In the realm of outdoor maintenance, comprehending the intricate workings of lawn care machinery is essential for optimal performance and longevity. A well-structured visual representation of the various elements that make up these machines can serve as an invaluable resource for both enthusiasts and professionals alike. This section delves into the specifics of a popular model, emphasizing the importance of each component and its role in the overall functionality.

Every piece within these machines has a distinct purpose, contributing to their efficiency and effectiveness. From the cutting blades to the engine, understanding how each element interacts can help users make informed decisions regarding maintenance and repairs. Furthermore, a clear layout allows for easier identification of parts when seeking replacements or upgrades.

By familiarizing yourself with the essential features of this equipment, you empower yourself to tackle common issues, ensuring a well-maintained lawn and a reliable tool at your disposal. This knowledge not only enhances your gardening experience but also extends the lifespan of your machinery.

Understanding Honda HRX 217 Components

Gaining insight into the various elements of a lawn care machine can significantly enhance your maintenance experience and operational efficiency. This understanding allows for more effective troubleshooting and repairs, ensuring your equipment runs smoothly for years to come.

Each machine consists of several critical components, each serving a specific purpose. Here are some key elements you should be familiar with:

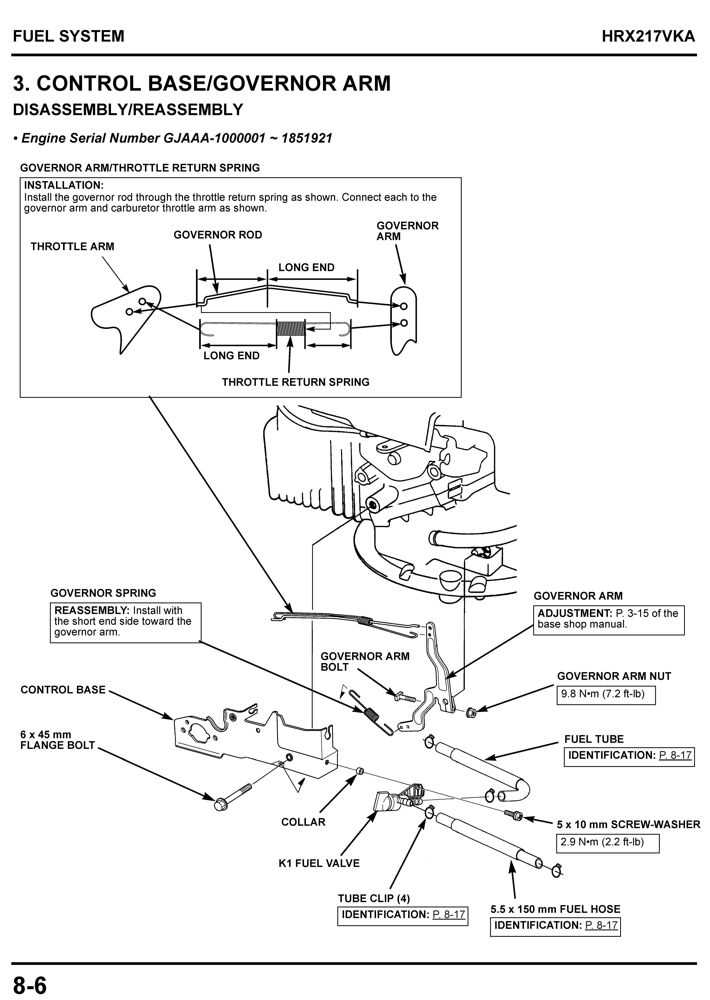

- Engine: The powerhouse of the device, responsible for generating the necessary energy for operation.

