Understanding the internal structure and essential elements of outdoor equipment is crucial for efficient maintenance and repair. This section will explore the primary mechanical systems, offering a detailed look into how various elements work together to ensure smooth operation. By breaking down each critical system, we aim to provide clarity on their function and relevance.

Whether you’re a seasoned professional or simply maintaining your equipment for personal use, recognizing the different mechanical elements is invaluable. Each section of the equipment plays a vital role, from ensuring precise cutting mechanisms to maintaining overall performance efficiency. Dive deeper into the specifics to gain a better understanding of how these systems are interconnected.

Overview of Exmark 30 Inch Mower Components

This section provides a comprehensive review of the essential mechanisms and systems that contribute to the smooth operation and reliability of this cutting tool. The design includes various interconnected elements that work together to ensure optimal performance, making it suitable for maintaining outdoor areas efficiently. Each part plays a critical role in the overall functionality, ensuring precision and ease of use.

Core Mechanical Structures

Key mechanical assemblies include the driving system, cutting mechanism, and structural frame. These elements are engineered for durability, providing stability and support during extended usage. The propulsion unit offers consistent power, while the cutting device ensures clean, even results. Attention to material strength ensures that each section withstands regular wear and tear, enhancing the product’s lifespan.

Functional Components and Adjustments

Adjustable features allow users to modify settings such as cutting

Main Features of Exmark 30 Inch Mower

The machine is known for its durability and high performance in maintaining large areas efficiently. Its design is intended to maximize productivity while ensuring ease of use and comfort for the operator. Below are some of the key attributes that make this equipment stand out in its category.

| Feature |

Description |

| Engine Power |

Equipped with a powerful engine, the machine delivers reliable performance, enabling it to handle tough terrain and dense grass with ease. |

| Cutting Width |

With a broad cutting capacity, the device efficiently reduces the time spent on covering large areas, providing a uniform and clean finish. |

How to Identify Key Parts of the Mower

Recognizing the main components of your outdoor equipment is essential for effective use and maintenance. Understanding how different elements interact can help you troubleshoot issues, perform routine check-ups, and ensure longevity. Let’s explore how to easily pinpoint these critical sections.

Engine Section

The power source is the heart of the equipment. Identifying the engine and its surrounding components, such as the fuel tank and air filter, will give you control over performance and efficiency. Regular inspection of these areas is crucial for smooth operation.

- Fuel Tank: Check for leaks or damage.

- Air Filter: Ensure it’s clean to maintain airflow.

- Oil Cap: Monitor oil levels regularly.

Cutting Area

The section responsible for trimming the grass requires special attention to keep the blades sharp and balanced. Make sure this part is in good condition to ensure a clean and even result.

- Blades: Inspect

Blade System and Cutting Mechanism

The blade setup and cutting functionality play a pivotal role in ensuring efficient grass management. This section explores how the cutting tools operate in unison to provide a smooth, even trim, delivering both performance and durability. By understanding the core components and their operation, one can maintain an effective and precise cutting system.

Main Components of the Blade Setup

- Blade: Responsible for slicing through grass efficiently, offering clean and consistent results.

- Spindle Assembly: The core that supports the blade, ensuring it rotates smoothly during operation.

- Blade Shaft: Connects the blade to the assembly, providing the necessary force transmission.

Cutting Mechanism Operation

- The blade rotates at high speed, creating the necessary force to slice through grass evenly.

Drive Belt and Transmission Overview

The drive system is crucial for the efficient functioning of any cutting equipment, ensuring smooth movement and consistent performance. The interaction between the belt and the transmission allows the machine to transfer power effectively, driving both speed and maneuverability. Understanding this connection is key for maintaining proper operation and longevity of the system.

