In the world of professional painting and coating, having a clear grasp of your equipment’s structure is essential for optimal performance. Whether you’re a seasoned contractor or a DIY enthusiast, familiarizing yourself with the various elements that make up your spraying apparatus can significantly enhance your workflow. Knowledge of these components allows for more efficient maintenance, repairs, and troubleshooting.

Each unit is composed of intricate parts, each playing a vital role in the overall functionality. From the primary motor to the various attachments and connectors, understanding how these pieces interact is crucial. Recognizing the layout of these components can simplify the process of identifying issues, ensuring that you spend less time on repairs and more time achieving flawless results.

This exploration will provide insight into the individual sections of your spraying setup, offering a detailed overview of how each component contributes to the system as a whole. By mastering this knowledge, you’ll not only enhance your technical skills but also improve your overall efficiency in projects, leading to professional-grade finishes every time.

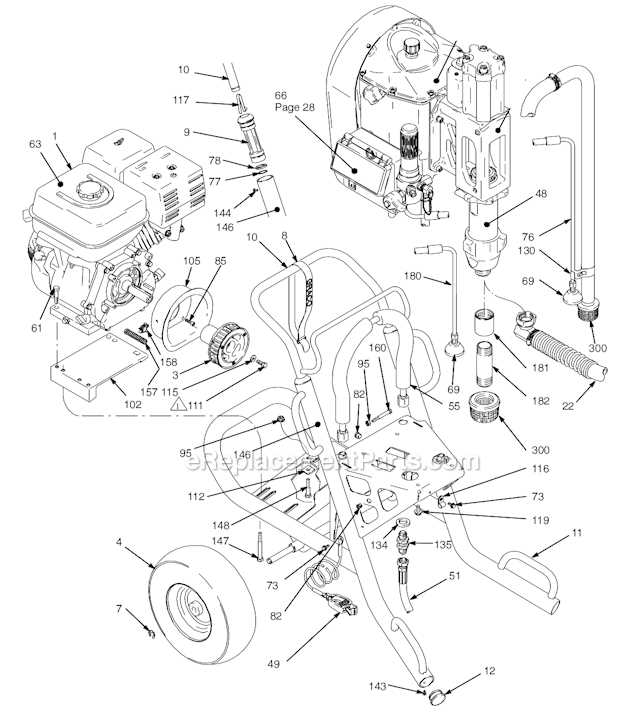

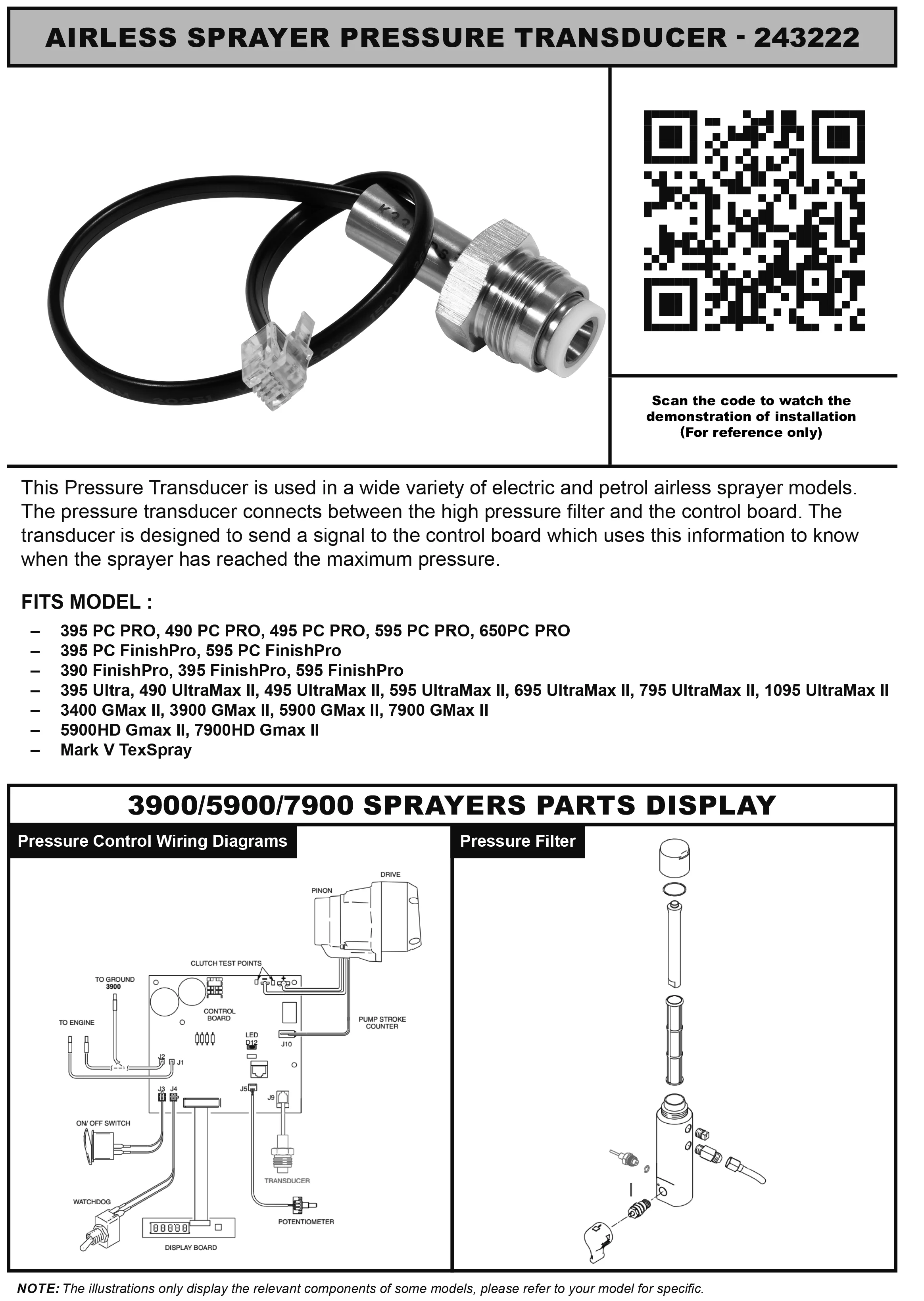

Understanding Graco Ultra Max 695

