In the world of off-road adventures and competitive racing, mastering the intricacies of a vehicle’s suspension system is crucial for achieving optimal performance. This section aims to explore the essential elements that contribute to a well-tuned ride, enhancing both comfort and handling. A deep understanding of these components allows enthusiasts to make informed choices, ultimately leading to a superior driving experience.

To fully appreciate the nuances involved, it is important to delve into the various mechanisms that work together within this system. Each element plays a significant role, and recognizing their functions can significantly impact a vehicle’s responsiveness and stability. As we dissect these components, we will uncover how they interact and contribute to the overall efficiency of the setup.

Equipped with this knowledge, enthusiasts can embark on a journey of customization and enhancement. Whether for competitive racing or recreational use, understanding these foundational aspects is the ultimate step toward achieving peak performance and a smoother ride. Join us as we explore these vital elements and their contributions to an exceptional driving experience.

Overview of Fox 2.0 Shock Components

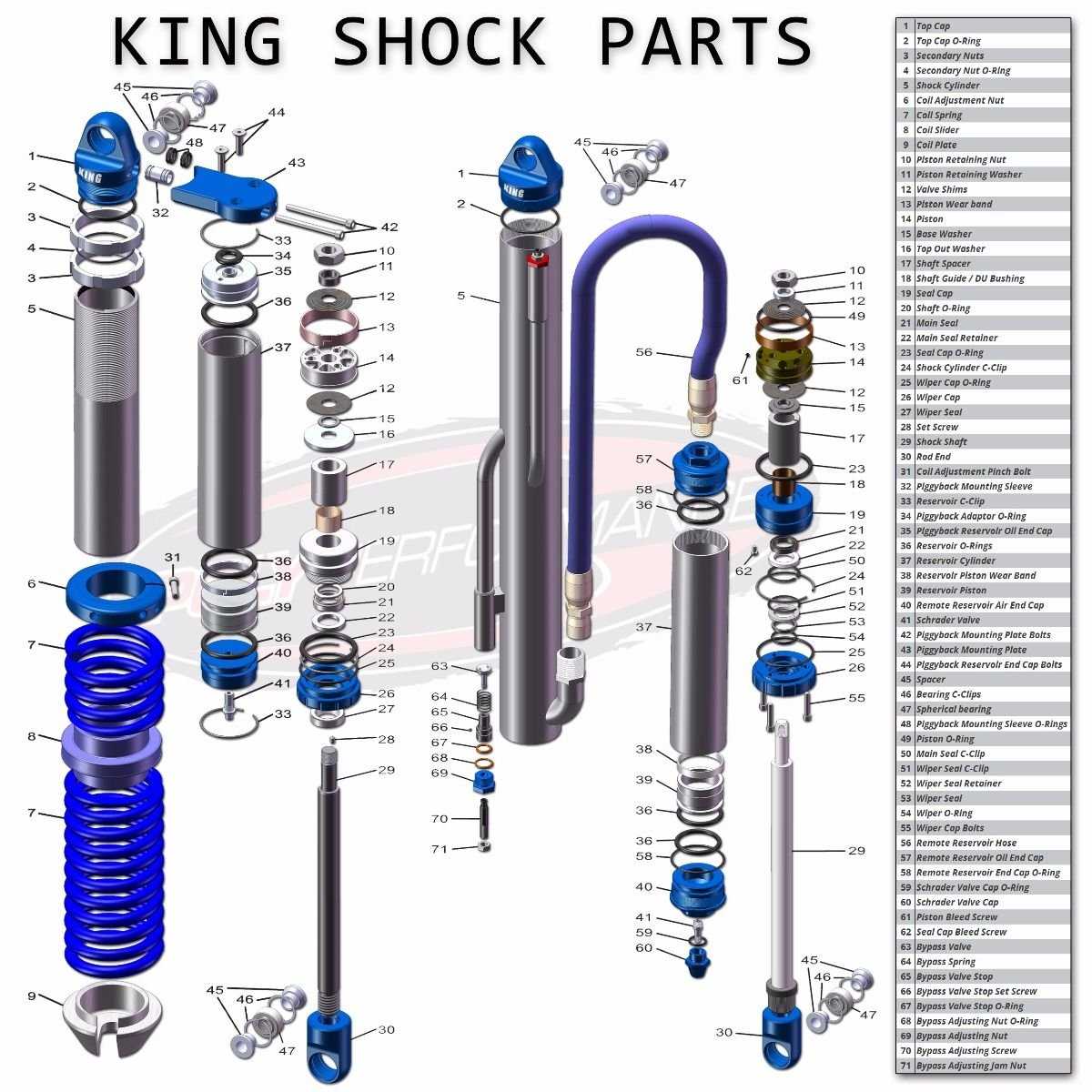

The performance and durability of a suspension system heavily depend on the individual elements that work together to absorb impact and provide a smooth ride. Understanding how each component functions is key to maintaining optimal performance and ensuring longevity. This section provides a detailed look at the core components involved, emphasizing their roles and how they contribute to the overall mechanism.

Main Elements

The primary elements within the system include the main body, the damping unit, and the coil or air spring. Each of these elements plays a distinct role in absorbing forces and controlling movement. The main body houses the internal components, while the damping unit controls the flow of fluid to adjust the ride’s compression and rebound characteristics. The spring provides the necessary resistance to forces encountered during use.

