In the realm of land management and earthmoving, a specific implement serves as an essential tool for achieving smooth and level surfaces. This device consists of various essential elements, each playing a crucial role in its overall functionality. Gaining insight into these components not only enhances operational efficiency but also aids in maintenance and repairs.

Every segment of this implement is designed to work in harmony, contributing to its ultimate effectiveness in soil preparation and grading tasks. From the structure that provides stability to the mechanisms that ensure precise adjustments, understanding each part’s function can significantly impact performance. This knowledge empowers operators to utilize the implement to its fullest potential.

Moreover, a detailed examination of these elements reveals their intricate relationships and the importance of proper alignment and maintenance. By delving into the specifics, users can make informed decisions, ultimately enhancing productivity and extending the lifespan of their equipment. This article aims to clarify the various components involved, offering a comprehensive look at their roles and significance.

Understanding Box Blade Components

The various elements that make up this essential agricultural tool play a crucial role in its functionality and efficiency. Each component is designed to work harmoniously, allowing users to achieve precise land leveling, grading, and other vital tasks. Familiarity with these elements not only enhances operational effectiveness but also aids in maintenance and repair.

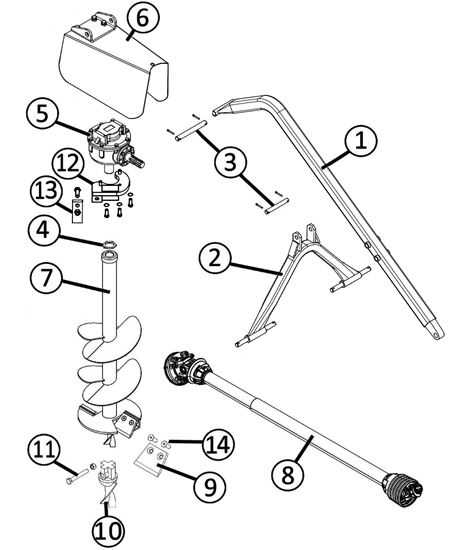

Main Elements

The main components of this implement include structural parts, attachments, and control mechanisms. Understanding their functions can help users optimize performance and adapt the tool to specific tasks.

| Component | Function |

|---|---|

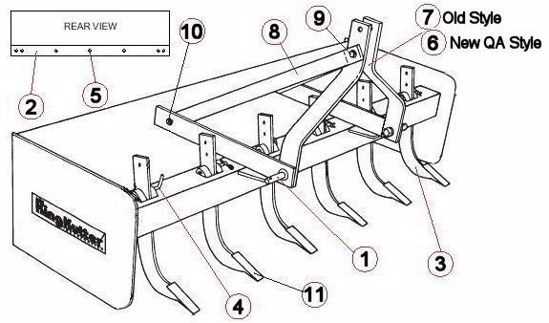

| Frame | Provides stability and support for the entire unit. |

| Shanks | Penetrate the ground for effective soil manipulation. |

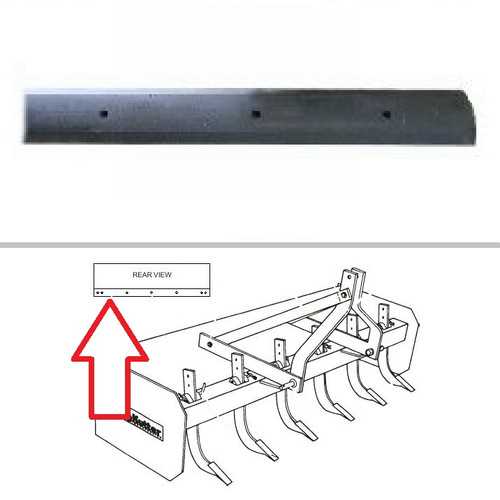

| Cutting Edge | Facilitates smooth cutting and grading of the soil. |

| Adjustable Rippers | Allow customization of depth for various soil types. |

Importance of Each Element

Each of these components contributes to the overall efficiency and versatility of the tool. Understanding their roles can significantly impact performance, ensuring that operators can tackle diverse projects with ease. Regular inspection and maintenance of these elements are essential for long-lasting functionality and optimal results.

Essential Parts of a Box Blade

Understanding the fundamental components of this agricultural tool is crucial for maximizing its effectiveness. Each element plays a specific role in achieving efficient land leveling and soil preparation. Familiarity with these key features will enhance both operation and maintenance, ensuring optimal performance in various tasks.

Main Structure

The primary framework serves as the backbone, providing stability and support during use. It is typically made from durable materials, capable of withstanding significant forces. This sturdy construction is vital for maintaining the integrity of the implement while performing demanding tasks in the field.

