In the realm of agricultural machinery, the functionality of equipment is often dictated by the intricate relationships between its various elements. These components work in unison to ensure optimal performance, enhancing the efficiency of tasks related to crop management and maintenance.

Recognizing the significance of each individual piece is essential for operators aiming to maximize their productivity. A comprehensive overview of these essential units provides insights into their roles and interactions, facilitating better maintenance and troubleshooting practices.

Moreover, detailed visual representations serve as invaluable resources for anyone seeking to deepen their understanding of machinery configurations. By examining these illustrations, one can identify potential areas for improvement, ensuring that every operation runs smoothly and effectively.

Understanding County Line Sprayers

Exploring the functionality and components of these essential agricultural tools reveals their significance in efficient crop management. These devices are designed to deliver liquids evenly across various terrains, ensuring optimal coverage and effectiveness in application. Familiarity with their structure can enhance performance and maintenance, leading to better results in the field.

Key Features of Agricultural Application Equipment

Modern equipment for liquid application boasts several advanced characteristics. Precision is a primary factor, allowing users to adjust settings for various tasks and terrains. Additionally, the durability of these machines ensures they withstand harsh conditions, prolonging their operational life. Understanding these features helps in selecting the right model for specific agricultural needs.

Maintenance and Troubleshooting

Regular upkeep is crucial for the longevity and efficiency of these tools. Familiarity with the common issues that can arise, along with their remedies, enables farmers to minimize downtime. Proper care and timely repairs not only enhance performance but also contribute to cost savings over time.

Essential Components of County Line Sprayers

Understanding the crucial elements of a liquid application system is vital for optimal performance and maintenance. Each component plays a significant role in ensuring the efficient distribution of chemicals or nutrients, ultimately enhancing the effectiveness of agricultural practices.

Tank serves as the primary reservoir, holding the solution that will be dispersed. Its capacity varies based on the model, allowing for tailored usage depending on the area and type of treatment required.

Pump is the powerhouse of the setup, generating the necessary pressure to deliver the fluid from the tank through the system. Selecting the right pump type and size is essential for achieving desired application rates.

Hoses are critical for transporting the solution from the tank to the application site. High-quality, durable materials ensure resistance to wear and tear, as well as chemical compatibility.

Nozzles determine the spray pattern and droplet size, influencing the uniformity and efficiency of the application. Different nozzle types are available, catering to various tasks and conditions.

Control system allows operators to manage application rates and monitor performance. Advanced models may feature automated settings for improved accuracy and convenience.

Frame provides the structural integrity necessary to support all components during operation. A well-designed frame contributes to stability and ease of maneuverability in the field.

Familiarity with these key components enables users to optimize their equipment’s performance and ensure successful application of liquids, leading to healthier crops and more efficient farming practices.

Importance of Diagrams in Maintenance

Visual representations play a crucial role in the upkeep and servicing of machinery. They provide an intuitive way to understand complex systems, making it easier for technicians and operators to perform necessary tasks efficiently. Utilizing these illustrations helps in identifying components, troubleshooting issues, and ensuring that maintenance is conducted correctly.

Benefits of Using Visual Representations

- Clarity: Diagrams simplify intricate designs, allowing users to grasp the relationships between various elements quickly.

- Efficiency: By following visual guides, maintenance tasks can be completed faster, reducing downtime.

- Accuracy: Clear depictions help ensure that repairs and replacements are done precisely, minimizing the risk of errors.

- Training Aid: These illustrations serve as valuable educational tools for new personnel, facilitating quicker learning curves.

Key Aspects of Effective Maintenance Visuals

- Detail: Adequate information should be included to cover all essential components.

- Accessibility: Diagrams should be readily available to users when needed.

- Updates: Regular revisions must be made to reflect any changes in design or components.

In summary, visual aids are indispensable in the maintenance process, enhancing understanding and effectiveness while reducing potential mistakes. Their role in facilitating smooth operations cannot be overstated.

Common Issues with Sprayer Parts

When it comes to agricultural equipment, various components may experience difficulties over time, affecting overall performance and efficiency. Understanding these common challenges can help in maintaining optimal function and longevity.

- Clogged Filters: Debris can obstruct flow, leading to uneven distribution.

- Leaking Seals: Worn seals can result in fluid loss, impacting application rates.

- Corroded Components: Exposure to harsh chemicals can deteriorate metal parts, causing failures.

- Faulty Nozzles: Damaged or worn nozzles can affect spray patterns and coverage.

- Pump Issues: Problems with the pump can lead to inadequate pressure, resulting in poor application.

Regular inspection and timely replacement of these components are essential for maintaining efficiency and effectiveness in agricultural tasks.

