Every heating structure relies on an intricate network designed to ensure efficient operation and safety. Recognizing the individual elements within this system is essential for maintenance and troubleshooting. Each segment plays a pivotal role, contributing to the overall functionality and effectiveness of the setup.

In this exploration, we will delve into the essential constituents, examining their specific purposes and interconnections. From the initial collection of byproducts to their eventual expulsion, understanding these components offers insight into optimal performance and potential issues that may arise.

Moreover, familiarity with these elements not only enhances your knowledge but also empowers you to make informed decisions regarding installation and upkeep. By grasping the ultimate layout and function of each component, you can ensure a safe and efficient environment.

Understanding Chimney Structure

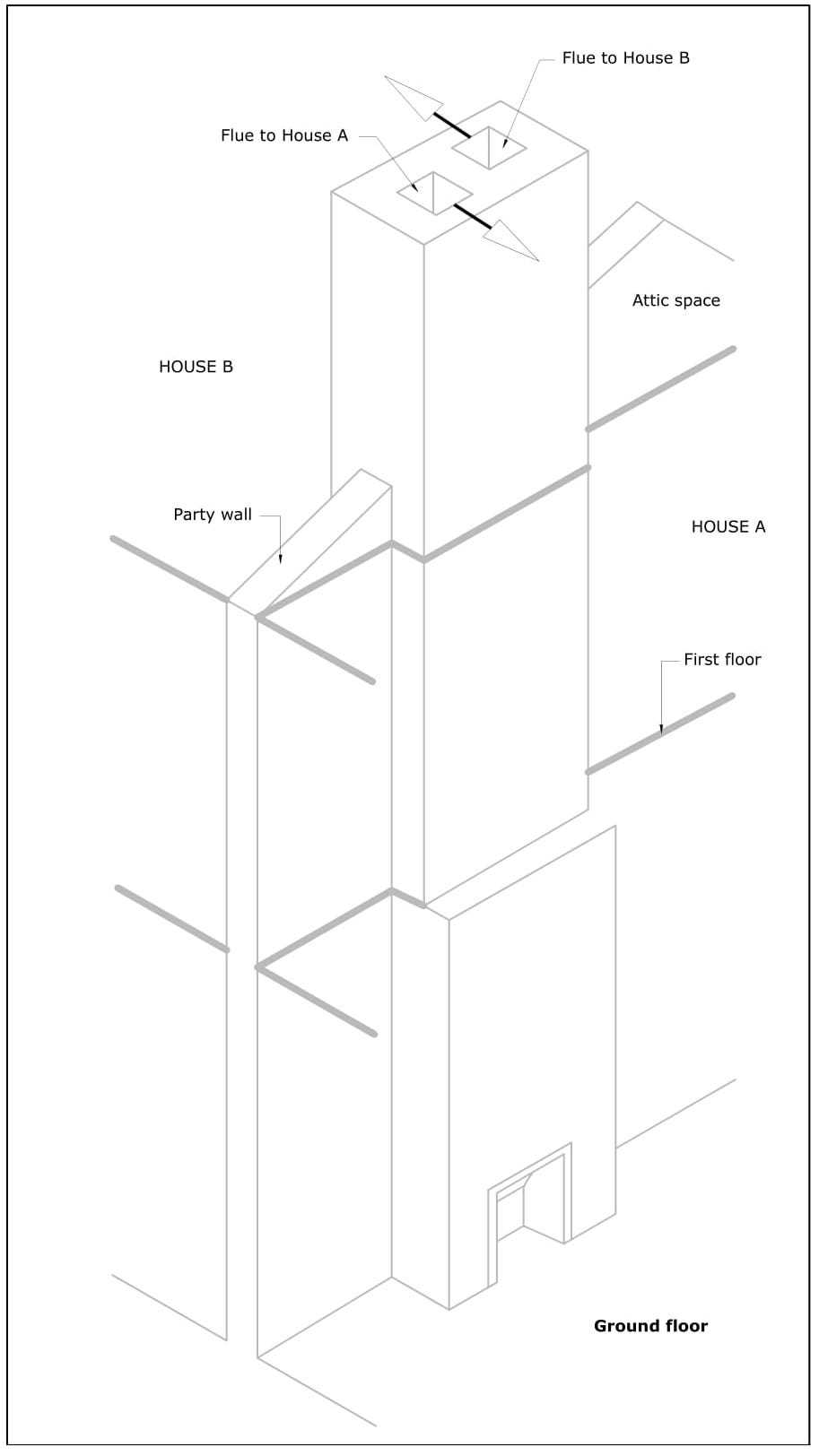

Every vertical flue system consists of various components that work together to ensure efficient ventilation and safety. Recognizing the function and arrangement of these elements is essential for proper maintenance and optimal performance. This knowledge helps in identifying potential issues and facilitates effective troubleshooting.

Key Elements of the Flue System

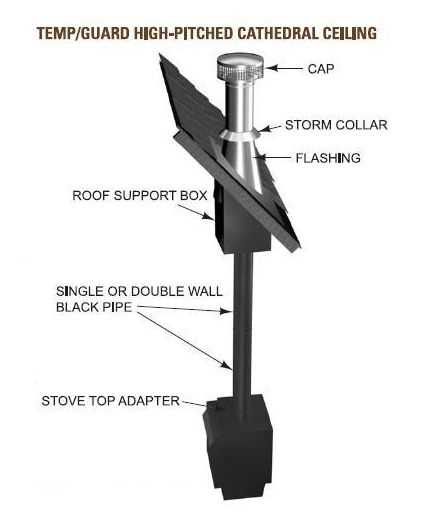

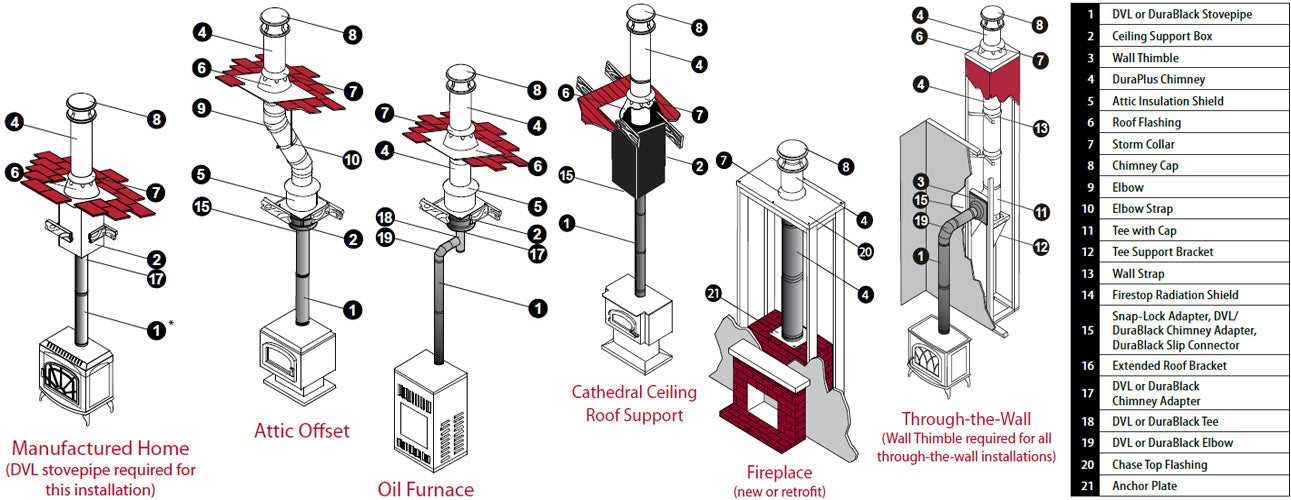

At the core of this system lies the vertical shaft, designed to expel smoke and gases generated by combustion. Surrounding this are protective casings that shield against external elements and enhance structural integrity. Additionally, the connection to heating appliances is crucial, ensuring that exhaust is directed safely and efficiently.

