The intricate design of a fastening mechanism plays a vital role in various applications, from fashion to industrial uses. Each element contributes to the overall functionality, ensuring that items remain securely closed while allowing for ease of use. A closer look at this assembly reveals how each section interacts with the others to provide a seamless experience.

At the heart of this fastening system lies a series of interconnected elements that work in harmony. These components not only enhance durability but also influence the aesthetic appeal of the product. Recognizing the significance of each section allows for a deeper appreciation of its engineering and design.

In this exploration, we will delve into the individual segments of this mechanism, examining their specific roles and how they contribute to the efficacy of the entire unit. By understanding these distinct elements, one can gain insights into the complexities behind a seemingly simple closure solution.

Understanding Zipper Anatomy

Exploring the structure of this common fastening mechanism reveals a fascinating interplay of components that work harmoniously to provide functionality and durability. Each element plays a crucial role, contributing to the overall efficiency and ease of use.

The Key Components

At the heart of this mechanism lies a series of interlocking elements, designed to securely bind two edges together. The precise arrangement of these elements ensures smooth operation and reliability, making it essential to comprehend how they interact.

Functionality and Design

Beyond mere utility, the construction of these fasteners showcases innovative engineering. Understanding the layout not only enhances usability but also opens up avenues for creative applications in various industries.

