The efficient operation of a specialized sprayer relies on a comprehensive understanding of its various elements. Each component plays a crucial role in ensuring that the machine functions optimally, providing precise and effective application of coatings. A detailed exploration of these elements allows users to identify potential maintenance needs and facilitate repairs when necessary.

In this section, we will delve into the intricacies of the individual segments that comprise the equipment. By analyzing the layout and function of each part, operators can gain insights into how they work together to achieve superior performance. Recognizing the significance of each component can enhance the user’s ability to troubleshoot issues and implement effective solutions.

Additionally, familiarizing oneself with the arrangement of these components can significantly improve the overall user experience. Whether for routine maintenance or specific repairs, understanding the structure can aid in making informed decisions, ultimately prolonging the lifespan of the equipment and enhancing its effectiveness in the field.

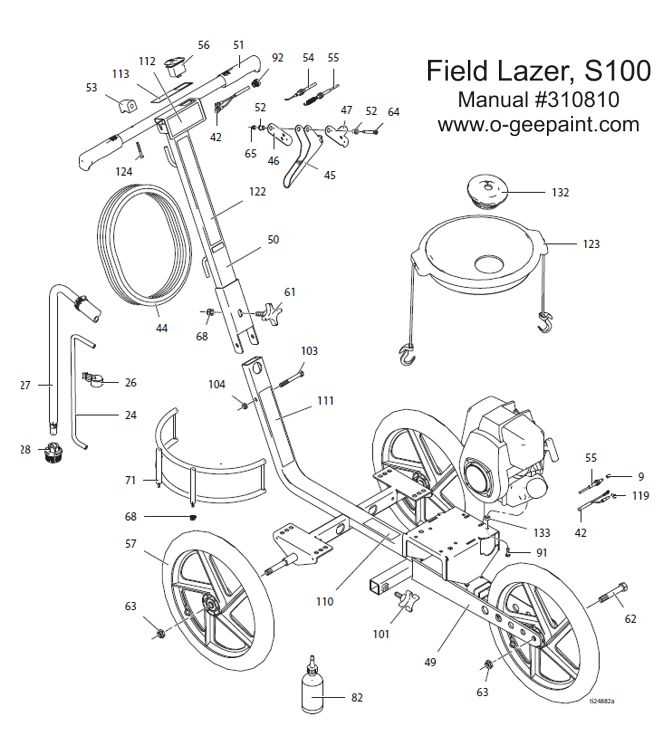

Overview of Graco FieldLazer S100

This section provides an in-depth look at a premier line-marking machine designed for various applications, ensuring precision and efficiency in marking sports fields, parking lots, and other surfaces. Known for its durability and advanced features, this equipment is essential for professionals seeking high-quality results.

Key Features

- Durable construction for long-lasting performance.

- Lightweight design enhances maneuverability.

- Advanced spraying technology for even distribution.

- Multiple spray patterns for versatility in applications.

Benefits of Use

- Increased productivity due to faster operation.

- High-quality results with minimal overspray.

- Cost-effective solution for regular marking tasks.

- Easy maintenance ensures longevity and reliability.

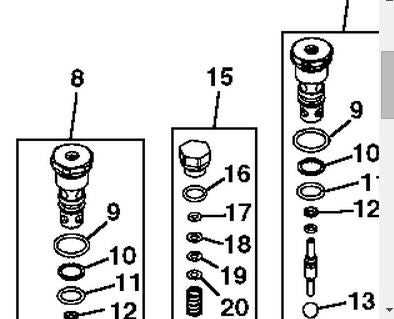

Importance of Parts Diagrams

Understanding the configuration of a device is crucial for effective maintenance and repair. Visual representations serve as essential tools that enable users to identify individual components, their relationships, and the overall structure of the equipment. These illustrations simplify the troubleshooting process, making it easier to locate issues and determine the necessary actions for resolution.

Clarity and Efficiency: Accurate visual aids enhance clarity, allowing technicians and operators to quickly reference and comprehend the system’s layout. This efficiency translates into reduced downtime and more effective repairs, ultimately leading to improved operational performance.

Facilitating Communication: Diagrams also play a vital role in facilitating communication among team members. They provide a common language that aids in discussions regarding maintenance strategies and repairs, ensuring everyone is on the same page and understands the system’s intricacies.

