The effectiveness of winter maintenance machinery heavily relies on the intricate assembly of its elements. Each component plays a crucial role in ensuring that operations run smoothly and efficiently. Familiarity with these elements not only aids in proper functioning but also enhances the overall performance of your equipment during harsh weather conditions.

When it comes to optimizing your snow management tools, recognizing the relationship between different parts is essential. Knowing how each piece interacts can prevent potential issues and extend the lifespan of your machinery. This knowledge empowers operators to make informed decisions regarding maintenance and repairs, ultimately leading to a more productive winter season.

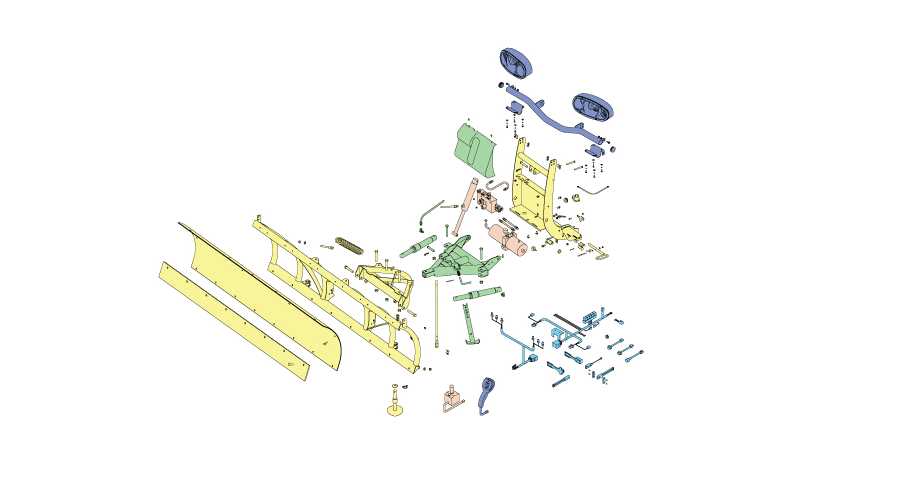

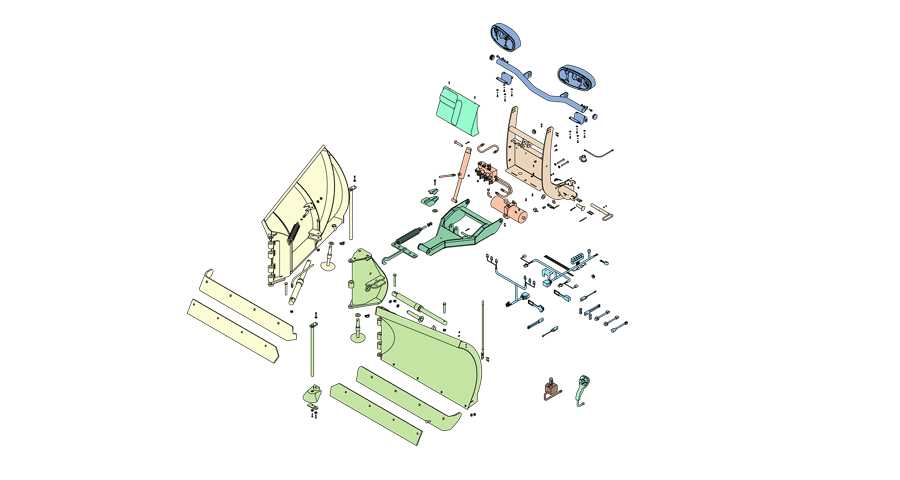

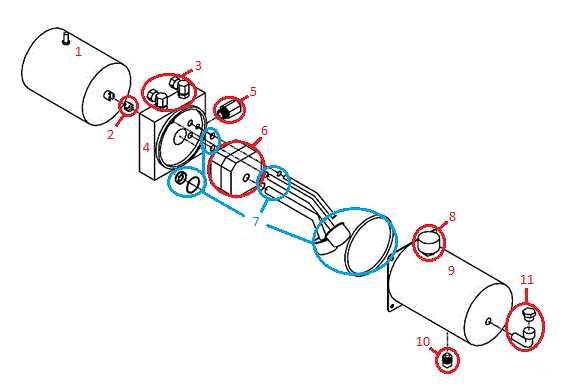

Additionally, having a visual representation of the machinery’s structure can be invaluable. Such illustrations provide clarity on how various components are arranged and can assist in troubleshooting and identifying necessary replacements. A comprehensive overview aids in understanding the complexity of your equipment, making it easier to address any challenges that arise.