Working Elements

The working edges are designed to cut, grade, and reshape the terrain. Equipped with adjustable mechanisms, these components allow for precise depth control and angle adjustments. Properly maintaining these features is essential for achieving desired results and prolonging the lifespan of the tool.

Regular inspections and careful adjustments will ensure that each part functions harmoniously, leading to increased efficiency and productivity in soil management activities.

Functionality of Each Component

This section delves into the various elements that contribute to the overall efficiency and performance of the implement. Each component plays a vital role, working in harmony to achieve optimal results in land leveling, grading, and soil management.

Key Elements and Their Roles

Each section of the implement has a distinct function. For instance, the primary framework provides stability and support, ensuring that the implement can withstand rigorous use. The adjustable arms allow for versatility in height and angle, enabling the operator to adapt to different terrains and tasks.

Supporting Mechanisms

Additional features, such as the scraping edges, are designed to efficiently move soil and debris. These edges are crafted to endure wear while maintaining sharpness for effective cutting. Moreover, the connection system facilitates easy attachment and detachment from various machinery, enhancing usability and reducing downtime.

Overall, understanding the functionality of each component is essential for maximizing performance and ensuring longevity in the field.

Common Materials Used in Construction

In the realm of construction, various substances serve as the backbone for creating structures that stand the test of time. These materials, each with distinct properties, are carefully selected based on the requirements of a project. Understanding the diverse types available is essential for architects and builders alike.

Concrete is one of the most widely utilized materials, known for its strength and durability. This composite substance is made from a mixture of cement, water, and aggregates, providing a solid foundation for countless structures.

Steel, another popular choice, offers exceptional tensile strength and flexibility. It is often used in frameworks, reinforcing bars, and other applications where resilience is paramount.

Wood remains a timeless material, valued for its aesthetic appeal and ease of manipulation. It is frequently employed in residential buildings, providing warmth and character to spaces.

Brick is celebrated for its thermal properties and fire resistance. This classic material is often used in walls, offering both structural support and visual appeal.

Lastly, glass plays a crucial role in modern architecture, enhancing natural light and visual connectivity. Its use in facades and windows creates an inviting atmosphere while contributing to energy efficiency.

In summary, the selection of materials in construction significantly impacts the performance, sustainability, and aesthetic qualities of any building project. Each substance brings unique characteristics that cater to the varying demands of construction endeavors.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of your equipment. Regular attention to various components not only enhances performance but also prevents premature wear and costly repairs. By following a structured maintenance routine, you can ensure that your machinery remains in optimal condition.

Regular Inspections

Conduct frequent evaluations of all mechanical elements to identify any signs of wear or damage. Look for loose fittings, corrosion, and other potential issues. Early detection can save time and resources in the long run.

Lubrication Practices

Ensure adequate lubrication of moving parts to minimize friction and heat buildup. Use the appropriate lubricants as specified by the manufacturer and apply them regularly to maintain smooth operation and prevent breakdowns.

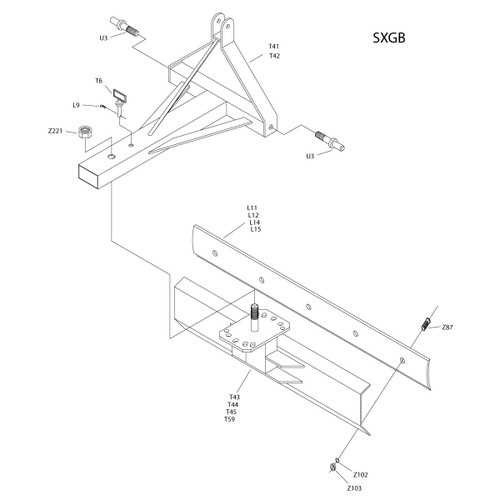

How to Assemble a Box Blade

Assembling this essential piece of equipment requires careful attention to detail and a clear understanding of its components. Proper assembly ensures optimal performance and longevity, allowing for effective ground leveling and grading tasks.

Follow these steps for a successful assembly:

- Gather all necessary tools and components.

- Identify each piece and review the assembly instructions.