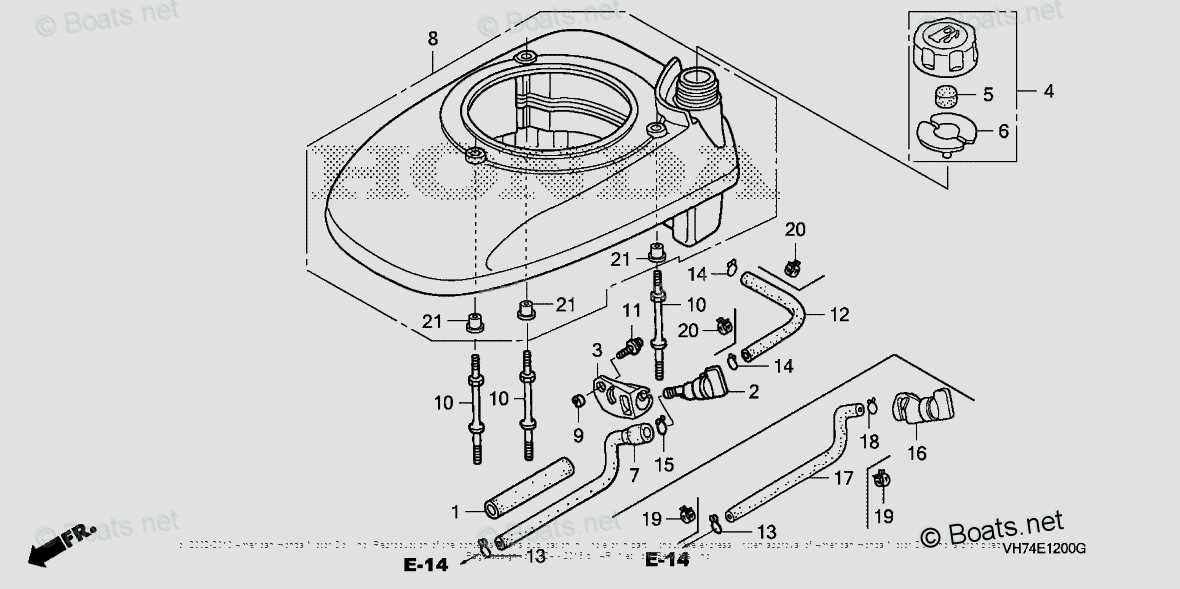

- Deck: The housing that protects internal components and provides the cutting surface for grass.

- Blades: Sharp implements designed to cut grass evenly, requiring regular maintenance for optimal performance.