Understanding Boss RT3 V Plow Components

When dealing with a snow-clearing attachment, it’s essential to grasp the various elements that contribute to its functionality and efficiency. Each component plays a significant role in ensuring optimal performance, allowing for seamless operation in challenging conditions. This section aims to break down the key features of such an implement, emphasizing their importance and interconnectivity.

Main Elements

- Blade Assembly

- Mounting Frame

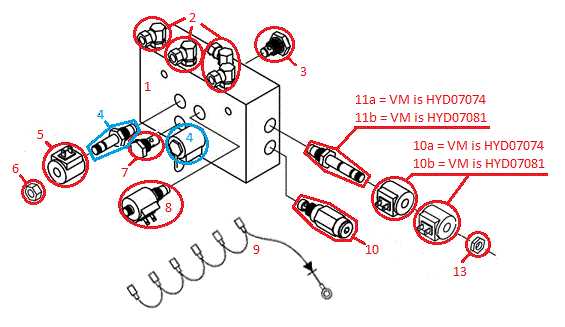

- Hydraulic System

- Control Mechanism

- Wear Shoes

- Blade Assembly: The primary interface with snow, designed for durability and efficiency.

- Mounting Frame: Connects the attachment to the vehicle, ensuring stability and strength during operation.

- Hydraulic System: Powers the movement and adjustments of the blade for versatility in varying conditions.

- Control Mechanism: Allows the operator to manipulate the angle and height of the blade easily.

- Wear Shoes: Protect the blade’s edge and enhance the lifespan by minimizing ground contact wear.

Understanding these components will aid in the effective maintenance and operation of the attachment, ultimately enhancing the clearing experience during winter months.

Essential Parts of Boss RT3 V Plow

When it comes to snow removal equipment, understanding the key components is crucial for optimal performance. Each element plays a significant role in ensuring efficiency and reliability during operation. Familiarizing yourself with these essentials can enhance your experience and extend the lifespan of your equipment.

Core Components

- Blade: The primary surface for clearing snow, designed for durability and effectiveness.

- Mounting Frame: Provides the necessary support and stability for the entire setup.

- Hydraulic System: Enables smooth lifting and angling of the clearing surface, allowing for versatility in different conditions.

- Controls: The interface used by the operator to maneuver and adjust the equipment with ease.

Additional Features

- Cutting Edge: A replaceable strip that enhances the blade’s ability to cut through snow.

- Wiring Harness: Ensures proper electrical connections between the components for functionality.

- Lights: Improve visibility during nighttime operations, enhancing safety.

- Skid Shoes: Protect the blade and surface underneath, preventing damage to pavements.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and assembly. Such illustrations provide a clear overview of individual elements, their relationships, and how they fit together within a larger system. Familiarizing yourself with these representations can streamline your repair or installation processes.

Key Elements to Identify

Begin by examining the various symbols and labels used in the illustration. Each component is typically marked with a unique identifier, often accompanied by a brief description. Colors and shapes can also convey important information regarding the type or category of each element, aiding in quick identification.

Reading Component Relationships

Pay attention to the connections and lines between different parts. These lines often indicate how components interact or are connected. Arrows might denote directionality or movement, while groupings can show which parts are associated or work together. Understanding these relationships is crucial for a successful assembly or repair.

Common Issues with Boss Plow Parts

When operating snow removal equipment, users often encounter a range of common challenges that can affect performance and reliability. Identifying these issues early can help maintain efficiency and prolong the lifespan of the machinery.

Mechanical Failures

One prevalent problem involves mechanical breakdowns, which can stem from wear and tear over time. Components such as hydraulic systems may develop leaks, leading to decreased functionality. Regular inspections are crucial to detect these issues before they escalate.

Electrical Malfunctions

Electrical issues are another significant concern, often manifesting as faulty wiring or connector problems. These malfunctions can disrupt communication between the control systems and the machinery, causing erratic behavior. Ensuring all electrical connections are secure can mitigate these risks.