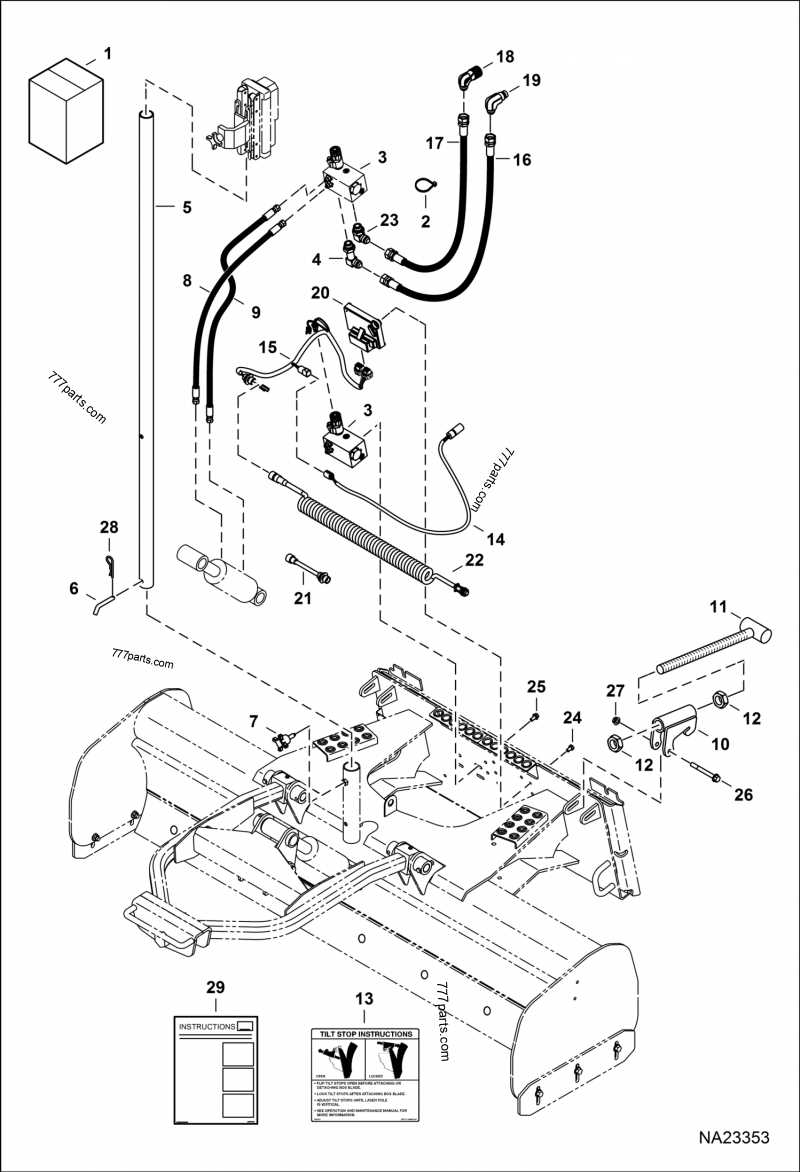

- Start by attaching the main frame:

- Align the support brackets with the frame.

- Secure them using bolts and washers.

- Position it at the appropriate angle.

- Use locking pins to secure it in place.

- Ensure all hoses are free of kinks.

- Attach hoses to the designated ports.

After assembly, perform a thorough inspection to confirm that everything is properly secured and functioning. Regular maintenance will prolong the lifespan of the equipment and enhance its efficiency during use.

Upgrades for Enhanced Performance

Improving the functionality of your equipment can significantly boost productivity and efficiency. By investing in various enhancements, users can achieve better results, making tasks easier and more effective. Below are some suggested modifications that can lead to superior performance.

- Enhanced Cutting Edges

- Adjustable Width Features

- Weight Distribution Enhancements

- Upgraded Attachments

- Improved Hydraulic Systems

Upgrading to high-quality cutting edges can provide improved durability and precision, ensuring a cleaner finish.

Incorporating adjustable components allows for versatility in handling different project sizes, adapting to various job requirements.

Modifying weight distribution can enhance stability, making it easier to manage heavy loads without compromising control.

Adding specialized attachments can expand the range of tasks that can be accomplished, from grading to leveling.

Investing in more efficient hydraulic systems can lead to quicker response times and better overall performance during operation.

These enhancements not only improve efficiency but also extend the lifespan of the equipment, ultimately leading to better return on investment.

Safety Considerations When Using

When operating heavy machinery designed for ground leveling and grading, it is crucial to prioritize safety. Awareness of potential hazards and implementing preventive measures can significantly reduce the risk of accidents. This section outlines essential safety practices to follow during use.

Pre-Operation Safety Checks

- Inspect the equipment for any signs of wear or damage.

- Ensure all safety guards and devices are in place and functioning.

- Verify that fluid levels, such as oil and hydraulic fluid, are adequate.

- Check that all fasteners and connections are secure.

Operating Procedures

- Always wear appropriate personal protective equipment, including gloves and safety glasses.

- Maintain a safe distance from bystanders and pets while operating the machinery.

- Follow the manufacturer’s guidelines for operation and maintenance.

- Be cautious of uneven terrain and obstacles that may pose risks during operation.

By adhering to these safety considerations, operators can ensure a safer working environment while effectively using their machinery.