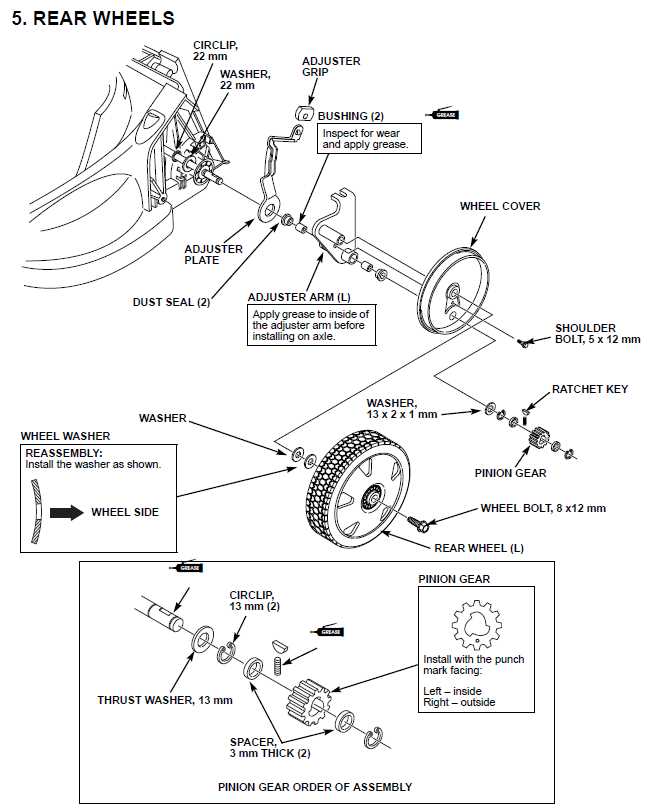

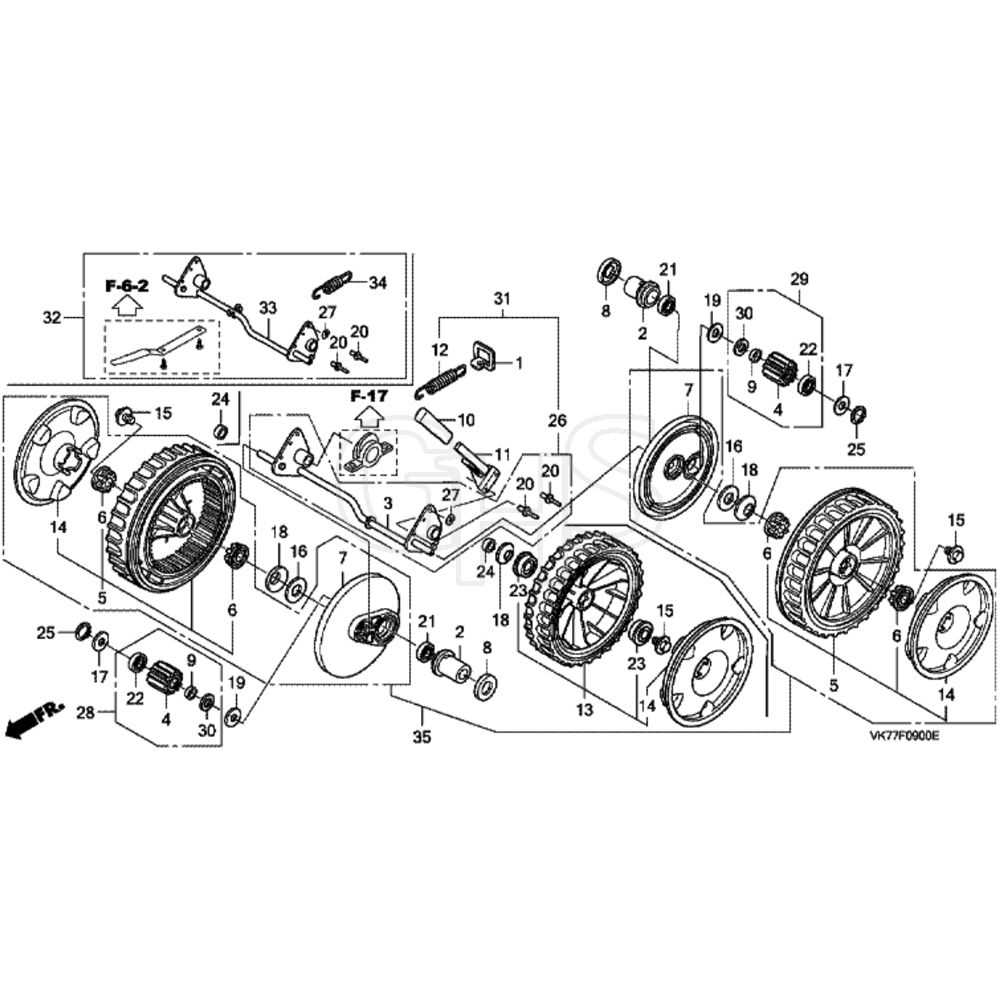

- Wheels: Facilitating mobility, their size and tread can influence handling and ease of use.

