The inner workings of any machinery can often seem complex, yet gaining insight into their structure is crucial for effective maintenance and repair. By examining the layout of various elements, users can ensure the longevity and optimal performance of their equipment. This knowledge empowers individuals to address issues with confidence and precision.

In this exploration, we will uncover a detailed representation of each segment, highlighting their functions and interconnections. Recognizing how these components interact is essential for troubleshooting and enhancing the overall efficiency of the system. As we delve deeper, the ultimate goal is to provide clarity and practical guidance for users seeking to familiarize themselves with their machinery.

Equipped with this information, enthusiasts and operators alike can navigate their tasks with improved understanding. Whether it’s for routine upkeep or specific repairs, a solid grasp of the assembly’s structure fosters a proactive approach, leading to better outcomes in performance and durability.

Coleman BT200X Overview

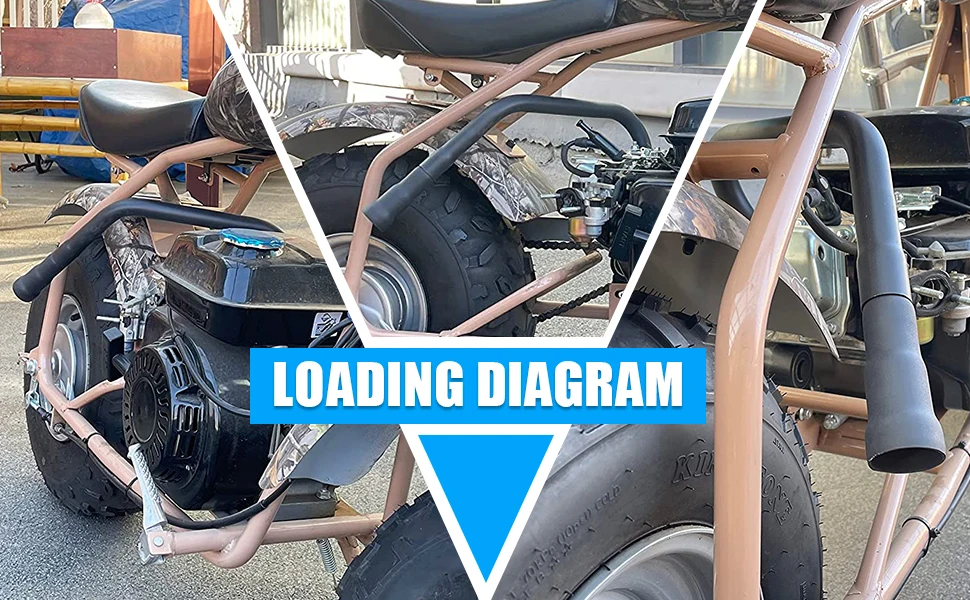

This section provides an in-depth look at a popular off-road vehicle designed for adventure enthusiasts. Known for its durability and reliability, this machine offers an enjoyable experience for riders seeking both fun and functionality.

Engine Performance: The vehicle is equipped with a powerful engine that ensures smooth acceleration and ample torque, making it ideal for various terrains.

Design Features: Its robust frame and innovative design elements contribute to enhanced stability and control, allowing users to navigate with confidence.

Safety: Equipped with essential safety features, this model prioritizes rider protection, making it a trusted choice for both novice and experienced users.

Overall, this vehicle represents the ultimate blend of power, design, and safety, appealing to those who seek adventure.

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair. This illustration provides a detailed view of individual elements, showcasing their arrangement and function within the overall system.

Key elements in such representations include labels that identify each component and lines that indicate connections or relationships between them. By exploring these visuals, users can enhance their understanding of how each piece contributes to the ultimate performance of the machine.

Moreover, familiarity with these graphics aids in troubleshooting, allowing users to pinpoint issues swiftly. Engaging with these resources can ultimately lead to improved operational efficiency and longevity of the equipment.

Key Components of BT200X

Understanding the essential elements of this specific model enhances both maintenance and performance. Each part plays a crucial role in the overall functionality, ensuring a smooth experience whether for leisure or work. Familiarity with these components helps users identify potential issues and optimize their use.

Engine and Transmission

The power unit is the heart of the vehicle, providing the necessary propulsion and torque. Coupled with a reliable transmission system, it ensures efficient power delivery to the wheels. Regular checks and maintenance of these parts are vital to avoid performance declines and mechanical failures.