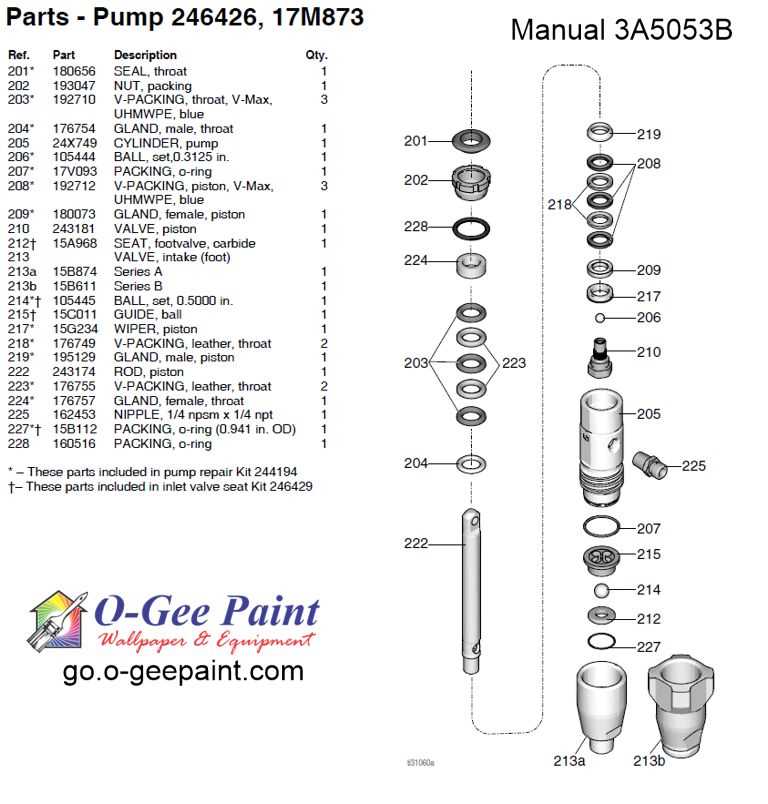

Key Components of the System

This section outlines the essential elements that contribute to the efficient operation of the equipment. Understanding these components is crucial for proper functionality, maintenance, and troubleshooting.

- Power Source: Provides the necessary energy for operation, ensuring that all system functions are powered adequately.

- Application Mechanism: Responsible for distributing materials uniformly across surfaces, playing a critical role in achieving optimal results.

- Control Panel: Serves as the interface for the operator, allowing adjustments to settings and monitoring system performance.

- Hose Assembly: Facilitates the transfer of materials from the supply tank to the application mechanism, designed for durability and flexibility.

- Supply Tank: Holds the materials to be applied, featuring a design that ensures easy filling and cleaning.

- Wheels and Chassis: Provides mobility and stability, enabling the equipment to traverse various terrains efficiently.

Each of these components plays a vital role in ensuring the seamless operation of the system, enhancing overall effectiveness and reliability.

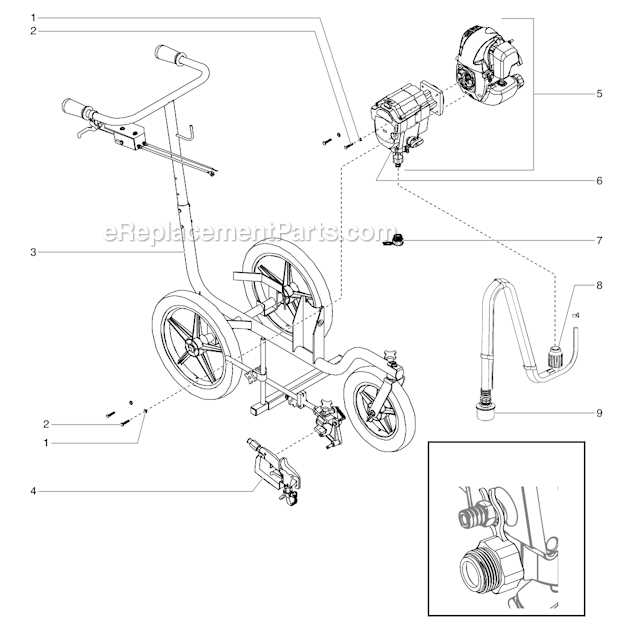

Understanding the Layout and Design

This section delves into the configuration and arrangement of components within the machine, emphasizing the importance of each element’s placement for optimal performance. A well-thought-out structure not only enhances functionality but also contributes to ease of maintenance and operation.

