When it comes to maintaining your cutting tool, having a clear understanding of its various elements is essential. Each component plays a critical role in ensuring optimal performance and efficiency. Familiarizing yourself with these parts can help you identify potential issues, streamline repairs, and enhance the longevity of your equipment.

In this section, we will explore the intricate arrangement of components within your machine. By delving into the layout, you will gain insights into how each piece interacts with others, contributing to the overall functionality. This knowledge will empower you to tackle maintenance tasks with confidence and precision.

Moreover, recognizing the distinct functions of each element can assist you in making informed decisions regarding replacements and upgrades. Whether you are a seasoned professional or a hobbyist, understanding the anatomy of your tool is vital for achieving optimal results in your cutting endeavors.

Understanding the Husqvarna 450 Model

This section delves into the intricacies of a well-known outdoor power equipment model. It is designed for efficiency and user comfort, making it a popular choice among enthusiasts and professionals alike. By exploring its components, functionalities, and maintenance practices, users can enhance their understanding and optimize their experience with this remarkable machine.

Key Features and Benefits

The subject of discussion is characterized by a powerful engine, ergonomic design, and advanced features that cater to both novice and experienced operators. Its robust construction ensures durability, while the lightweight design enhances maneuverability, allowing for ease of use in various applications.

Maintenance and Care

| Component | Description |

|---|---|

| Engine | Powerful unit designed for efficiency and longevity. |

| Handle | Ergonomically designed for comfort and control. |

| Fuel Tank | Ample capacity for extended operation without frequent refueling. |

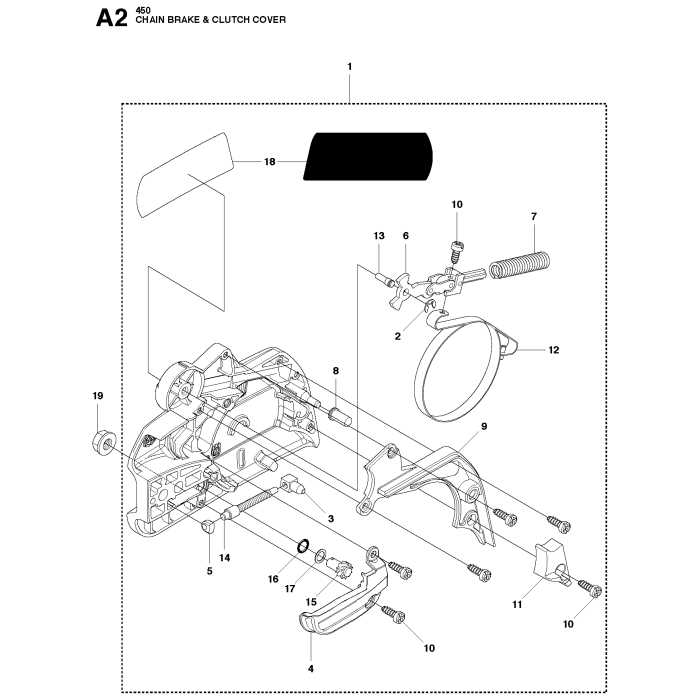

| Chain Brake | Safety feature to stop the chain quickly in case of kickback. |

Key Components of the Chainsaw

A chainsaw is a powerful tool designed for cutting through wood with efficiency and precision. Understanding its main elements is crucial for both operation and maintenance, ensuring optimal performance during use. Each component plays a significant role in the overall functionality of the device.

Engine: The heart of the machine, providing the necessary power to drive the cutting chain. Different models may feature various engine types, ranging from two-stroke to four-stroke, affecting fuel efficiency and torque.

Guide Bar: This elongated metal component acts as a track for the chain, allowing it to move smoothly while cutting. The length of the guide bar can influence the depth and speed of the cut, making it an essential factor in the tool’s capabilities.

Cutting Chain: A critical feature, this loop of metal links features sharp teeth that perform the actual cutting. The chain’s design varies, impacting its effectiveness in different types of wood and cutting conditions.

Clutch: This mechanism connects the engine to the cutting chain, allowing the user to control the chain’s movement. A well-functioning clutch is vital for safety, as it prevents the chain from spinning when the throttle is released.