Maintenance Tips for Plow Efficiency

Ensuring optimal performance during winter conditions requires attention to various components. Regular upkeep not only enhances functionality but also extends the lifespan of equipment, preventing costly repairs and ensuring reliable operation.

Routine Checks

- Inspect all moving components for wear and tear.

- Ensure hydraulic systems are free of leaks and operate smoothly.

- Check electrical connections for corrosion or damage.

Seasonal Preparation

- Clean and lubricate all parts before the first use of the season.

- Test functionality in dry conditions to identify any issues.

- Store equipment in a dry, sheltered area during off-season to prevent rust.

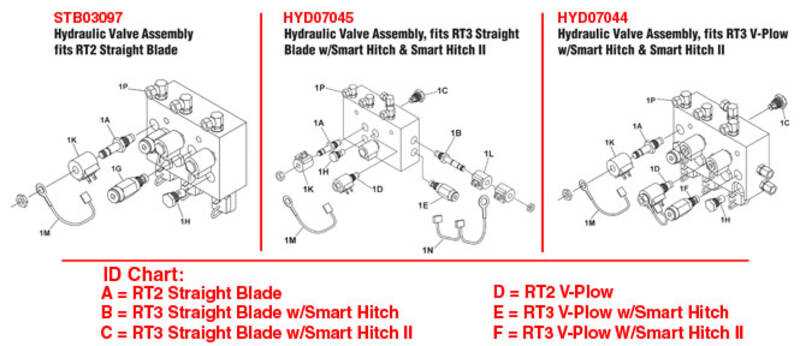

Identifying Replacement Parts Easily

Finding the correct components for equipment maintenance can be a straightforward task with the right approach. Understanding the essentials can streamline the replacement process and minimize downtime.

To enhance your identification skills, consider the following strategies:

- Refer to the owner’s manual for specific component details.

- Utilize online resources and community forums for shared experiences.

- Examine existing components for model numbers and labels.

- Keep a checklist of frequently replaced items for quick reference.

By employing these techniques, you can navigate the selection of essential elements with confidence and efficiency.

Comparing Boss RT3 with Other Models

This section delves into the differences and similarities between a specific model and its competitors. By examining various features, users can make informed decisions based on their unique needs and preferences.

When assessing different snow removal systems, several key aspects come into play:

- Performance: Evaluating the efficiency in various weather conditions and terrain types.

- Durability: Analyzing materials used and construction quality to determine longevity.

- Ease of Use: Considering the simplicity of installation and operation for users of all skill levels.

- Compatibility: Ensuring that the system works well with a variety of vehicles and accessories.

- Cost: Comparing initial investment versus long-term maintenance and performance value.

In the comparison, it is essential to look at:

- Design Features: Innovative designs can enhance functionality and user experience.

- Technology Integration: Modern systems often include advanced features for better control and efficiency.

- Customer Feedback: Real-world experiences provide valuable insights into the pros and cons of each model.

Ultimately, understanding these elements will help potential buyers choose the right system for their specific requirements, ensuring optimal performance and satisfaction during use.

Installation Guide for New Components

This section provides a comprehensive overview of how to properly install new elements within your system. Following these guidelines will ensure a seamless integration and optimal functionality of the new components, enhancing overall performance.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Review the manufacturer’s instructions to familiarize yourself with the specific requirements and procedures. Proper preparation is crucial for a smooth installation process.

Installation Procedure

Start by carefully removing any existing components that may interfere with the new elements. Ensure all connections are secure, and double-check alignment to prevent future complications. Once everything is in place, conduct a thorough inspection before finalizing the installation.

Resources for Plow Parts and Support

Finding reliable resources for components and assistance can greatly enhance your experience with snow management equipment. Access to accurate information and quality materials is essential for maintaining efficiency and safety during operation. This section highlights various avenues to explore for sourcing necessary items and expert guidance.

Online Resources

Numerous websites provide comprehensive catalogs, user manuals, and troubleshooting guides. These platforms often feature customer reviews, which can aid in making informed choices.

Local Dealers

Connecting with nearby suppliers can offer personalized service and immediate access to essential components. Local dealerships frequently have knowledgeable staff who can assist with inquiries and provide recommendations.

| Resource Type | Examples |

|---|---|

| Online Retailers | Amazon, eBay, specialized websites |

| Manufacturer Support | Official brand websites, customer service |

| Local Stores | Equipment dealers, hardware stores |