Components of a Zipper

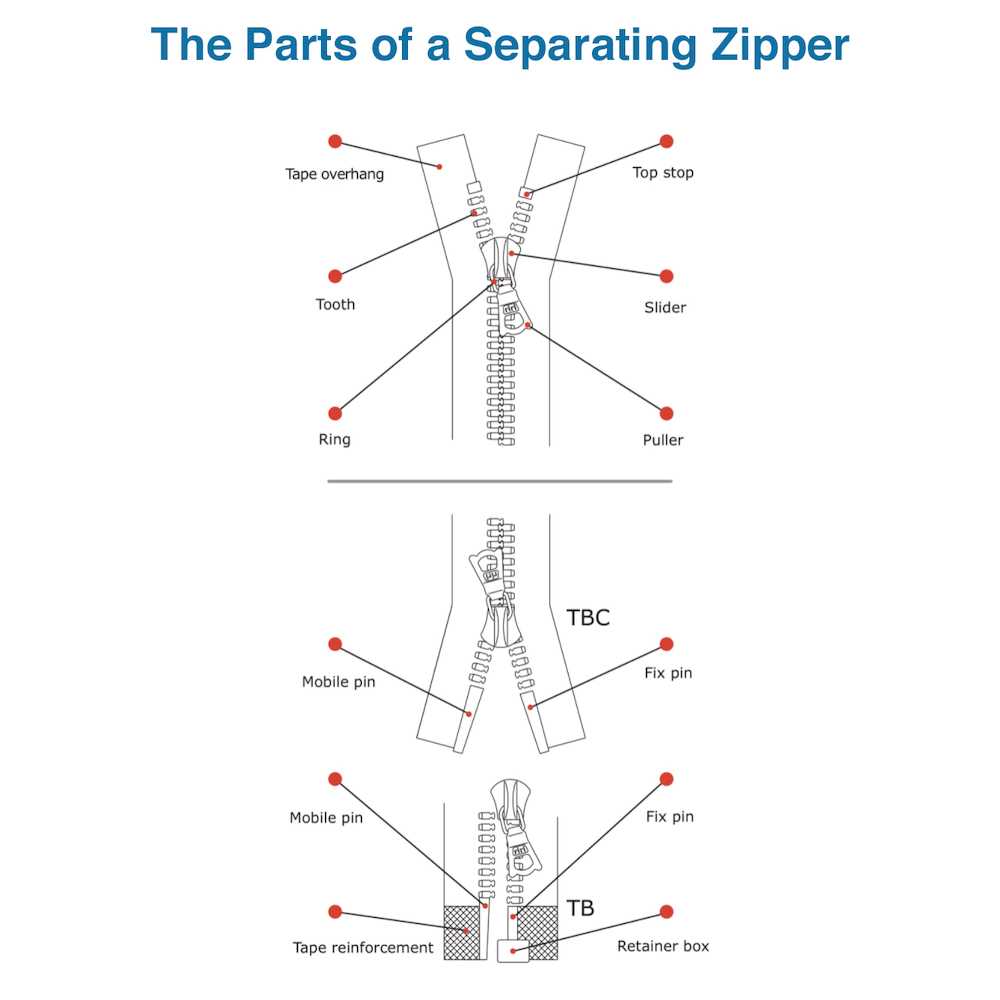

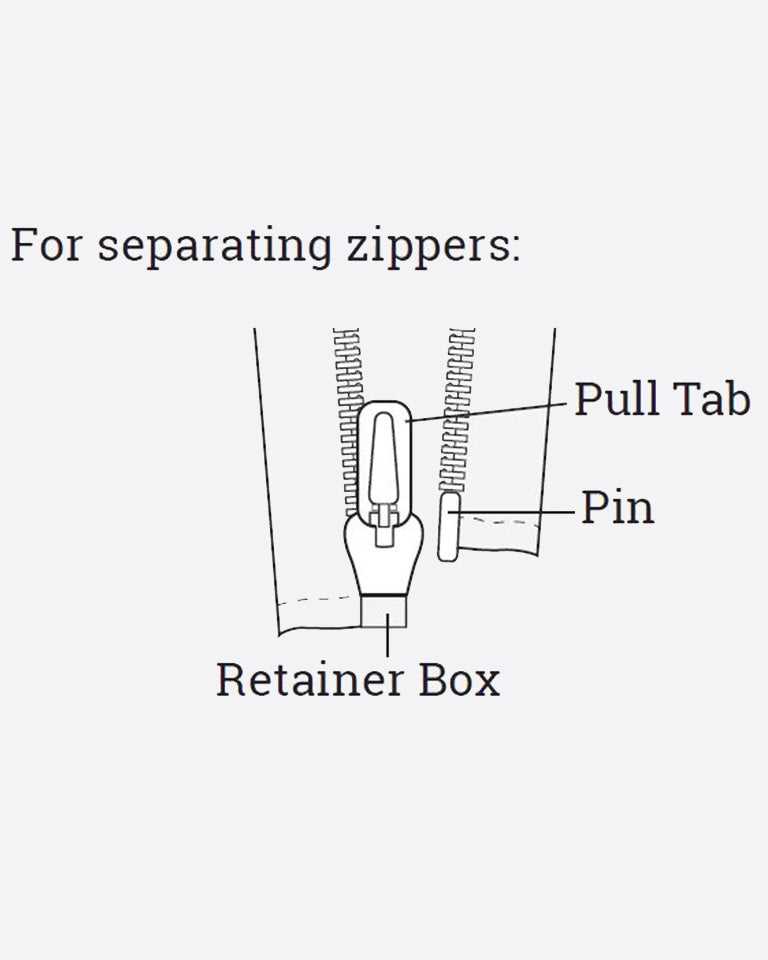

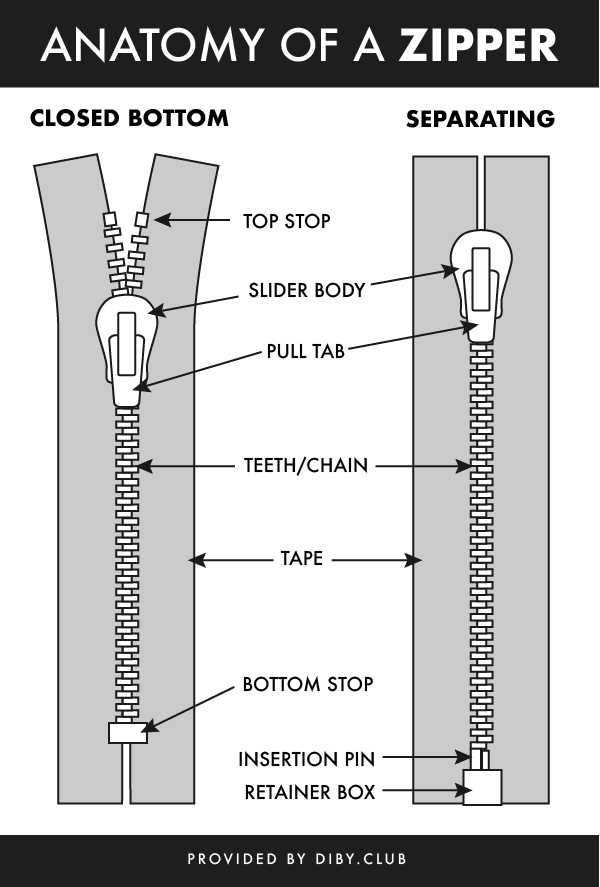

Understanding the individual elements that come together to create this essential fastening mechanism is crucial for appreciating its functionality and design. Each component plays a vital role in ensuring smooth operation and durability, contributing to the overall effectiveness of the closure.