Air Filter: Essential for maintaining engine performance, this component prevents dirt and debris from entering the engine. Regular cleaning or replacement of the air filter ensures optimal airflow and engine longevity.

Fuel Tank: This reservoir holds the mixture of fuel and oil necessary for engine operation. The size and accessibility of the fuel tank are important for extended use without frequent refueling.

Understanding these fundamental elements enhances the user’s ability to operate and maintain the chainsaw effectively, ensuring safety and efficiency in various cutting tasks.

Exploring the Parts Breakdown

Understanding the intricate components of a machine is essential for effective maintenance and repairs. This section delves into the various elements that make up the assembly, providing insights into their functions and relationships. A comprehensive view of these individual pieces aids in recognizing potential issues and streamlining the servicing process.

The following table outlines the key components, their descriptions, and relevant information to enhance your understanding:

| Component Name | Description | Function |

|---|---|---|

| Engine | The primary power source of the machinery. | Converts fuel into mechanical energy for operation. |

| Fuel Tank | Container that holds the fuel necessary for operation. | Supplies fuel to the engine for combustion. |

| Chain Brake | A safety feature that halts the chain’s movement. | Prevents accidents during operation by quickly stopping the chain. |

| Guide Bar | The long metal blade that supports the chain. | Guides the chain during cutting tasks. |

| Air Filter | Component that cleans the air entering the engine. | Ensures optimal performance by preventing dirt and debris from entering the engine. |

By familiarizing yourself with these components and their roles, you can better understand the overall functionality and performance of the machine, paving the way for efficient upkeep and troubleshooting.

