When working with complex equipment, having a clear understanding of the internal components and how they are connected is crucial for efficient maintenance and troubleshooting. In any advanced system, each piece serves a specific function that contributes to the overall performance, and knowing their layout can save time and prevent costly errors. Understanding the connections between these elements is key for ensuring smooth operation.

Each section within a technical setup is designed to work in harmony with the others, forming a seamless integration of different parts. Knowing the positioning and interaction of these elements can help users better navigate repairs or upgrades. This type of information is particularly useful when dealing with more advanced machinery where the arrangement of different pieces directly affects functionality.

Whether you’re looking to maintain optimal performance or diagnose potential issues, knowing how individual components relate to one another is essential. By gaining insight into these relationships, users can make informed decisions and improve the overall efficiency of their equipment.

Overview of Graco Magnum Pro X9

This advanced painting tool is designed for both professionals and DIY enthusiasts, offering exceptional performance in medium to large-scale projects. It efficiently handles a variety of coating materials, providing smooth and even coverage with minimal effort. The machine is built for reliability and ease of use, making it a go-to solution for those looking for efficiency and high-quality results.

- Suitable for both interior and exterior tasks

- Capable of handling different types of coatings

- Equipped with high-pressure capabilities for faster application

- User-friendly controls for precise adjustments

- Portable and durable for long-lasting performance

The tool comes with several innovative features that make it ideal for users looking for high output and consistency in their painting projects. Its robust design ensures that even the most demanding tasks can be completed with ease.