Key Elements

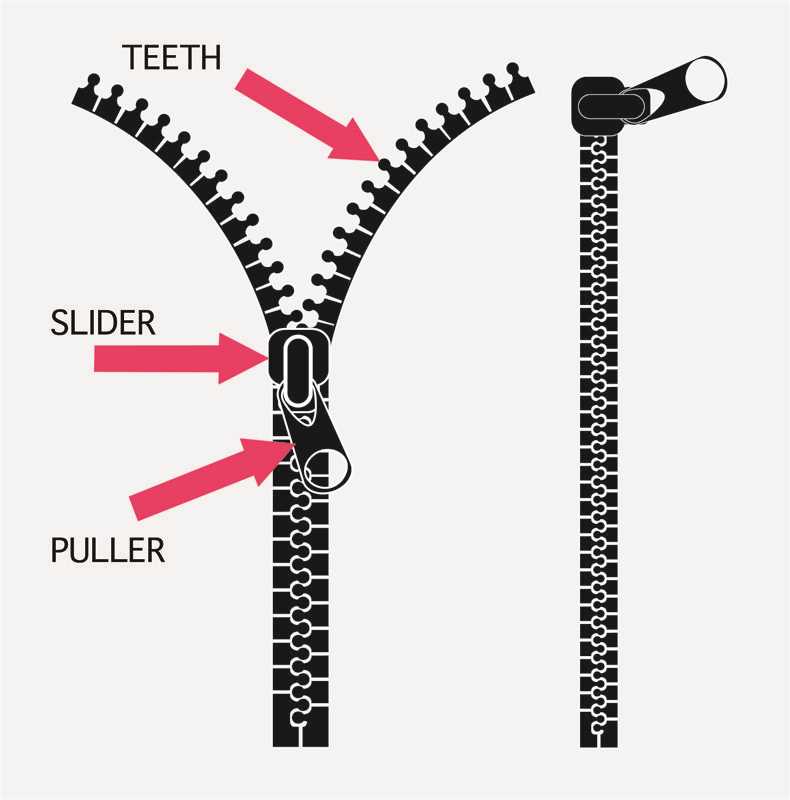

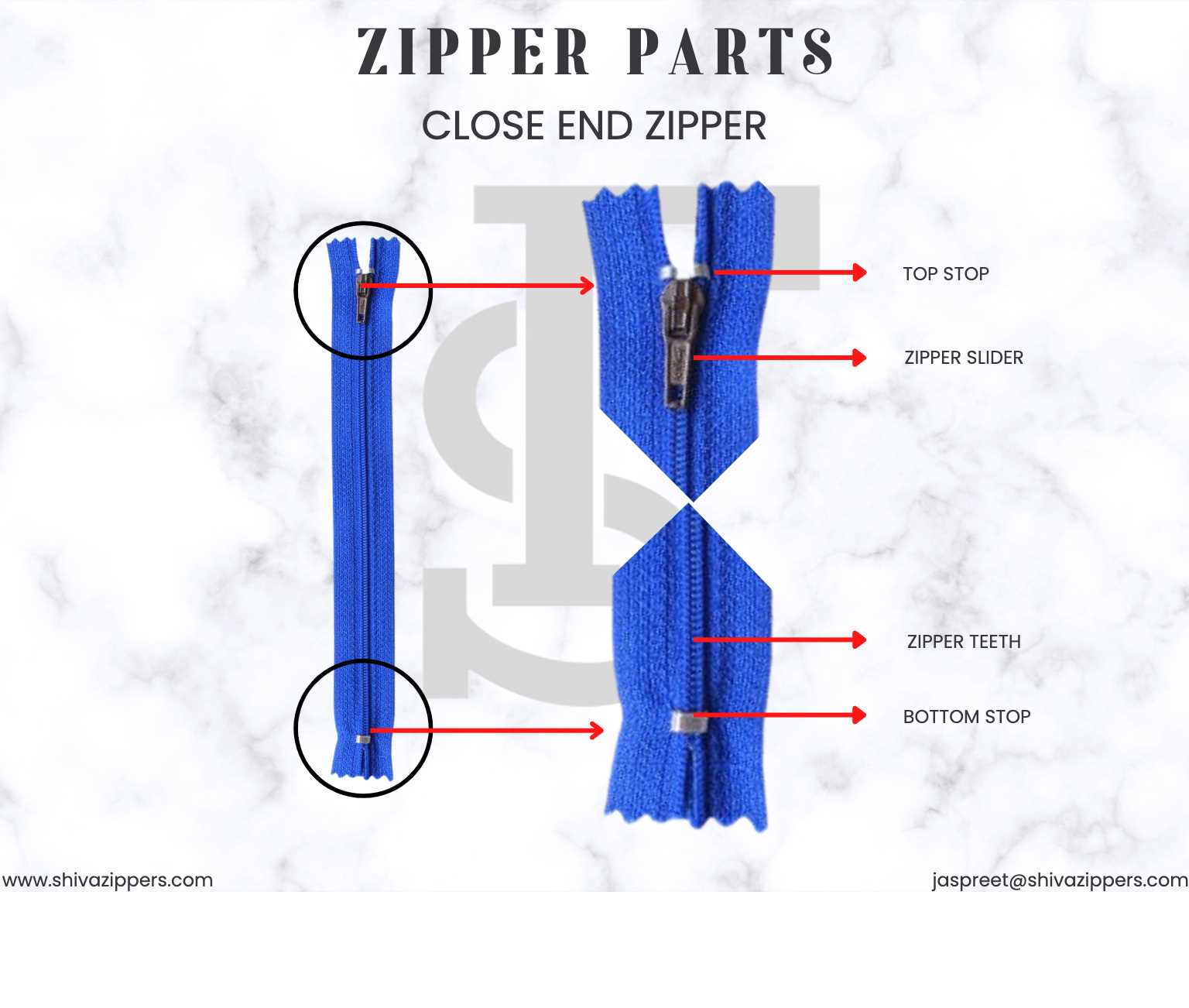

Among the primary constituents are the slider, which facilitates the opening and closing motion, and the teeth that interlock securely. The tape serves as the foundation, holding everything in place, while the stopper prevents the slider from detaching at either end.

Additional Features

Other notable components include the pull tab, which provides a grip for easy manipulation, and the box, which houses the slider mechanism. Each element is intricately designed to work in harmony, ensuring reliable performance in various applications.

Types of Zipper Fasteners

Fastening mechanisms come in various designs, each serving distinct purposes and applications. Understanding these options can enhance your choice of closure for garments, bags, and other items, ensuring both functionality and style.