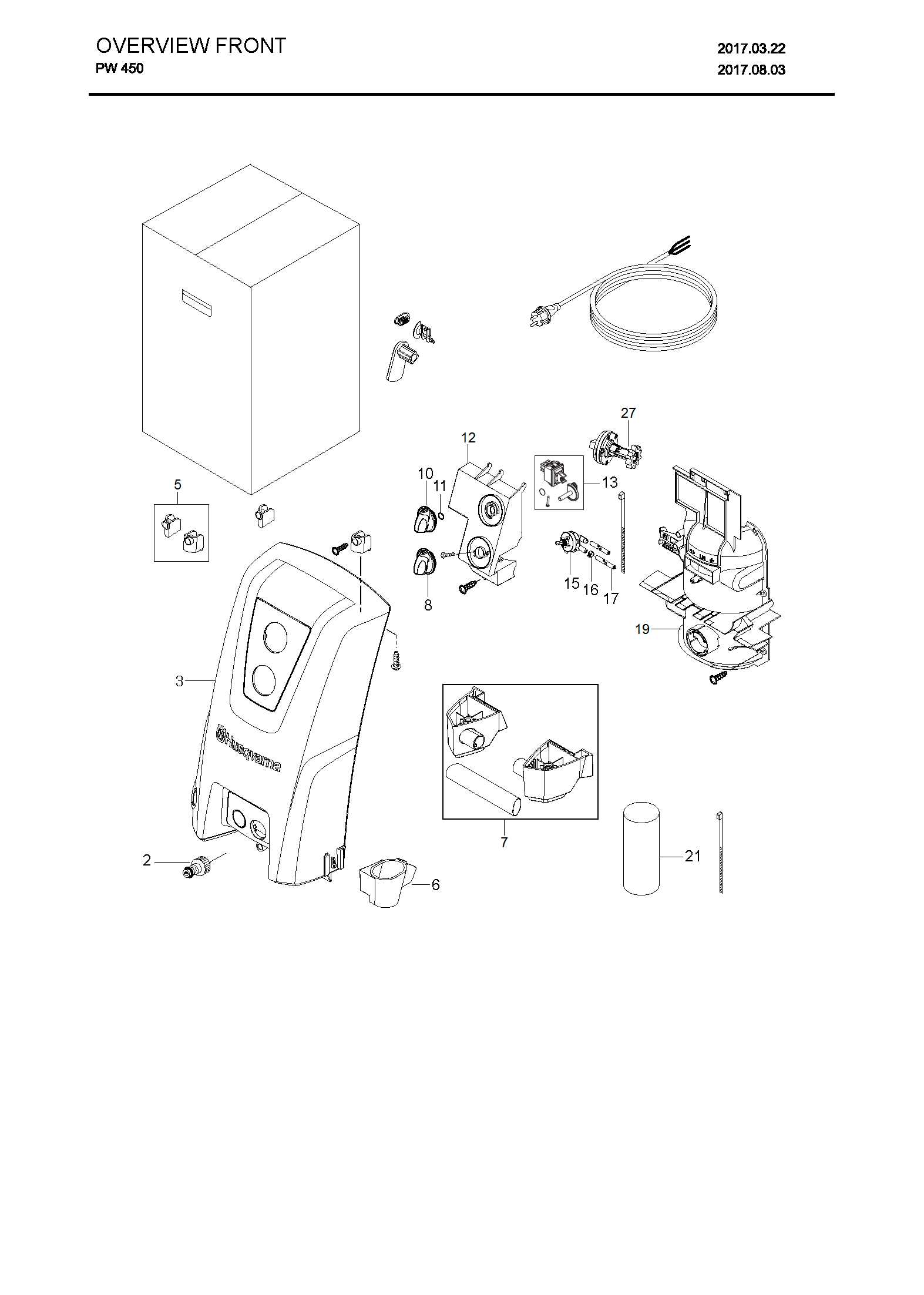

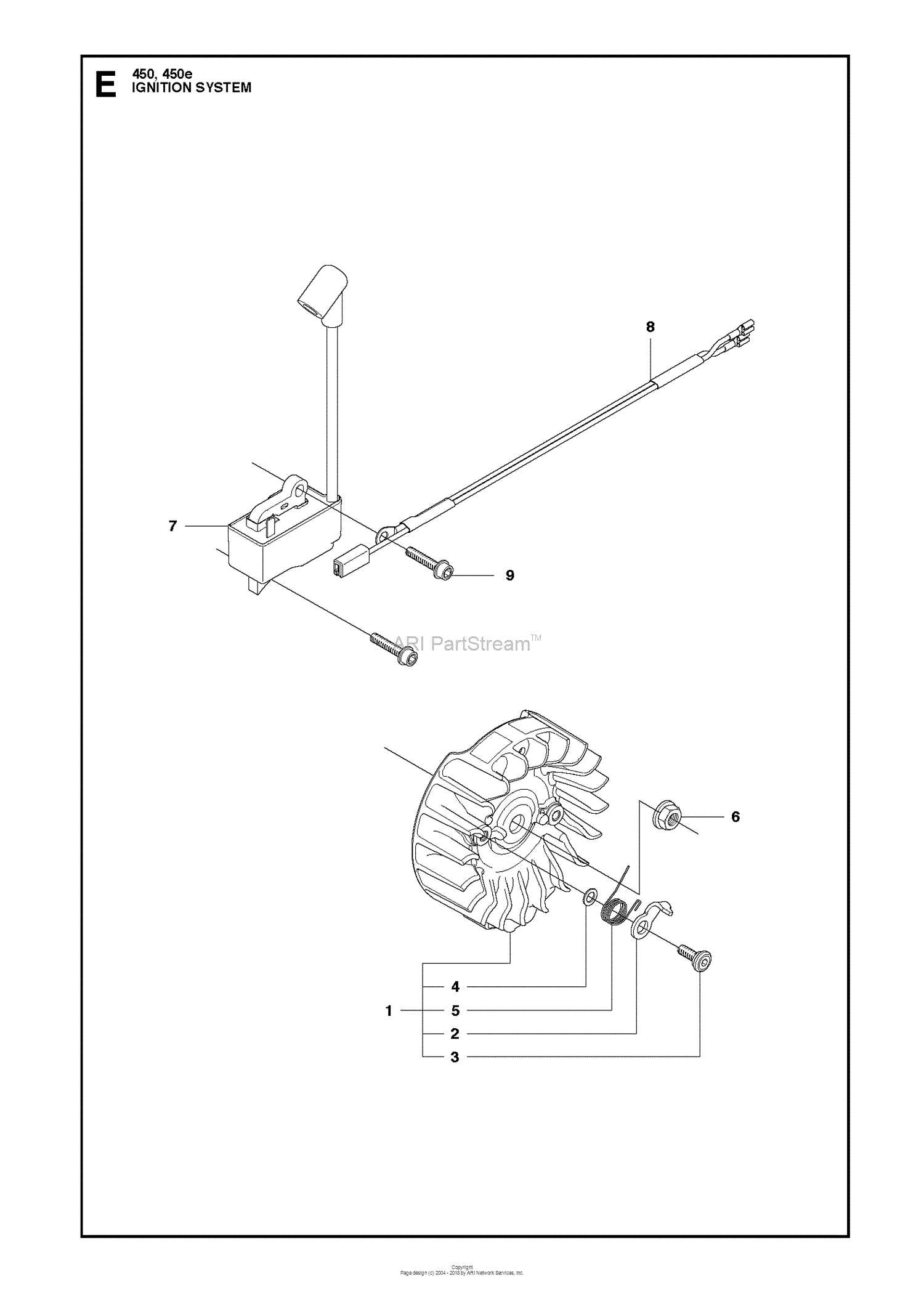

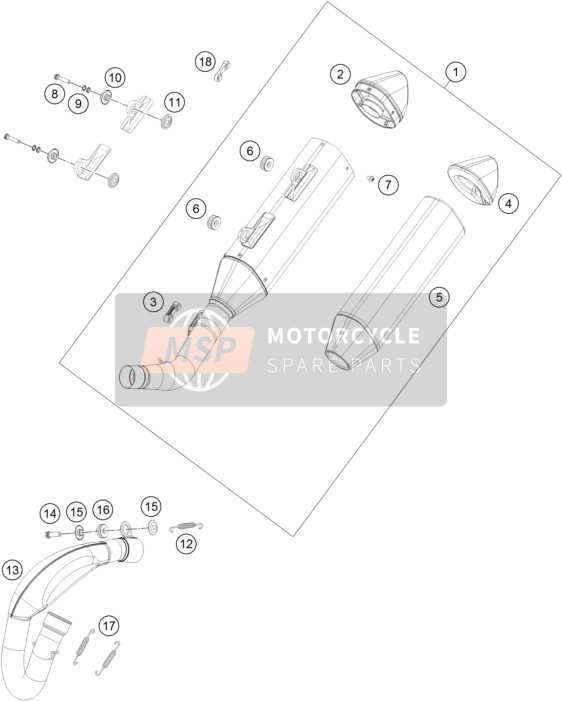

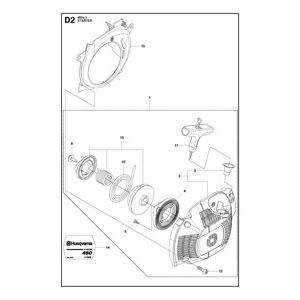

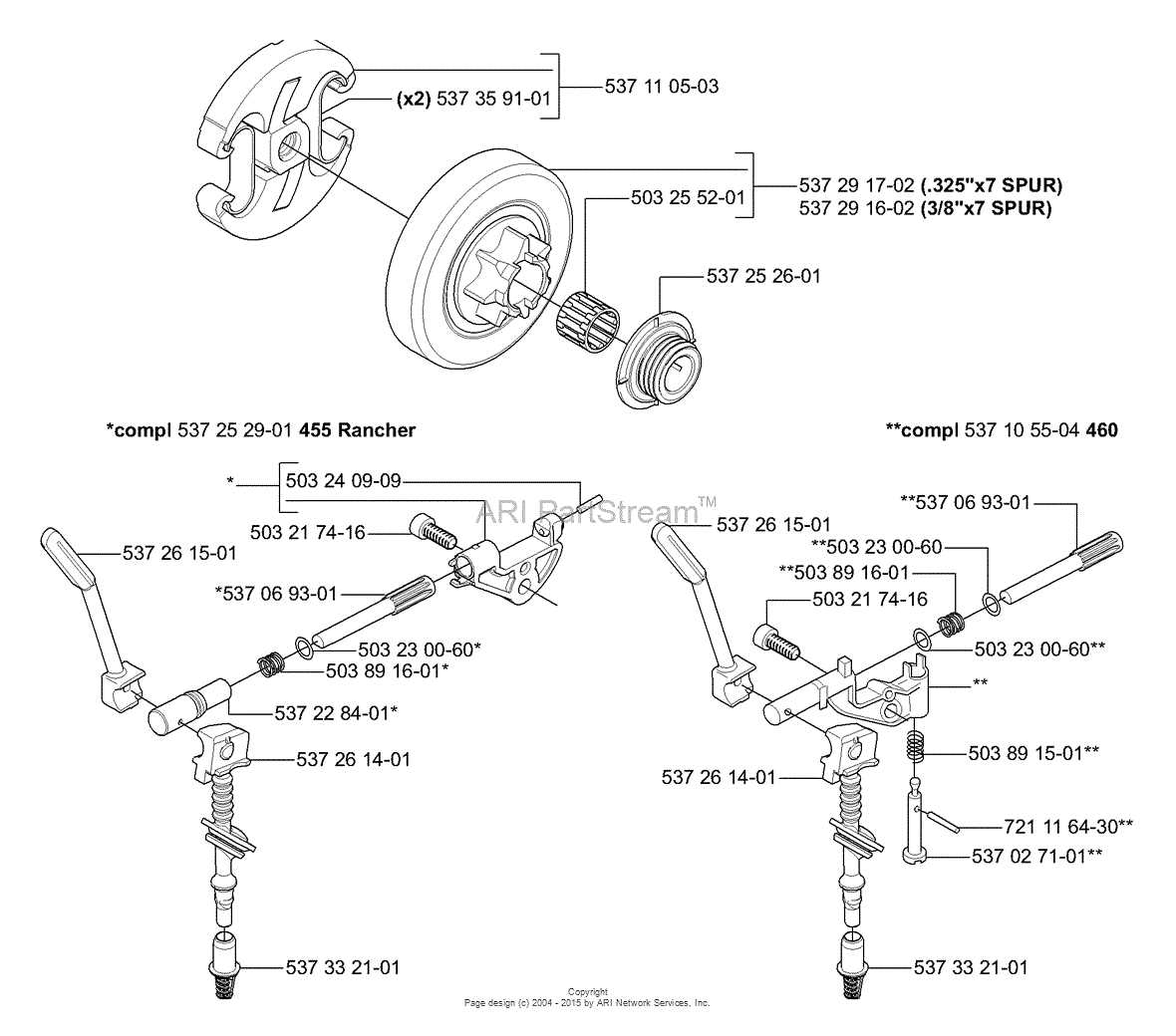

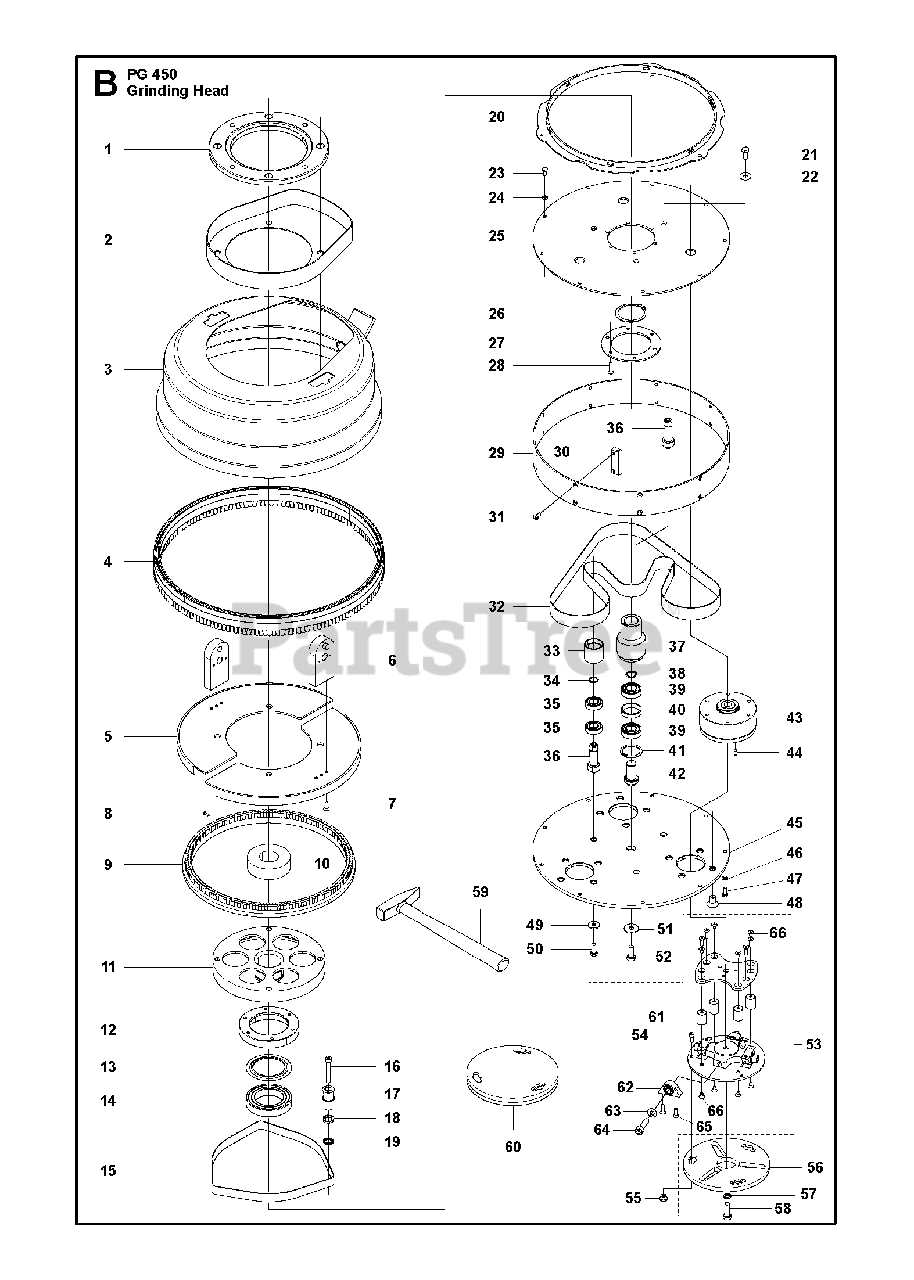

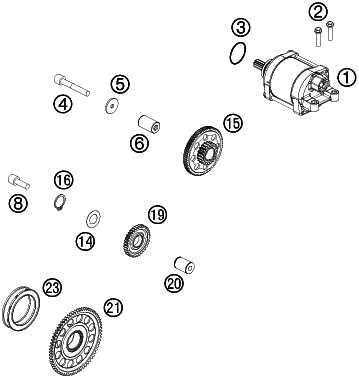

Assembly Diagram Overview

This section provides a comprehensive look at the structural representation of the equipment, showcasing the individual components and their interrelations. Understanding the assembly illustration is essential for effective maintenance and repairs, allowing users to identify each part’s location and function within the overall system.

