The effective operation of any aquatic system hinges on the interplay of its individual elements. Each component plays a pivotal role, ensuring that water is circulated efficiently and consistently. A comprehensive grasp of these integral parts can significantly enhance the overall performance and longevity of the system.

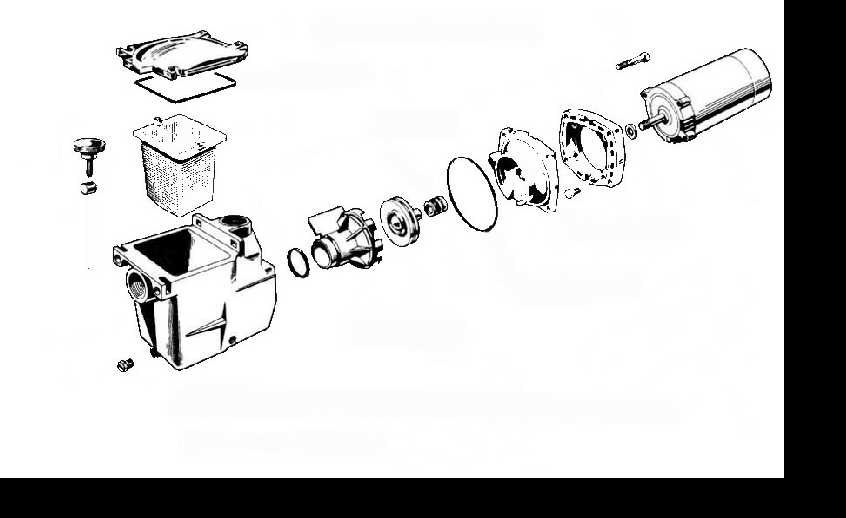

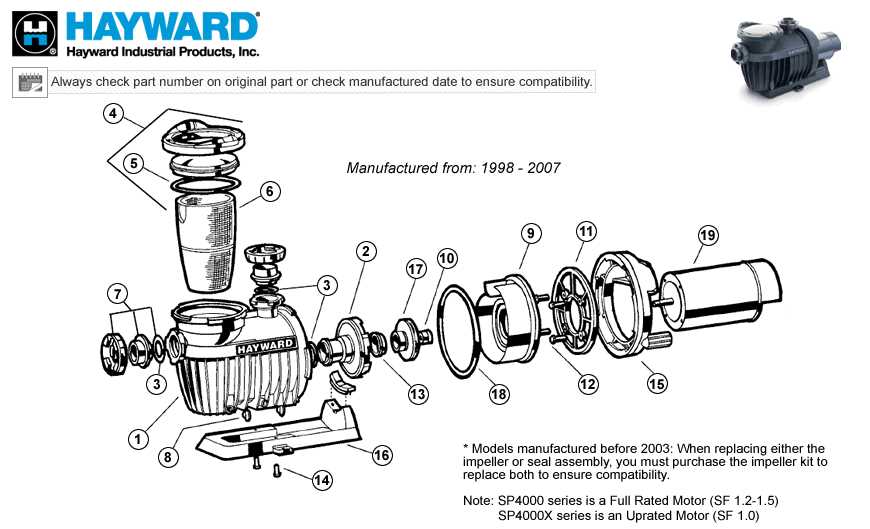

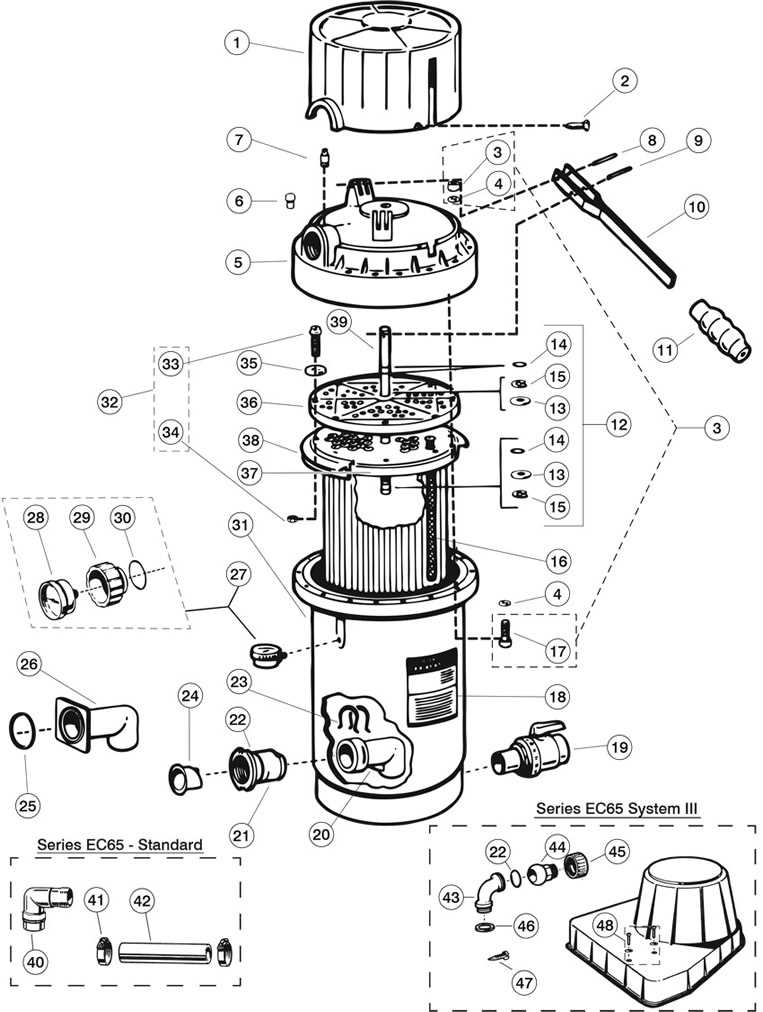

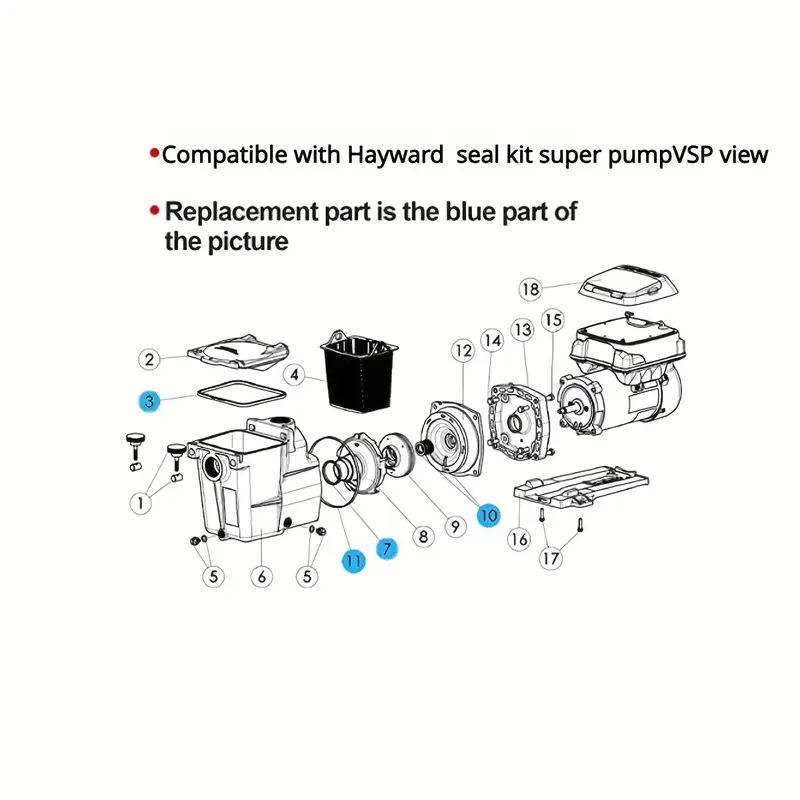

When tackling maintenance or troubleshooting issues, it is essential to familiarize oneself with the various segments that contribute to the functionality of the apparatus. From motor assemblies to filtration elements, each piece has its unique function and importance. Recognizing how these components interact can simplify repairs and optimize performance.

In this guide, we will delve into the various elements of your water circulation system, providing clear insights into their roles and configurations. With this knowledge, you will be better equipped to maintain, troubleshoot, and enhance your system, ensuring it operates smoothly and effectively.

Understanding Hayward Pump Components

To ensure optimal functionality and longevity of any water circulation system, it is essential to comprehend the various elements that contribute to its operation. Each component plays a crucial role in maintaining efficiency and performance, and understanding their interactions can help in troubleshooting and maintenance efforts.