Frame and Suspension

The structural framework supports the entire assembly, while the suspension system absorbs shocks and enhances stability during rides. A robust frame combined with an effective suspension mechanism contributes significantly to rider comfort and vehicle durability, making them critical for a pleasant experience.

Common Issues with BT200X Parts

When it comes to maintaining and repairing small motorized units, various components may encounter issues that can affect overall performance. Understanding these common problems is crucial for effective troubleshooting and ensuring longevity. Several parts are prone to wear and tear, which can lead to decreased efficiency or complete failure if not addressed promptly.

Frequent Component Failures

Some components tend to fail more often than others. This can be attributed to factors such as frequent usage, environmental conditions, and manufacturing inconsistencies. Recognizing these vulnerable parts can help in preventive maintenance and timely replacements.

Symptoms of Malfunctioning Components

Identifying signs of malfunction is essential for effective repairs. Here are common symptoms that may indicate issues with various parts:

| Component | Common Symptoms |

|---|---|

| Engine | Difficulty starting, unusual noises, or loss of power |

| Brakes | Delayed response, grinding sounds, or excessive wear |

| Tires | Flat spots, uneven wear, or air leaks |

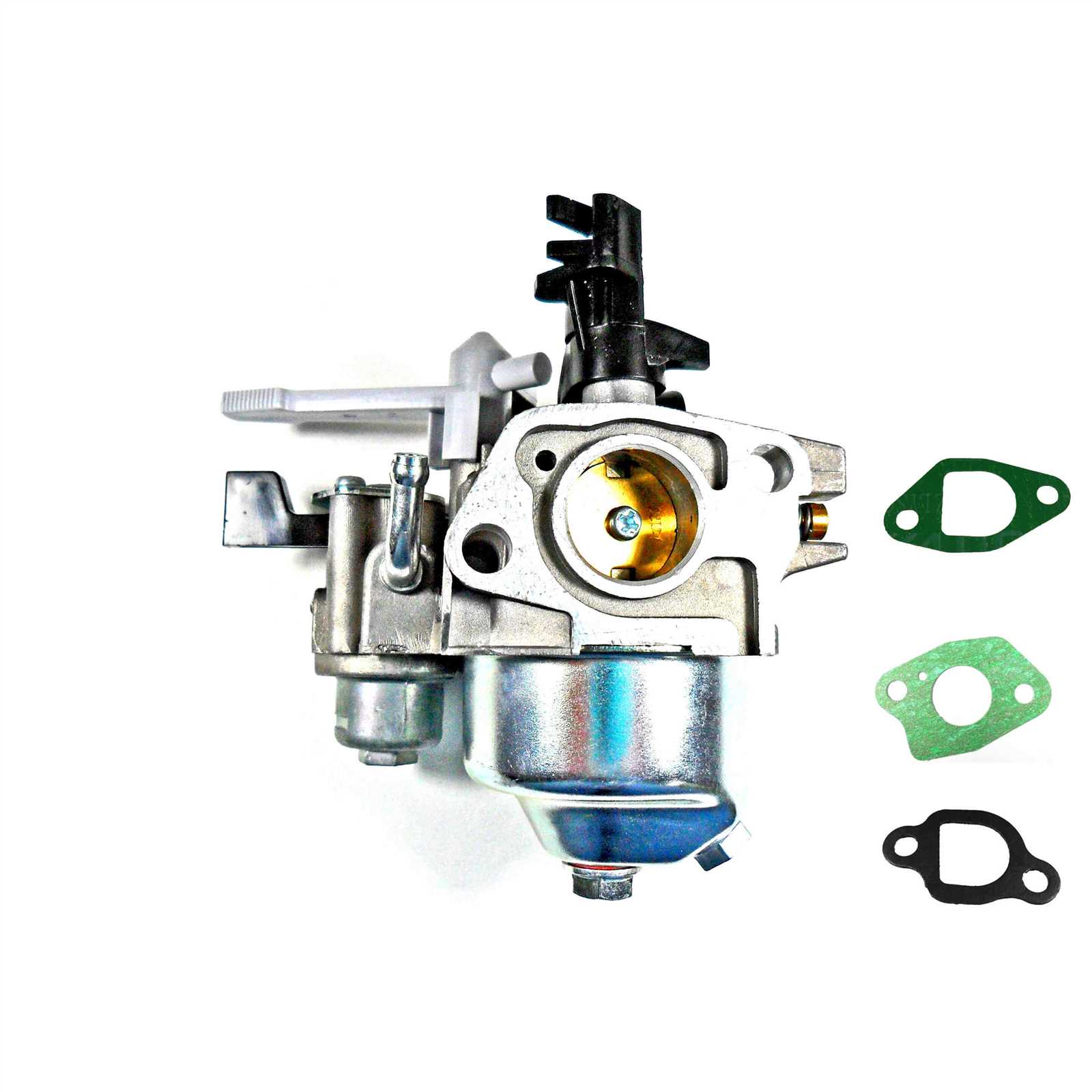

| Fuel System | Poor acceleration, stalling, or fuel leaks |

Replacing BT200X Components

Maintenance and repairs are essential for keeping your equipment in optimal condition. Understanding how to replace specific elements can enhance performance and prolong its lifespan. This guide will outline the necessary steps to successfully swap out components, ensuring everything functions smoothly.

Identifying the Components

Before beginning any replacement process, it’s crucial to pinpoint which parts require attention. Common signs of wear include unusual noises, decreased performance, or visible damage. Take the time to inspect each element thoroughly and make a list of the components that need to be replaced.

Replacement Procedure

Once you have identified the faulty parts, gather the appropriate tools and new components. Start by disconnecting the power source to ensure safety during the replacement. Follow these general steps:

- Remove the old component: Carefully detach the damaged part, taking note of how it is connected.

- Install the new part: Position the replacement securely, ensuring that it aligns properly with other elements.

- Reconnect and test: Once installed, reconnect the power source and test the equipment to confirm everything operates as intended.

Regular maintenance and timely replacements can significantly improve the reliability and efficiency of your machine, ensuring it serves you well for years to come.

Maintenance Tips for Longevity