Importance of Proper Maintenance

Regular inspection of the various components is vital for preventing blockages and deterioration. Neglecting maintenance can lead to dangerous situations, such as backdrafts or even fires. An understanding of the entire system allows homeowners to take proactive steps in preserving safety and efficiency.

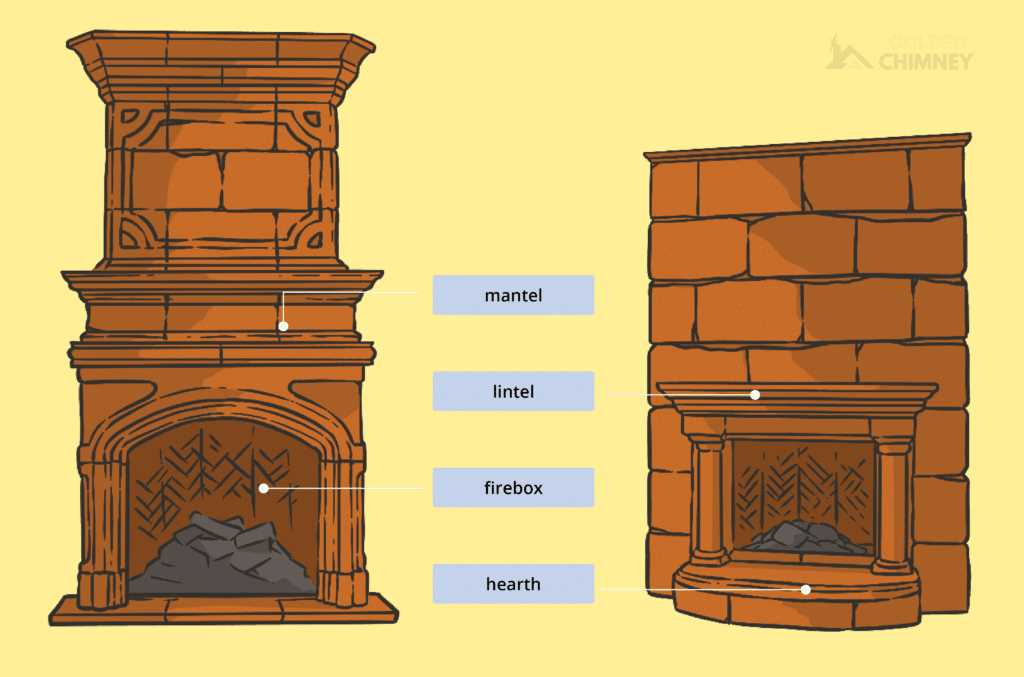

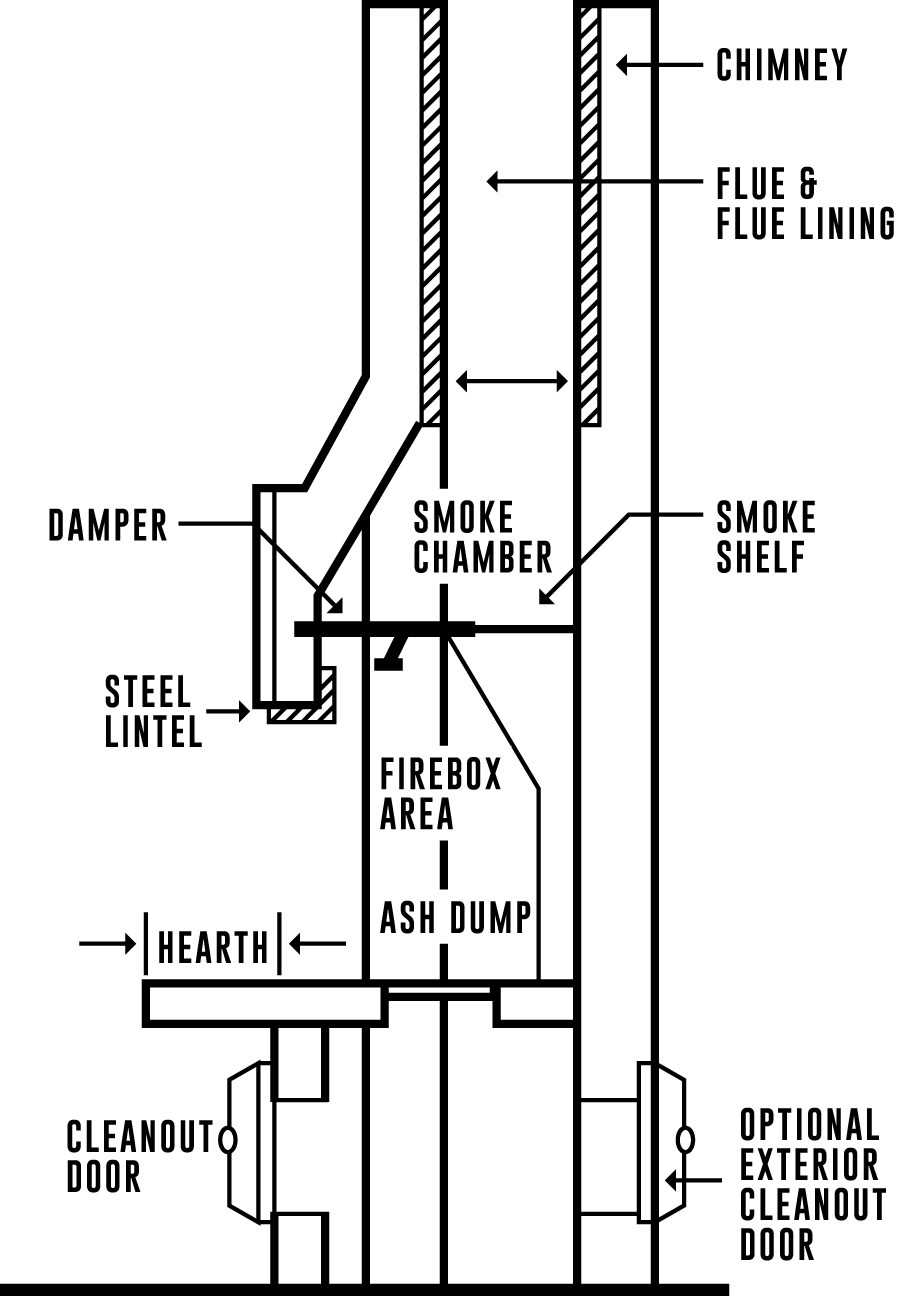

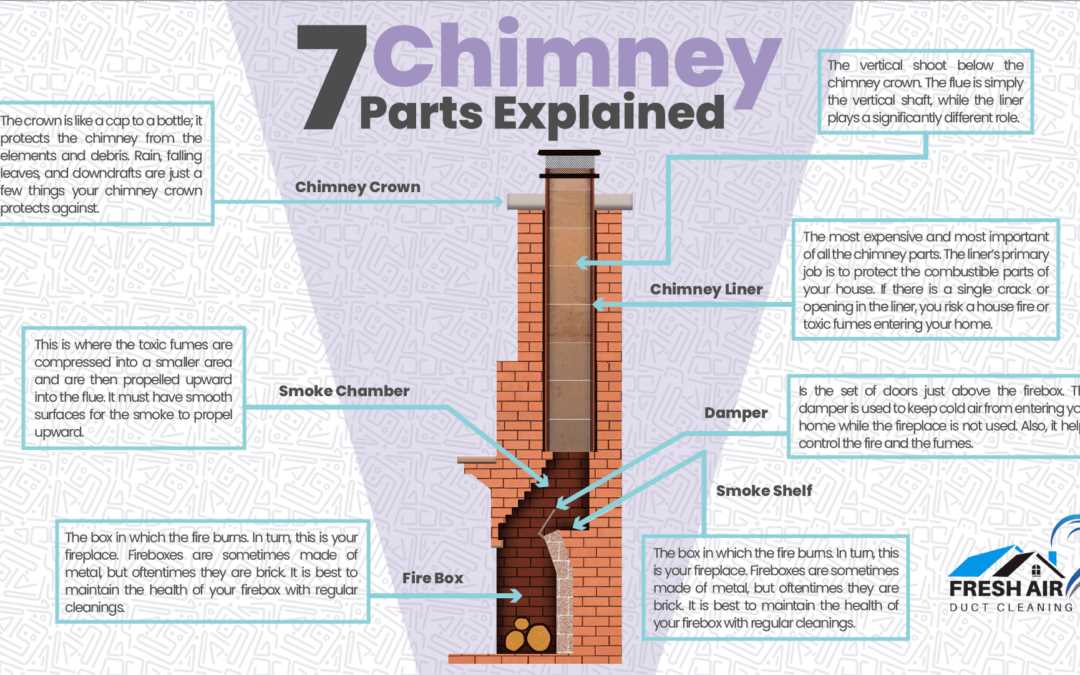

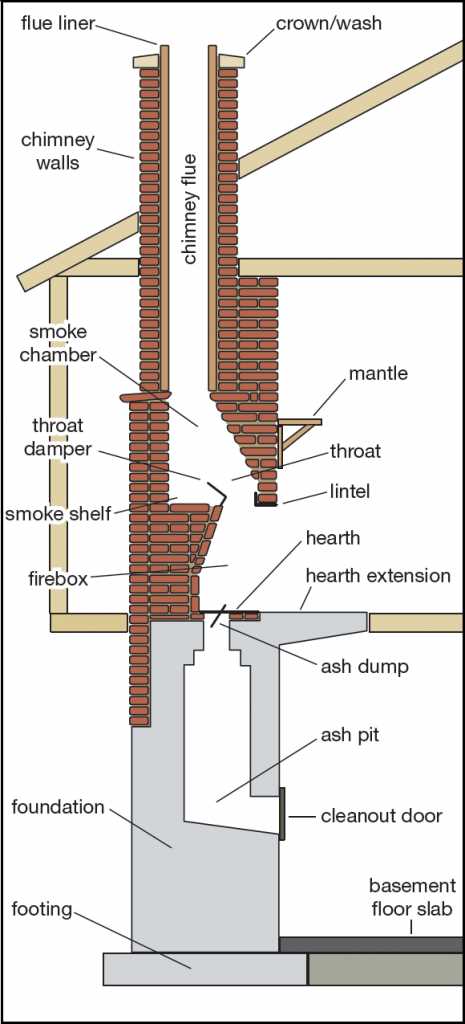

Main Components of a Chimney

Understanding the fundamental elements that constitute a flue structure is essential for ensuring efficient ventilation and safety in any building. Each component plays a vital role in the proper functioning of the entire system, contributing to the effective expulsion of smoke and gases while maintaining structural integrity.

Key Elements

The upper section serves as the termination point, allowing for the safe release of exhaust while preventing rain and debris from entering. Below, the vertical shaft acts as the main conduit, facilitating the upward flow of emissions. Insulation materials are crucial in protecting the surrounding areas from heat, reducing the risk of fire hazards.

Supporting Structures

Additionally, various fittings and connectors ensure a secure and seamless assembly, while cleanout doors provide access for maintenance and inspection. These supporting structures work in harmony to enhance the overall efficiency and longevity of the system, making regular upkeep indispensable.

Importance of Chimney Diagrams

Visual representations of ventilation structures play a crucial role in understanding and maintaining their functionality. They provide essential information for installation, troubleshooting, and safety inspections.

- Facilitates clear communication among professionals.

- Enhances comprehension of complex systems.

- Aids in identifying components and their interactions.

- Supports effective maintenance strategies.

Utilizing these illustrations can ultimately lead to safer and more efficient usage of these systems, minimizing risks associated with improper functioning.

