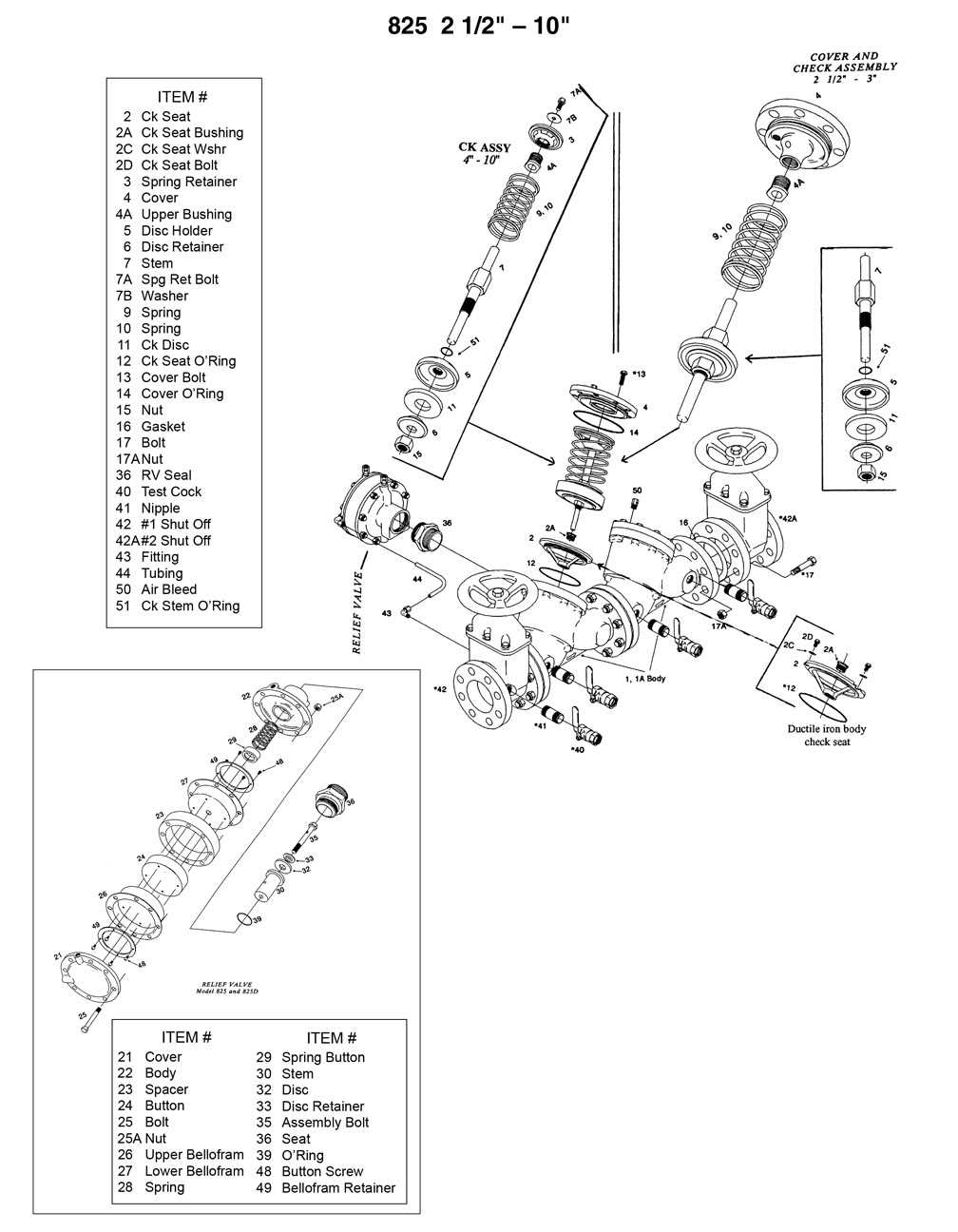

In the realm of mechanical systems, grasping the intricate arrangement of various elements is crucial for effective maintenance and repair. A comprehensive visualization of these components not only aids in troubleshooting but also enhances the overall efficiency of the system. This section delves into the structured representations that highlight the interrelations among different parts.

By examining the configuration of these crucial units, users can gain insight into their functionalities and the role each piece plays within the larger mechanism. Such illustrations serve as valuable references, making it easier to identify specific elements and their corresponding functions. Mastering this knowledge empowers technicians to perform tasks with greater precision and confidence.

Moreover, familiarizing oneself with these layouts fosters a deeper understanding of the operational dynamics involved. This knowledge is essential for anyone looking to optimize performance or undertake any necessary repairs. With a clear roadmap at hand, navigating through the complexities of the system becomes a more manageable endeavor.

Understanding the Febco 825Y Assembly

The assembly in question is a crucial component in the realm of irrigation systems, designed to facilitate efficient water management. By grasping its structure and functionality, one can enhance system performance and maintenance practices. This section delves into the key elements and their roles, providing a clearer picture of how everything works together.

