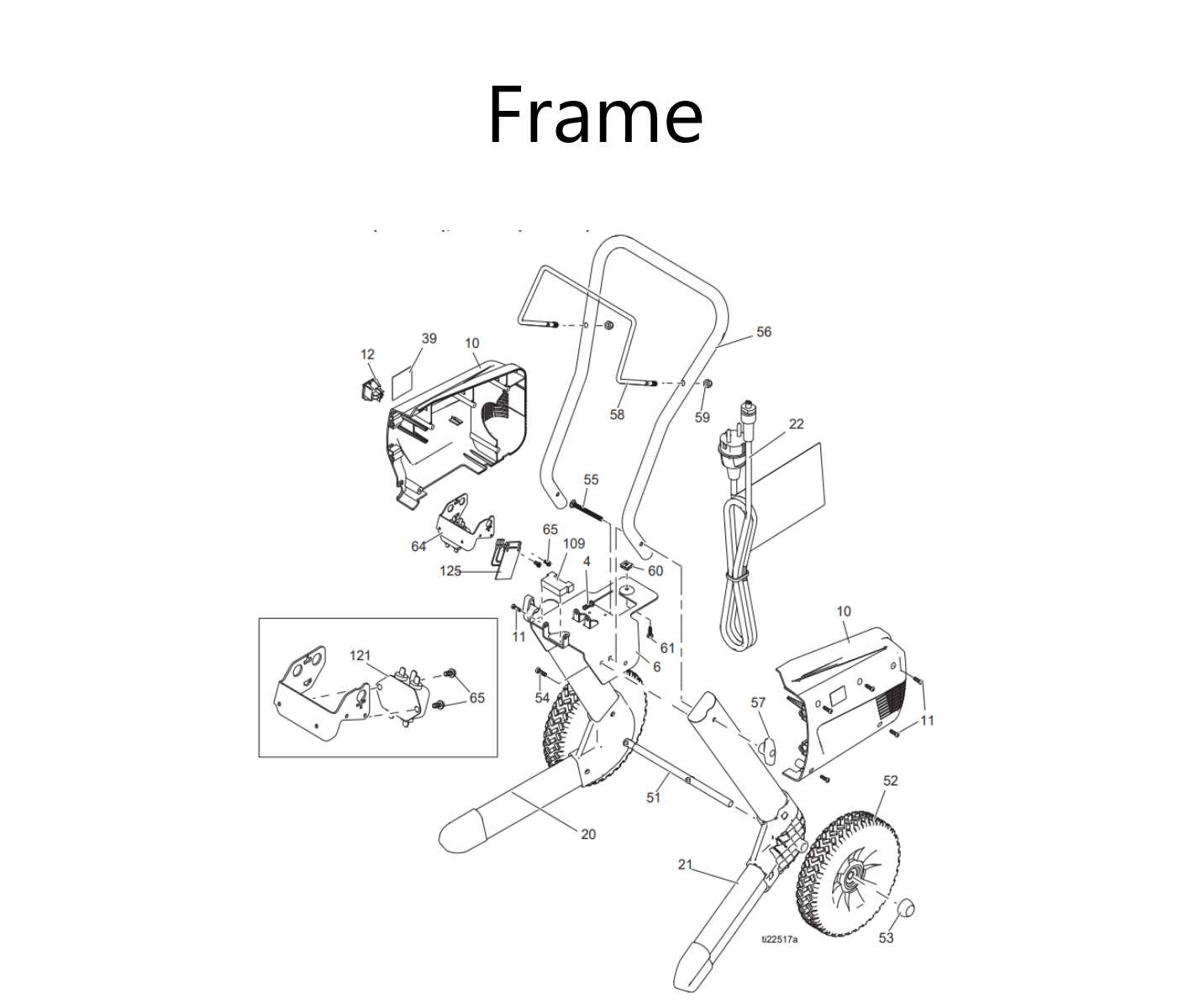

When it comes to maintaining and optimizing your spray equipment, having a clear understanding of its components is essential. A detailed representation of the various elements not only aids in troubleshooting but also enhances your ability to perform regular maintenance effectively. This knowledge empowers users to ensure their devices operate at peak efficiency.

Each piece plays a crucial role in the overall functionality of the system. Familiarity with the layout and interactions of these components can significantly simplify repair processes and replacement tasks. By delving into the intricate assembly, users can gain insights into how to prolong the lifespan of their equipment while ensuring consistent performance.

In this section, we will explore an organized overview of the different elements, highlighting their purposes and interconnections. Understanding these details will provide you with the confidence needed to tackle any issues that may arise and make informed decisions regarding upkeep and repairs.

Understanding Graco Magnum LTS 17

This section aims to provide a comprehensive overview of a versatile paint application system designed for efficient and high-quality results. By exploring its components, functionality, and user benefits, readers will gain a deeper understanding of its operation and maintenance.

Key Features

- High-pressure capability for a variety of coatings.

- Durable construction ensuring longevity.

