Every effective water circulation system relies on a combination of essential elements that work together to maintain cleanliness and clarity. These systems are designed to ensure that unwanted debris is removed, keeping the water pristine and safe for use. To achieve this, a network of interconnected parts plays a vital role in both the efficiency and durability of the system.

The structure consists of various components that handle the flow, separation, and maintenance processes. Each element is uniquely designed to perform a specific function, contributing to the overall operation. Whether dealing with mechanical or hydraulic aspects, the correct setup ensures long-lasting performance and easy upkeep.

In the following sections, we will explore the detailed functions of these crucial elements, providing an overview of their arrangement and how they interact with each other. This understanding will help in troubleshooting, enhancing system efficiency, and ensuring the longevity of the water cleaning equipment.

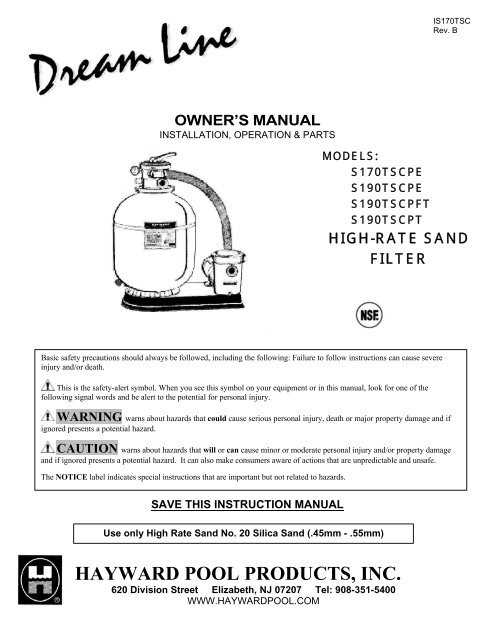

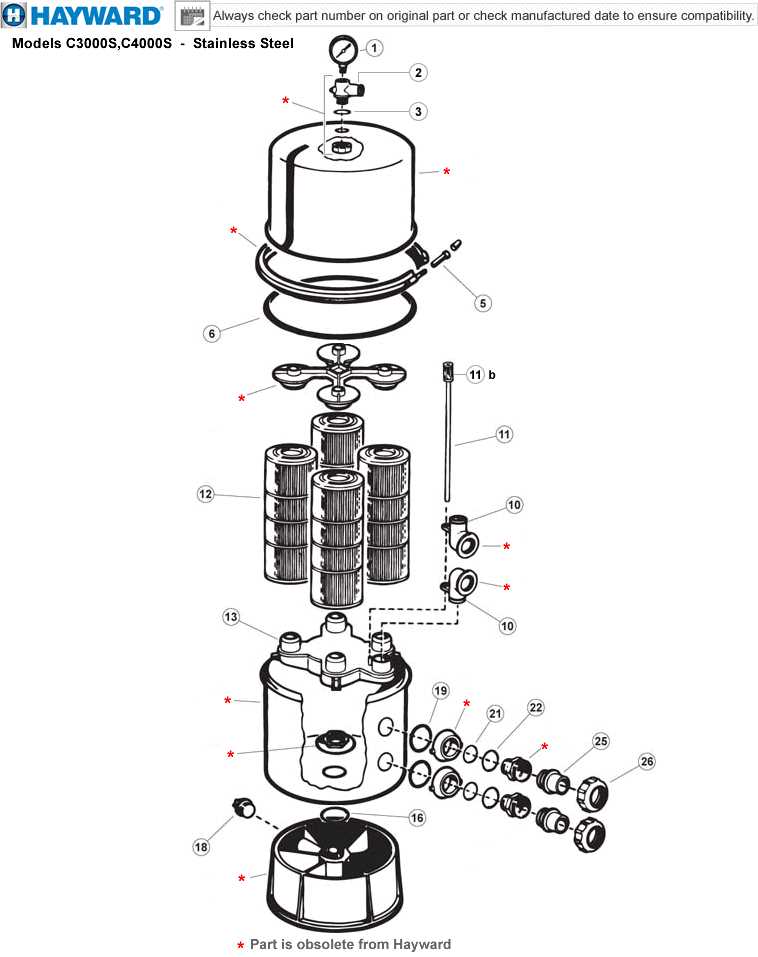

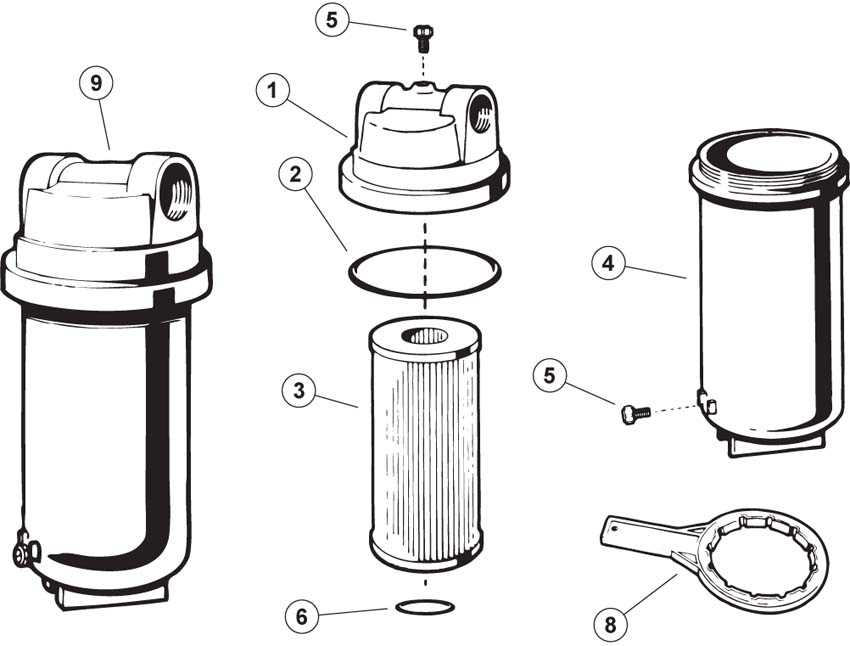

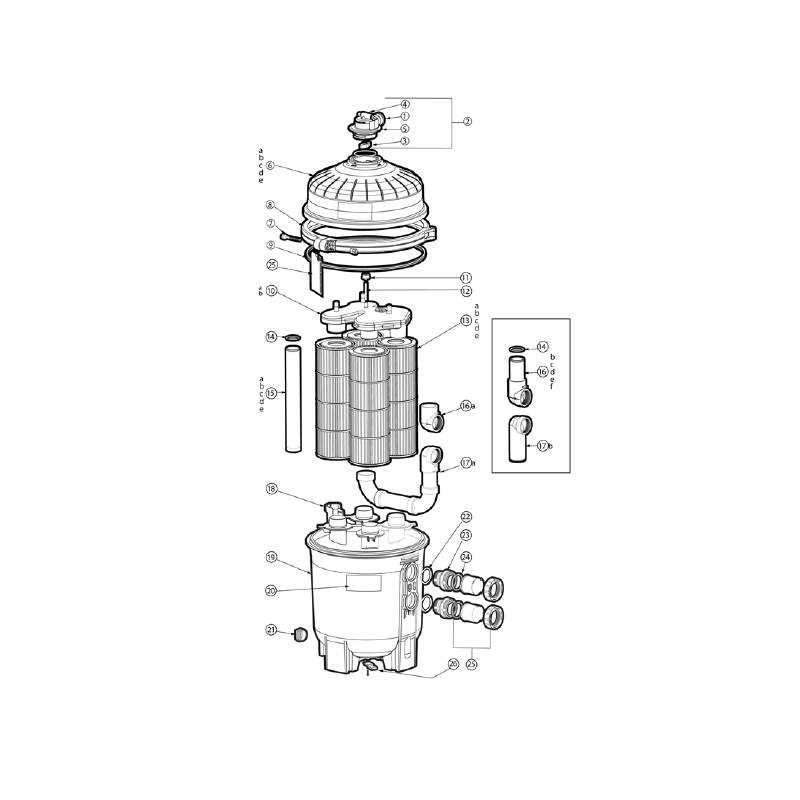

Hayward Pool Filter Parts Overview

The system responsible for keeping water clean and clear consists of several crucial elements, each playing a unique role in the overall maintenance process. These components work together to ensure optimal circulation and debris removal, allowing for efficient water treatment. Understanding how each element contributes to the system’s function can help with both troubleshooting and regular upkeep.

