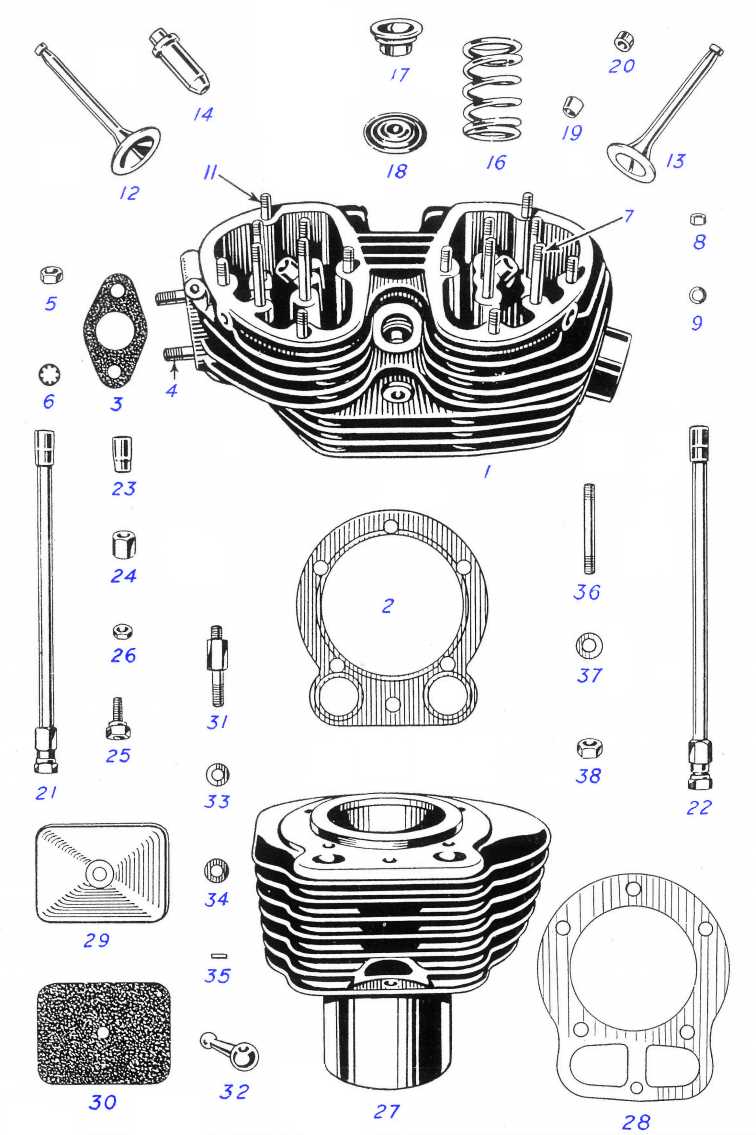

The intricate design of modern firearms relies on a variety of elements working together seamlessly. Each component plays a vital role in ensuring functionality, accuracy, and safety. Understanding how these elements interact is essential for both enthusiasts and professionals in the field. This section delves into the critical structures that form the backbone of these complex mechanisms.

From the core structure that houses the firing mechanism to the various accessories that enhance performance, each piece contributes uniquely to the overall operation. Knowledge of these individual components not only aids in maintenance and repair but also fosters a deeper appreciation for the craftsmanship involved in firearm design.

Exploring these intricate systems allows for greater insight into the engineering principles that govern their operation. Whether for educational purposes or practical applications, a comprehensive grasp of these components is crucial for anyone involved in the handling or modification of firearms.

