The intricate design of small engine machinery plays a vital role in ensuring optimal performance and reliability. A comprehensive overview of these mechanical systems aids in both maintenance and troubleshooting, allowing users to navigate the complex web of components efficiently. By familiarizing oneself with the layout of each element, individuals can enhance their understanding of how these engines function as a whole.

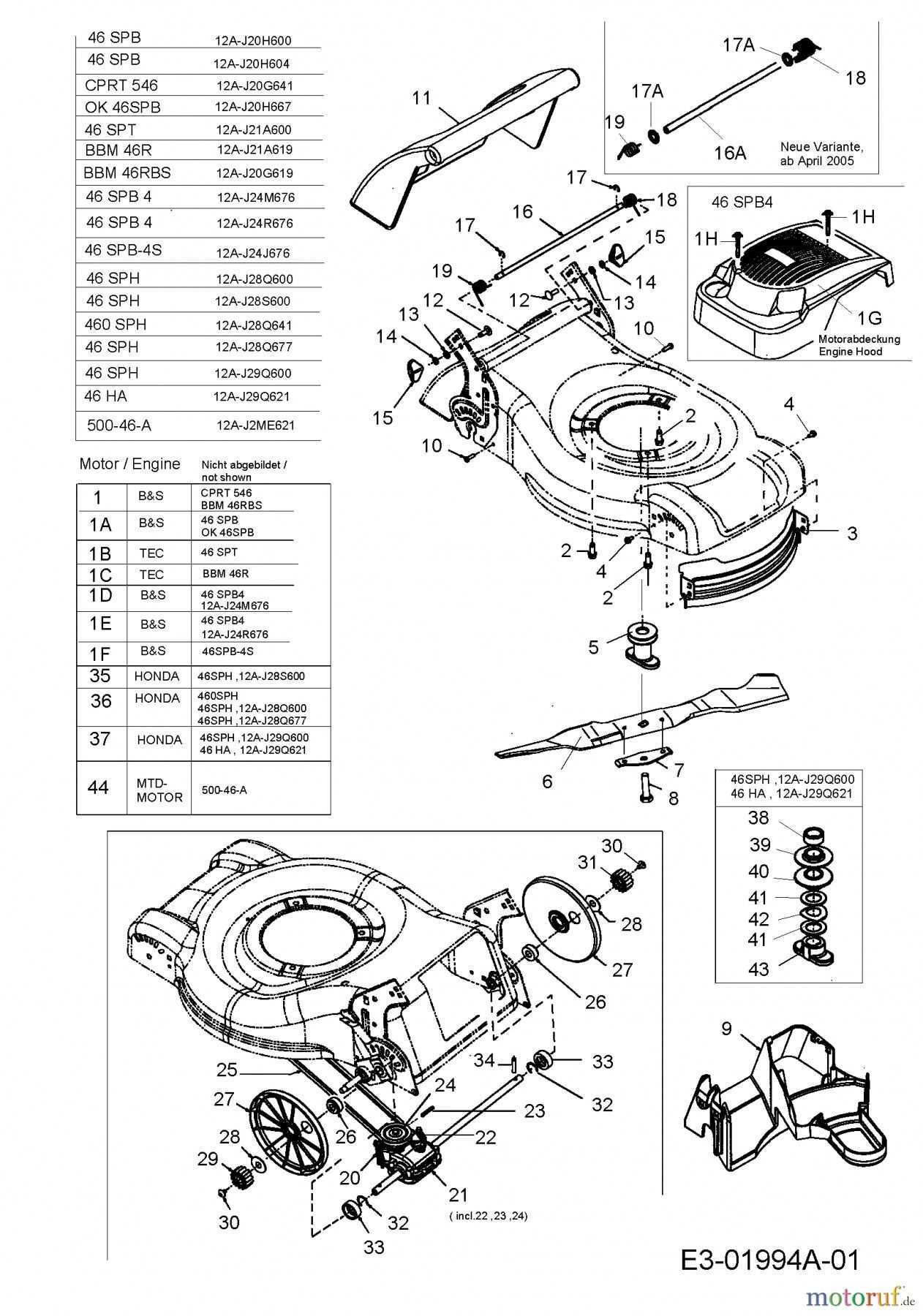

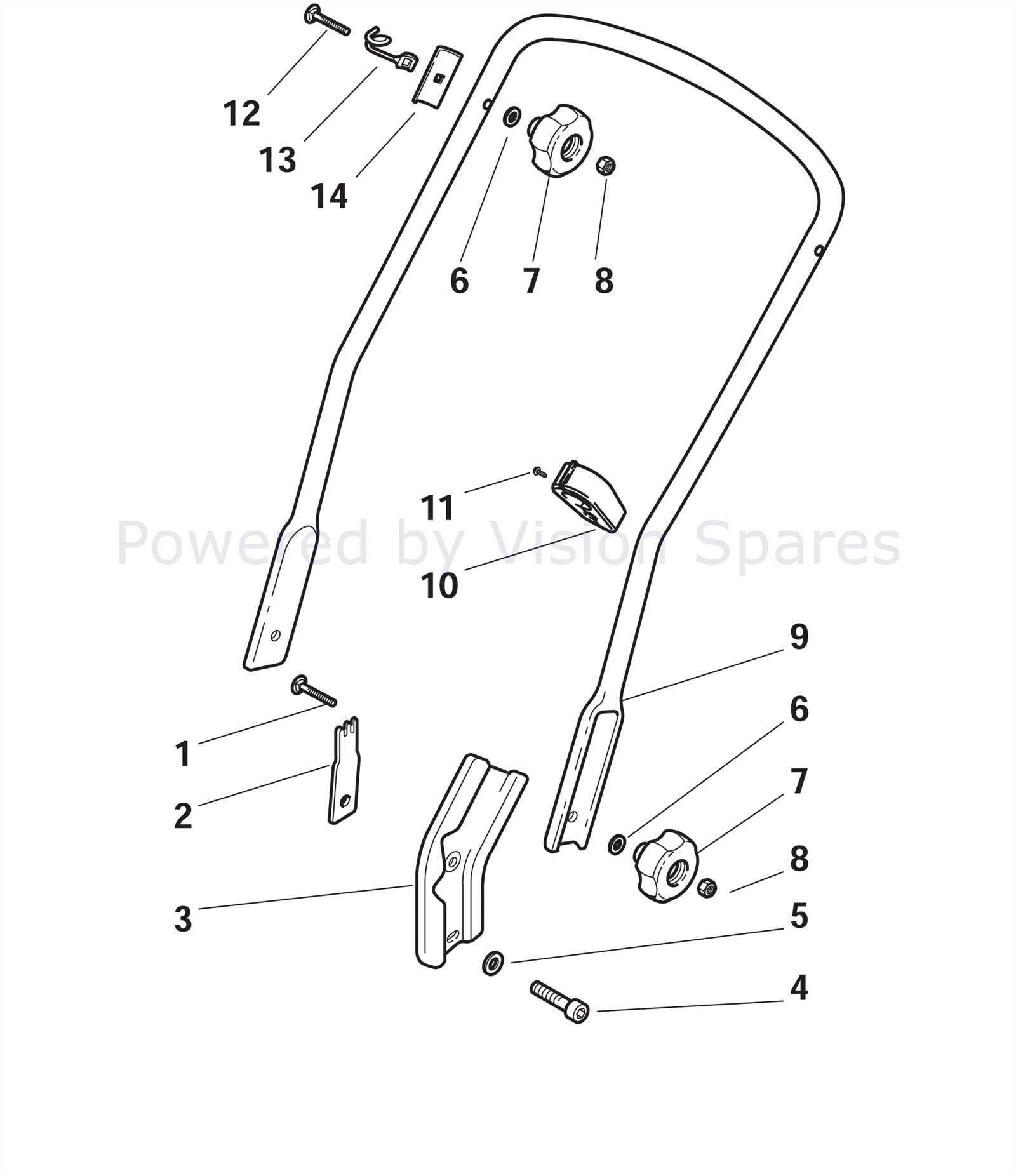

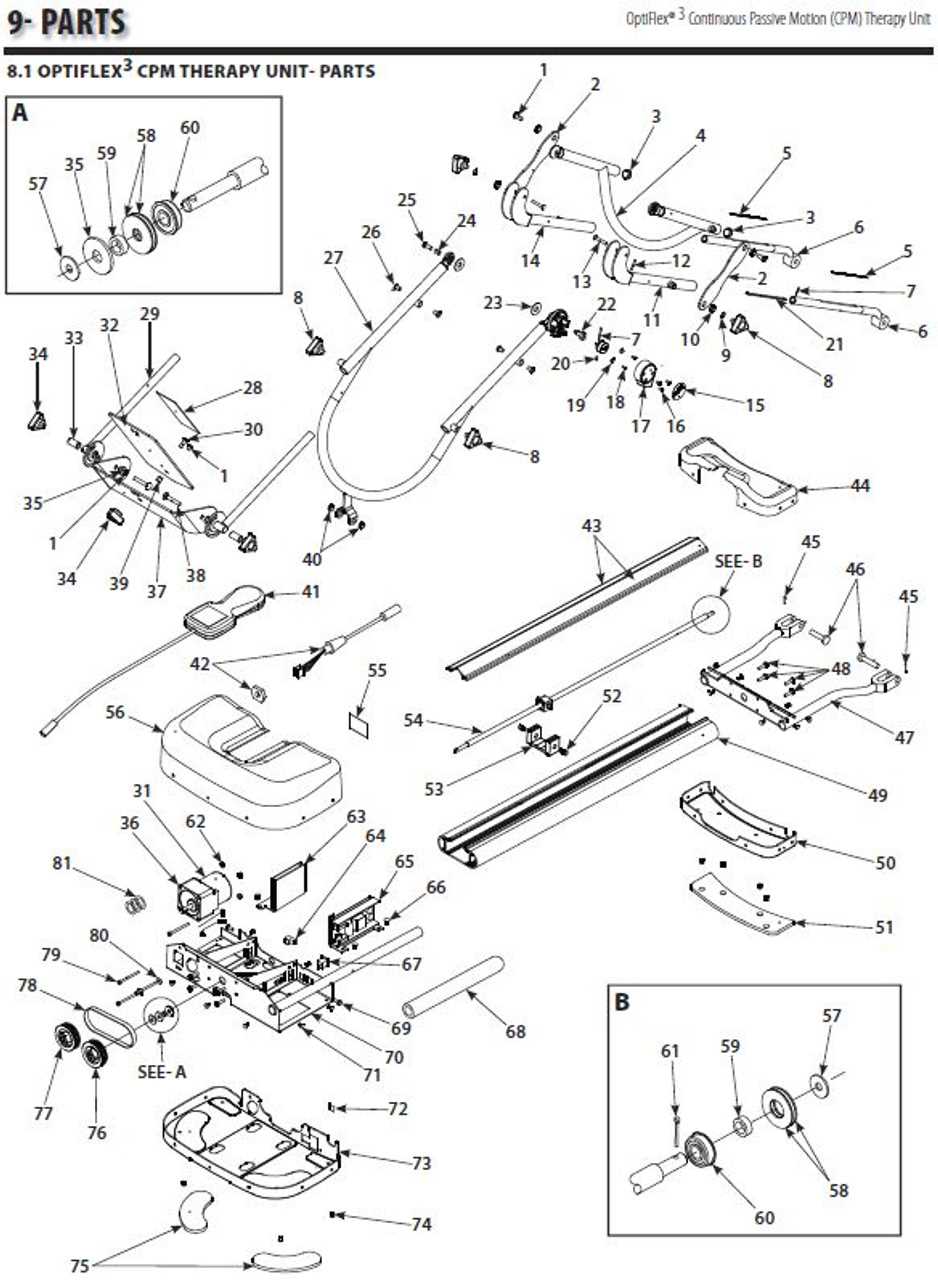

Detailed representations serve as invaluable resources for those seeking to engage in repair or enhancement tasks. Visual aids not only simplify the identification of specific elements but also streamline the process of acquiring replacements or upgrades. Mastery of these schematics fosters greater confidence in tackling potential issues, ultimately contributing to the longevity and efficiency of the engine.