Main Structural Elements

The core elements include a variety of mechanisms designed to trap contaminants, manage water flow, and maintain the system’s

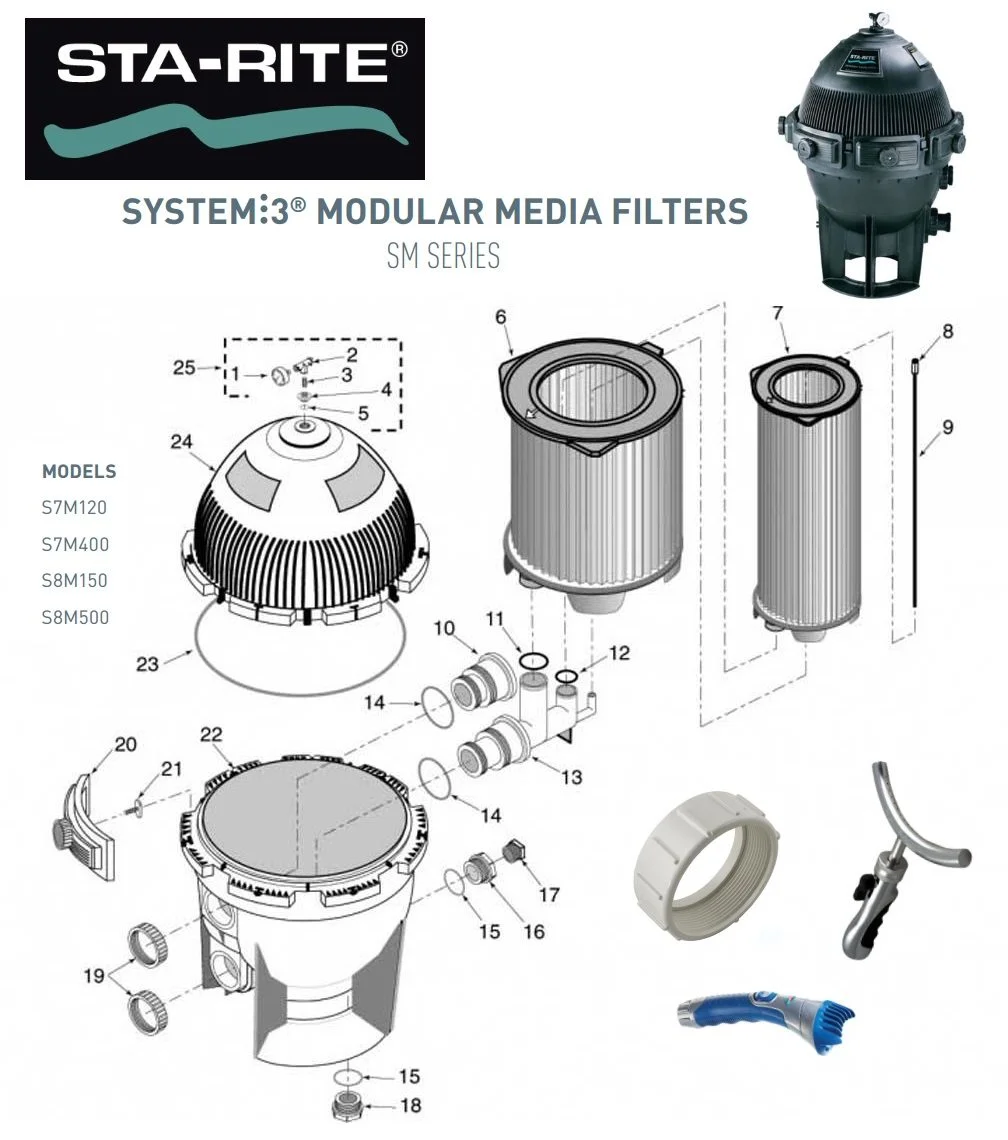

Understanding Key Components

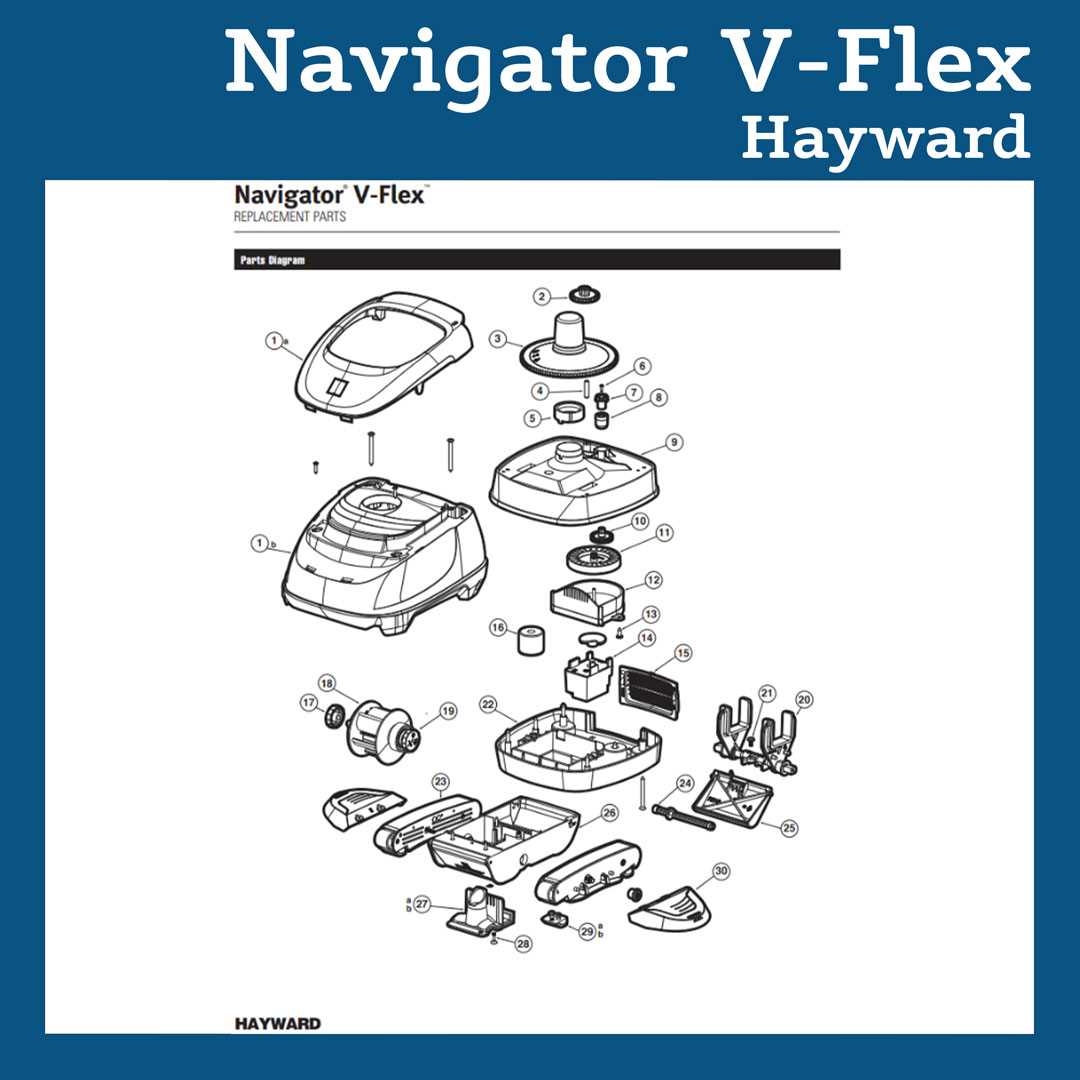

To maintain the proper operation of a water circulation system, it’s essential to recognize the critical elements that work together to keep everything running smoothly. Each element has a specific role, contributing to the system’s overall functionality. By understanding how these parts interact, you can ensure efficiency and longevity.