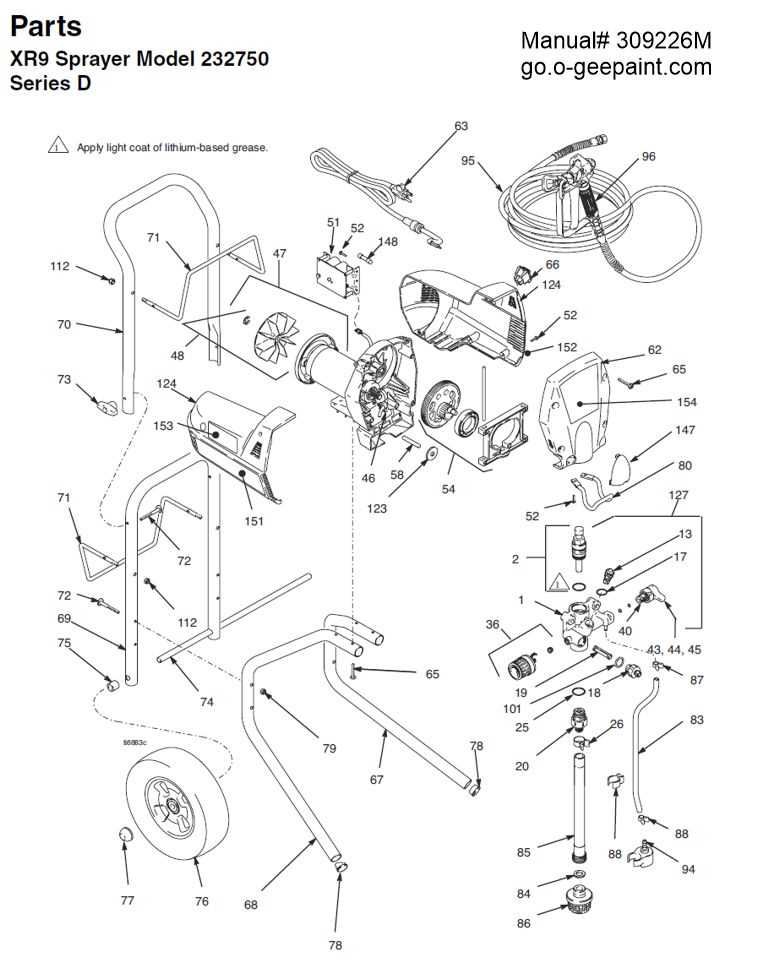

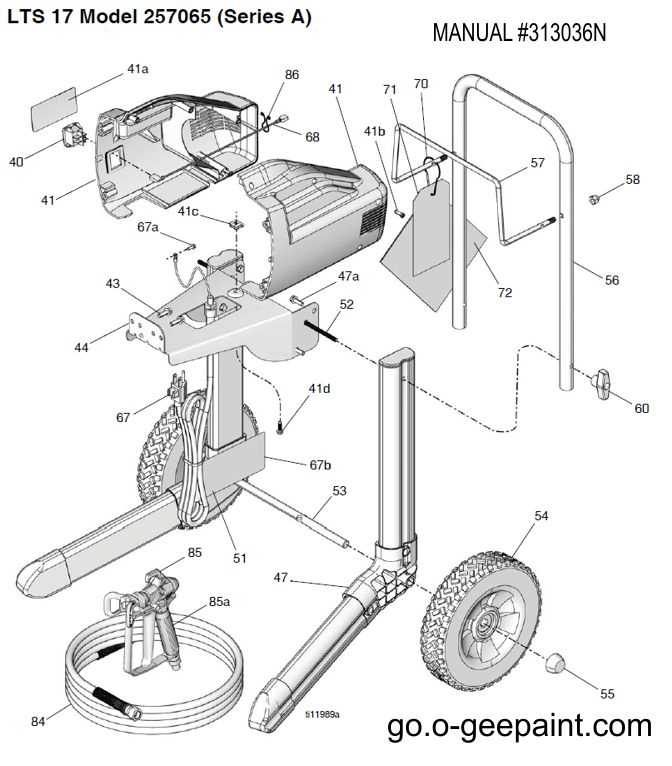

Key Components of the Spray System

The functionality of a high-performance spray system relies on the harmonious operation of its individual elements. These essential parts work together to ensure efficient flow, pressure control, and precise application of the material. Understanding these components helps in maintaining, troubleshooting, and optimizing the system for various tasks.

Pump – The core of the system, this component generates the necessary force to push the material through the various stages. Without a reliable pumping mechanism, maintaining consistent pressure would be impossible.

Hose – This flexible conduit allows for the smooth transfer of the material from the source to the point of application. Durability and proper length ensure uninterrupted operation during extended usage.

Spray Gun – Serving as the final stage, the gun delivers the material to the surface with precision. A well-maintained gun ensures even distribution and smooth application, reducing the chance of overspray or clogging.

Filters – Integrated within the system to prevent debris from entering critical parts, filters play a crucial role in extending the life of the equipment and maintaining the quality of the output.

Pressure Regulator – This element allows for adjustments in the pressure, ensuring that the material

Maintenance Tips for Optimal Performance

Ensuring smooth operation and longevity of your equipment requires regular upkeep and attention to specific details. Proper maintenance prevents breakdowns and helps achieve consistent, efficient results over time. In this section, we’ll cover essential tips to keep your tool performing at its best.

Regular Cleaning and Inspection

- Thoroughly clean after each use to remove any buildup or residue.

- Inspect key components regularly for wear and tear, replacing any damaged parts promptly.

- Pay close attention to any signs of leakage or blockages that may affect functionality.

Proper Lubrication

- Use the recommended lubricant for moving parts to ensure smooth operation.

- Apply lubrication as part of your routine maintenance, especially after prolonged use.

- Avoid over-lubrication, as this can attract debris and cause performance issues.

By adhering to these simple guidelines, you can ensure that your equipment remains reliable, extending its service life and optimizing performance.

Common Replacement Parts and Their Functions

When maintaining any spray system, understanding the role of key components is essential for ensuring efficient operation. Regular wear and tear can lead to the need for replacements, and knowing which elements are most prone to damage can save time and improve performance. In this section, we will explore some of the most frequently substituted components and their specific purposes in the overall operation of the equipment.

Essential Components

- Pump Assembly: Responsible for creating the necessary pressure to move the fluid through the system, this part is vital for ensuring smooth, even spraying.

- Hose Connections: These links are crucial for transporting the material from the reservoir to the applicator. Ensuring secure and undamaged connections can prevent leaks and maintain steady flow.

- Spray Nozzle: This component determines the spray pattern and flow rate. Over time, it can wear out due to material buildup or consistent use, affecting precision.

Additional Functional Parts

- Filters: Positioned to catch debris and impurities, these parts are essential for preventing clogs and ensuring a clean, uninterrupted spray.

- Pressure Valves:

Troubleshooting the Graco Magnum Pro X9

Tackling issues with your spray equipment can be daunting, but understanding common problems and their solutions can streamline the process. This section will guide you through identifying and resolving typical challenges encountered with this advanced painting tool, ensuring optimal performance and longevity.

1. Uneven Spray Pattern: An inconsistent spray can result from a clogged nozzle or filter. To rectify this, inspect and clean the components regularly. Ensure the fluid tip is suitable for the material being used, as a mismatch can also lead to poor application.