Key Elements of the System

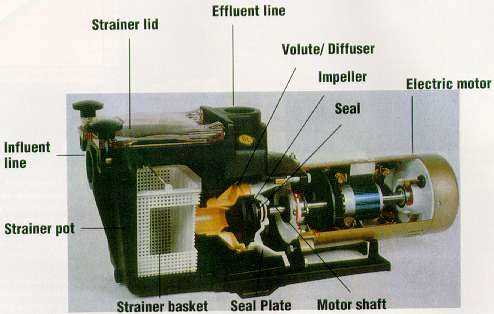

Among the primary components, the motor serves as the heart, providing the necessary energy to drive the entire assembly. Coupled with an impeller, it generates flow, ensuring that water circulates effectively. Other critical elements include the filter and strainer, which are vital for maintaining water clarity by removing debris and contaminants.

Importance of Regular Maintenance

Regular inspection and upkeep of these components are vital to prevent potential failures. Cleaning the strainer and checking for wear and tear on the motor can significantly enhance performance. Moreover, replacing worn-out seals and gaskets promptly prevents leaks, contributing to the overall efficiency of the system.

In conclusion, understanding the fundamental elements and their maintenance is key to achieving a well-functioning water circulation system, ensuring that it operates smoothly for years to come.

Importance of Pump Diagrams

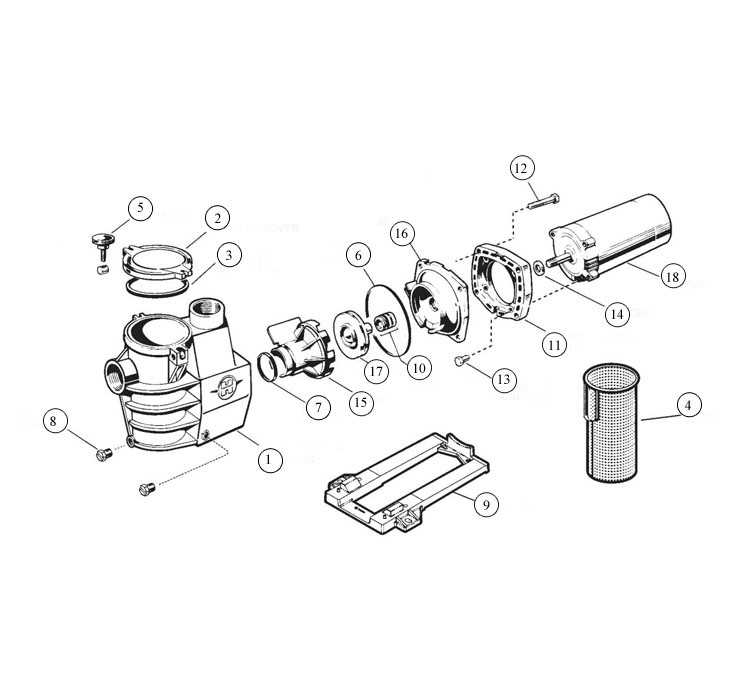

Understanding the layout and components of machinery is essential for effective maintenance and troubleshooting. Visual representations serve as valuable tools for technicians, offering insights into the intricate relationships between various elements and enhancing overall operational efficiency.

Facilitating Maintenance

Clear illustrations aid technicians in identifying components quickly, making it easier to perform repairs and routine inspections. A well-structured visual guide minimizes downtime and streamlines maintenance procedures.

Enhancing Safety

Accurate representations help ensure safe operation by providing necessary information about the system’s setup. This clarity reduces the risk of errors during installation or service, ultimately protecting personnel and equipment.

| Benefits | Description |

|---|---|

| Quick Identification | Facilitates rapid recognition of components. |

| Efficient Troubleshooting | Streamlines the process of diagnosing issues. |

| Operational Clarity | Offers a clear understanding of system relationships. |

| Increased Safety | Reduces risk of operational errors. |

Common Parts of Hayward Pumps

Understanding the essential components of a water circulation system is crucial for effective maintenance and operation. These elements work in unison to ensure optimal performance, longevity, and efficiency of the system. Familiarity with each component allows for easier troubleshooting and repair, ultimately enhancing user experience.

The motor serves as the heart of the assembly, providing the necessary power for operation. Coupled with it is the impeller, responsible for moving water through the system, creating the flow required for circulation. The housing encloses these vital components, protecting them from environmental factors and ensuring safety during operation.

