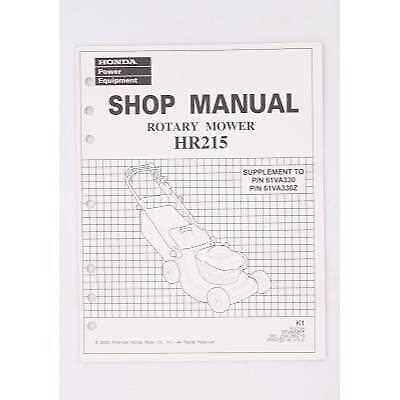

Understanding the internal structure of your equipment is essential for smooth operation and longevity. By familiarizing yourself with the different elements and their arrangement, you can ensure that every part performs optimally. Knowing the layout also helps you quickly identify and address potential issues before they become more significant problems.

Having a clear visual representation of how individual components connect allows for easier troubleshooting and replacement. This detailed insight into the machine’s build ensures that maintenance tasks are carried out accurately, preventing unnecessary wear and ensuring continued efficiency.

Equipping yourself with the right knowledge about the internal mechanisms improves not only the lifespan of your machine but also your ability to resolve issues with confidence. A well-organized approach to servicing ensures that every task, from minor adjustments to major repairs, can be handled with precision and care.

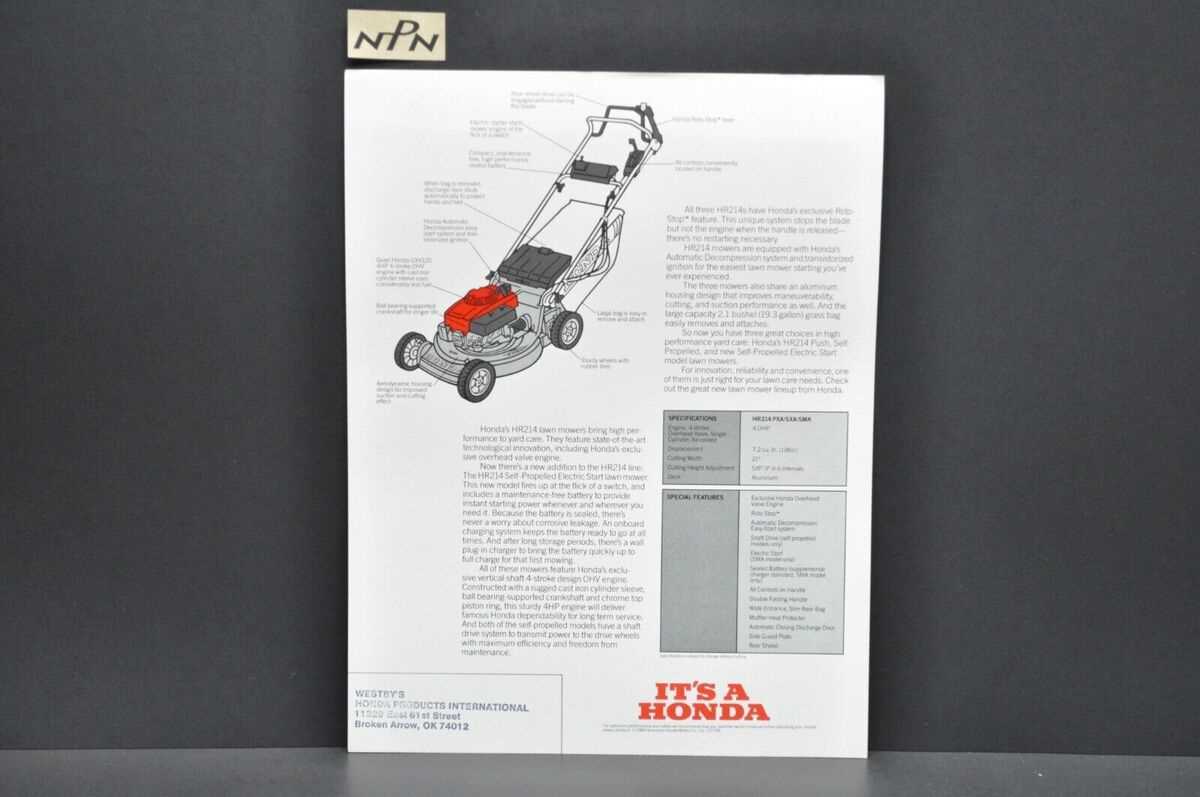

Honda HR214 Parts Overview

The mechanical structure of this lawn tool is composed of various essential components that work together to provide optimal performance. Understanding the layout of these elements allows for efficient maintenance and longer equipment life. Each piece, from the engine to the cutting deck, has a specific role in ensuring smooth operation and reliability.