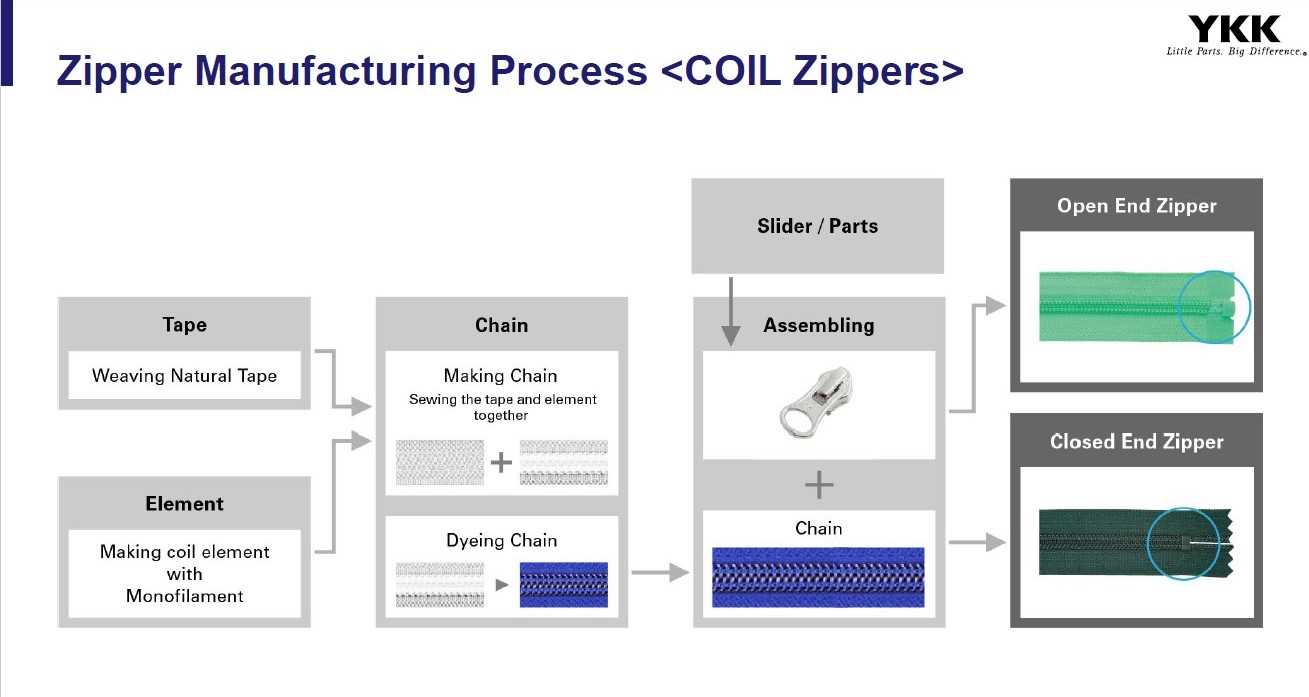

1. Coil Fasteners: These are made from a continuous coil of nylon or polyester. They are lightweight, flexible, and often found in casual wear and outdoor gear due to their durability.

2. Metal Fasteners: Constructed from brass, aluminum, or other metals, these closures offer a sturdy and stylish option. They are commonly used in jeans and high-end fashion items, adding a touch of elegance.

3. Plastic Fasteners: Lightweight and available in various colors, these are popular for their affordability and versatility. Often seen in children’s clothing and accessories, they can add a fun element to designs.

4. Invisible Fasteners: Designed to be hidden within seams, these closures provide a seamless look, ideal for formal attire and garments where aesthetics are paramount.

5. Waterproof Fasteners: These are specially designed to prevent water penetration, making them ideal for outdoor apparel and equipment, where moisture resistance is essential.

Each of these fastening types plays a crucial role in design and functionality, allowing for diverse applications across various industries.

Function of Zipper Teeth

The tiny interlocking components of a fastening mechanism play a crucial role in its overall functionality. Their design ensures a secure closure, allowing users to open and close effortlessly while maintaining durability and strength over time.

Interlocking Mechanism

The primary function of these elements is to interlace seamlessly. When pulled together by a slider, they create a robust seal that prevents separation. This interlocking feature is vital for the integrity of the item, whether it be clothing or bags.

Material and Durability

Typically crafted from materials like metal or plastic, these components are engineered to withstand repeated use. Their strength contributes to the ultimate reliability of the entire fastening system, ensuring it remains functional under various conditions.

Role of the Zipper Slider

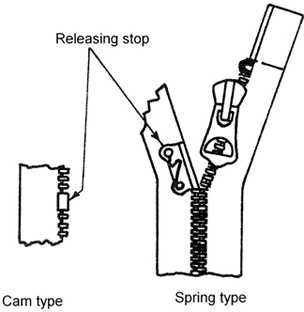

The slider serves as a pivotal component in the functionality of fastening mechanisms. It is responsible for the seamless operation of the closure, allowing for easy opening and closing. The efficiency and durability of this mechanism rely heavily on the design and materials used in the slider.

Functionality and Mechanism

Essentially, the slider facilitates the engagement and disengagement of the opposing elements that create a secure closure. Its design features play a significant role in ensuring that the mechanism operates smoothly. Key aspects include:

- Engagement: The slider moves along the tracks of the closure, aligning the interlocking components for a secure fit.

- Disengagement: By pulling the slider in the opposite direction, the closure elements separate, allowing for easy access.

- Guidance: The slider guides the teeth into their proper positions, ensuring a consistent and reliable function.

Materials and Durability

The longevity of the fastening system is influenced by the materials chosen for the slider. Common materials include:

- Metal: Provides strength and durability, often used in heavy-duty applications.

- Plastic: Lightweight and versatile, suitable for everyday use in various garments and accessories.

- Composite: Combines materials to enhance both strength and aesthetic appeal.

In conclusion, the slider is a crucial element in fastening systems, impacting both functionality and durability. Understanding its role aids in selecting the appropriate type for specific applications.

Materials Used in Zippers

The construction of fastening mechanisms involves a variety of materials, each contributing to the overall functionality, durability, and aesthetic appeal. Understanding these components helps in choosing the right type for specific applications, ensuring optimal performance and longevity.