Another key element is the strainer, which filters out debris and prevents clogging, thus maintaining the integrity of the system. Additionally, seals play a critical role in preventing leaks, ensuring that water remains contained within the unit. Lastly, various fittings and connections facilitate easy assembly and disassembly for maintenance purposes.

How to Read Pump Schematics

Understanding technical illustrations can significantly enhance your ability to troubleshoot and maintain equipment effectively. These visual representations often include symbols, lines, and annotations that convey essential information about the assembly and its functions. Familiarity with these elements allows users to navigate complex systems with confidence.

Key Elements of Technical Illustrations

When examining these schematics, pay attention to the following components:

| Element | Description |

|---|---|

| Symbols | Graphical representations that denote specific components such as valves, filters, and motors. |

| Lines | Indicate connections and flow paths between components, often differentiated by line type or thickness. |

| Labels | Text annotations that provide additional context, such as part numbers or operational details. |

Interpreting Connections and Flow

Focus on how components are interconnected and the direction of flow. Arrows often indicate movement, while dashed lines may represent secondary pathways. Understanding these connections is crucial for effective diagnostics and repairs, enabling you to pinpoint potential issues swiftly.

Troubleshooting Pump Issues

Addressing common operational challenges is essential for maintaining optimal functionality. By understanding potential symptoms and their corresponding remedies, users can effectively enhance the efficiency of their systems. This guide outlines typical concerns and provides solutions to restore performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| No Flow | Clogs, Air Lock, Electrical Failure | Inspect for blockages, bleed air, check power supply. |

| Unusual Noises | Loose Components, Cavitation, Wear | Tighten fixtures, reduce speed, replace worn parts. |

| Overheating | Insufficient Cooling, Excessive Load | Ensure adequate ventilation, reduce demand. |

| Leakage | Worn Seals, Loose Connections | Replace seals, tighten fittings. |

Regular maintenance and timely interventions can significantly extend the lifespan of the equipment. Always consult the manufacturer’s guidelines for specific recommendations tailored to your model.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. By following a few simple guidelines, you can ensure optimal performance and reduce the need for repairs. Regular care not only enhances efficiency but also saves time and money in the long run.

Here are some practical suggestions to maintain your system effectively:

| Task | Frequency | Tips |

|---|---|---|

| Inspect seals and gaskets | Monthly | Look for wear and replace as needed to prevent leaks. |

| Clean the housing | Bi-weekly | Use a soft brush to remove debris and dust build-up. |

| Check fluid levels | Weekly | Ensure levels are adequate to maintain proper operation. |

| Lubricate moving parts | Every three months | Use appropriate lubricant to minimize friction and wear. |

| Monitor performance | Daily | Listen for unusual sounds or changes in operation. |

Implementing these practices will help keep your equipment running smoothly and effectively for years to come. Regular attention to detail can make all the difference in preventing costly breakdowns and ensuring reliable functionality.

Upgrading Pump Parts Effectively

Enhancing the components of your equipment can significantly improve its efficiency and longevity. When considering replacements or upgrades, it is essential to analyze each element’s function and how it contributes to overall performance. Careful selection and installation of high-quality substitutes can lead to notable enhancements in functionality and reliability.

Identifying Key Components for Upgrade

Start by assessing the crucial elements that may require attention. Prioritizing areas based on wear, performance issues, or outdated technology can streamline the upgrade process. Focus on those components that directly influence efficiency and energy consumption.

Benefits of Quality Replacements

Investing in superior substitutes can yield long-term benefits. Not only do high-grade replacements enhance operational efficiency, but they also reduce the likelihood of future malfunctions, saving time and resources on repairs.

| Component | Benefits of Upgrade |

|---|---|

| Motor | Improved energy efficiency and reduced noise levels. |

| Seal | Enhanced durability and prevention of leaks. |

| Impeller | Increased flow rate and better hydraulic performance. |

| Strainer | Enhanced filtration and reduced maintenance frequency. |

Where to Purchase Replacement Parts

Finding quality components for your equipment is essential for maintaining optimal performance. Whether you’re seeking a specific item or just browsing for options, several avenues can help you secure what you need.

Online Retailers

- Check major e-commerce platforms for a wide selection.

- Visit specialized websites that focus on maintenance supplies.

- Explore manufacturer websites for direct purchases.

Local Suppliers

- Visit local hardware stores for immediate availability.

- Contact regional distributors who may offer competitive prices.

- Inquire at specialty shops that focus on outdoor equipment.