Key Elements and Functions

The most critical sections of this machine include the power source, the blade system, and the drive mechanisms. These elements are designed to offer precision and durability in a variety of working conditions. Regular inspections and replacements of these parts can prevent malfunctions and extend usability.

| Component | Function |

|---|---|

| Engine Assembly | Powers the entire machine for effective cutting performance. |

| Blade System | Ensures precise grass cutting and smooth operation. |

| Drive Mechanism | Allows controlled movement and direction during operation. |

Engine Components and Maintenance

The internal structure of any power unit relies on a series of vital elements working together efficiently. Regular upkeep is essential for ensuring smooth operation and prolonging the lifespan of the machine. Understanding the primary elements involved and knowing how to maintain them can prevent issues and ensure reliability.

Main Engine Elements

- Cylinder Block: The core housing where combustion occurs, forming the foundation of the system.

- Piston Assembly: Moves within the cylinder to generate the necessary force for operation.

- Crankshaft: Converts the linear movement of the pistons into rotational motion.

- Valves: Regulate the flow of air and fuel mixture in and out of the chamber.

Maintenance Tips

- Inspect the air filter regularly and clean or replace it to ensure optimal airflow.

- Change the oil at recommended intervals to maintain lubrication and prevent wear.

- Check the spark plug for any signs of damage or corrosion and replace it if necessary.

- Ensure the cooling system is functioning correctly to prevent overheating during operation.

By following these simple steps, the longevity and efficiency of the engine can be maintained with minimal effort.

Blade Assembly and Cutting Mechanism

The blade assembly is a critical component that ensures efficient grass cutting by maintaining sharpness and durability. It works in tandem with the cutting mechanism to achieve clean and precise cuts, optimizing the overall performance of the machine. This section delves into the interaction between these two elements and how they contribute to effective operation.

Components of the Blade Assembly

The blade assembly consists of multiple elements that work together to achieve optimal results. These include the rotating blade itself, which must be regularly maintained to ensure proper sharpness, and the fastening hardware that secures it in place. Proper alignment and balance of these components are essential to avoid uneven cuts or vibrations during operation.

Cutting Mechanism Overview

The cutting mechanism is designed to maximize efficiency by guiding the blade through the material with minimal resistance. It includes features that enhance airflow and reduce drag, allowing for smoother operation and reducing strain on the motor. Maintaining this mechanism in good condition ensures long-lasting performance.

| Component | Function |

|---|---|

| Blade | Responsible for cutting the material |

| Fastening Hardware | Keeps the blade securely attached |

| Airflow Enhancers | Improves cutting efficiency by reducing drag |

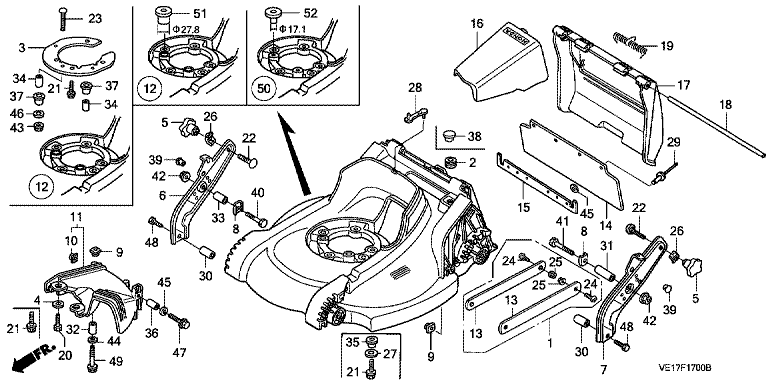

Deck Structure and Protection

The deck is a vital component, providing both the framework and surface required for optimal operation. Its design ensures strength and durability, allowing for smooth performance under various conditions. Proper care and attention to the structure are crucial to maintain longevity and functionality over time.

- Material Quality: The durability of the deck relies on the quality of materials used. Ensuring that the surface resists wear from environmental factors is key.

- Surface Coating: Applying protective coatings helps shield the structure from rust, corrosion, and debris build-up, which can affect performance.

- Reinforcement: For enhanced strength, reinforcements are incorporated into critical areas, providing added resistance to stress and bending.