In addition to the basic elements, there are specialized components that enhance the system’s performance. These may include preload adjusters, which allow riders to customize their ride’s stiffness, or reservoir systems that help maintain consistent performance by dissipating heat. Each added feature can significantly affect the overall feel and efficiency of the setup.

Maintenance and Upkeep are also crucial for ensuring that all parts continue to function as intended. Regular checks and servicing can extend the life of these key components, preventing wear and tear from reducing performance over time.

Understanding the Function of Each Part

Each component of a suspension system plays a crucial role in ensuring optimal performance and comfort. Understanding how each element works individually and in harmony with the others allows for proper maintenance and efficient operation. By examining the function of every piece, riders can identify areas for improvement or address issues more effectively.

Internal Mechanisms

Internally, the system is designed to manage energy from impacts and vibrations, converting it into controlled motion. The primary elements here are responsible for cushioning and damping, controlling the force exerted on the rider while maintaining a smooth ride. These mechanisms ensure that the system reacts properly to various terrain conditions, adjusting to sudden movements or sharp turns.

External Components

On the outside, elements like adjustment knobs and seals play a key role in personalizing the experience. Adjusters allow users to modify settings based on their preferences or riding conditions, while seals help maintain the integrity of the system by preventing dirt and moisture from causing damage. Proper maintenance of these external parts is essential for keeping the entire assembly functioning smoothly over time.