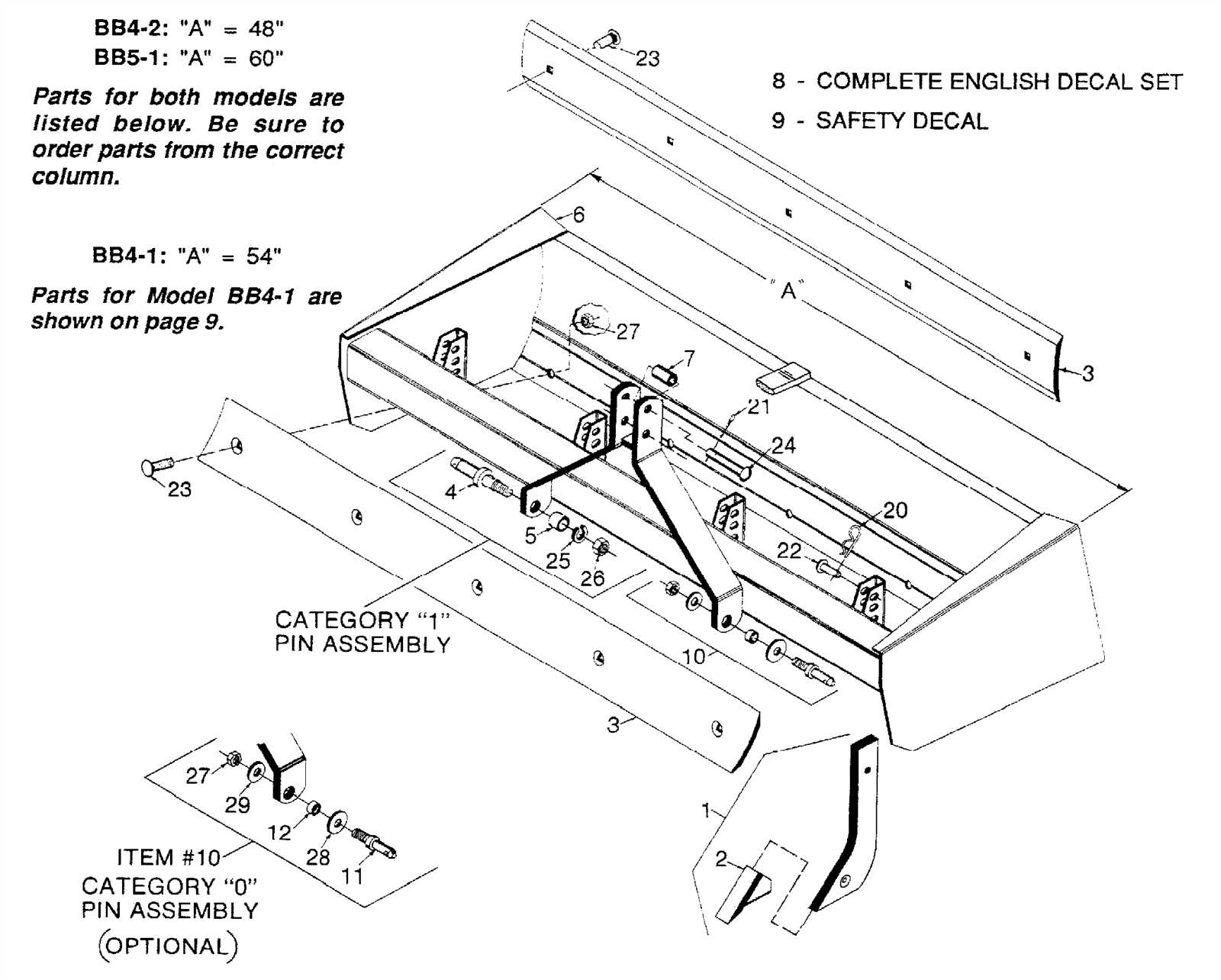

Comparing Different Box Blade Models

When it comes to land leveling and soil management, various equipment options offer unique features and capabilities. Understanding the differences among these implements can significantly impact performance and efficiency in various applications.

Key Features to Consider

- Construction Material: Different models use varying materials that affect durability and weight.

- Adjustability: Some implements provide more options for adjusting height and angle, enhancing versatility.

- Width Options: Available widths can influence the efficiency of large-scale operations versus smaller tasks.

- Weight Distribution: The design may affect how weight is distributed, impacting the ease of use and stability.

Popular Models

- Model A: Known for its robust construction and wide range of adjustments, ideal for heavy-duty tasks.

- Model B: Offers lightweight design, making it suitable for smaller tractors and easier maneuverability.

- Model C: Balances durability and weight, with specific features tailored for landscaping projects.

By evaluating these aspects, users can select the implement that best suits their needs, ensuring optimal performance for their specific projects.