In the world of off-road vehicles, comprehending the intricate elements that make up a high-performance machine is crucial for enthusiasts and operators alike. The X3 model represents a pinnacle of engineering, offering unmatched capabilities and reliability in challenging terrains. This section aims to delve into the various components that contribute to its outstanding performance.

For those looking to enhance their knowledge, visual representations of these elements serve as invaluable resources. By familiarizing oneself with the layout and functions of each section, users can gain insights into maintenance, upgrades, and troubleshooting. This understanding not only fosters better care for the vehicle but also empowers owners to make informed decisions regarding modifications and repairs.

Moreover, navigating the intricacies of the X3’s structure can simplify the process of sourcing replacements and improvements. By exploring the connections between different systems, enthusiasts can appreciate the craftsmanship involved and ensure that their vehicles operate at peak efficiency. Whether for recreational purposes or competitive events, mastering the essentials of this remarkable model is a journey worth undertaking.

This section will explore the intricate makeup of various elements within a specific vehicle model, providing insights into their functions and interrelations. By breaking down these components, readers will gain a clearer understanding of how they contribute to overall performance and maintenance.

-

Overview of the Vehicle’s Core Framework

-

Examination of the Suspension System

-

Insights into the Engine Mechanics

-

Analysis of the Brake System

-

Understanding the Transmission Components

-

Importance of Electrical Systems

-

Role of the Cooling Mechanism

-

Maintenance of Tires and Wheel Assembly

This section will detail the main structure that supports the entire assembly, highlighting its significance in stability and durability.

cssCopy code

An in-depth look at the system responsible for absorbing shocks and ensuring smooth rides over various terrains.

This part will dissect the heart of the vehicle, explaining its mechanics and how it powers performance.

A critical evaluation of the braking components, emphasizing safety and control during operation.

Exploring the gears and systems that facilitate efficient power delivery from the engine to the wheels.

This section will focus on the wiring and electronic components that ensure functionality and reliability.

Describing the systems in place to prevent overheating, which is crucial for maintaining engine efficiency.

A guide to understanding the significance of tire health and wheel alignment for optimal performance.

Identifying Crucial Elements and Their Roles

Understanding the essential components of a complex system is vital for effective maintenance and enhancement. Each element plays a specific role, contributing to the overall functionality and performance.

Key Components Overview

- Engine: The powerhouse driving the vehicle.

- Transmission: Facilitates the transfer of power from the engine to the wheels.

- Suspension: Ensures stability and comfort during operation.

- Braking System: Provides safety by controlling speed and stopping.

- Electrical System: Powers various functionalities, from ignition to lighting.

Importance of Each Element

- Engine: Determines the overall speed and efficiency.

- Transmission: Influences acceleration and handling.

- Suspension: Affects ride quality and vehicle control.

- Braking System: Critical for safe maneuvering and stopping.

- Electrical System: Essential for operational readiness and convenience.

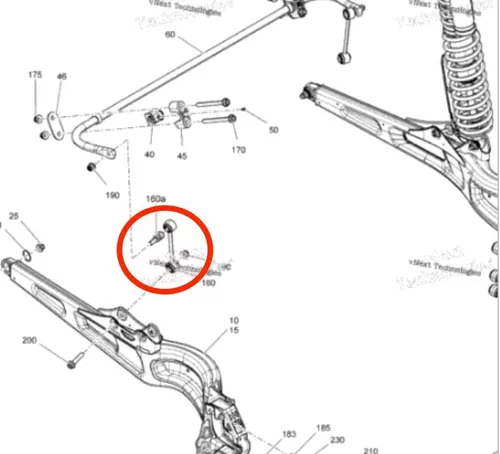

Exploring Suspension System Configuration

The suspension framework plays a crucial role in vehicle dynamics, influencing both handling and comfort. Understanding how this system operates is essential for optimizing performance in various terrains. This section delves into the key elements and arrangements that contribute to effective suspension design.

Key Components of the Suspension Framework

- Shocks and Struts: These elements absorb bumps and impacts, ensuring a smoother ride.