This section explores the essential components and functionalities of a high-performance spray equipment model designed for professional applications. By examining the intricacies of its structure and operation, users can better appreciate the innovation and engineering that enhance efficiency and productivity in various projects.

Key Features

The machine boasts advanced technology, ensuring smooth operation and consistent output. Its robust design accommodates a wide range of materials, making it suitable for various applications, from residential to industrial tasks.

Maintenance Tips

Essential Components of the Sprayer

Understanding the fundamental elements of a painting apparatus is crucial for effective usage and maintenance. Each component plays a vital role in the functionality and efficiency of the device, ensuring that users achieve their desired results with ease.

| Component | Description |

|---|---|

| Pump | Transports paint from the container to the spray nozzle, ensuring consistent flow. |

| Nozzle | Regulates the spray pattern and flow rate, influencing the coverage and finish. |

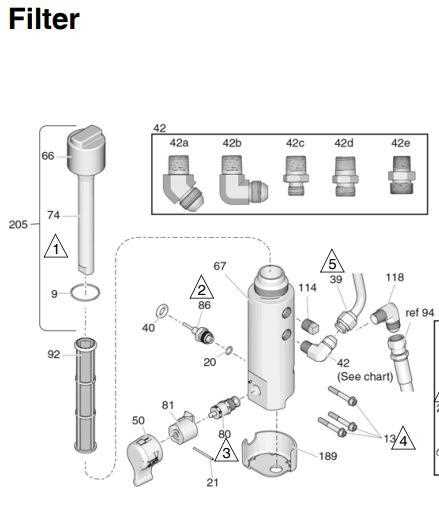

| Filter | Prevents debris from clogging the nozzle, maintaining smooth operation. |

| Pressure Control | Allows adjustment of the spray pressure for different applications. |

| Hose | Connects the pump to the nozzle, transporting paint while minimizing loss. |