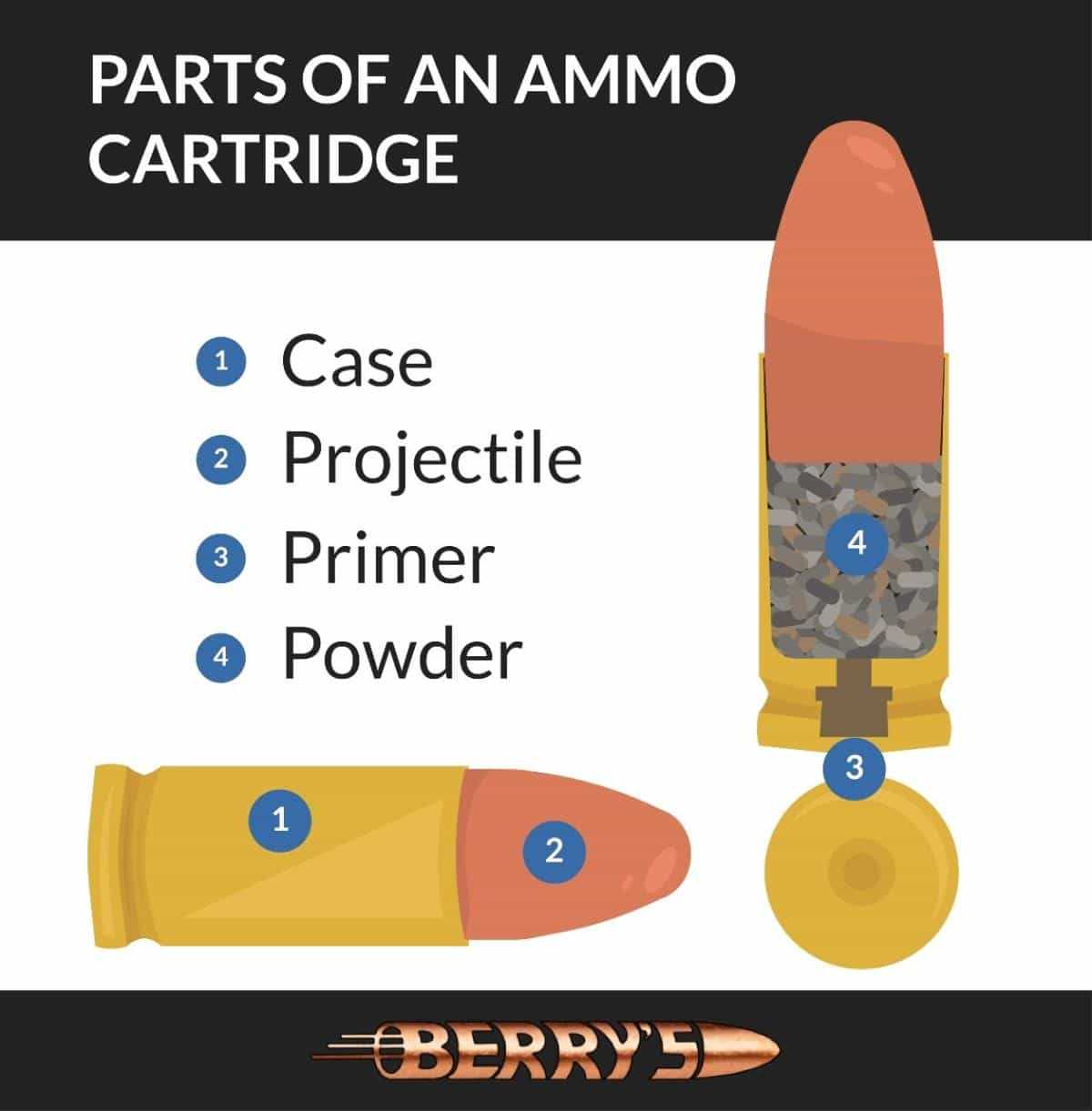

Understanding the structure of ammunition is crucial for both enthusiasts and professionals in various fields. Each component plays a significant role in the overall functionality and performance of the cartridge. This section will delve into the essential elements, their interactions, and how they contribute to the projectile’s effectiveness.

Key Components of Ammunition

- Projectile: The front portion designed to deliver force upon impact.

- Case: The outer shell that contains all other elements and holds the propellant.

- Propellant: The material that ignites to create gas, propelling the projectile forward.

- Primer: A small explosive device that ignites the propellant when struck by the firing pin.

Functionality of Each Element

- The projectile must have an aerodynamic shape to enhance stability and accuracy.

- The case must be durable enough to withstand high pressure but flexible for extraction after firing.

- The propellant needs to be consistent to ensure reliable performance in different conditions.

- The primer should react instantly to the firing mechanism to ensure a quick ignition of the propellant.

Understanding these key elements and their interactions is essential for grasping the complexities of ammunition design and functionality. Each component must work harmoniously to achieve the desired outcome, whether for sport shooting, hunting, or defense.