In the realm of engine maintenance, knowledge is power. By comprehensively grasping the arrangement and function of various components, users can more effectively diagnose problems and implement solutions. This understanding is essential for anyone looking to maintain their machinery in peak condition, ensuring that each part operates harmoniously within the larger system.

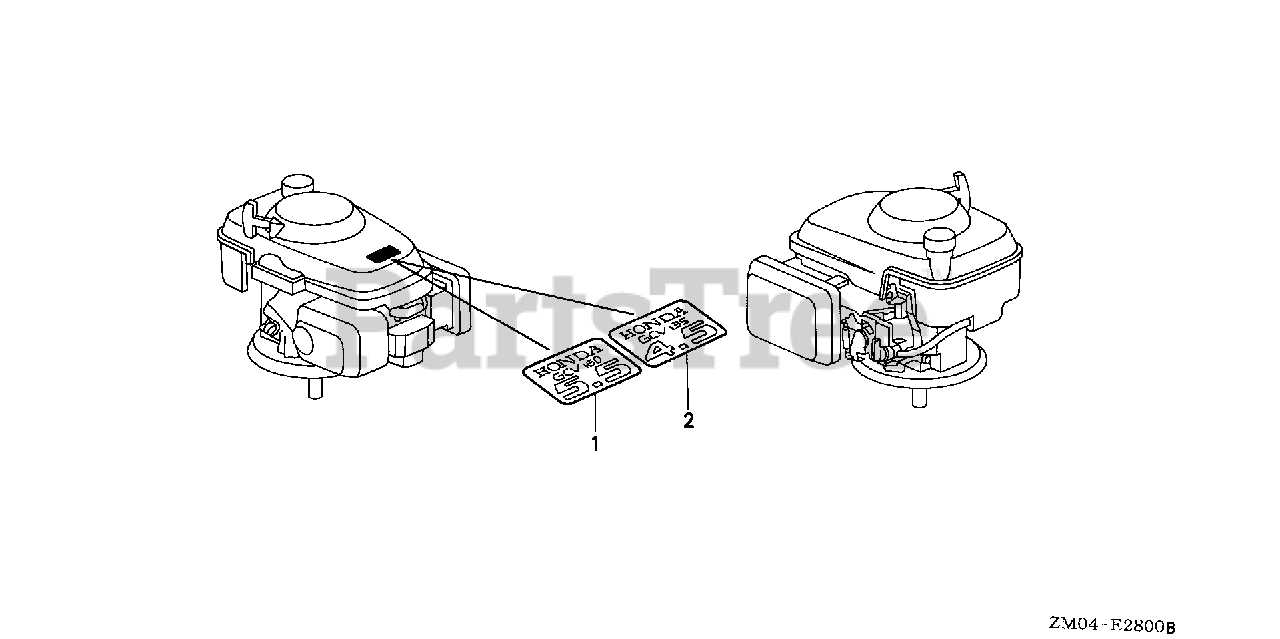

Overview of Honda GCV160 Engine

This section provides a comprehensive examination of a widely utilized small engine, known for its reliability and efficiency. Designed primarily for outdoor equipment, this power unit excels in delivering consistent performance across various applications.

Key features of this engine include:

- Four-stroke design for improved fuel efficiency

- Compact size, making it suitable for a range of machinery

- Lightweight construction, facilitating easy handling and installation

- Robust construction for enhanced durability and longevity

The engine’s structure consists of several critical components that work together to ensure optimal functionality:

- Crankshaft: A vital element that converts linear motion into rotational energy.

- Cylinder: The chamber where combustion occurs, playing a crucial role in the engine’s performance.