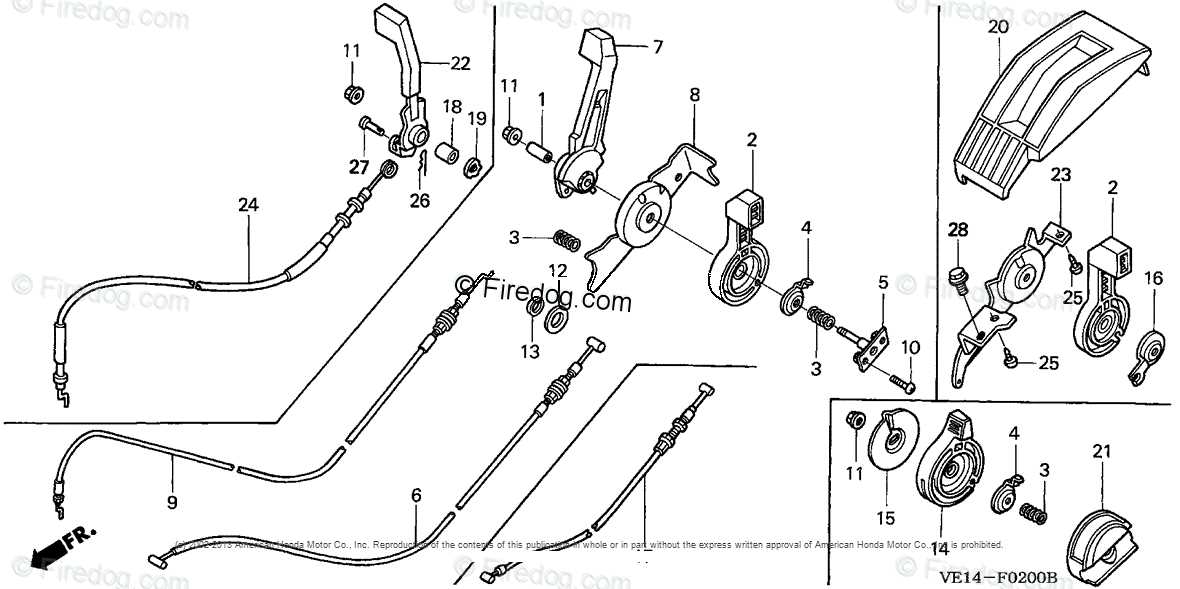

- Handle: The user interface for steering and control, often adjustable for comfort.

Understanding these elements can empower you to make informed decisions regarding repairs and upgrades. Regular inspection and maintenance of these components can prolong the lifespan of your machine and improve its performance.

Importance of Parts Diagrams

Understanding the intricate details of machinery requires a clear visual representation of its components. Such illustrations serve as essential tools for both professionals and enthusiasts, enabling them to navigate the complexities of assembly and maintenance. By offering a detailed view, these visuals help in identifying individual elements, ensuring that repairs and replacements are carried out accurately.

Efficiency in Repairs is significantly enhanced when one has access to a visual guide. It streamlines the process of locating specific items, thereby reducing downtime and frustration. When every part is clearly labeled, technicians can quickly determine what needs to be replaced or fixed, leading to faster resolutions.

Improved Understanding of the overall design is another benefit of these illustrations. They not only depict how components fit together but also highlight the functionality of each piece. This understanding is invaluable for users who wish to deepen their knowledge about their equipment and enhance their skills in maintenance and repair.

Furthermore, having a visual reference encourages better organization during the repair process. It allows individuals to gather the necessary components before starting work, minimizing the risk of misplacing items or overlooking essential steps. This preparation ultimately contributes to a more effective and hassle-free experience.

In summary, clear visual representations of machinery elements are indispensable for anyone involved in maintenance or repair. They facilitate efficiency, deepen understanding, and promote organization, ensuring that users can engage confidently with their equipment.

Key Features of HRX 217 Model

This model stands out in the lawn care equipment category due to its innovative design and user-friendly functionality. It combines efficiency and power, making it suitable for a variety of mowing tasks. The unique features enhance performance and provide a reliable experience for users.

Performance Enhancements

Equipped with advanced technologies, this model delivers superior cutting capabilities. Its robust engine ensures optimal power, while the cutting height adjustment allows for precise grass management.

User Convenience

The ergonomic design promotes comfort during operation, reducing fatigue. Additionally, features like a quick-release handle make it easy to transport and store.

| Feature | Description |

|---|---|

| Powerful Engine | Delivers high torque for effective cutting. |

| Adjustable Cutting Height | Customizes grass length to user preference. |

| Lightweight Design | Facilitates easy maneuverability. |

| Ergonomic Handle | Enhances comfort and control during use. |

Identifying Essential Spare Parts

Understanding the key components of your equipment is crucial for maintaining optimal performance. Knowing which elements may need replacement can save time and enhance efficiency. This section will guide you through the process of recognizing vital replacement items, ensuring your machinery runs smoothly.

When assessing what may require attention, consider the following categories:

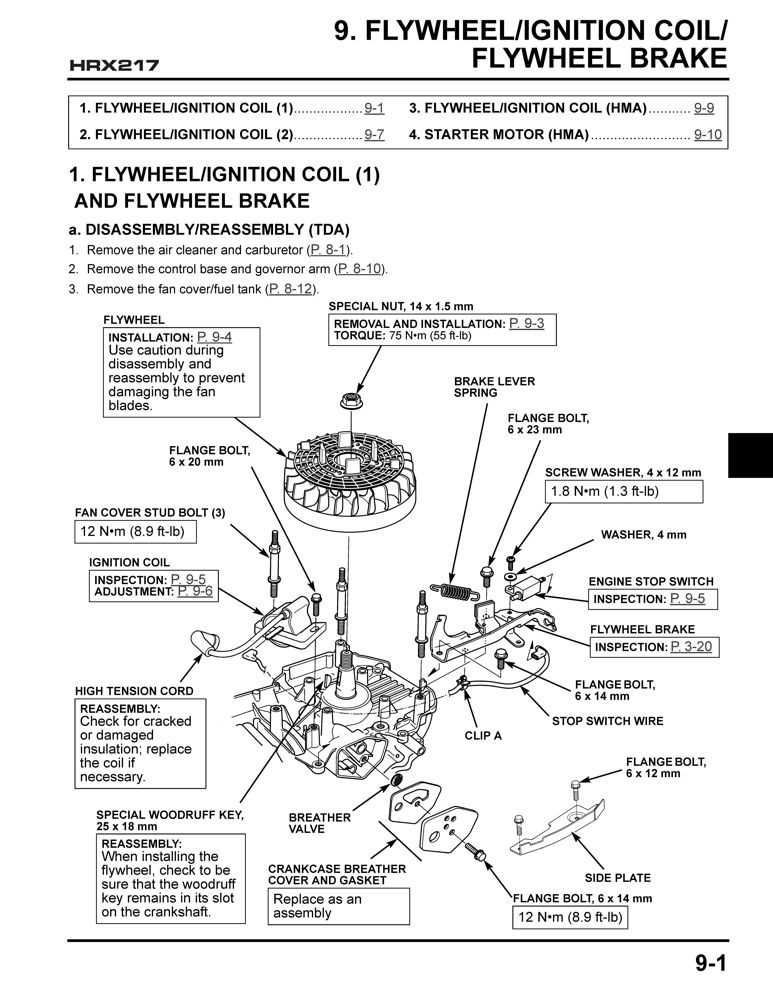

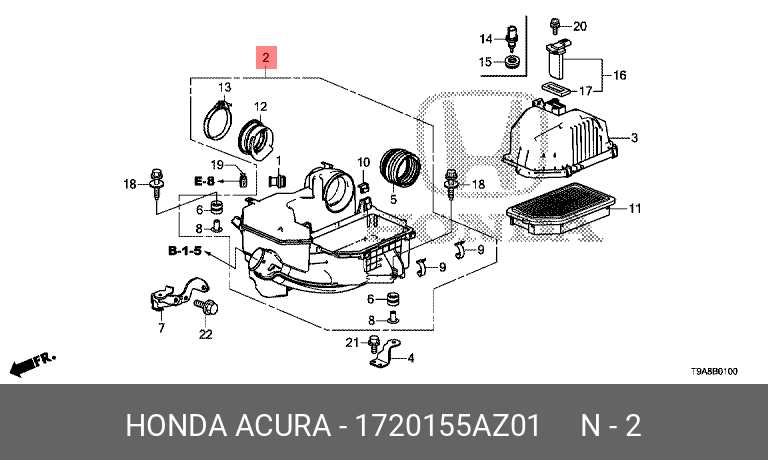

- Engine Components: These include the spark plug, air filter, and fuel lines. Regular checks can prevent larger issues.

- Cutting Elements: Blades and blade adapters are essential for effective operation. Keep an eye on their wear and sharpness.

- Chassis and Frame Parts: The overall structure may have components like wheels, handles, and brackets that can deteriorate over time.

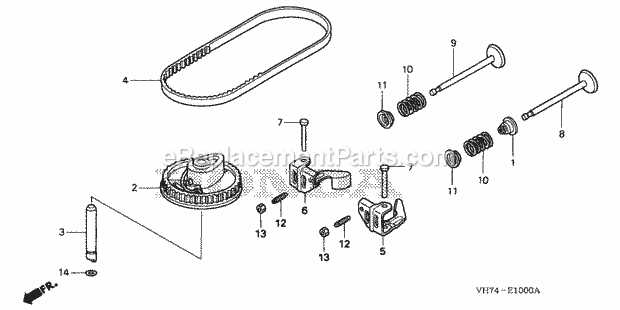

- Transmission and Drive Parts: Belts and gears facilitate movement. Inspect these regularly to avoid breakdowns.

To ensure you are prepared, create a checklist of these components, and monitor their condition during routine maintenance. This proactive approach will help you identify what needs replacing before it affects performance.