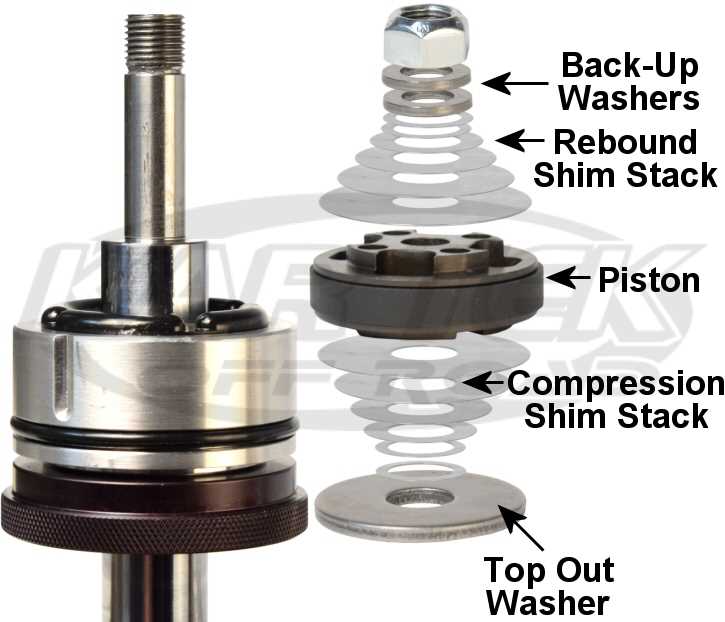

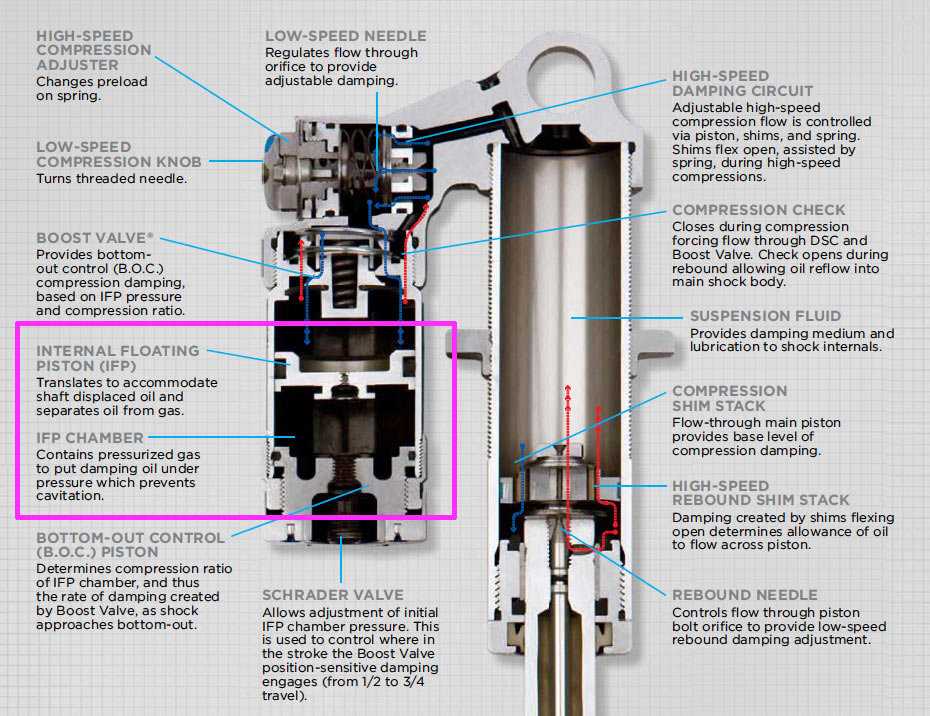

Exploring Fox 2.0 Shock’s Internal Mechanisms

This section delves into the intricate workings of a popular suspension device used in various vehicles. Understanding its internal components and their interactions is crucial for optimizing performance and ensuring longevity.

Key Components

- Reservoir: Maintains fluid levels and pressure.

- Piston: Regulates damping by controlling fluid flow.

- Spring: Provides resistance and absorbs energy.

- Valves: Adjust the flow of fluid for varying conditions.

Functionality Overview

The ultimate performance relies on how these elements interact. When weight shifts during movement, the piston compresses, allowing fluid to pass through the valves, which adapt to different terrains. This dynamic adjustment ensures stability and comfort during rides.

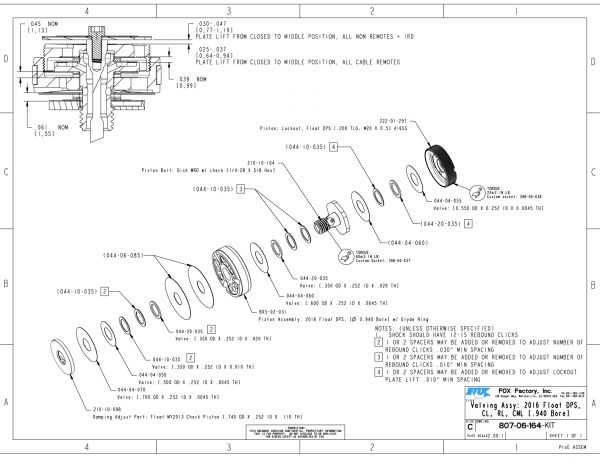

How Valving and Rebound Control Work

The performance of a suspension system heavily relies on its ability to manage energy and movement effectively. This is achieved through a combination of components designed to regulate the flow of fluid, ensuring a smooth and controlled response to various terrains and driving conditions.