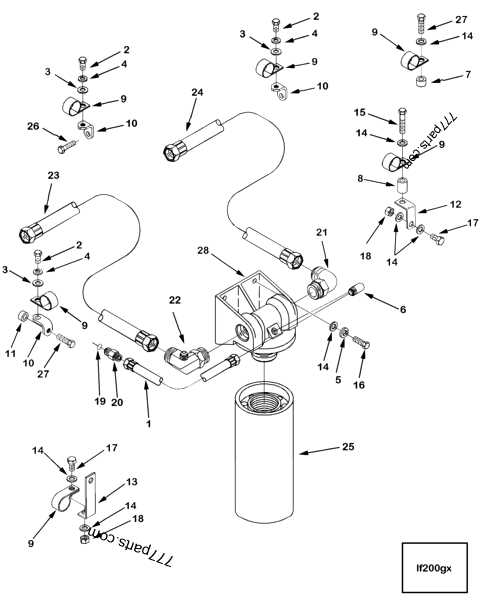

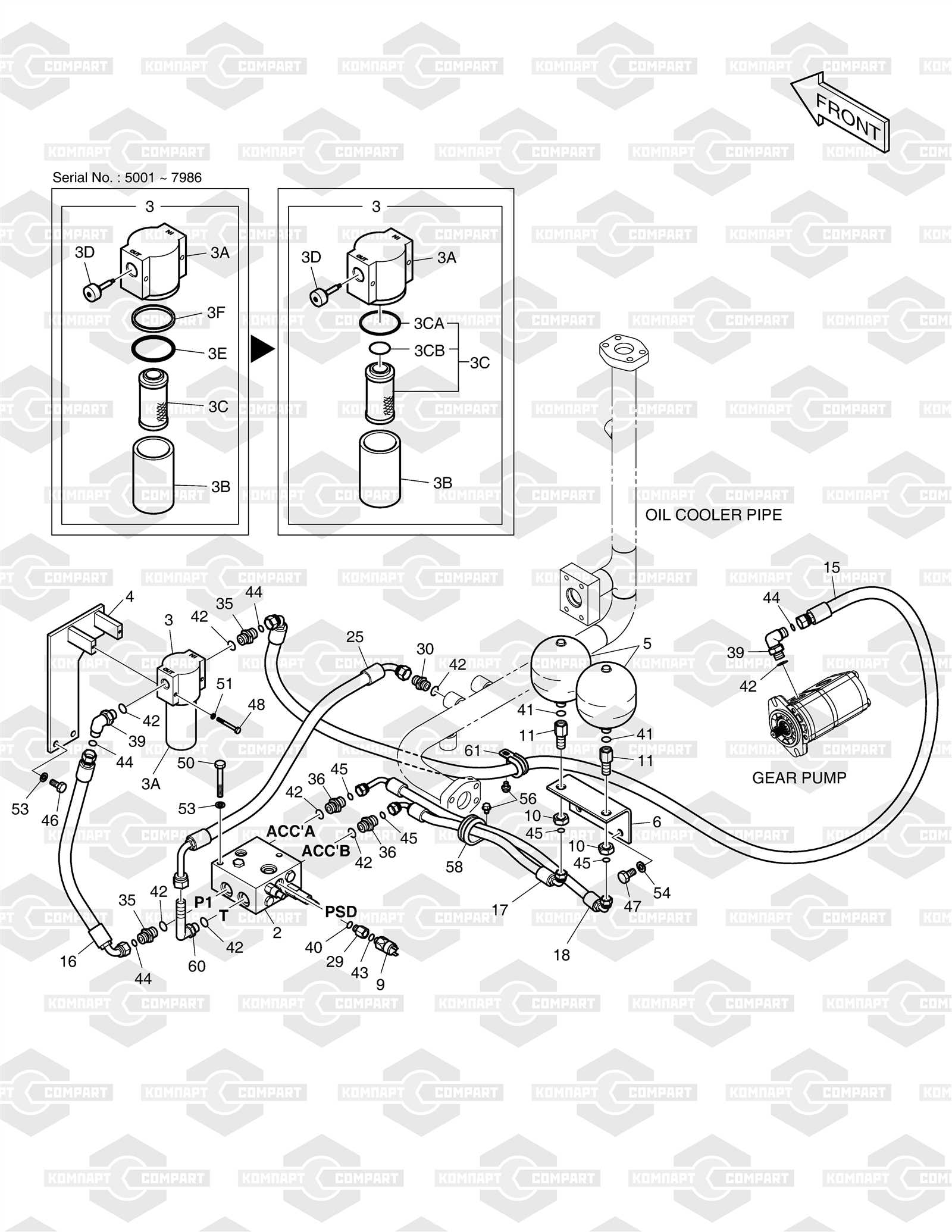

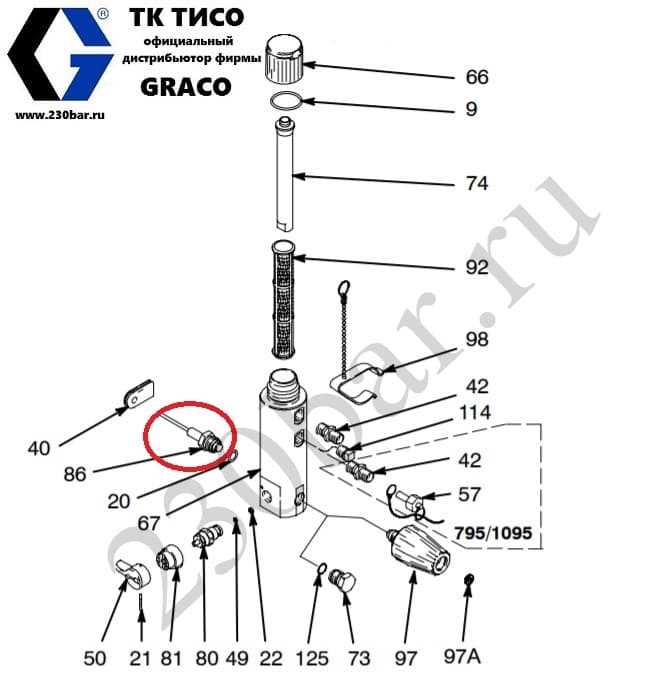

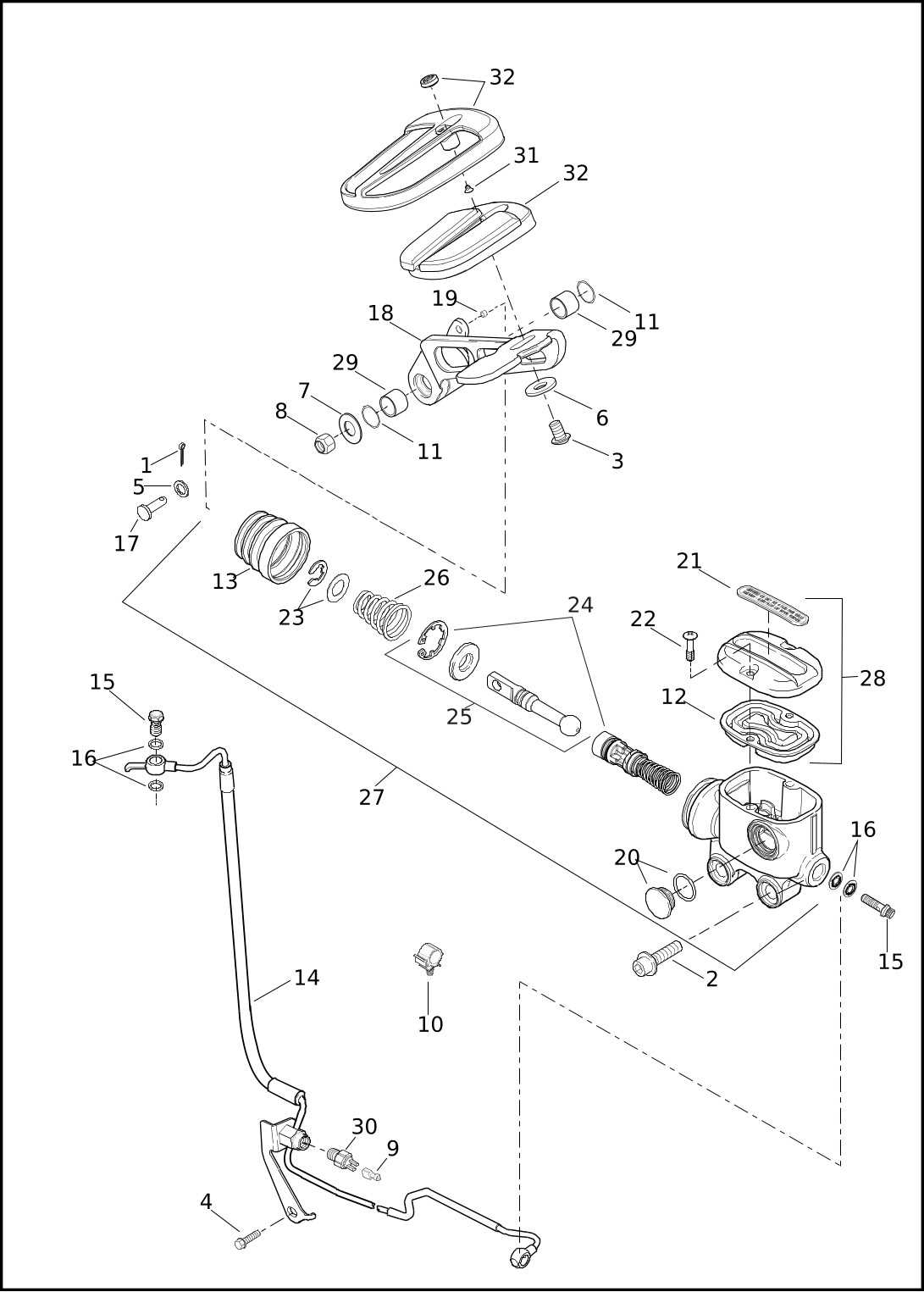

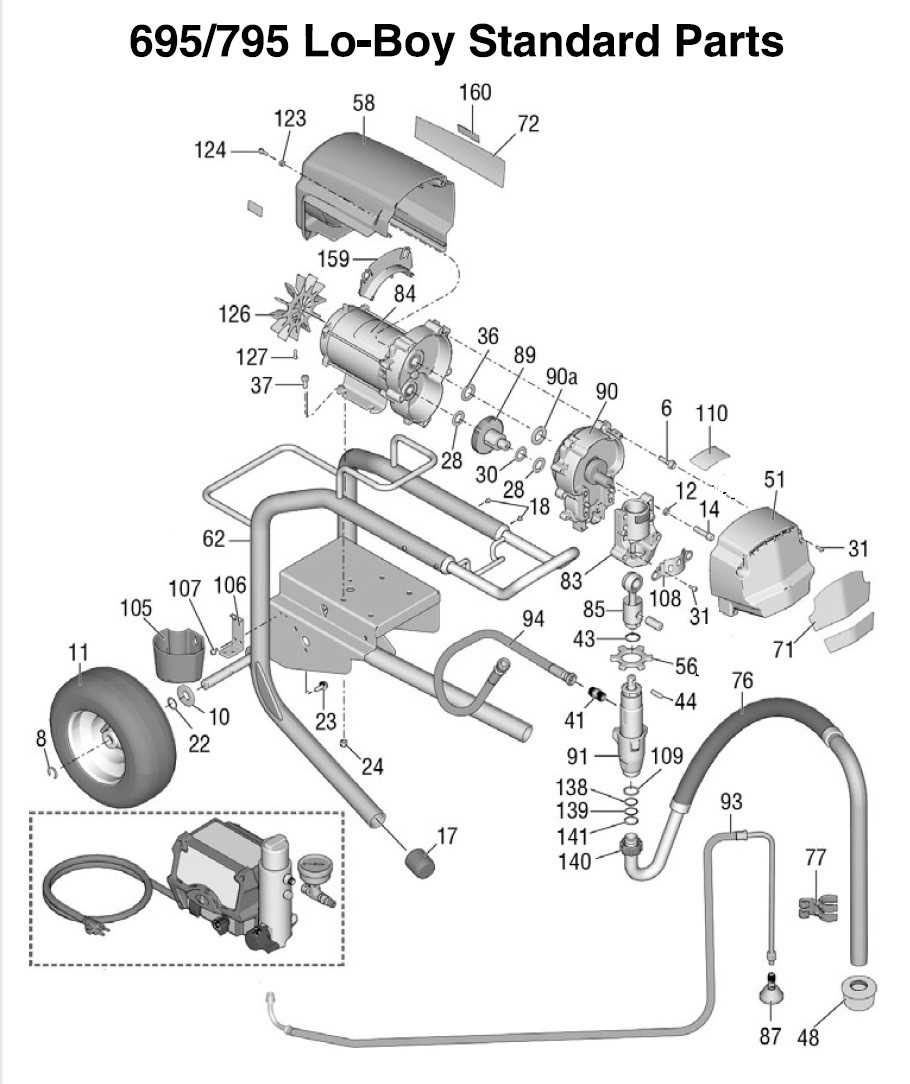

How to Interpret the Parts Diagram

Understanding an equipment schematic is essential for effective maintenance and repair. Such illustrations provide a visual representation of components, helping users identify parts, their functions, and how they interconnect within the system. By familiarizing yourself with these diagrams, you can streamline troubleshooting and enhance your operational efficiency.

Key Elements of the Illustration

Each section of the schematic is typically labeled, indicating the specific elements and their roles. Pay attention to the numbering