How to Read Parts Diagrams

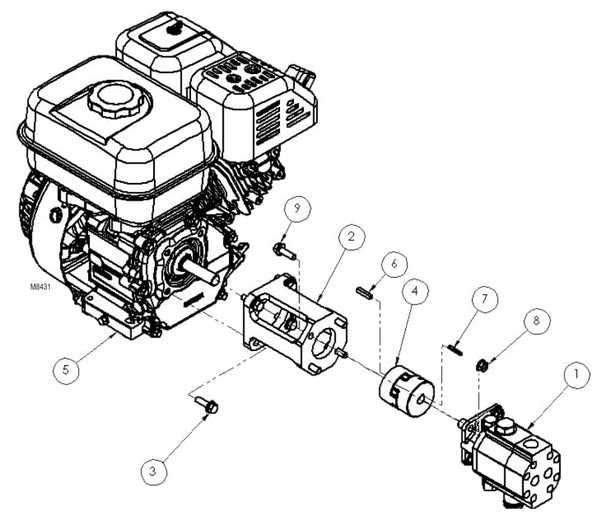

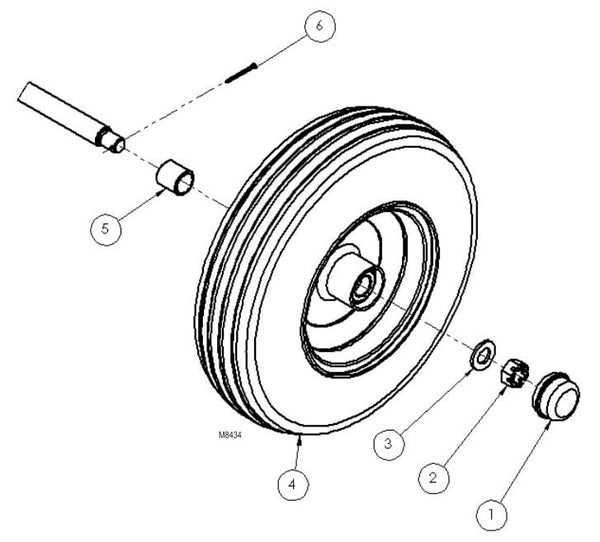

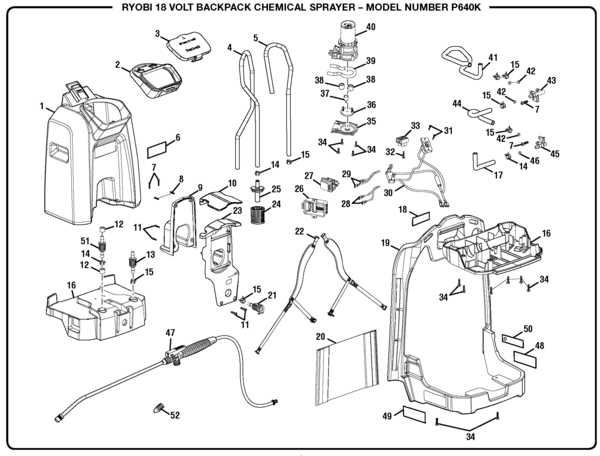

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a clear overview of individual elements, their relationships, and functions within a system. Familiarity with the symbols and layout used in these visuals can significantly enhance your ability to identify and source the necessary items.

Key Components of Illustrations

Most visual guides include several essential features. First, the labeling of each element often corresponds to a reference number or letter, which can be found in accompanying lists or catalogs. This linkage simplifies the identification process. Additionally, exploded views demonstrate how parts fit together, giving insights into assembly and disassembly.

Tips for Effective Interpretation

To effectively interpret these visuals, take the time to familiarize yourself with common symbols and conventions. Colors may indicate different categories or functions, while lines can show connections or movement paths. Always refer to the accompanying documentation for further details on each component, ensuring that you have a complete understanding of the system.

Replacing Worn Out Components Effectively

Maintaining equipment in optimal condition is crucial for performance and longevity. Regularly addressing deteriorated elements ensures efficiency and prevents further damage.

Identifying Worn Components

Recognizing when parts are nearing the end of their lifespan is essential. Here are some indicators:

- Visible wear or damage

- Reduced functionality

- Unusual noises during operation

- Inconsistent performance

Steps for Replacement

- Gather necessary tools and replacement components.

- Disconnect power sources for safety.

- Carefully remove the damaged parts.

- Install new components, ensuring a secure fit.

- Reconnect power and test for proper operation.

Following these steps will enhance performance and extend the lifespan of your equipment.

Tips for Sprayer Care and Longevity

Maintaining equipment in optimal condition is essential for ensuring efficient operation and extending its lifespan. Regular upkeep not only enhances performance but also prevents costly repairs and replacements. Here are some practical suggestions to help you care for your machinery effectively.

First, always clean the equipment thoroughly after each use. Residual chemicals can lead to corrosion and damage if left unattended. Rinse all components with water and use appropriate cleaning agents to remove any buildup. Pay special attention to nozzles and filters, as these areas are prone to clogs.

Next, perform routine inspections to identify any signs of wear and tear. Check hoses, fittings, and seals for leaks or cracks. Addressing small issues promptly can prevent more significant problems down the road.

Store your equipment in a sheltered area when not in use. Exposure to harsh weather conditions can deteriorate materials over time. A cool, dry space will help maintain functionality and appearance.

Finally, refer to the manufacturer’s guidelines for maintenance schedules and recommended procedures. Following these instructions ensures that your machinery remains in top shape and operates efficiently for years to come.

Where to Find Replacement Parts

Finding suitable components for your equipment can significantly enhance its performance and longevity. Here are several avenues to consider when searching for these essential items.

- Manufacturer Websites: Check the official sites for a comprehensive list of available components and detailed specifications.

- Local Dealers: Visit nearby suppliers who often carry a selection of items that meet your needs.

- Online Marketplaces: Explore platforms such as eBay and Amazon, where numerous vendors list various items.

- Specialty Retailers: Seek out stores that specialize in agricultural or industrial equipment for more targeted options.

- Forums and Community Groups: Engage with online communities where members often share tips on sourcing rare items.

By utilizing these resources, you can effectively locate the components required to maintain and optimize your machinery.