- Fuel System: Responsible for delivering the necessary fuel-air mixture for efficient combustion.

- Ignition System: Initiates combustion, ensuring the engine starts and runs smoothly.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

Understanding the intricacies of this engine allows users to appreciate its capabilities and maintenance requirements, ensuring it continues to perform at its best over time.

Importance of Parts Diagram

A comprehensive visual representation of components is crucial for understanding the assembly and functionality of machinery. This resource serves as a valuable reference for both professionals and enthusiasts, facilitating effective maintenance and repairs.

By examining this visual guide, users can:

- Quickly identify individual elements and their respective roles within the system.

- Understand the relationship between various components, enhancing overall comprehension.

- Streamline the troubleshooting process by locating specific parts that may require attention.

Additionally, such illustrations play a significant role in:

- Assisting technicians in accurately ordering replacements, ensuring compatibility.

- Providing clarity during disassembly and reassembly, reducing the risk of errors.

- Enhancing communication among team members by providing a common reference point.

In conclusion, a detailed visual representation of components is indispensable for maintaining equipment efficiency and longevity. It empowers users to perform tasks confidently, ensuring that machinery operates smoothly.

Common Issues with Honda GCV160

Many users encounter a range of challenges with small engines designed for outdoor equipment. These issues can vary from minor inconveniences to significant performance problems, impacting the overall functionality of the machinery. Understanding these common complications can help owners maintain their equipment more effectively.

One prevalent issue is difficulty in starting the engine. This can stem from various factors, including a drained battery, stale fuel, or clogged air filters. Regular maintenance, such as cleaning the spark plug and ensuring proper fuel levels, can alleviate this problem.

Another frequent concern is the engine stalling during operation. This can result from fuel delivery issues or an obstruction in the air intake system. Keeping the fuel system clean and ensuring adequate airflow can prevent these interruptions and ensure smooth performance.

Additionally, excessive vibration is a common complaint among users. This may indicate a misaligned component or worn-out parts. Regular inspections and timely replacements of any damaged components can help mitigate excessive shaking and enhance operational stability.

Finally, overheating can pose a serious risk to engine longevity. This issue often arises from inadequate lubrication or blocked cooling fins. It is crucial to regularly check oil levels and keep cooling systems clear to prevent overheating and prolong the life of the machinery.

Finding Replacement Parts Online

In the digital age, sourcing components for your machinery has never been easier. With a vast array of online platforms available, you can conveniently find the items you need from the comfort of your home. The key is knowing where to look and what to consider when making your purchase.

Where to Search

Several reputable online retailers and marketplaces specialize in replacement components for various equipment. Here are some reliable options:

- Manufacturer’s official website

- Dedicated machinery part suppliers

- General e-commerce platforms like Amazon or eBay

- Local hardware store websites with online inventories

Considerations When Purchasing

When looking for components online, keep the following factors in mind:

- Compatibility: Ensure the item is suitable for your specific model.

- Quality: Opt for high-quality replacements to guarantee longevity and performance.

- Reviews: Check customer feedback for insights on reliability and service.

- Return Policy: Familiarize yourself with the return options in case the component does not meet your expectations.

By utilizing online resources effectively, you can easily locate the necessary items for your equipment and ensure optimal functionality.

Understanding Engine Components

The inner workings of a motor rely on various essential elements, each playing a pivotal role in overall functionality and performance. Recognizing these components is crucial for effective maintenance and troubleshooting, ensuring optimal operation and longevity of the machinery. This section aims to demystify the fundamental parts found in a typical engine, enhancing the user’s understanding of how each piece contributes to the engine’s performance.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix and ignite to create power. |

| Piston | A cylindrical part that moves up and down within the cylinder, converting fuel energy into mechanical work. |

| Crankshaft | A shaft that translates the linear motion of the piston into rotational motion to drive the machine. |

| Valves | Open and close to allow fuel and air in and exhaust gases out, regulating the engine’s breathing process. |

| Camshaft | Controls the timing of the opening and closing of the valves, ensuring they operate in sync with the piston movement. |

| Ignition System | Generates the spark that ignites the fuel-air mixture, crucial for initiating the combustion process. |

Step-by-Step Maintenance Guide

Proper upkeep of your small engine is crucial for optimal performance and longevity. This guide will walk you through essential maintenance tasks, ensuring that your equipment runs smoothly and efficiently. Regular attention to these aspects can help prevent major issues and enhance the overall functionality.