Valving serves as a critical mechanism that influences how quickly or slowly the damping fluid moves through the system. By altering the size and arrangement of the passages within the assembly, it allows for precise tuning of compression and rebound characteristics. This tuning can significantly impact ride quality and handling, as it dictates how the vehicle reacts to bumps and changes in the road surface.

On the other hand, rebound control specifically addresses the extension phase of the suspension. After compression, the ability of the system to return to its original position is vital for maintaining stability and traction. By adjusting the resistance encountered during this phase, engineers can prevent the vehicle from bouncing excessively and ensure that all four tires remain in contact with the ground, optimizing grip and control.

In conclusion, the interaction between valving and rebound mechanisms is essential for achieving a well-balanced suspension setup. Mastering these elements allows for enhanced performance, providing a better driving experience regardless of the environment.

Key Differences Between Fox 2.0 Shock Models

Understanding the distinctions among various models of the renowned suspension system is essential for enthusiasts seeking optimal performance. Each variant boasts unique characteristics tailored to different applications and rider preferences, which can significantly affect handling and comfort.

- Compression Settings: Different models offer varying levels of compression adjustability, allowing users to fine-tune responsiveness according to terrain types.

- Rebound Control: The rebound damping features can differ, impacting how quickly the suspension returns after being compressed, which influences stability on rough surfaces.

- Spring Rate: Each version may come with distinct spring rates, affecting ride height and overall stiffness, suitable for various weights and riding styles.

- Travel Length: The travel distance varies across models, which can alter the overall ride experience and handling characteristics.

- Weight: Some iterations are designed to be lighter, enhancing performance without compromising strength, making them suitable for competitive scenarios.

Choosing the right variant involves considering these factors to match the system with specific riding needs and conditions.

Comparing Performance Across Variants

When evaluating the capabilities of different suspension systems, it is essential to understand how various models influence ride quality and handling characteristics. Each version presents unique attributes that cater to specific riding styles and terrain types, making direct comparisons vital for enthusiasts seeking optimal performance. This analysis delves into the distinguishing features and overall effectiveness of the available options.

Key Factors Influencing Performance

Several elements contribute to the performance metrics of each variant. These include the tuning of compression and rebound settings, the overall weight, and the materials used in construction. Variations in these factors can significantly affect responsiveness and comfort, allowing riders to tailor their experience based on personal preferences and environmental conditions.

Real-World Applications and Feedback

User experiences play a crucial role in understanding how different models perform in practical scenarios. Feedback from various riding disciplines highlights the strengths and weaknesses of each option, showcasing how they adapt to diverse challenges. By examining these insights, prospective users can make informed decisions that align with their specific needs and expectations.

Common Fox 2.0 Shock Maintenance Tips

Proper care and routine checks are essential to ensure the longevity and optimal performance of your suspension system. Regular maintenance prevents premature wear, minimizes the risk of failure, and enhances the overall riding experience. By following a few simple procedures, you can keep your equipment running smoothly and reliably throughout its lifespan.

- Regular Cleaning: Clean your suspension after every ride to remove dirt, mud, and debris. This prevents contaminants from damaging seals and internal components.

- Lubrication: Ensure all moving parts are properly lubricated. This reduces friction and prevents corrosion, extending the life of seals and bushings.

- Check for Leaks: Periodically inspect for any oil or air leaks. Leaks can compromise performance, so addressing them quickly is crucial.

- Inspect Seals and Bushings: Over time, seals and bushings may wear out. Check for any signs of deterioration, such as cracking or excessive play, and replace them when necessary.

- Maintain Proper Pressure: Adjust the air pressure or fluid levels according to the manufacturer’s recommendations. Incorrect pressure can affect the suspension’s responsiveness and handling.