The drive belt plays a vital role in linking the power source with the movement mechanism. Meanwhile, the transmission controls how that power is distributed, affecting forward and reverse movement as well as overall control. Below is a breakdown of the key components involved in this system.

| Component |

Function |

| Drive Belt |

Connects the engine to the transmission, enabling the transfer of power. |

| Transmission |

Regulates speed and direction by adjusting power distribution to the wheels. |

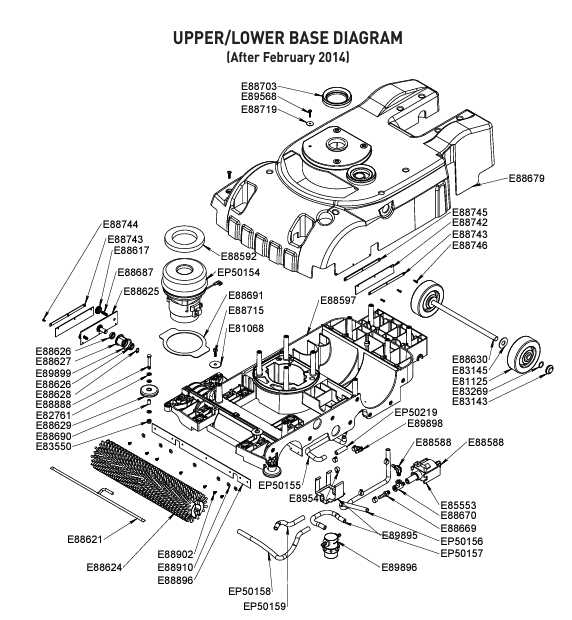

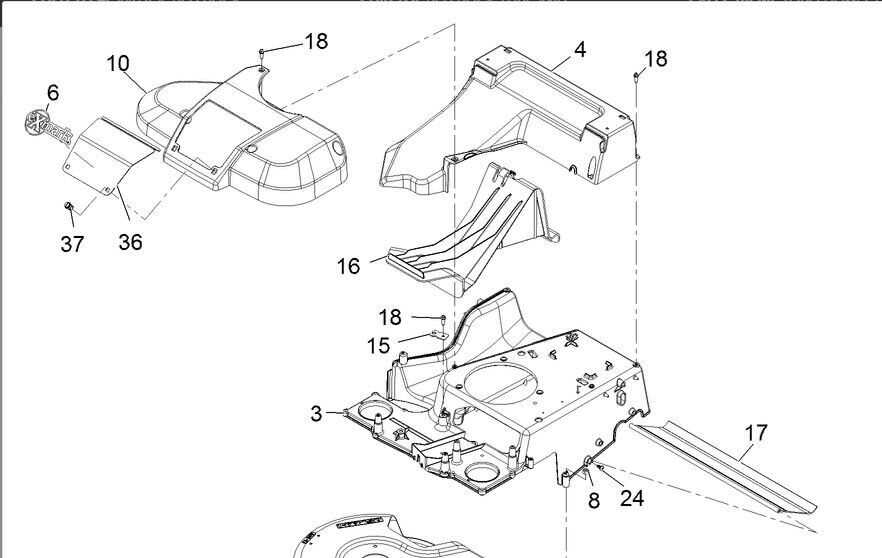

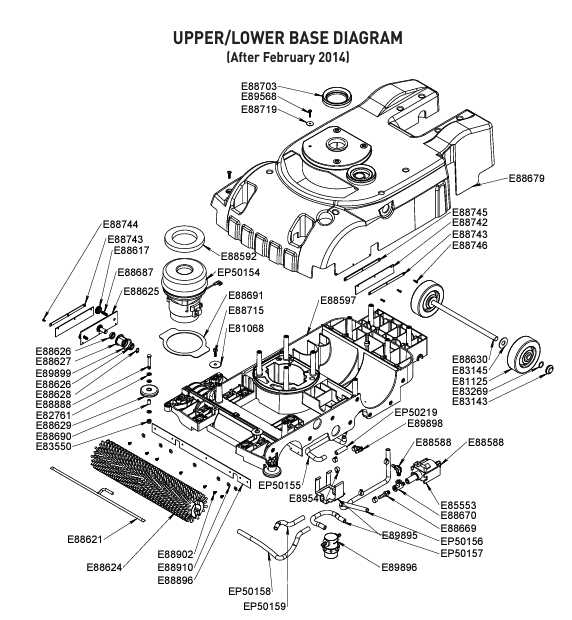

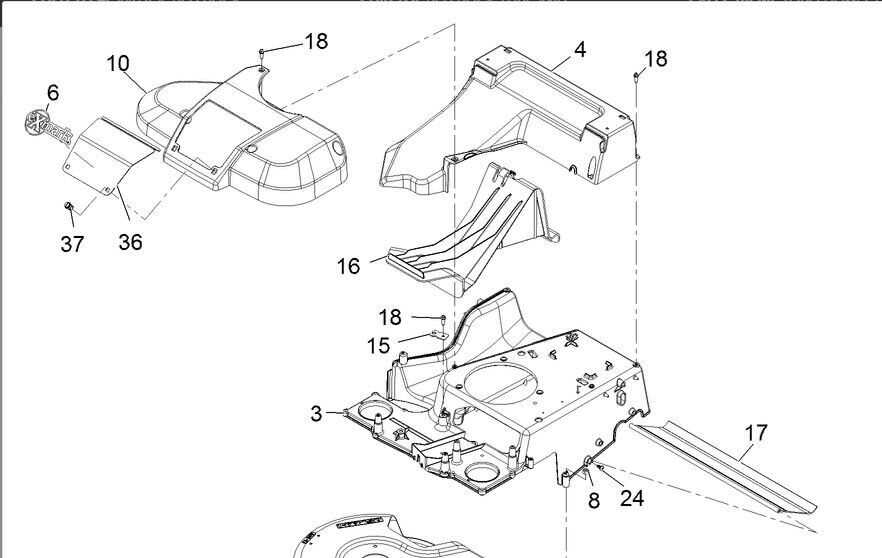

Understanding the Mower’s Deck Assembly

The deck assembly is a crucial component in any lawn cutting equipment, responsible for housing the blades and ensuring efficient grass trimming. Proper understanding of this structure allows for better maintenance and operation, which can significantly extend the lifespan of the equipment and improve cutting performance. This section provides an overview of how the deck is constructed and its role in overall functionality.

The deck consists of multiple integrated parts designed to work together seamlessly. These elements include the blade housing, spindles, pulleys, and belts, which synchronize to deliver smooth and even cutting. The quality and alignment of these parts are essential for optimal performance and ensuring the grass is cut uniformly.

Another important aspect of the deck is its adjustment capability. Depending on the terrain and desired cut height, the assembly allows for precise alterations, ensuring the equipment can handle various conditions. Understanding how to adjust these settings properly helps achieve consistent results regardless of the lawn’s complexity.

By familiarizing yourself with the deck structure, its main components, and how they interact, you’ll be able to maintain the system more effectively, ensuring long-term functionality and superior cutting performance.