Main Components

The assembly consists of several integral parts that contribute to its overall efficiency. Below are the primary elements:

- Body: The main housing that contains all components.

- Diaphragm: A flexible membrane that regulates flow and pressure.

- Spring: Provides tension to the diaphragm, ensuring proper sealing.

- Inlet and Outlet Ports: Entry and exit points for fluid movement.

Functionality Overview

Understanding how each part functions can significantly improve the effectiveness of water distribution:

- The body serves as the framework, holding all elements securely.

- The diaphragm opens and closes to manage the flow of water based on pressure changes.

- The spring maintains the diaphragm’s position, allowing for responsive adjustments to varying conditions.

- The ports facilitate the movement of fluid, ensuring a continuous supply to the irrigation network.

By familiarizing oneself with these components and their interactions, users can achieve better maintenance outcomes and operational efficiency in their irrigation systems.

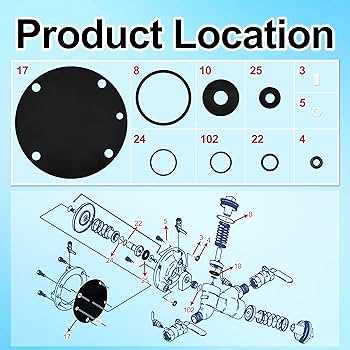

Key Components of Febco 825Y

This section explores the essential elements that contribute to the efficient operation of a crucial device used in various plumbing systems. Understanding these components can enhance maintenance and troubleshooting efforts, ensuring longevity and optimal performance.

The primary structure includes a reliable housing designed to withstand pressure and prevent leaks. Integral to its function are the check valves, which prevent backflow, maintaining a safe and clean water supply. Additionally, an adjustable pressure relief feature plays a vital role in regulating flow and safeguarding against excessive pressure.

Further, a precise actuator controls the device’s operation, allowing for quick responses to system changes. Gaskets and seals ensure a tight fit, minimizing the risk of failure. Each part works in harmony, underscoring the importance of regular inspections to maintain peak functionality.

Importance of Diagrams in Maintenance

Visual representations play a crucial role in the upkeep and repair of complex systems. They provide clear guidance, ensuring that technicians can efficiently identify components and understand their interconnections.

- Enhance comprehension of system layouts.

- Facilitate faster troubleshooting and repairs.

- Reduce the risk of errors during maintenance tasks.

Incorporating such visuals can ultimately lead to improved operational efficiency and extended equipment lifespan.

- Identify potential issues quickly.

- Streamline the maintenance process.

- Support training for new technicians.

Overall, employing these tools ensures a more systematic and effective approach to maintenance challenges.

Common Issues with Febco 825Y Parts

Understanding the frequent problems associated with a specific model can greatly assist users in maintaining optimal performance. Various components may experience wear and tear over time, leading to inefficiencies and malfunctions. Awareness of these common challenges is essential for effective troubleshooting.

One prevalent concern involves leaks, often resulting from degraded seals or improper installation. Such issues can lead to significant water loss and increased operational costs. Regular inspection of these elements can help identify potential failures before they escalate.

Additionally, pressure irregularities may arise due to obstructed pathways or damaged regulators. This can impact the overall functionality, causing inconsistent flow rates. Keeping the system clean and replacing worn elements promptly is crucial in mitigating this risk.

Furthermore, mechanical wear can affect moving parts, leading to sluggish operation or complete failure. Routine maintenance, including lubrication and timely replacements, can extend the life of these components and enhance overall reliability.

Lastly, improper adjustments during installation can result in suboptimal performance. Ensuring that all settings align with manufacturer specifications is vital for achieving the best results. Regular training and resources can support users in this aspect, enhancing their operational success.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of equipment. These visual representations provide a clear overview of the components and their relationships, allowing users to identify necessary elements quickly.

To efficiently interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration employs specific symbols and notations. Take time to learn their meanings, as this will enhance your comprehension.

- Identify Key Components: Focus on the main parts highlighted in the image. Usually, these elements are critical to the functioning of the entire assembly.

- Understand the Layout: Pay attention to how components are arranged. This will help you grasp the flow and interaction between different pieces.

- Refer to the Legend: Most illustrations come with a legend that provides explanations of the symbols used. Use it as a guide while studying the image.

- Take Notes: As you analyze the visual, jot down any important details or questions that arise. This practice will solidify your understanding.

By following these steps, you can navigate technical illustrations with confidence, making your maintenance tasks more efficient and informed.