Ensuring the extended life of your outdoor equipment requires regular care and attention. Implementing a few simple practices can significantly enhance performance and durability. By focusing on maintenance routines, you can prevent wear and tear, ensuring your investment remains reliable for years to come.

1. Regular Inspections: Periodically examine your machinery for signs of wear. Check for loose screws, cracks, or any unusual noises. Early detection of issues can save you from more extensive repairs later.

2. Cleanliness is Key: Keeping your device clean is essential. Remove dirt and debris after each use. Use a soft brush or cloth to avoid scratches, ensuring all components remain in optimal condition.

3. Lubrication: Regularly apply appropriate lubricants to moving parts. This reduces friction and helps prevent corrosion, allowing for smooth operation and extending the life of mechanical elements.

4. Fuel Management: Use high-quality fuel and store it correctly. Stale or contaminated fuel can cause performance issues and damage internal components. Always replace old fuel with fresh supplies.

5. Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule outlined by the manufacturer is crucial. This includes regular oil changes, air filter replacements, and spark plug checks.

6. Proper Storage: When not in use, store your equipment in a dry, cool place. Cover it to protect it from dust and moisture, which can lead to rust and degradation.

By incorporating these practices into your routine, you can ensure that your outdoor machinery remains efficient and reliable, maximizing its lifespan and performance.

Where to Buy Replacement Parts

Finding suitable components for your outdoor equipment can enhance its performance and longevity. Whether you are looking for specific items or general supplies, there are several avenues to explore that can help you locate what you need.

- Official Retailers: Check the manufacturer’s website or authorized dealers for genuine components.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized outdoor gear sites often have a wide range of options.

- Local Repair Shops: Visit local shops that specialize in outdoor equipment; they may have parts on hand or be able to order them for you.

- Salvage Yards: Some salvage yards or second-hand stores offer used parts that can be both affordable and functional.

Before making a purchase, it’s advisable to verify compatibility and quality to ensure optimal performance of your equipment.

Assembly Instructions for BT200X

Putting together your unit is a straightforward process that ensures optimal performance and safety. Following these guidelines will help you navigate each step effectively, resulting in a well-assembled machine.

Tools Needed

- Screwdriver

- Wrench set

- Allen keys

- Safety goggles

Assembly Steps

- Begin by laying out all components on a flat surface.

- Identify the main frame and attach the wheels using the provided bolts.

- Secure the handlebar to the main frame, ensuring it is tightened properly.

- Attach the seat and adjust it to your preferred height.

- Connect any additional components as per the instructions included in your manual.

- Finally, perform a thorough check to confirm all parts are securely fastened.