- Easy-to-use design suitable for both professionals and DIY enthusiasts.

- Lightweight and portable for enhanced maneuverability.

Components Overview

- Motor: Powers the system and ensures consistent flow.

- Spray Gun: Provides precision application with adjustable settings.

- Hoses: Allow flexibility in movement while preventing leaks.

- Filters: Protect the system from debris, ensuring smooth operation.

By familiarizing oneself with these features and components, users can maximize the performance of their painting equipment, leading to superior finishes in their projects.

Essential Components of the Sprayer

Understanding the key elements of a painting apparatus is crucial for effective operation and maintenance. Each part plays a significant role in ensuring optimal performance and durability, contributing to a smooth and efficient painting process.

1. Pump: The heart of the system, this component generates the pressure needed to push the paint through the hose. A reliable pump ensures consistent flow and application.

2. Hose: This flexible conduit carries the material from the pump to the nozzle. Quality hoses are designed to withstand high pressure and prevent leaks, ensuring a clean and precise application.

3. Nozzle: The part that determines the spray pattern and flow rate. Various nozzle sizes and types allow users to adjust the spray according to the project’s needs, from fine mist to wide coverage.

4. Filter: Essential for maintaining the quality of the output, this component prevents clogs by trapping debris and particles before they reach the nozzle.

5. Spray Gun: This handheld device controls the spray pattern and pressure, allowing for precision in application. Ergonomically designed guns reduce fatigue, making long jobs more manageable.

By familiarizing oneself with these vital components, users can enhance their experience and achieve professional results with greater ease.

How to Read the Parts Diagram

Understanding the visual representation of components is crucial for effective maintenance and repair of equipment. This guide will help you interpret the schematic, allowing you to identify individual elements and their relationships within the system.

To begin, familiarize yourself with the layout. Components are usually arranged logically, often grouped by function. Look for labels and numbers that correspond to a key, which will provide additional details about each element.

| Symbol | Description |

|---|---|

| A | Main unit |

| B | Power supply |

| C | Connecting hose |

| D | Nozzle attachment |

| E | Control valve |

Take note of the arrows and lines connecting various symbols. These indicate flow paths and interactions between different parts. Understanding these connections is essential for troubleshooting and assembly tasks.

Finally, refer to the accompanying documentation for any specific details or guidelines. This will provide clarity on maintenance protocols and ensure that you are equipped with the necessary knowledge to handle repairs efficiently.

Common Issues and Solutions

In the realm of high-performance spraying equipment, various challenges may arise during operation. Understanding these common problems and their respective remedies can significantly enhance the efficiency and longevity of your device. Below are frequent issues encountered by users along with practical solutions to address them.

Frequent Problems

| Issue | Description |

|---|---|

| Poor Spray Pattern | This occurs when the spray is uneven or lacks consistency. |

| Clogged Nozzle | A blockage in the nozzle can disrupt the flow of material. |

| Low Pressure | Inadequate pressure may lead to unsatisfactory coverage. |

| Leaks | Fluid leaks can compromise performance and safety. |

Solutions

| Issue | Solution |

|---|---|

| Poor Spray Pattern | Check and adjust the nozzle settings or replace it if worn out. |

| Clogged Nozzle | Clean the nozzle thoroughly with appropriate solvents or replace it. |

| Low Pressure | Inspect the hose for kinks and ensure all connections are secure. |

| Leaks | Examine seals and gaskets; replace any damaged components. |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. Adopting a systematic approach to maintenance can significantly extend its lifespan and enhance efficiency. Here are some essential tips to consider:

- Regular Cleaning: Keep surfaces free from dust and debris. This prevents wear and ensures smooth operation.

- Check for Wear: Frequently inspect components for signs of wear and tear. Early detection can prevent more significant issues.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and enhance performance.

In addition to these practices, it’s vital to follow specific guidelines:

- Refer to the Manual: Always consult the manufacturer’s manual for recommended maintenance schedules and procedures.

- Use Quality Supplies: Invest in high-quality materials and accessories that match your equipment specifications.

- Store Properly: Keep the equipment in a dry, cool place when not in use to avoid rust and damage.

By implementing these maintenance strategies, you can ensure that your tools operate efficiently and last for many years to come.

Upgrading Parts for Better Performance

Enhancing the functionality of your equipment can significantly improve efficiency and output quality. By selecting superior components, you can ensure a smoother operation, reduce downtime, and extend the lifespan of your device.

When considering enhancements, focus on the following key areas:

- Spray Nozzles: Upgrading to high-quality nozzles can provide a finer spray pattern and improved coverage.

- Filters: Better filtration systems can prevent clogs and maintain consistent flow, which is crucial for achieving optimal results.

- Hoses: Durable and flexible hoses can enhance maneuverability and reduce pressure loss during operation.

- Motor Components: Investing in a more powerful motor can increase performance, allowing for faster work completion.

- Seals and Gaskets: Quality seals prevent leaks, ensuring that your equipment runs efficiently without wasting materials.

