Understanding the inner workings of an engine can be crucial for ensuring its long-term efficiency and performance. By breaking down the key elements involved, users can gain valuable insights into how to maintain and repair their equipment more effectively. Each element plays a vital role in the overall functionality, contributing to the smooth operation and durability of the machine.

In this guide, we’ll take a closer look at the various essential components, highlighting their purpose and how they interact within the system. Whether you’re performing routine maintenance or troubleshooting, knowing these elements will empower you to make more informed decisions, keeping your engine in top shape.

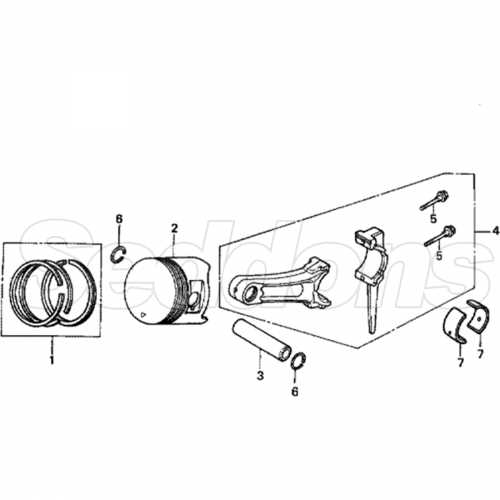

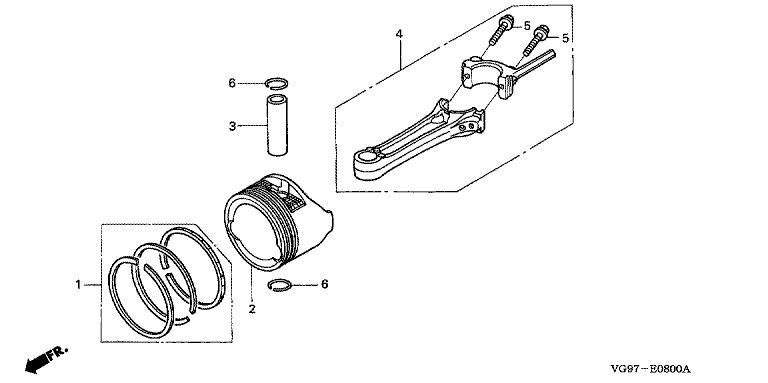

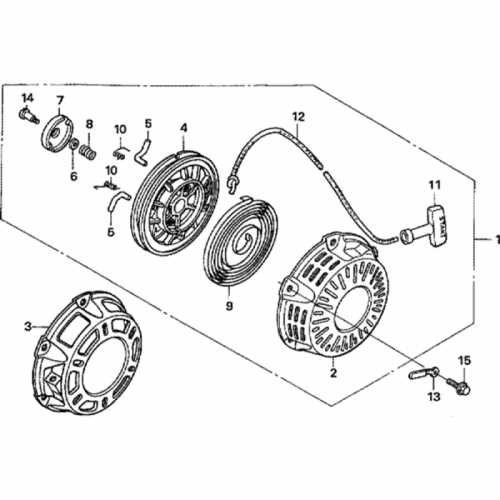

Detailed diagrams can serve as an excellent reference, offering a visual representation of how different elements are assembled. With a clear understanding of these elements, you can tackle mechanical issues with greater confidence, ensuring your machine operates at its best for years to come.

Overview of the Honda GX620 Engine

The discussed model is known for its reliability and high performance. It features a robust build that ensures durability in a wide range of demanding applications. Its design allows for efficient fuel consumption, making it an excellent choice for various power equipment. The engine operates smoothly under heavy loads, delivering consistent power output. Thanks to its precise engineering, it provides a stable and dependable operation in both commercial and residential settings.

With an emphasis on longevity and minimal maintenance, this motor includes features that enhance both its ease of use and lifespan. It has been tailored to meet the needs of users who require a versatile and powerful source of energy. The careful balance between power and efficiency allows it to maintain a high level of performance while keeping operational costs manageable. These attributes make it a standout option for anyone seeking a reliable energy solution.

Main Components of the Honda GX620

The mechanical structure of this engine model is composed of several key elements that ensure its optimal performance and durability. These elements work together to provide efficient power generation, making the motor reliable in various applications. Understanding the roles of these components is essential for maintaining and enhancing the overall functionality of the engine.

Core Elements of the Engine

One of the fundamental parts of this engine is the cylinder block, which houses the pistons and other critical mechanisms. This block is designed to withstand high pressure and temperatures, ensuring consistent output. The pistons themselves are responsible for transferring the force generated by fuel combustion to the crankshaft, creating the power needed for operation.

Power Distribution Mechanisms

The engine’s crankshaft plays a central role in converting linear motion into rotational energy. Connected to the crankshaft is the camshaft, which regulates the timing of valve operations, ensuring that the intake and exhaust valves open and close at the right intervals. These synchronized movements are vital for the smooth running of the engine and fuel efficiency.

Understanding the Function of Key Engine Parts

To ensure optimal performance, it is essential to comprehend the role that each component plays in an engine. Every element contributes to the overall efficiency, power delivery, and longevity of the machine. By understanding how these mechanisms work together, one can maintain the engine more effectively and troubleshoot issues with greater precision.

| Component | Function | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder | Acts as the chamber where combustion occurs, converting fuel into mechanical power. | ||||||||||||||

| Piston | Moves within the cylinder, transferring the force generated by combustion to the crankshaft. | ||||||||||||||

| Crankshaft | Converts the linear motion of the piston into rotational motion to drive the output shaft. | ||||||||||||||

| Camshaft | Controls the opening and closing of the engine’s valves, ensuring proper air-fuel mixture intake and exhaust gas expulsion. | ||||||||||||||

Carburetor

Detailed Diagram of the GX620 EngineThe intricate layout of this specific engine model reveals its well-designed mechanical structure, where every component works together to ensure optimal performance. From the internal combustion system to the various external fittings, each part plays a crucial role in maintaining the engine’s functionality. Understanding the positioning and connectivity of these elements is key for both maintenance and troubleshooting, providing a clear visual guide for anyone looking to comprehend the system better. The engine layout features a combination of moving and static components that are organized systematically. Essential areas, including the fuel delivery system, cooling mechanisms, and exhaust pathways, are strategically placed to ensure efficiency and longevity. By studying the entire setup, one can gain insights into how the different sections are integrated, ensuring smooth operation under various conditions. Common Wear and Tear Parts

In any engine, certain components tend to degrade over time due to regular usage and the stresses of operation. Recognizing these elements early and understanding their role in the overall performance is key to maintaining long-term functionality. Keeping track of these frequently replaced elements can help prevent larger mechanical issues and ensure smooth operation.

|