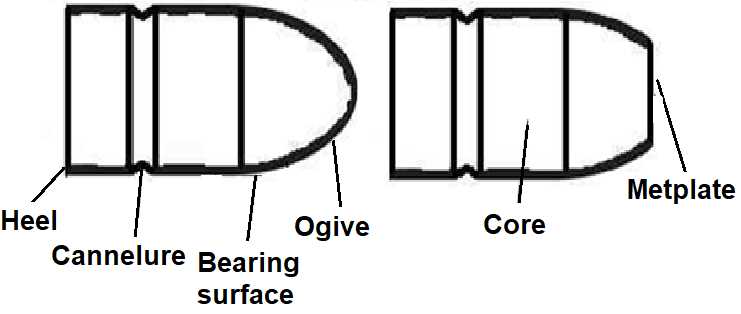

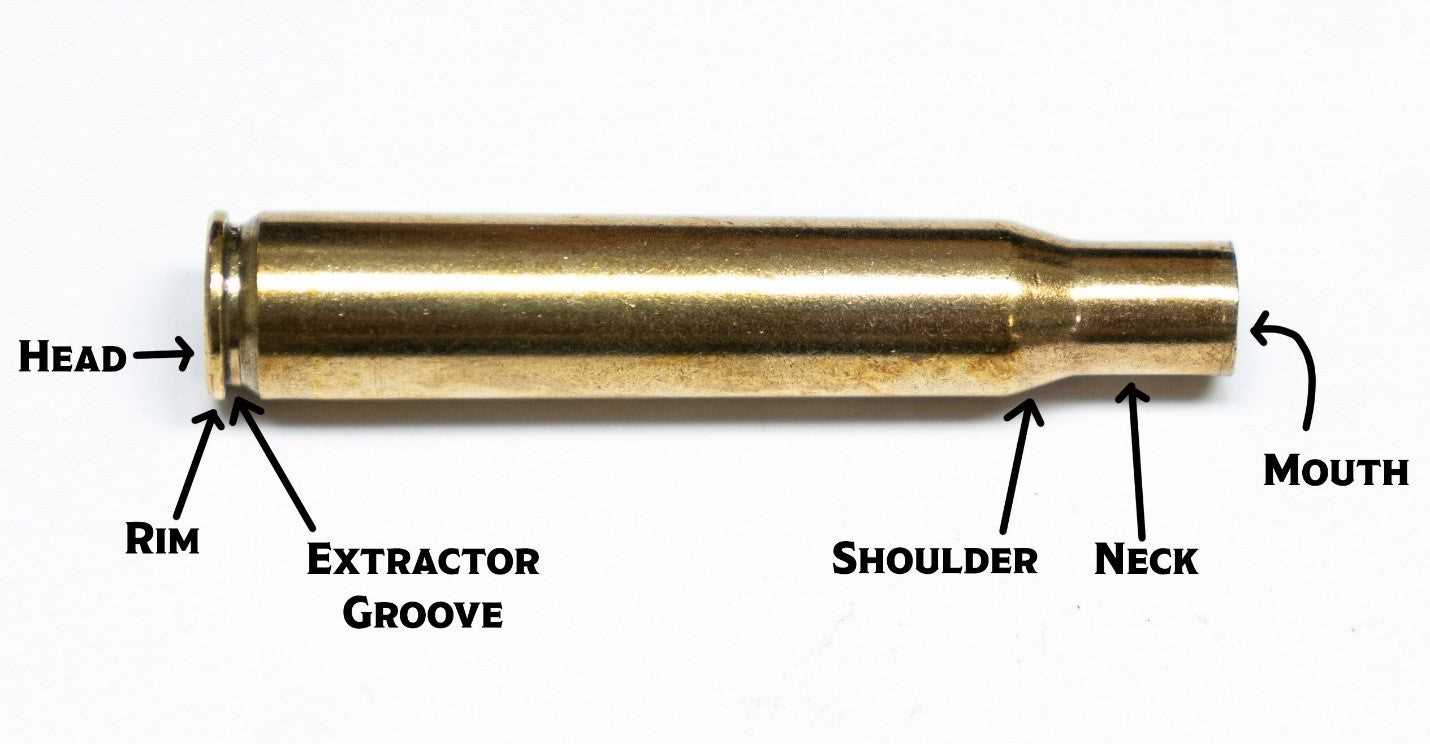

Key Components of a Bullet

Understanding the essential elements of ammunition is crucial for grasping how these projectiles function effectively. Each component plays a significant role in the overall performance, influencing factors such as accuracy, speed, and impact. Below are the primary constituents that contribute to the efficacy of a cartridge.

- Projectile: This is the front portion designed to be expelled from the casing. Its shape and weight affect aerodynamics and lethality.

- Casing: The container that holds the other elements together. It is usually made of brass, steel, or aluminum, providing the necessary pressure to propel the projectile.

- Propellant: A chemical substance that ignites and generates gas, pushing the projectile forward. The type and amount of this material determine the velocity and distance the projectile can travel.

- Primer: A small component located at the base of the casing, responsible for igniting the propellant when struck by the firing pin. This initiates the entire firing sequence.

- Wad: Found in certain types of ammunition, this element separates the propellant from the projectile, helping to optimize pressure and improve accuracy.