- Springs: Springs support the vehicle’s weight and help maintain ride height.

- Control Arms: These connect the chassis to the wheels, allowing for controlled movement.

- Stabilizer Bars: These minimize body roll during cornering, enhancing stability.

Configurations and Their Benefits

- Independent Suspension:

- Improved handling and ride quality.

- Better traction on uneven surfaces.

- Solid Axle Suspension:

- Increased durability and strength.

- Simplified design with fewer moving parts.

- Adjustable Suspension:

- Customization for various driving conditions.

- Ability to fine-tune ride characteristics.

By exploring these configurations, one can appreciate the intricacies of suspension design and its impact on overall vehicle performance.

Detailed Analysis of Suspension Components

The suspension system plays a crucial role in ensuring a smooth and controlled ride. This analysis aims to explore the various elements that contribute to the overall performance and comfort of the vehicle, focusing on their functions and interrelationships.

Key Elements of the Suspension System

- Shock Absorbers: These components mitigate the impact of bumps and irregularities on the road.

- Springs: They support the vehicle’s weight and absorb shocks during movement.

- Control Arms: These connect the chassis to the wheels, allowing for controlled motion.

- Ball Joints: These pivot points enable smooth movement between various parts.

Importance of Each Component

- Shock Absorbers: Vital for maintaining tire contact with the road, enhancing stability.

- Springs: Their elasticity affects ride quality and handling characteristics.

- Control Arms: They dictate wheel alignment, impacting tire wear and performance.

- Ball Joints: Ensuring proper articulation is crucial for steering and suspension efficiency.

Brake Assembly Layout and Functionality

The brake assembly is a critical component of any vehicle, designed to ensure safety and control during operation. Understanding its arrangement and how each element interacts can enhance performance and reliability. This section delves into the structural design and operational principles of the braking mechanism.

Key Components of the brake system include the master cylinder, brake lines, calipers, and pads. Each part plays a vital role in the overall functionality, converting the driver’s input into effective deceleration. The master cylinder initiates hydraulic pressure, which travels through the brake lines to activate the calipers.

The calipers are particularly important as they house the brake pads and create the friction necessary to slow down or stop the vehicle. When the hydraulic pressure is applied, the calipers clamp down on the pads, which in turn grip the brake rotor. This process transforms kinetic energy into thermal energy, effectively reducing speed.

Moreover, maintenance of the brake assembly is crucial. Regular inspections and timely replacements of worn-out components can prevent brake failure and ensure optimal performance. Understanding how each part works together can assist in troubleshooting issues and maintaining safety on the road.

In summary, familiarity with the layout and functionality of the braking assembly empowers operators to make informed decisions regarding maintenance and performance enhancement. A well-functioning brake system is essential for safe operation, making knowledge of its components invaluable.

Key Details of the Brake System

The braking mechanism is a critical component in any off-road vehicle, ensuring safety and control during operation. Understanding its intricacies can significantly enhance performance and reliability. This section delves into the essential elements that make up the braking system, highlighting their functions and importance.

Components of the braking system include calipers, rotors, and pads, each playing a vital role in creating the necessary friction to halt the vehicle. The calipers house the brake pads and apply pressure to the rotors, while the rotors are attached to the wheels and provide the surface against which the pads grip.

Maintaining the integrity of these components is crucial. Regular inspection for wear and tear can prevent catastrophic failures. The choice of high-quality materials for brake pads and rotors can also enhance longevity and performance, especially in demanding environments.

Additionally, the hydraulic system that operates the brakes is essential for effective performance. This system relies on brake fluid to transfer force from the pedal to the calipers, making regular fluid checks and replacements important for maintaining responsiveness.

Ultimately, a well-maintained braking system not only improves safety but also enhances the overall driving experience. Understanding these key details empowers users to make informed decisions regarding maintenance and upgrades.