system used, as it often corresponds with a detailed list that outlines specifications and replacement options. Understanding these labels can save time and reduce confusion when sourcing components.

Using the Legend

Most schematics include a legend that clarifies symbols and notations. This section is crucial for decoding the illustration, as it translates complex symbols into understandable terms. Refer to the legend whenever you encounter unfamiliar markings to ensure accurate interpretation and application in your repair process.

Common Issues and Troubleshooting Tips

When operating high-performance spray equipment, users may encounter various challenges that can impact efficiency and output quality. Understanding these common problems and knowing how to address them can enhance the overall experience and prolong the life of the equipment.

1. Inconsistent Spray Pattern: One frequent issue is an uneven or blotchy spray pattern. This can result from a clogged nozzle or improper pressure settings. Regularly clean the nozzle and ensure that the pressure is set according to the manufacturer’s recommendations.

2. Paint Leaking: Leakage around the connection points or from the spray gun itself can be problematic. This often indicates worn seals or improper assembly. Inspect all fittings and replace any damaged seals to prevent further issues.

3. Poor Paint Flow: If the material is not flowing smoothly, it may be due to a blocked intake or inadequate viscosity. Check for any blockages in the intake line and consider thinning the paint if necessary to achieve optimal flow.

4. Excessive Overspray: Overspray can be a nuisance, resulting in wasted material and messy surfaces. Adjusting the spray pressure and distance from the surface can help mitigate this problem. Experimenting with different nozzle sizes may also yield better results.

5. Motor Issues: If the motor is running inconsistently or not at all, check the power supply and connections. Ensure that the circuit is functioning properly and that all electrical components are secure. If problems persist, consulting a professional may be necessary.

By being aware of these common difficulties and implementing effective troubleshooting strategies, users can maintain optimal performance and achieve excellent results with their equipment.

