is vital for anyone involved in equipment maintenance. Regular inspection and timely servicing of the lubrication system can significantly enhance performance and extend the lifespan of the machinery.

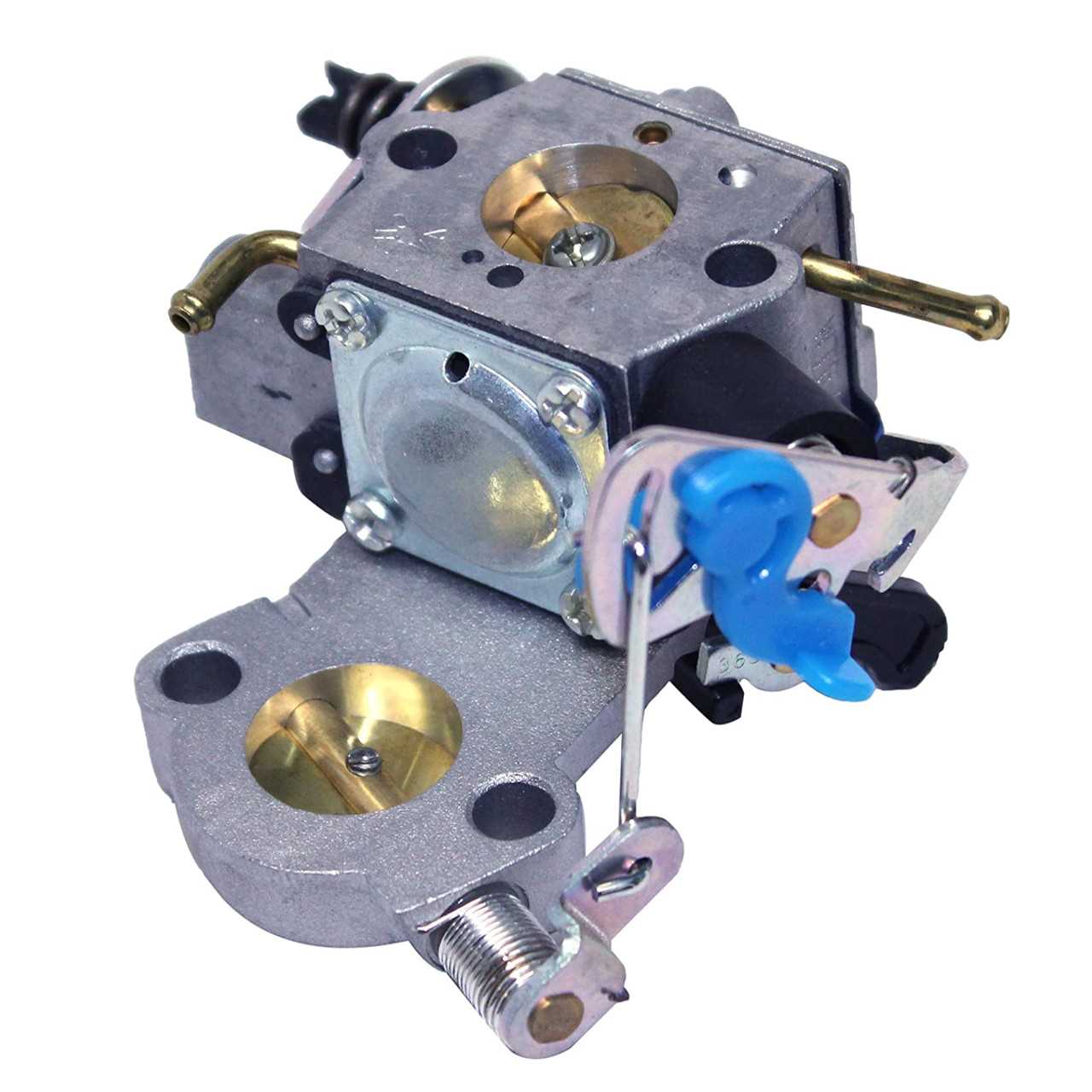

Air Filter and Carburetor Functionality

The efficiency of a small engine relies significantly on the proper functioning of its air intake and fuel delivery systems. These components work together to ensure that the engine receives the right mixture of air and fuel, which is crucial for optimal performance and longevity. Understanding their roles helps in maintaining the equipment effectively.

Importance of Air Filters

The air filter is designed to prevent dust, debris, and other contaminants from entering the engine. A clean air filter promotes better airflow, enhancing combustion efficiency. Regular maintenance of this component is essential, as a clogged filter can lead to reduced power output and increased fuel consumption. Therefore, monitoring the condition of the air filter and replacing it as needed is vital for sustained engine performance.

Role of Carburetors

The carburetor plays a crucial role in mixing air and fuel in the correct proportions. This process is essential for efficient combustion. It regulates the amount of fuel that enters the engine based on the air intake, adjusting for varying speeds and loads. Proper adjustment and maintenance of the carburetor ensure smooth operation and can prevent issues such as stalling or poor acceleration. Keeping both the air filter and carburetor in optimal condition is key to achieving peak performance from the equipment.

Throttle Control and Ignition Parts

The throttle control and ignition components play a crucial role in the operation of outdoor power equipment, ensuring optimal performance and responsiveness. Understanding the function and arrangement of these elements can enhance maintenance and troubleshooting efforts, leading to improved efficiency and longevity of the machine.

Throttle control is responsible for regulating the engine’s power output, allowing the user to adjust the speed according to the task at hand. The ignition system ignites the fuel-air mixture, enabling the engine to start and run smoothly. Both systems must work in harmony for the machinery to function effectively.

Component Description Throttle Trigger Controls the engine speed by varying the airflow into the carburetor. Throttle Cable Connects the throttle trigger to the carburetor, transmitting user input. Ignition Coil Generates the spark needed to ignite the fuel-air mixture in the combustion chamber. Spark Plug Delivers the electric spark to ignite the fuel mixture, crucial for engine startup. Kill Switch Stops the engine by interrupting the ignition system, ensuring user safety. Replacing Sprockets and Clutch Assembly

Maintaining the optimal performance of a cutting tool requires periodic replacement of specific components, particularly the sprockets and clutch assembly. These parts play a critical role in the effective transfer of power from the engine to the cutting chain. Ensuring these elements are in good condition is essential for the smooth operation and longevity of the equipment.

Before initiating the replacement process, it is important to gather the necessary tools and understand the steps involved. Here is a basic overview of the procedure:

Step Description 1 Disconnect the power source to ensure safety. 2 Remove the protective cover to access the components. 3 Detach the old sprocket and clutch assembly carefully. 4 Install the new sprocket and clutch assembly, ensuring proper alignment. 5 Reattach the protective cover and reconnect the power source. Following these steps will help maintain the functionality of the tool, allowing for efficient cutting and operational effectiveness. Regular inspections of these components can also help prevent unexpected breakdowns, ensuring a seamless workflow.