Electrical Wiring Connections Overview

Understanding the intricacies of electrical connections is essential for effective maintenance and troubleshooting. A well-organized wiring setup ensures the reliable operation of various systems, providing seamless communication between components. This section will explore the critical aspects of electrical connections, highlighting their importance in overall vehicle functionality.

Key Components of Electrical Connections

Electrical connections consist of various elements, including terminals, connectors, and wiring harnesses. Each component plays a pivotal role in transmitting power and signals. Terminals serve as points of contact for wires, while connectors facilitate secure and efficient links between different circuits. The wiring harness itself organizes and protects the electrical pathways, minimizing the risk of damage.

Best Practices for Maintenance

Regular inspection and maintenance of electrical connections are vital for preventing issues. Ensuring that connections are tight and free from corrosion can significantly enhance the reliability of the electrical system. Utilizing appropriate connectors and following manufacturer recommendations for wiring can also improve performance and longevity, safeguarding the vehicle’s electrical integrity.

Mapping Out Electrical Links and Circuits

Understanding the interconnections within a vehicle’s electrical system is essential for effective maintenance and troubleshooting. By visualizing how various components interact, one can better identify potential issues and streamline repairs. This section focuses on the key elements that contribute to a well-functioning electrical network.

Key Components of the Electrical System

The electrical system is composed of several crucial elements, each playing a vital role in ensuring seamless operation. These components include the battery, wiring harnesses, switches, fuses, and connectors. Mapping out their relationships helps in diagnosing faults and understanding the flow of electricity throughout the system.

Connection Mapping Table

| Component | Function | Location |

|---|---|---|

| Battery | Power source for the electrical system | Under the hood |

| Wiring Harness | Transmits electrical signals | Throughout the vehicle |

| Switches | Controls various electrical functions | Dashboard and other accessible areas |

| Fuses | Protects circuits from overloads | Fuse box location |

| Connectors | Joins different wiring sections | Near component junctions |

By closely examining these components and their interconnections, one can gain valuable insights into the overall performance and reliability of the electrical system.

Cooling Mechanism Parts Breakdown

The efficiency of any vehicle’s thermal management system is crucial for optimal performance. This section will explore the various components that contribute to the cooling process, ensuring that the engine operates within safe temperature limits.

Radiator is a fundamental element that dissipates heat from the coolant. It allows air to flow through, cooling the fluid that circulates in the engine. A well-functioning radiator is vital for preventing overheating.

Water Pump plays a pivotal role by circulating the coolant throughout the system. Its proper operation ensures consistent flow, contributing to effective heat exchange.

Thermostat regulates the temperature by controlling the flow of coolant. It opens and closes at specific temperatures, maintaining an optimal operating range.

Cooling Fans assist in air circulation, particularly when the vehicle is stationary or moving slowly. These components activate to provide additional airflow to the radiator, enhancing cooling efficiency.

Understanding the interplay of these elements is essential for anyone looking to delve deeper into vehicle maintenance and performance, ultimately leading to improved reliability and longevity.

Analyzing the Cooling System Design

The efficiency of any high-performance vehicle significantly hinges on the effectiveness of its cooling mechanism. A well-designed cooling system is crucial for maintaining optimal operating temperatures, preventing overheating, and ensuring longevity of engine components. This section delves into the intricacies of cooling system architecture, focusing on its components, functionality, and potential areas for improvement.

Key Components of the Cooling Mechanism

The primary elements of the cooling system include the radiator, coolant reservoir, water pump, and thermostat. Each component plays a vital role in regulating temperature and ensuring the engine operates within its ideal range. Understanding how these parts interact can illuminate areas for optimization.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant to the air. |

| Coolant Reservoir | Holds excess coolant and allows for expansion. |

| Water Pump | Circulates coolant throughout the system. |

| Thermostat | Regulates coolant flow based on temperature. |

System Performance and Enhancements

Analyzing the performance of the cooling assembly reveals opportunities for enhancements. Factors such as airflow, coolant quality, and maintenance practices directly influence the efficiency of heat dissipation. Implementing upgraded components or improved airflow designs can lead to significant performance gains, providing a competitive edge in high-demand environments.