Main Elements of the System

- Enclosure Unit: This serves as the primary housing, ensuring protection and organization for all internal components.

- Control Valves: Responsible for regulating the flow and pressure within the system, ensuring optimal water movement.

- Cleansing Media: A specialized material used to remove impurities, ensuring clarity and cleanliness of the water.

- Drainage System: Designed to eliminate excess water, preventing overflow and maintaining balanced levels.

Additional Features to Consider

- Pressure Indicators: These gauges monitor the internal pressure, helping to identify when maintenance or cleaning is required.

- Sealing Mechanisms: These are essential for preventing leaks and ensuring that all connections remain secure.

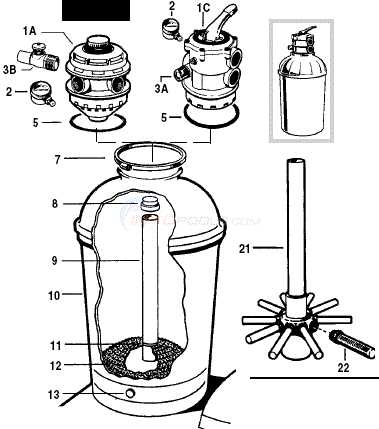

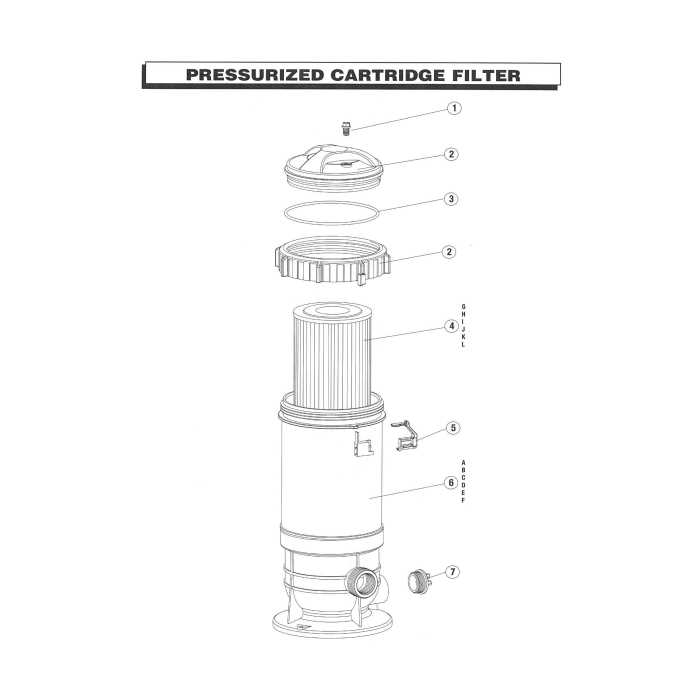

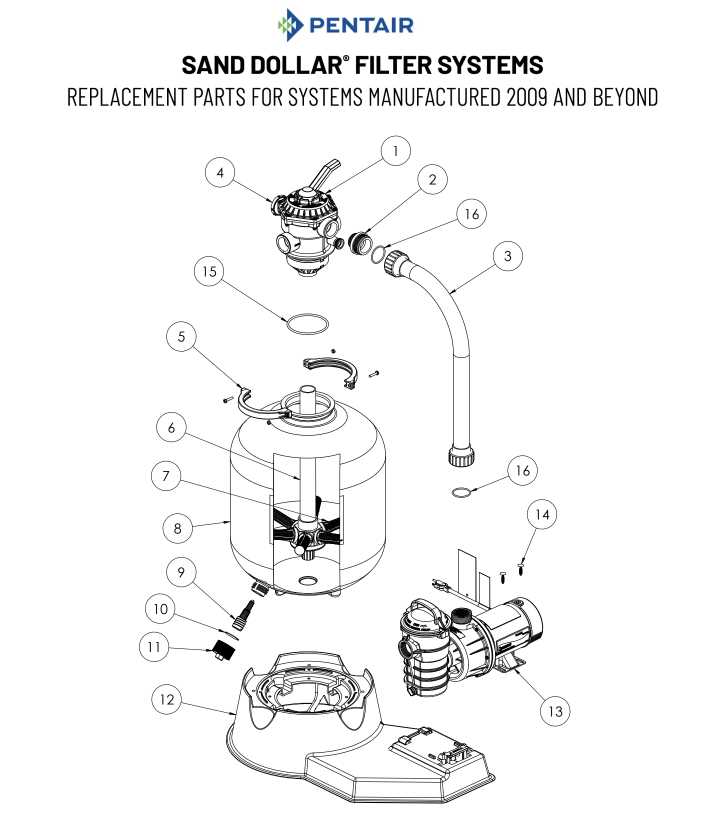

How Filtration Systems Work

The process of cleaning and maintaining water clarity involves a structured system designed to remove unwanted particles and contaminants. This system operates by circulating water through various stages where debris is trapped and clean liquid is returned. Understanding this mechanism is essential to ensuring the system functions effectively.

- Initial Stage: Water is drawn into the system, where larger debris is captured.

- Processing Stage: Finer particles are filtered out as the water passes through specialized components.

- Return Stage: Clean water is pumped back, ensuring continuous circulation and purification.