How to Access Parts Diagrams

Locating the necessary illustrations for components is essential for effective maintenance and repair of your equipment. Understanding where to find these visuals can greatly enhance your ability to identify and order the correct elements for your machine. This guide will walk you through various methods to access detailed schematics, ensuring you have the right resources at your fingertips.

Online Resources

The internet is a treasure trove of information, offering numerous websites dedicated to providing detailed breakdowns of machinery components. Official manufacturer websites often feature sections where you can search for your specific model, accessing both schematics and additional specifications. Online forums and user communities can also be invaluable, as members frequently share links and resources that may not be readily available elsewhere.

Local Dealers and Service Centers

Your local dealer or service center is another reliable source for obtaining component illustrations. These establishments usually have access to comprehensive catalogs and technical documents. Visiting in person or contacting them directly can yield the necessary diagrams and even personalized assistance from experienced technicians who can guide you through the repair process.

Common Issues and Solutions

This section addresses frequent challenges encountered with lawn care equipment and provides effective remedies to ensure optimal performance and longevity.

- Engine Won’t Start

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the choke is properly adjusted.

- Uneven Cutting

- Examine the blade for sharpness and damage.

- Adjust the cutting height as needed.

- Inspect the wheels for proper alignment.

- Excessive Vibration

- Check for loose bolts or screws.

- Inspect the blade for imbalance.

- Ensure the equipment is on a level surface.

- Overheating

- Clear any debris from the air intake.

- Change the oil regularly.

- Check for fuel flow restrictions.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of any outdoor power equipment. Regular attention not only ensures optimal performance but also helps to prevent costly repairs down the line. By incorporating simple maintenance practices into your routine, you can enjoy a reliable and efficient machine for years to come.

Routine Checks

Establishing a schedule for regular inspections can greatly enhance the durability of your equipment. Here are some key areas to focus on:

- Inspect the air filter regularly and clean or replace it as needed.

- Check the spark plug for wear and replace it if necessary to ensure smooth ignition.

- Examine the blades for sharpness and damage; sharpen or replace them to maintain cutting efficiency.

- Monitor fuel levels and quality; use fresh fuel to prevent engine issues.

Seasonal Maintenance

Different seasons can present unique challenges. Adapting your maintenance routine accordingly can help safeguard your equipment:

- Spring: Start the season with a thorough cleaning and oil change.

- Summer: Regularly clean grass and debris from under the deck to prevent rust.

- Fall: Prepare for winter storage by draining fuel and protecting against moisture.

- Winter: Store in a dry, sheltered location to prevent damage from the elements.

By following these maintenance tips, you can enhance the longevity and performance of your outdoor machinery, ensuring it remains a valuable tool in your gardening or landscaping tasks.

Aftermarket vs. OEM Parts

When it comes to maintaining and repairing outdoor equipment, the choice between original components and alternative options can significantly impact performance and longevity. Understanding the differences between these categories helps consumers make informed decisions tailored to their needs.

Original components are produced by the manufacturer and are designed to fit and function precisely as intended. These items often come with warranties and guarantees, providing peace of mind regarding quality and compatibility.

- Advantages of Original Components:

- Exact fit and performance

- Manufacturer support and warranty

- Higher resale value

- Disadvantages of Original Components:

- Higher cost

- Limited availability

On the other hand, alternative options are made by third-party manufacturers. These components can offer cost savings and may provide features that are not available with original items.

- Advantages of Alternative Options:

- More affordable pricing

- Wider variety of choices

- Potential for enhanced performance

- Disadvantages of Alternative Options:

- Variable quality

- Possible compatibility issues

- Limited or no warranty

Ultimately, the decision between original and alternative components should be based on factors such as budget, intended use, and the importance of quality assurance. Weighing the pros and cons will help ensure optimal performance and satisfaction with the chosen solution.

Resources for Further Research

This section aims to guide enthusiasts and technicians in their quest for in-depth knowledge regarding maintenance and repair components for various outdoor machinery. By leveraging credible resources, users can enhance their understanding and improve their skills in managing these devices effectively.

Online Communities

Participating in forums and social media groups dedicated to outdoor equipment can provide valuable insights. Members often share experiences, tips, and resources, creating a collaborative environment for troubleshooting and advice.

Manufacturer Websites

Visiting official websites of manufacturers is essential for accessing manuals, technical specifications, and updates on new products. These platforms often contain comprehensive guides and support resources to assist users in their maintenance endeavors.