Each of these components works in harmony to ensure reliable and effective operation, reflecting the intricate design that goes into creating high-performance ammunition.

How Bullet Design Influences Performance

The construction and form of ammunition significantly affect its functionality and effectiveness in various applications. Every aspect, from the material composition to the geometry, plays a crucial role in determining how well the projectile performs upon discharge. Understanding these elements helps in selecting the right type for specific situations.

Key design features that impact performance include:

- Shape: The aerodynamic profile influences flight stability and accuracy. Streamlined designs reduce drag, allowing for better precision over distance.

- Weight: Heavier projectiles may deliver more energy upon impact, while lighter ones typically allow for faster speeds and flatter trajectories.

- Material: The choice of materials affects penetration and expansion characteristics. For instance, softer materials may expand more upon impact, creating a larger wound channel.

- Length: The length of the projectile can influence stability during flight. Longer designs may provide improved balance but could affect speed and agility.

- Base design: The configuration of the base can impact how gases are utilized for propulsion, directly influencing the velocity achieved.

In summary, the various design elements collectively determine the performance characteristics of a projectile, making it essential to consider these factors when selecting ammunition for specific tasks.

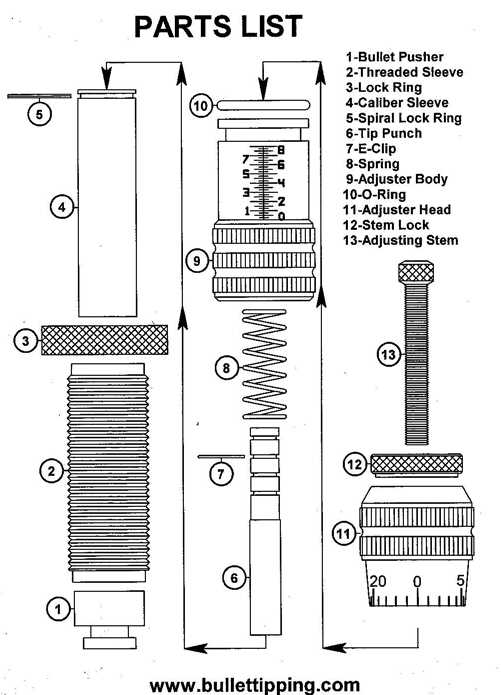

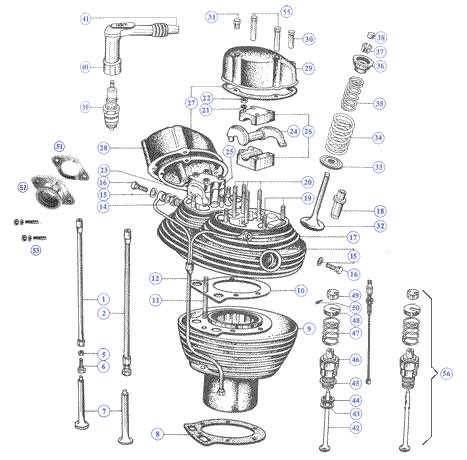

Diagram Overview of Bullet Parts

This section aims to provide a comprehensive visual representation of the various components that make up a projectile. Understanding the intricate design and functionality of these elements is essential for both enthusiasts and professionals in the field of ballistics. Each segment plays a crucial role in the overall performance and efficiency of the ammunition.

Key Elements: The main sections include the casing, which serves as the outer shell, the propellant that generates the necessary force, and the projectile itself, designed for precise targeting. Additionally, there are critical features like the primer, which ignites the propellant, and the wad that may be present in certain types of ammunition.

Functionality: Each component is meticulously engineered to work in harmony, ensuring optimal performance. The casing provides structural integrity, while the propellant’s composition influences the speed and distance the projectile can achieve. Understanding how these parts interact helps in grasping the complexities involved in ammunition design.

In summary, this visual representation encapsulates the essential elements and their respective functions, allowing for a deeper appreciation of the technology and craftsmanship behind each round.