Each of these stages plays a critical role

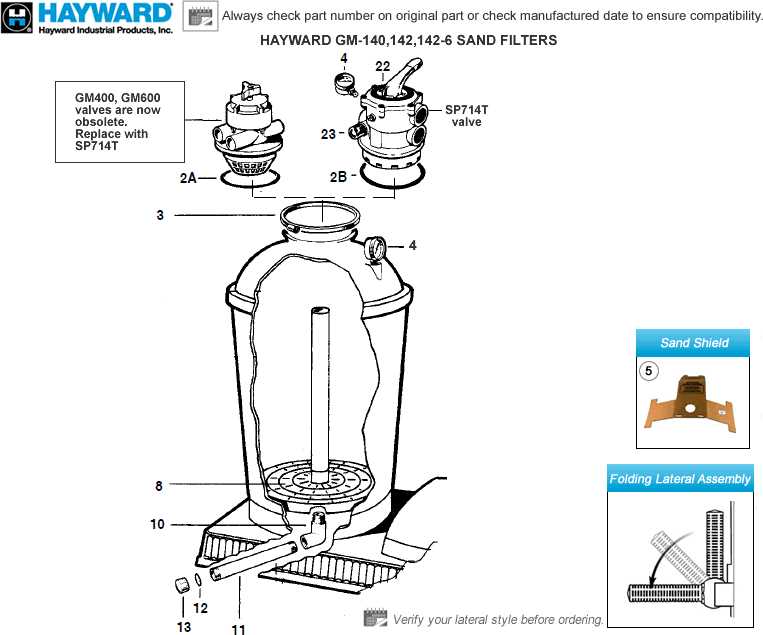

Identifying Common Replacement Parts

Understanding the key elements within a water filtration system is crucial for maintaining optimal performance. Over time, certain components may wear out and need to be swapped out for new ones to ensure the system operates smoothly.

Main Components

The core sections of a filtration setup typically include elements responsible for capturing debris, regulating pressure, and ensuring water circulation. These components work together to maintain the clarity and cleanliness of the system.

Frequent Replacements

Among the most commonly replaced parts are those exposed to constant flow and pressure. Items like the pressure regulator and gaskets often wear down due to regular usage, requiring timely attention to prevent larger issues.

Maintenance Tips for Long-Lasting Performance

To ensure optimal operation and longevity of your equipment, regular upkeep is essential. Proper care minimizes the risk of breakdowns and keeps everything running efficiently, saving you time and money in the long run.

Inspect components frequently to spot any signs of wear and tear. Addressing minor issues early prevents larger problems from developing.

Regularly cleaning internal systems ensures they remain clear of debris, which can hinder performance over time. Also, make sure to replace any worn-out or damaged elements as needed.

Adopting these simple practices will help extend the lifespan of your system, keeping it in top shape for years to come.