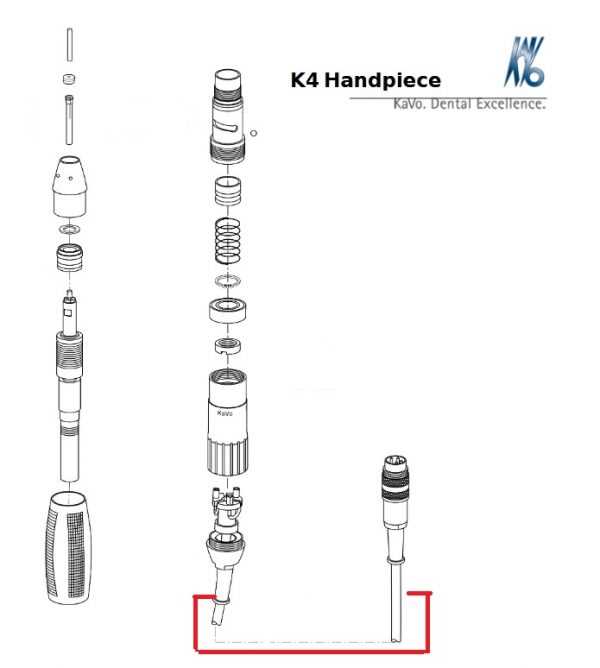

Replacing Worn Parts Effectively

Maintaining equipment in optimal condition is essential for ensuring performance and longevity. When components wear out, timely replacement can significantly enhance functionality and prevent further damage. Understanding the signs of wear and knowing how to address them is crucial for any user looking to maintain efficiency.

Identifying Signs of Wear

Regular inspection of machinery is vital. Look for irregularities such as unusual noises, leaks, or decreased efficiency. Early detection allows for prompt action, minimizing potential issues down the line.

Steps for Effective Replacement

Once a worn component is identified, consult the manufacturer’s guidelines for the correct procedure. Gather the necessary tools and parts before beginning. Follow step-by-step instructions carefully, ensuring all connections are secure to restore optimal operation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. Regular attention to maintenance can significantly enhance its efficiency and reliability. Implementing a few key practices can help extend the life of your machinery and reduce the risk of unexpected breakdowns.

Regular Cleaning

Keeping your equipment clean is fundamental. Accumulated dust and debris can hinder performance and lead to wear. Use a soft brush and cloth to remove particles from all surfaces, paying special attention to moving parts.

Periodic Inspections

Conduct routine checks on all components to identify any signs of wear or damage. Look for leaks, cracks, or loose fittings. Early detection can prevent more severe issues, ensuring your machinery operates at its best.

Upgrades and Aftermarket Parts Options

Enhancing your equipment can significantly improve its performance and longevity. Exploring various upgrades and alternative components allows users to customize their machines according to specific needs, resulting in more efficient operation and better results.

| Upgrade Option | Description |

|---|---|

| High-Performance Nozzles | These specialized nozzles provide finer control and improved spray patterns, ideal for detailed work. |

| Extended Hose Kits | Longer hoses enhance mobility and reach, allowing for larger projects without frequent repositioning. |

| Enhanced Filters | Upgraded filters ensure cleaner operation, reducing maintenance and prolonging the life of the machine. |

| Advanced Pressure Regulators | These regulators maintain consistent pressure, ensuring optimal performance across various applications. |

Finding Reliable Replacement Parts

Ensuring the longevity and performance of your equipment requires access to trustworthy components. Sourcing high-quality alternatives can be challenging, but it is essential for maintaining efficiency and reliability. With the right approach, you can discover dependable resources that offer the best options for your needs.

Identifying Trusted Suppliers

Begin by researching reputable vendors known for their commitment to quality. Look for those who provide detailed specifications and warranty information. Reading reviews and seeking recommendations can further enhance your confidence in their reliability.

Evaluating Quality and Compatibility

When selecting components, prioritize those that meet or exceed original specifications. Always verify compatibility with your equipment to avoid operational issues. Investing in durable materials can lead to improved performance and reduce the frequency of replacements in the long run.

Safety Precautions During Repairs

When undertaking maintenance tasks, prioritizing safety is essential to prevent accidents and injuries. A systematic approach ensures that all necessary precautions are observed, thereby safeguarding both the individual performing the repairs and the equipment itself.

Always wear appropriate personal protective equipment, including gloves, goggles, and masks, to shield against potential hazards. Ensure that the workspace is well-lit and free from clutter to minimize the risk of tripping or mishandling tools.

Before starting any repair, disconnect power sources and depressurize equipment to avoid unexpected activations. Familiarize yourself with the specific components and procedures involved, as understanding the mechanics can help prevent mistakes.

Utilizing the right tools for the job is crucial; using improvised equipment can lead to injuries or damage. Keep a first-aid kit accessible and ensure that emergency contact numbers are readily available in case of an accident.