- Regular Rebuilds: Depending on usage, consider rebuilding the internal components at regular intervals. This ensures that the suspension performs at its best and avoids unexpected failures.

By following these basic maintenance practices, you’ll ensure that your suspension system continues to perform at a high level, providing you with a smooth and controlled ride over time.

Keeping Your Suspension in Top Shape

Maintaining optimal performance of your vehicle’s suspension system is crucial for a smooth and safe ride. Regular checks and timely maintenance can significantly enhance your driving experience and prolong the life of your equipment.

Routine Inspections should be a part of your maintenance schedule. Look for signs of wear, such as leaks or unusual noises, as these can indicate underlying issues that need addressing.

Cleaning your suspension components is also vital. Dirt and grime can accumulate, leading to corrosion and reduced functionality. Use appropriate cleaners and ensure all moving parts remain free from debris.

Proper Lubrication plays a key role in performance. Regularly apply lubricant to joints and bushings to prevent stiffness and ensure smooth operation.

Ultimately, by taking proactive steps to delve into maintenance routines, you can keep your suspension system in excellent condition, ensuring a reliable and enjoyable driving experience.

Diagnosing Issues with Fox 2.0 Shocks

Identifying problems with suspension systems can sometimes be challenging, but with the right knowledge and tools, you can pinpoint the cause of performance issues. Whether you’re experiencing unusual noises, reduced responsiveness, or inconsistent damping, it’s important to systematically approach the diagnosis process. This will help you identify the root of the issue and avoid unnecessary replacements or repairs.

Common Symptoms and Their Causes

The most common issues with suspension components can often be traced back to a few key areas. When diagnosing performance drops or mechanical failures, check the following symptoms and their potential causes:

- Excessive Bounce: This can indicate issues with damping performance or internal fluid breakdown. Insufficient oil or air pressure may also cause this behavior.

- Unusual Noises: Rattling or knocking sounds can signal loose components, worn seals, or an improperly mounted system.

- Loss of Control: If you notice reduced traction or stability, the issue could stem from incorrect compression or rebound settings, or worn-out internal seals.

Step-by-Step Diagnostic Approach

To effectively troubleshoot and resolve issues, follow this process to ensure no detail is overlooked:

- Inspect for Leaks: Check for any fluid leakage around the unit. Leaking fluid often points to damaged seals or improperly tightened fittings.

- Evaluate Pressure and Setting: Confirm that air pressure or preload settings are within the manufacturer’s recommendations. Incorrect adjustments can lead to poor performance.

- Disassemble and Examine Internals: If you suspect internal damage, carefully disassemble the unit to check for signs of wear, scoring, or debris that could be causing friction or improper damping.

- Check Mounting Points: Loose or misaligned mounting points can cause erratic behavior. Tighten and verify the integrity of all mounting hardware.

By addressing these common causes and following a structured approach to troubleshooting, you’ll be able to restore your suspension to optimal condition and improve your overall riding experience.

How to Identify Common Problems

Understanding the symptoms of issues with suspension components is crucial for maintaining optimal performance. Regular inspections and knowing what to look for can help you detect problems early, preventing further damage and ensuring a smooth ride. Many common issues stem from wear and tear, improper adjustments, or environmental factors. Identifying these problems early can save time, money, and hassle in the long run.

Leaks and Fluid Loss

One of the most common issues is fluid leakage, which can be caused by seals wearing out or becoming damaged over time. When this happens, you might notice excessive oil or grease around the suspension unit, or feel a reduction in performance. Leaks can lead to inadequate damping, resulting in an uncomfortable and unsafe ride. It’s essential to check for any visible signs of leakage and address the issue promptly to avoid further damage.

Unusual Noises and Performance Issues

If you hear odd noises such as clunks, rattles, or squeaks while riding, it could indicate internal damage or misalignment. These sounds are often a result of parts becoming loose, worn, or improperly lubricated. In some cases, the suspension may feel less responsive, or the ride may become rougher. Any noticeable change in performance, especially when combined with noise, should be investigated thoroughly to avoid further degradation of the system.