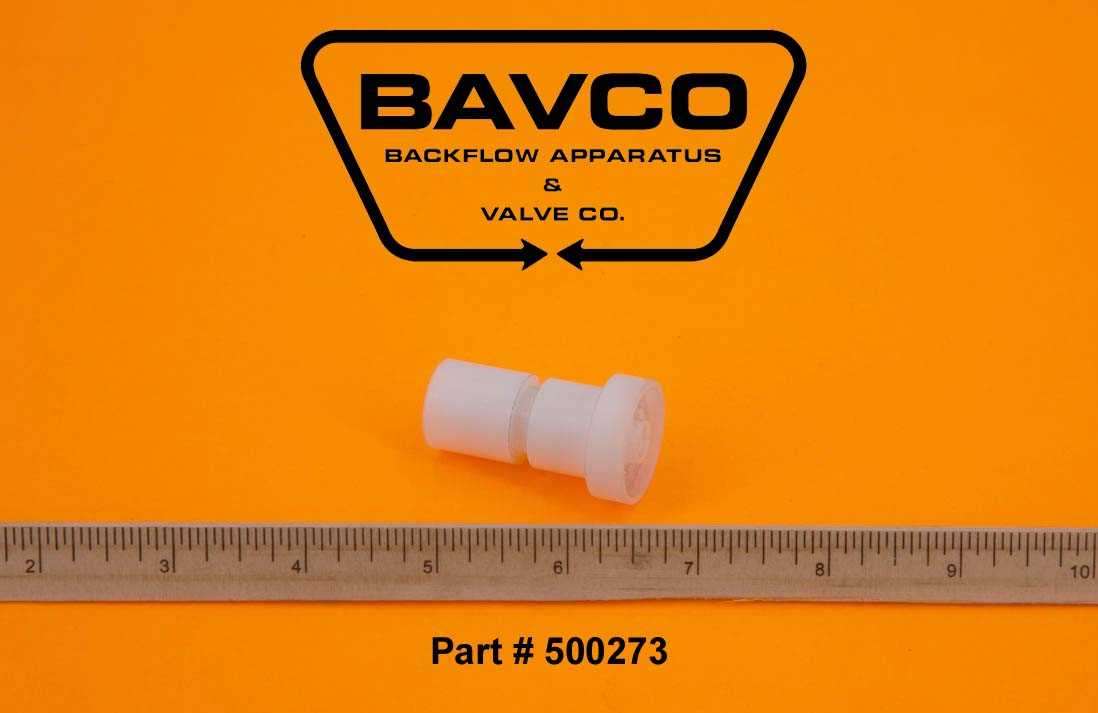

Replacing Febco 825Y Components

Maintaining a reliable irrigation system often requires the replacement of specific elements to ensure optimal performance. Understanding how to properly replace these components can significantly enhance efficiency and prolong the lifespan of the system. This section will guide you through the essential steps involved in swapping out various parts, focusing on common issues that may arise and the tools needed for a successful replacement.

Before beginning the replacement process, it is crucial to identify which components are malfunctioning. Common signs of wear may include leaks, reduced pressure, or irregular flow. Once identified, gather the necessary tools, such as wrenches, screwdrivers, and replacement parts. Familiarizing yourself with the assembly will facilitate a smoother operation.

Begin the replacement by shutting off the water supply to prevent any accidents. Carefully disassemble the affected area, noting the arrangement of each piece for easier reassembly. Clean any debris or buildup that may have accumulated, as this can affect the efficiency of the new parts. Install the new components according to the manufacturer’s specifications, ensuring a snug fit to avoid future leaks.

After reassembly, turn the water supply back on and test the system for proper function. Monitor for any leaks or irregularities, and make adjustments as necessary. Regular maintenance and timely replacements can keep your irrigation system running smoothly and effectively.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of any mechanical system requires regular attention and care. By implementing a consistent maintenance routine, you can significantly extend the lifespan of your equipment, prevent unexpected failures, and optimize performance. Here are some key practices to keep in mind for achieving long-lasting reliability.

Regular Inspections

Conducting periodic assessments is crucial for identifying potential issues before they escalate. Check for signs of wear, leaks, or corrosion regularly. This proactive approach allows for timely interventions, ensuring components remain in good working order.

Proper Lubrication

Maintaining adequate lubrication is essential for reducing friction and wear on moving parts. Use the recommended lubricants and apply them according to the manufacturer’s guidelines. Keeping parts well-lubricated not only enhances performance but also minimizes the risk of breakdowns.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the necessary components can be a daunting task. Fortunately, there are several reliable avenues to explore that can help you locate the required elements for efficient repairs and upkeep.

Online Retailers

One of the most convenient options is to browse through various online marketplaces. Websites dedicated to plumbing and mechanical supplies often offer a wide range of items. Utilizing the search functionality can quickly lead you to the specific components you need. Additionally, many sites provide user reviews that can assist in assessing the quality and reliability of the products.

Local Distributors and Suppliers

Another effective method is to visit local distributors or suppliers specializing in plumbing and mechanical equipment. These establishments usually maintain a well-stocked inventory and can provide valuable guidance. Speaking with knowledgeable staff can help you identify the right replacements and even suggest compatible alternatives.

Whether you choose to shop online or visit a local store, ensuring you have the correct specifications will streamline the process and enhance your chances of finding the perfect replacements for your needs.