The visual guide highlights critical elements, making it easier to comprehend how various pieces fit together. It serves as a valuable resource for technicians and enthusiasts alike, facilitating a deeper understanding of the machinery’s design and enhancing repair efficiency.

By analyzing this representation, users can better plan their assembly or disassembly procedures, ensuring that each component is correctly handled. This overview not only aids in troubleshooting issues but also promotes proper reassembly, reducing the likelihood of errors during maintenance tasks.

Common Replacement Parts Explained

In any mechanical device, there are components that frequently require replacement due to wear and tear over time. Understanding these essential elements can help users maintain optimal performance and extend the life of their equipment. This section delves into the most commonly replaced components, highlighting their functions and importance.

| Component | Description | Signs of Wear |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean airflow. | Reduced performance, increased engine noise, or visible dirt accumulation. |

| Spark Plug | Ignites the air-fuel mixture in the combustion chamber, crucial for engine starting. | Difficult starting, poor acceleration, or misfiring engine. |

| Chain | Transfers power from the motor to the cutting tool, essential for effective operation. | Excessive stretching, visible damage, or irregular cutting. |

| Fuel Filter | Filters contaminants from the fuel before it enters the engine, ensuring smooth operation. | Engine stalling, reduced power, or difficulty starting. |

| Bar | Supports the cutting chain and guides it during operation. | Uneven wear, warping, or noticeable nicks along the edges. |

Maintenance Tips for Longevity

To ensure the extended life of your equipment, regular upkeep is essential. Proper maintenance not only enhances performance but also prevents costly repairs in the long run. By following a few straightforward practices, you can significantly improve the durability and reliability of your machinery.