Implementing these upgrades not only enhances performance but also contributes to a more enjoyable user experience. Evaluating the specific needs of your operation will guide you in making the best choices for improvements.

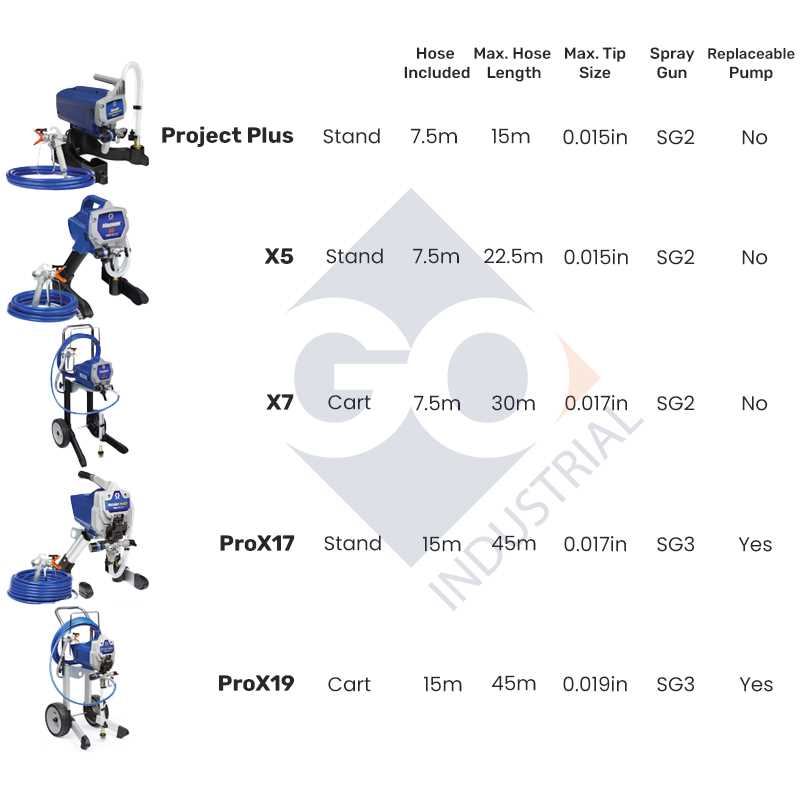

Comparing Graco Models for Efficiency

When evaluating various models of paint sprayers, efficiency becomes a crucial factor for both professionals and DIY enthusiasts. Understanding the differences in performance, usability, and maintenance can significantly impact project outcomes. This section explores how different designs cater to diverse needs, emphasizing the advantages and drawbacks of each type.

Performance Metrics

Efficiency often hinges on several performance metrics, including flow rate, pressure output, and coverage area. High-output machines are ideal for large-scale projects, delivering consistent results over expansive surfaces. Conversely, models designed for smaller tasks offer precision, making them suitable for detailed work. Choosing the right machine based on these metrics can enhance productivity and minimize waste.

Usability and Maintenance

The ease of use is another critical aspect that affects overall efficiency. Some units feature user-friendly controls and quick setup processes, allowing for immediate application. Additionally, maintenance requirements can vary significantly. Models that are easier to clean and maintain often lead to lower downtime and greater satisfaction. Investing in a sprayer that balances performance with straightforward operation ensures a smoother workflow and better results.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance and longevity. Various avenues are available for locating high-quality replacements that fit your needs.

One effective approach is to explore official distributors and retailers that specialize in machinery and tools. These establishments often have comprehensive inventories and knowledgeable staff who can assist in finding the exact items required. Additionally, online marketplaces provide a wide selection of components, often at competitive prices, making it easy to compare options from the comfort of your home.

Another valuable resource is user forums and community groups dedicated to equipment maintenance. Members frequently share insights about where to find specific items and may even offer recommendations for reliable suppliers. Utilizing these platforms can lead to discovering unique solutions that may not be readily available elsewhere.

Finally, consider reaching out to local repair shops or service centers. These professionals often have access to various suppliers and can help you locate hard-to-find components, ensuring your machinery operates smoothly for years to come.

User Experiences and Reviews

This section aims to provide insights into user feedback regarding a popular painting equipment model. By examining firsthand accounts and opinions, potential buyers can gain a deeper understanding of the product’s strengths and weaknesses. Experiences shared by users can illuminate various aspects such as performance, durability, and ease of use, helping others make informed decisions.

Performance Insights

Many users have reported that the equipment delivers consistent results, making it suitable for both amateur and professional projects. Several reviews highlight its efficiency in covering large areas quickly, with minimal overspray. However, some users have noted that it requires practice to master its operation effectively, particularly for intricate work.

Durability and Maintenance

Users frequently mention the build quality, praising its sturdy design that withstands regular use. Maintenance is generally considered straightforward, with many recommending regular cleaning to prolong the lifespan. Some reviews, however, point out that certain components may wear out faster than expected, necessitating replacements over time.