2. Difficulty in Starting: If the unit fails to start, check the power supply and ensure all connections are secure. A blown fuse or tripped circuit breaker may also be the culprit. Inspect the motor for any visible damage or wear that could impede operation.

3. Excessive Pressure Build-Up: High-pressure readings can indicate a blockage in the hose or a faulty regulator. Carefully examine these parts and replace any worn or damaged components to maintain safe operating conditions.

4. Pulsation in Spray: Pulsation often occurs due to air in the system. To eliminate this, ensure the fluid is primed correctly, and check for any leaks in the suction line. Additionally, using a higher quality material can help mitigate this issue.

5. Overheating: If the equipment becomes excessively hot, it may be working beyond its capacity. Allow for adequate cooling periods and avoid prolonged use. Regular maintenance checks can prevent overheating and prolong the life of the unit.

Importance of Regular Part Inspection

Routine examination of equipment components is crucial for maintaining optimal performance and extending the lifespan of machinery. Regular checks not only ensure that all elements are functioning correctly but also help in identifying potential issues before they escalate into significant problems. This proactive approach minimizes downtime and enhances the overall efficiency of operations.

Benefits of Routine Checks

- Preventive Maintenance: Regular inspections can uncover wear and tear, allowing for timely replacements or repairs.

- Increased Safety: Identifying faulty components reduces the risk of accidents and injuries in the workplace.

- Cost Efficiency: Early detection of issues can lead to lower repair costs and less unexpected downtime.

Key Areas to Focus On

- Inspecting seals and gaskets for leaks.

- Checking hoses and connectors for signs of wear.

- Monitoring the condition of valves and other mechanical parts.

Where to Find Genuine Replacement Parts

Locating authentic components for your equipment is crucial for maintaining its performance and longevity. Using original items ensures compatibility and reliability, preventing potential issues that can arise from using inferior alternatives.

One of the best sources for acquiring genuine components is the manufacturer’s official website. They typically provide a comprehensive catalog of available items, along with detailed specifications. Additionally, authorized retailers and local distributors are excellent options, as they often carry a range of products that meet the necessary standards.

Online marketplaces can also serve as useful platforms, but caution is advised. Always verify the seller’s credibility and check for customer reviews to ensure that you are purchasing from a reputable source. Look for guarantees or return policies that protect your investment.

Lastly, consider joining forums or user groups dedicated to your equipment. These communities often share valuable insights and may provide recommendations for trustworthy suppliers, enhancing your chances of finding the right components for your needs.

Steps for Disassembling the Unit Safely

When it comes to taking apart a mechanical device, ensuring safety and proper technique is crucial. A systematic approach not only prevents damage to the equipment but also protects the user from potential hazards. Follow these essential steps to effectively disassemble the unit while maintaining a secure working environment.

Preparation Before Disassembly

- Ensure the device is unplugged from any power source.

- Gather the necessary tools, such as screwdrivers, wrenches, and pliers.

- Wear appropriate safety gear, including gloves and goggles.

- Clear the workspace of any clutter to prevent accidents.

Disassembly Process

- Start by removing any exterior covers or panels to access the internal components.

- Carefully document the arrangement of parts and screws as you remove them. This can be helpful for reassembly.

- Loosen and detach any screws or fasteners using the appropriate tools.

- Gently pull apart components, taking care to avoid forcing any parts that may be stuck.

- Keep small parts organized in labeled containers to simplify reassembly.

Upgrading Your Graco Magnum Pro X9

Enhancing the performance and functionality of your painting equipment can significantly improve your project outcomes. This section will explore various methods and components to consider when looking to elevate your sprayer’s efficiency and usability.

When contemplating an upgrade, it’s essential to identify the key areas that can be enhanced:

- Fluid Delivery: Evaluate options for improved fluid flow, which can lead to more consistent application.

- Pressure Regulation: Consider advanced pressure controls for better management of spray patterns and finishes.

- Replacement Accessories: Upgrading hoses, filters, and spray tips can enhance overall performance and ease of use.

To maximize the benefits of these enhancements, you may want to follow these steps:

- Research compatible components that suit your current model.

- Consult user manuals or online resources for guidance on installation.

- Take note of your specific painting needs to ensure the upgrades align with your projects.

- Regularly maintain the upgraded components for optimal performance.

By carefully selecting upgrades, you can transform your equipment into a more efficient tool, tailored to meet your individual requirements.