1. Inspecting and Replacing the Air Filter

The air filter plays a vital role in maintaining engine efficiency. Begin by removing the cover to access the filter. Inspect it for dirt and debris. If it’s clogged, clean it thoroughly or replace it if necessary. A clean filter ensures optimal airflow, which is essential for performance.

2. Checking the Spark Plug

The spark plug ignites the fuel-air mixture, making it crucial for starting and running the engine. Remove the plug and check its condition. Look for wear signs such as carbon buildup or corrosion. Replace it if needed to ensure smooth ignition.

3. Oil Change

Regular oil changes are vital for engine health. Start by warming the engine for a few minutes to thin the oil, making it easier to drain. Then, remove the oil drain plug and let the used oil flow out completely. Replace it with fresh oil, following the manufacturer’s specifications for type and quantity.

4. Fuel System Maintenance

Ensure that the fuel is fresh and free of contaminants. If the engine has been idle for an extended period, consider draining old fuel and replacing it with new. Additionally, check the fuel lines for leaks or cracks that could affect performance.

5. Cleaning the Exterior

A clean exterior not only improves appearance but also helps prevent overheating. Use a soft brush or cloth to remove dirt and debris from the engine surface. Avoid using water directly on the engine to prevent moisture accumulation in critical areas.

6. Seasonal Checks

Before the start of each season, perform a comprehensive check of your equipment. Inspect belts, cables, and other components for wear or damage. This proactive approach can save you from unexpected breakdowns and ensure reliable operation.

By following these steps diligently, you can enhance the performance and extend the lifespan of your small engine. Regular maintenance is a key aspect of responsible ownership, ensu

Visual Reference for Repairs

When tackling maintenance or repair tasks, having a clear visual guide can significantly enhance the process. This section emphasizes the importance of graphical representations that assist in identifying components and their arrangement, making it easier to address issues effectively. Such resources serve as invaluable tools for both novices and experienced technicians alike, ensuring that every aspect of the repair is well understood.

Using illustrations can clarify complex assembly structures and highlight specific features that may not be immediately apparent. Diagrams can illustrate the layout of individual elements, showing how they connect and function within the larger system. These visual aids not only facilitate accurate repairs but also contribute to a deeper understanding of the machinery.

For effective troubleshooting, it is crucial to reference these graphics, as they provide a roadmap for the process. By following a visual guide, one can ensure that each part is appropriately addressed, leading to more efficient and successful repairs. Investing time in reviewing these resources can pay off significantly when facing mechanical challenges.

Expert Tips for Engine Longevity

Ensuring the extended lifespan of your engine requires a combination of proper maintenance, timely interventions, and attentive care. By following a few expert recommendations, you can significantly enhance the performance and durability of your machine. These practices not only contribute to longevity but also optimize efficiency, making your engine operate smoothly for years.

Regular inspections are crucial in identifying potential issues before they escalate. Check for signs of wear and tear, and replace worn components promptly to prevent further damage. Consistent oil changes are essential; using high-quality lubricant minimizes friction and reduces overheating, ensuring that all parts function seamlessly.

Additionally, maintaining a clean air filter allows for optimal airflow, which is vital for combustion efficiency. A clean fuel system promotes better performance and can prevent clogs that may lead to engine strain. It’s also beneficial to store your equipment properly, especially during off-seasons, to protect it from environmental factors that could cause deterioration.

Finally, follow the manufacturer’s guidelines regarding usage and maintenance schedules. Adhering to these recommendations fosters a healthy engine environment and can lead to fewer repairs, lower costs, and a more reliable machine overall. Investing time in these practices will pay dividends in the long run.