One of the fundamental aspects of maintenance is routine inspections. Regularly checking key components helps identify potential issues before they escalate. Additionally, keeping your machine clean is vital, as dirt and debris can lead to wear and tear. Ensure all parts are free from contaminants and that lubrication is applied where necessary.

Another crucial factor is adhering to the manufacturer’s guidelines for maintenance schedules. This includes replacing filters, sharpening blades, and checking fuel and oil levels. Using high-quality fuel and lubricants will also contribute to the overall health of your equipment.

| Maintenance Task | Frequency |

|---|---|

| Inspect Filters | Every 25 hours |

| Sharpen Blades | Every 50 hours |

| Change Oil | Every 50 hours |

| Check Fuel Levels | Before each use |

| Clean Exterior | After each use |

By incorporating these practices into your maintenance routine, you can enjoy improved performance and extended lifespan of your equipment. Remember that consistent care is the key to reliability and efficiency.

Tools Required for Assembly

To ensure a smooth and efficient assembly process, it is essential to have the right tools at hand. Proper equipment not only aids in accuracy but also enhances safety and minimizes the risk of damage to components.

The following is a list of recommended tools that will facilitate the assembly process:

- Socket Set: A comprehensive set of sockets in various sizes is crucial for loosening and tightening bolts effectively.

- Torque Wrench: This tool helps apply the correct amount of torque to fasteners, ensuring secure and reliable connections.

- Philips and Flathead Screwdrivers: Both types are needed for different screws throughout the assembly.

- Pliers: These are useful for gripping and manipulating small parts during the assembly process.

- Allen Wrenches: Often required for hexagonal screws, these tools are vital for certain components.

- Utility Knife: Ideal for cutting packaging materials or adjusting small components as needed.

In addition to these basic tools, having a clean and organized workspace can significantly improve efficiency. Ensuring all tools are readily accessible will streamline the assembly process and help avoid potential frustrations.

Finding Genuine Husqvarna Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using original materials not only guarantees compatibility but also enhances the reliability of your machine. This section will explore effective strategies to locate legitimate items that will keep your equipment running smoothly.

1. Authorized Dealers: One of the most reliable ways to acquire original components is through official distributors. These outlets offer a wide selection of items and can provide guidance on the right choices for your model. Ensure that the dealer you choose is recognized by the manufacturer to avoid counterfeit options.

2. Online Retailers: Numerous reputable online platforms specialize in outdoor machinery components. Look for websites that have clear return policies and customer reviews, which can provide insights into their legitimacy. Always verify that the items listed are genuine and suited for your specific model.

3. Manufacturer’s Website: Visiting the official website can be beneficial for both information and shopping. Many manufacturers provide detailed catalogs and allow you to order directly from them. This is often the safest method to guarantee that you are purchasing authentic materials.

4. Community Forums: Engaging with fellow enthusiasts through online forums can be invaluable. Users often share their experiences and recommend reliable sources for authentic components. This can also help you learn about potential issues and solutions related to your equipment.

5. Local Repair Shops: Inquiring at local service centers can yield valuable insights. Technicians often have access to original items and can assist in identifying what you need. They may also offer installation services, ensuring that everything is fitted correctly.

In conclusion, ensuring you have access to authentic materials for your equipment is vital for its performance and durability. By utilizing authorized dealers, reliable online platforms, and community resources, you can confidently maintain your machinery for years to come.

FAQs About Husqvarna 450 Parts

This section addresses common inquiries regarding components of a popular chainsaw model. Understanding these elements is crucial for effective maintenance and repairs. Below, you will find answers to frequently asked questions to enhance your knowledge of this machinery.

| Question | Answer |

|---|---|

| What types of components are available for this model? | Various components such as blades, filters, spark plugs, and oil caps can be sourced for optimal functionality. |

| Where can I find replacement components? | Replacement items can be found at authorized retailers, online marketplaces, or through specialized distributors. |

| How do I know if a component is compatible? | Checking the model number and specifications listed in the user manual can help confirm compatibility with specific components. |

| Is it necessary to use original manufacturer components? | While original components are recommended for best performance, high-quality aftermarket options may also be suitable. |

| What should I do if a component breaks? | If a part breaks, it is advisable to replace it immediately to ensure safe and efficient operation of the equipment. |