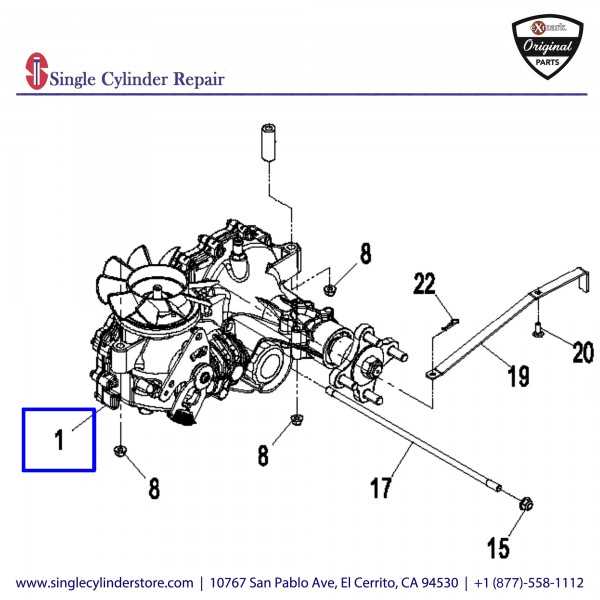

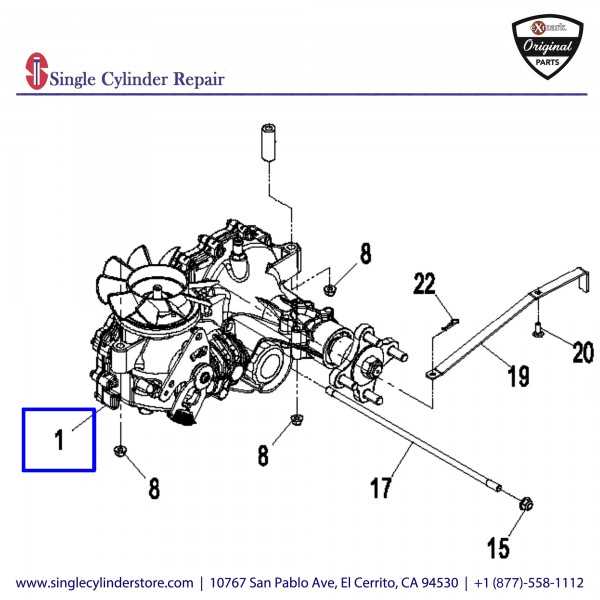

Engine Components and Their Functions

The motor system in any outdoor power equipment relies on various elements working together to ensure smooth operation and efficiency. Understanding the key parts and how they interact can help maintain performance and extend the lifespan of the machine. Below is an overview of the essential components and their roles.

- Cylinder Block: This is the foundation of the motor, housing several critical components like the pistons and crankshaft, providing the structure needed for combustion.

- Pistons: Positioned within the cylinder, pistons move up and down to convert fuel combustion into mechanical motion, driving the entire machine.

- Crankshaft: The crankshaft transforms the linear motion of the pistons into rotational energy, which is essential for powering the cutting mechanism.

- Valves: These control the intake of air and fuel and the release of exhaust gases, ensuring the combustion process operates efficiently.

- Carbure

Maintenance Tips for Longevity of Mower Parts

Regular upkeep is essential for ensuring the extended lifespan of your equipment components. By following proper maintenance practices, you can significantly reduce wear and tear, enhance performance, and avoid costly repairs. This section outlines essential tips to help maintain your machinery efficiently.

First and foremost, always keep your tools clean and free from debris. Dirt and grass clippings can accumulate and cause parts to function improperly. Cleaning after each use is a simple yet effective way to maintain optimal performance. Additionally, check for any loose connections or damaged components regularly, as early detection can prevent further issues.

Another critical aspect of maintenance is to ensure proper lubrication. Various mechanisms require specific lubricants to function smoothly. Refer to the manufacturer’s recommendations for the right type of oil and lubrication intervals. Consistent oil changes can help keep moving parts functioning correctly and reduce friction.

| Maintenance Task |

Frequency |

Notes |

| Clean tools and equipment |

After each use |

Remove debris and dirt |

| Inspect for damage |

Weekly |

Check for loose parts or wear |

| Lubricate moving parts |

Monthly |

Use recommended lubricants |

| Replace filters |

Every season |

Ensure airflow and performance |

Lastly, store your equipment in a dry and protected environment. Exposure to moisture can lead to rust and degradation of materials. Proper storage not only protects your tools but also ensures they remain in excellent condition for the next use.

Troubleshooting Common Issues with Exmark Mowers

When operating outdoor lawn care equipment, users may encounter various challenges that can impact performance. Identifying and resolving these issues promptly can enhance efficiency and extend the lifespan of the machinery. This section provides guidance on common problems faced by operators and suggests potential solutions.

Engine Not Starting: If the engine fails to start, check the fuel level and ensure that fresh fuel is being used. Inspect the spark plug for wear or damage, as a faulty plug can prevent ignition. Additionally, examine the battery connections and wiring for any loose or corroded terminals.

Uneven Cutting: An uneven cutting pattern can result from dull blades or improper height adjustments. Regularly sharpen the cutting blades to ensure a clean cut. Also, verify that the cutting height is set correctly according to the manufacturer’s recommendations.

Excessive Vibration: Vibration during operation may indicate that the blades are unbalanced or damaged. Inspect the blades for nicks or bends and replace them if necessary. Additionally, ensure that all nuts and bolts are tightened properly to maintain stability.

Overheating: If the engine overheats, check the air filter and cooling fins for blockages. Clean or replace the air filter as needed to improve airflow. Make sure the oil level is adequate, as low oil can lead to increased friction and heat buildup.

Difficulty Maneuvering: If maneuverability is compromised, inspect the wheels and tires for damage or proper inflation. Adjust the tire pressure according to the specifications, and check for any debris lodged in the wheel assembly that may hinder movement.

By systematically addressing these common concerns, users can ensure optimal performance and reliability from their lawn maintenance equipment.