Key aspects to consider in the layout include:

- Component Positioning: The location of each part is crucial for efficient workflow and accessibility.

- Flow Design: The movement of materials and operations should be streamlined to minimize delays.

- Ergonomics: The design must cater to user comfort and ease of use, ensuring that operators can work effectively.

In order to appreciate the intricacies of the configuration, it is important to explore the following elements:

- Frame Structure: This provides the foundation and support for the entire assembly.

- Control Interfaces: The placement of levers, buttons, and displays should be intuitive for operators.

- Maintenance Access: Components should be arranged to allow for straightforward inspections and repairs.

Ultimately, a thorough understanding of the layout and design will empower users to maximize efficiency and ensure longevity in their operations.

Common Issues with Parts

Maintaining equipment often involves encountering various challenges related to its components. Understanding these common problems can enhance efficiency and prolong the lifespan of the machine.

Several typical concerns may arise:

- Wear and Tear: Over time, components can degrade due to frequent use, leading to diminished performance.

- Improper Installation: Incorrect assembly can cause malfunctions, impacting overall functionality.

- Compatibility Issues: Using incompatible components may result in suboptimal operation and could damage the machinery.

- Corrosion: Exposure to harsh environments can lead to rust and deterioration, affecting both aesthetics and functionality.

- Blockages: Accumulation of debris in the system can hinder performance, causing operational delays.

Addressing these concerns promptly ensures smoother operation and minimizes downtime.

Replacement Parts and Availability

When it comes to maintaining and enhancing the performance of your equipment, understanding the options for substitute components is crucial. Accessibility of these elements plays a significant role in ensuring your machinery operates smoothly and efficiently, minimizing downtime and repair costs.

Identifying Required Components

To ensure optimal functionality, it’s essential to know how to identify which components need replacement. Regular inspections and routine maintenance can help in recognizing worn-out or malfunctioning parts. Keeping an inventory of commonly used substitutes can expedite the repair process and enhance overall performance.

Sources for Procurement

Numerous suppliers offer a variety of replacement elements, catering to different models and specifications. Authorized dealers often provide the most reliable options, ensuring compatibility and quality. Additionally, online marketplaces can offer competitive prices and accessibility, but it’s vital to verify the authenticity of the components to avoid potential issues in performance.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent attention and care. Regular maintenance not only enhances performance but also minimizes the risk of breakdowns, leading to increased efficiency and reduced operational costs.

1. Regular Inspections: Conduct frequent checks for any signs of wear and tear. Look for cracks, leaks, or any irregularities that could affect functionality.

2. Cleaning: Keep all components clean from debris and dirt. Use appropriate cleaning solutions that won’t harm the surfaces and ensure all areas are free from buildup.

3. Lubrication: Apply suitable lubricants to moving parts to reduce friction. This helps in maintaining optimal performance and prevents overheating.

4. Storage: When not in use, store your equipment in a dry and safe environment. Protect it from extreme temperatures and moisture to prevent rust and degradation.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule outlined by the manufacturer. This will ensure all necessary procedures are completed on time, contributing to the longevity of your equipment.

6. Use Genuine Accessories: Whenever replacements are necessary, opt for original accessories. Using compatible components can lead to better performance and avoid potential issues.

By implementing these strategies, you can significantly enhance the lifespan of your equipment, ensuring it remains reliable and efficient for years to come.

Resources for Further Assistance

For those seeking additional help and support, a variety of resources are available to enhance your understanding and maintenance of your equipment. These resources provide valuable insights, troubleshooting tips, and comprehensive guides that can assist in resolving any issues you may encounter.

Manufacturer Support

Connecting with the manufacturer’s customer service can provide expert advice and specific guidance tailored to your equipment. They often offer detailed manuals, FAQs, and direct support through phone or email, ensuring you receive the most accurate information.

Online Forums and Communities

Engaging with online communities dedicated to similar machinery can be incredibly beneficial. These forums allow users to share experiences, ask questions, and discuss various topics. Participating in these discussions can lead to practical solutions and innovative ideas from fellow users.