Types of Bullets and Their Uses

Understanding the various forms of ammunition and their applications is essential for anyone involved in shooting sports, hunting, or self-defense. Each type of projectile is designed with specific characteristics that cater to distinct requirements, ensuring optimal performance in different scenarios.

| Type | Description | Common Uses |

|---|---|---|

| Full Metal Jacket (FMJ) | Characterized by a lead core encased in a harder metal shell, providing enhanced penetration. | Target shooting, military applications |

| Hollow Point (HP) | Designed with a hollowed-out tip that expands upon impact, increasing stopping power. | Self-defense, law enforcement |

| Soft Point (SP) | Features a soft lead tip that allows for controlled expansion upon impact. | Hunting, medium game |

| Wad Cutter | Flat-fronted design intended for clean cuts in paper targets, enhancing accuracy. | Target shooting, competitions |

| Armor Piercing (AP) | Constructed with hardened materials capable of penetrating armor and barriers. | Military, law enforcement |

Common Materials Used in Bullet Manufacturing

In the production of ammunition, various substances play a crucial role in ensuring reliability, performance, and safety. Each material is selected based on its properties, contributing to the overall effectiveness of the finished product. Understanding these components helps to appreciate the intricacies involved in creating high-quality ammunition.

| Material | Description | Function |

|---|---|---|

| Lead | A dense and malleable metal often used for the core. | Provides weight and stability during flight. |

| Brass | An alloy of copper and zinc, commonly used for casings. | Ensures durability and reliable extraction from the chamber. |

| Nickel | A corrosion-resistant metal used for plating. | Enhances the casing’s resistance to tarnishing and increases smooth feeding. |

| Copper | A highly conductive metal used for jackets. | Reduces barrel fouling and enhances aerodynamic properties. |

| Polymer | A synthetic material used for various components. | Reduces weight and can improve feed reliability in certain designs. |

Safety Considerations in Bullet Handling

Ensuring safety during the manipulation of ammunition is paramount for preventing accidents and promoting responsible usage. A thorough understanding of safety measures can significantly reduce risks associated with mishandling and improper storage. It is essential to implement strict protocols that prioritize the well-being of individuals and the environment.

General Safety Guidelines

- Always treat ammunition as if it is live, regardless of the situation.

- Keep firearms unloaded until ready to use, and ensure that no rounds are chambered during handling.

- Store ammunition in a cool, dry place, away from direct sunlight and sources of ignition.

- Use appropriate containers designed for storing ammunition to minimize the risk of accidental discharge.

- Keep ammunition out of reach of children and unauthorized individuals.

Handling Procedures

- Wear safety glasses and ear protection when working with firearms.

- Always follow the manufacturer’s instructions when loading and unloading.

- Be aware of your surroundings and ensure a clear path when moving or transporting ammunition.

- Check for any signs of damage or deterioration before use, and properly dispose of any compromised items.

- Report any incidents or concerns to the appropriate authorities immediately.

Maintenance Tips for Bullet Longevity

To ensure the durability and performance of your ammunition, it is essential to adopt a systematic approach to upkeep. Proper maintenance practices can significantly enhance the lifespan and reliability of your rounds, allowing for optimal performance when needed.

Regular Inspection: Frequently examine your ammunition for any signs of wear, corrosion, or damage. A thorough visual check can help identify potential issues before they affect functionality.

Storage Conditions: Store your rounds in a cool, dry place, away from direct sunlight and humidity. This environment helps prevent deterioration and maintains the quality of the materials used in manufacturing.

Handling with Care: Avoid dropping or mishandling your ammunition. Proper handling minimizes the risk of damage and ensures that each round remains in optimal condition.

Cleaning and Lubrication: Periodically clean your ammunition, especially after use. Use appropriate cleaning solutions to remove any residue and ensure that all components are functioning correctly. If necessary, apply a suitable lubricant to enhance performance.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance. This includes understanding the specific requirements for each type of ammunition, which can vary widely based on design and intended use.

By implementing these practices, you can significantly extend the life of your ammunition, ensuring reliability and effectiveness for years to come.

Advancements in Bullet Technology

The evolution of projectiles has seen remarkable innovations that enhance performance, precision, and safety. Researchers and engineers continually explore new materials and designs, aiming to create ammunition that meets the demands of modern applications, whether in defense, sport shooting, or hunting. This progress reflects a broader understanding of physics and materials science, leading to enhancements that improve efficiency and effectiveness.

Innovative Materials and Designs

Recent developments have introduced lighter and stronger materials, allowing for greater velocity and stability in flight. These advancements enable the creation of rounds that are not only more effective but also reduce recoil for a more manageable shooting experience. Additionally, the incorporation of aerodynamic shapes helps to minimize drag, resulting in increased accuracy over longer distances.

Smart Technology Integration

Another significant trend is the integration of smart technology into ammunition. Systems equipped with sensors can now provide real-time data, enhancing user awareness and decision-making. This technological leap allows shooters to adjust their strategies based on environmental conditions and performance feedback, ultimately leading to improved outcomes in various shooting scenarios.

As the industry continues to innovate, the focus remains on achieving a balance between performance, safety, and user experience, ensuring that advancements benefit enthusiasts and professionals alike.