Typically, the materials can be categorized into several key types:

- Teeth: The interlocking elements are often made from:

- Metal: Known for its strength and durability, metal teeth are commonly used in heavy-duty applications.

- Plastic: Lightweight and often available in various colors, plastic teeth are favored for casual and fashion items.

- Nylon: Flexible and resistant to wear, nylon teeth provide a balance between strength and lightness.

- Tape: The fabric that houses the interlocking elements can be made from:

- Cotton: Natural fibers offer a soft feel and are typically used in apparel.

- Polyester: Known for its durability and resistance to stretching, polyester is widely used in various products.

- Nylon: This synthetic option is strong and flexible, often chosen for outdoor and sports gear.

- Slider: The mechanism that operates the interlocking elements may be crafted from:

- Metal: Provides a robust and reliable operation, ideal for heavy-use applications.

- Plastic: Lightweight and often more affordable, plastic sliders are common in fashion items.

Each of these components plays a vital role in the performance and usability of fastening devices. By selecting the appropriate materials, manufacturers can ensure that the final product meets the desired standards of strength, aesthetics, and functionality.

Zipper Pulls: Purpose and Design

Functional elements of fasteners serve not only as practical components but also as opportunities for creativity and personalization. These attachments facilitate easy manipulation of the closure mechanism, making them essential for users of all ages. Their design often reflects a blend of aesthetics and usability, influencing the overall appeal of garments and accessories.

Importance of Attachments

The role of these functional accessories goes beyond mere utility. They enhance the user experience by ensuring that opening and closing mechanisms are straightforward and accessible. Moreover, these features can be designed to complement the overall style of the item, serving as a statement piece in itself. Various materials and shapes allow for diverse applications, making them versatile in both fashion and practicality.

Design Variations

The creative freedom in crafting these elements results in a multitude of designs, each catering to different consumer preferences. From minimalist approaches to bold, artistic expressions, the diversity can be seen across various products. The choice of materials, colors, and shapes plays a significant role in their effectiveness and appeal.

| Material | Common Uses | Advantages |

|---|---|---|

| Plastic | Clothing, bags | Lightweight, cost-effective |

| Metal | Jackets, outdoor gear | Durable, sturdy |

| Fabric | Fashion items, soft goods | Flexible, customizable |

Common Zipper Problems

Issues with fasteners can be frustrating and often lead to dissatisfaction with clothing or accessories. Understanding the typical complications that arise can help users troubleshoot effectively and extend the lifespan of their belongings. This section explores frequent dilemmas encountered with these fastening mechanisms, along with possible solutions to resolve them.

Jamming or Sticking

One of the most prevalent issues is the inability to move the slider smoothly along the track. This can occur due to debris, fabric caught in the mechanism, or misalignment. To remedy this, gently clean the area around the slider and ensure no material is obstructing movement. Lubricating the track with a wax or a specialized lubricant can also provide relief.

Broken Teeth

Another common complication involves the teeth, which may become damaged or misaligned. If one or more teeth are missing, it can result in failure to secure the two sides together. In some cases, replacing the entire assembly may be necessary, but if the damage is minimal, a simple repair using a needle and thread to secure the surrounding fabric can suffice. For larger repairs, consider seeking professional assistance to maintain the integrity of the item.

Maintenance Tips for Zippers

Proper care and attention can significantly enhance the longevity and performance of fastening mechanisms. Implementing a few simple practices can prevent common issues and ensure smooth operation for years to come. Here are some essential tips to keep these functional elements in optimal condition.

Cleaning Techniques

Regular cleaning is crucial for maintaining the functionality of fastening devices. Dirt and debris can accumulate in the track, causing malfunction. Use the following methods to clean effectively:

| Method | Description |

|---|---|

| Brush Cleaning | Use a soft brush or toothbrush to gently remove dirt and lint from the track. |

| Soap Solution | Mix mild soap with water, apply with a cloth, and wipe the area carefully to avoid residue buildup. |

| Compressed Air | Utilize compressed air to blow out any debris lodged in the mechanism without causing damage. |

Lubrication Tips

Applying lubricant can improve the movement of the fastening mechanism, making it easier to use. Select the appropriate type and follow these guidelines:

| Lubricant Type | Application Method |

|---|---|

| Wax | Rub a small amount along the track for a smooth glide. |

| Silicone Spray | Spray lightly on the track, ensuring even distribution without excess. |

| Graphite Powder | Apply sparingly to avoid messy buildup while ensuring efficient operation. |