How to Read Chimney Diagrams

Understanding the structure and components of a ventilation system is essential for ensuring its effective operation and maintenance. Familiarizing yourself with the visual representations of these systems can greatly aid in identifying each element and its function. This knowledge not only supports proper installation but also enhances troubleshooting skills when issues arise.

Identifying Key Components

When examining a visual schematic, look for various symbols and lines that represent different sections. Typically, elements such as flues, connectors, and terminations are depicted in a standardized manner. Recognizing these symbols will allow you to easily interpret the layout and the relationships between each part.

Understanding Flow Direction

Pay close attention to arrows and lines that indicate the flow of gases or air. These indicators are crucial for grasping how the system operates as a whole. Knowing the intended direction of flow can help diagnose potential blockages or inefficiencies that may affect performance.

Common Chimney Problems

Issues related to exhaust structures can lead to significant safety hazards and inefficiencies in heating systems. Recognizing these problems early is crucial for maintaining optimal performance and ensuring the safety of the home. Various factors, including wear and tear, environmental conditions, and improper installation, contribute to these challenges.

Structural Integrity Issues

Cracks and deterioration in the external casing can compromise functionality. Weather elements, such as rain and snow, can infiltrate these cracks, leading to further damage. Regular inspections are essential to identify and address these issues before they escalate.

Obstructions and Blockages

Blockages caused by debris, animal nests, or soot buildup can impede airflow. This can result in dangerous smoke backup and reduced efficiency of heating appliances. Regular cleaning and maintenance are vital to ensure a clear passage for exhaust gases.

Maintenance Tips for Chimney Parts

Regular upkeep is essential to ensure the efficiency and longevity of your system. By following a few straightforward guidelines, you can prevent potential issues and enhance performance. Maintaining these structures not only ensures safety but also optimizes functionality.

Routine Inspections

Conducting regular assessments is crucial. Check for any signs of wear or damage, especially after severe weather. Look for blockages that may hinder airflow and ensure that everything is in proper working condition.

Cleaning Procedures

Keeping your system clean is vital. Utilize specialized tools to remove soot and debris that can accumulate over time. This not only prevents hazards but also improves efficiency, allowing for better ventilation and overall performance.

Choosing Quality Chimney Materials

Selecting high-quality components for ventilation systems is crucial for ensuring safety, efficiency, and durability. The materials used can significantly impact the overall performance and longevity of the installation. It’s essential to consider various factors that influence the selection process, including resistance to heat, weather conditions, and the potential for corrosion.

Material Options

Common choices include stainless steel, clay, and concrete. Stainless steel is favored for its resilience and resistance to rust, making it ideal for varying climates. Clay offers excellent insulation properties, while concrete provides durability and strength. Each option has unique benefits and drawbacks, so understanding their characteristics is vital for making an informed decision.

Certification and Standards

Always look for materials that meet established safety standards and certifications. Products that comply with regulations ensure reliability and minimize risks. Investing in certified components not only enhances performance but also provides peace of mind regarding safety and compliance.

Safety Considerations for Chimney Installation

Ensuring the safe assembly and maintenance of ventilation systems is crucial for the well-being of any dwelling. Proper practices can prevent hazards, including fire risks and carbon monoxide exposure. This section highlights essential safety measures that should be observed during installation.

Common Risks and Precautions

Several dangers can arise if safety protocols are not followed. Understanding these risks can lead to better protective strategies. Key considerations include:

| Risk | Precaution |

|---|---|

| Fire Hazards | Maintain proper clearance from combustible materials. |

| Carbon Monoxide Poisoning | Ensure proper sealing and ventilation to prevent gas accumulation. |

| Structural Damage | Use materials and installation methods that comply with local codes. |

| Inadequate Draft | Assess design for airflow efficiency during installation. |

Professional Assistance

Engaging experienced professionals for installation and inspection can significantly reduce risks. Experts understand local regulations and best practices, ensuring the system operates safely and effectively. Regular maintenance checks are also essential to identify potential issues before they become serious threats.