- Maintenance: Regular cleaning and inspections ensure that the structure remains free from damage, reducing the risk of long-term issues.

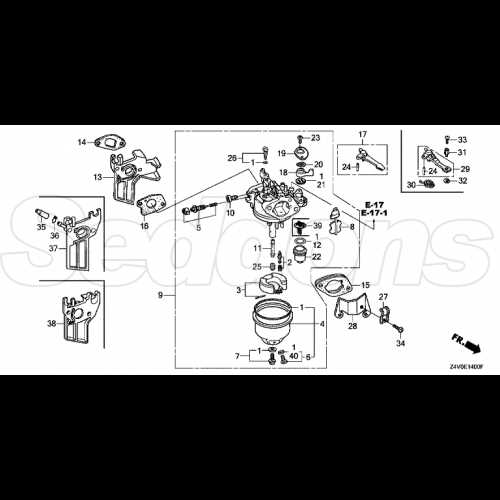

Fuel System Parts and Functionality

The fuel delivery mechanism ensures efficient transfer of energy necessary for smooth operation. It includes several interconnected elements designed to regulate the flow and mixture of fuel with air, optimizing the combustion process and overall engine performance. These components work together, ensuring proper ignition and steady power output.

Key Components in the System

Among the crucial elements are the fuel container, responsible for storage, and the delivery line that transports liquid energy to the combustion area. Additionally, the regulation valve controls the amount of fuel entering the system, while the filter ensures only clean, impurity-free fuel is utilized. Each element plays a significant role in maintaining efficiency and extending the machine’s lifespan.

Functionality Overview

The system’s functionality hinges on precise coordination between each element. The valve adjusts the flow based on power demands, while the delivery line ensures a consistent supply. The filter, meanwhile, safeguards the internal components by preventing contaminants from entering the sensitive areas, thus promoting smooth operation and preventing engine issues.

Transmission and Drive System Breakdown

The transmission and drive system in a lawn care machine is responsible for transferring power efficiently from the engine to the wheels, ensuring smooth operation and maneuverability. This system involves various interconnected components that work together to control speed, direction, and overall movement, allowing for precise handling and efficient cutting performance.

Main Components

The drive system typically consists of a clutch mechanism, drive belt, gearbox, and axles. These elements collaborate to translate engine energy into motion, maintaining optimal performance while mowing. Proper maintenance and understanding of how these parts interact can prolong the life of the equipment and enhance its functionality.

| Component | Function |

|---|---|

| Clutch | Engages and disengages the drive mechanism |

| Drive Belt | Transfers power from the engine to the transmission |

| Gearbox | Controls the speed and torque distribution |

| Axles | Connect the wheels to the drive system, enabling movement |

Handle and Control Features

The design of the handle and control elements is crucial for ensuring a comfortable and efficient user experience. These features not only enhance maneuverability but also provide intuitive access to various functions, allowing for smooth operation in different conditions.

Ergonomic Design

Ergonomically shaped handles are essential for reducing fatigue during prolonged use. These grips are crafted to fit the natural contours of the hand, providing optimal comfort and control, thus allowing users to navigate with ease.

Control Accessibility

Strategically placed controls ensure that operators can quickly access essential functions without interrupting their workflow. This accessibility enhances safety and efficiency, allowing users to focus on the task at hand while maintaining precise control.

Air Filter and Exhaust System Details

The air filtration and exhaust mechanisms play a crucial role in maintaining optimal performance and efficiency in outdoor power equipment. Understanding their components and functions can significantly enhance operational longevity and reduce maintenance needs.

Air Filter Components

- Element: Captures dust and debris, ensuring clean air intake.

- Cover: Protects the filter and secures it in place.

- Mounting Bracket: Facilitates easy installation and removal.

Exhaust System Elements

- Exhaust Pipe: Directs harmful gases away from the engine.

- Muffler: Reduces noise produced during operation.

- Gasket: Ensures a tight seal between components to prevent leaks.

Regular checks and replacements of these parts are essential for peak performance and efficiency.

Wheel and Axle Assembly Components

The wheel and axle assembly is a critical component of any wheeled machine, ensuring smooth mobility and effective power transfer. This assembly comprises various elements that work together to facilitate movement, support weight, and provide stability during operation.

Key Components

The primary components of this assembly include the wheel, axle, bearings, and spacers. The wheel provides traction, while the axle serves as the central shaft around which the wheel rotates. Bearings reduce friction, allowing for smoother movement, and spacers maintain proper alignment between the wheel and axle.

Importance of Quality Materials