Upgrading Your Filter for Efficiency

Enhancing the effectiveness of your cleaning system is essential for optimal performance and longevity. By investing in modern upgrades, you can significantly improve the overall functionality and reduce energy consumption. This section outlines key considerations and steps for achieving a more efficient setup.

When contemplating an upgrade, consider the following aspects:

- Compatibility: Ensure that new components are suitable for your existing system to avoid compatibility issues.

- Energy Efficiency: Look for options that promise reduced energy consumption while maintaining superior performance.

- Advanced Filtration: Opt for technology that enhances debris removal and improves water clarity.

- Maintenance Requirements: Choose solutions that minimize upkeep, making it easier to maintain the system over time.

To implement upgrades effectively, follow these steps:

- Assess the current setup and identify areas for improvement.

- Research available options that align with your efficiency goals.

- Consult with professionals if necessary to ensure proper installation and integration.

- Monitor the system after upgrading to evaluate performance improvements and adjust as needed.

By carefully selecting and integrating modern upgrades, you can create a more efficient cleaning experience, ultimately saving time and resources.

Troubleshooting Common Filter Issues

Addressing frequent problems related to water purification systems can enhance their performance and longevity. Understanding the typical challenges and their solutions is essential for maintaining optimal operation. Below are common concerns along with practical approaches to resolve them.

- Insufficient Water Clarity:

If the water remains cloudy despite regular maintenance, check for the following:

- Verify the filtration media for wear or clogging.

- Ensure that the water circulation system is functioning effectively.

- Inspect the chemical balance to guarantee appropriate sanitation levels.

- Unusual Noises:

Strange sounds emanating from the system can indicate potential issues. Consider these steps:

- Look for debris trapped within the mechanism that may cause obstruction.

- Check for loose components that could be rattling during operation.

- Listen for signs of wear in the motor or pump that may require attention.

- Low Water Flow:

A decrease in flow rate can severely affect water clarity and quality. To troubleshoot:

- Inspect the hoses and connections for blockages or kinks.

- Evaluate the filtration unit to ensure it is clean and free of debris.

- Consider examining the pump for adequate power and functionality.

By systematically addressing these issues, users can effectively maintain their water purification systems, ensuring optimal performance and clarity.

Cleaning and Care Instructions

Maintaining the optimal performance of your aquatic maintenance system is crucial for longevity and efficiency. Regular upkeep not only ensures clarity in the water but also prolongs the lifespan of essential components. This section outlines the recommended practices for keeping your apparatus in excellent condition.

Routine Maintenance Procedures

Establishing a regular cleaning schedule is vital. Begin by inspecting the main components for any signs of wear or buildup. Use a soft brush or cloth to remove debris and contaminants from surfaces. It is advisable to rinse parts with fresh water to eliminate any lingering residues. Regular checks will help identify issues early and prevent more significant problems.

Deep Cleaning Techniques

For a thorough cleansing, disassemble the primary elements according to the manufacturer’s instructions. Utilize a mild detergent mixed with water to scrub components gently. Pay special attention to crevices where dirt may accumulate. After cleaning, rinse thoroughly with clean water to ensure no detergent remains. Allow all parts to dry completely before reassembling to prevent moisture-related damage.

Tip: Always refer to the specific guidelines provided for your system to ensure compatibility with cleaning agents.

Choosing the Right Filter Model

Selecting an appropriate model for your purification system is crucial for ensuring optimal performance and longevity. The right choice can enhance the efficiency of water circulation and maintenance, resulting in a more enjoyable experience. Various factors influence this decision, making it essential to understand your specific requirements.

- Size and Capacity: Consider the volume of water that needs to be processed. Larger systems may require models with higher throughput.

- Type of Filtration: Evaluate whether you need a sand, cartridge, or diatomaceous earth model based on your filtration preferences.

- Maintenance Requirements: Assess the upkeep involved with different models. Some may necessitate more frequent cleaning or replacement of components.

- Energy Efficiency: Look for models designed to operate with lower energy consumption, contributing to reduced operational costs.

- Durability: Investigate the materials used in construction, as sturdier designs can withstand environmental factors and last longer.

By taking these aspects into account, you can make a well-informed decision that meets your needs while promoting an effective and reliable operation.