In the world of refreshing beverages, the intricacies of dispensing systems play a crucial role in delivering the perfect pour. Each component works harmoniously to ensure that liquid flows smoothly, maintaining quality and taste. This section aims to explore the essential elements that contribute to an efficient serving experience.

The significance of knowing the various elements involved cannot be overstated. From controlling the flow to maintaining cleanliness, every piece is designed with a specific function in mind. Delving into the functionality of these systems reveals how they enhance both user experience and beverage preservation.

Ultimately, understanding these components allows enthusiasts and professionals alike to appreciate the craftsmanship behind each pour. This knowledge not only improves the serving process but also fosters a deeper connection to the craft of beverage enjoyment.

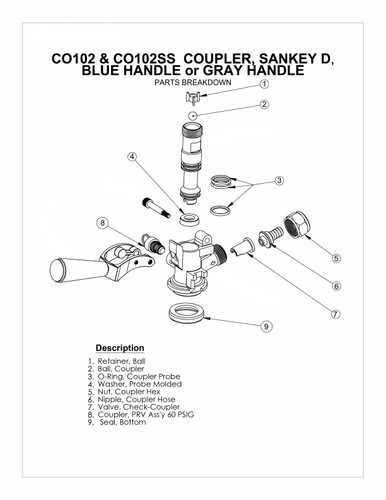

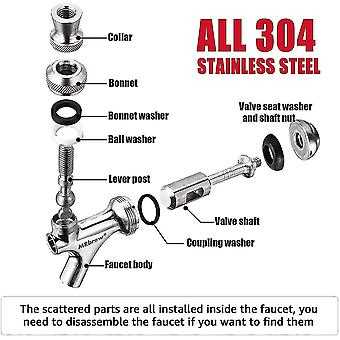

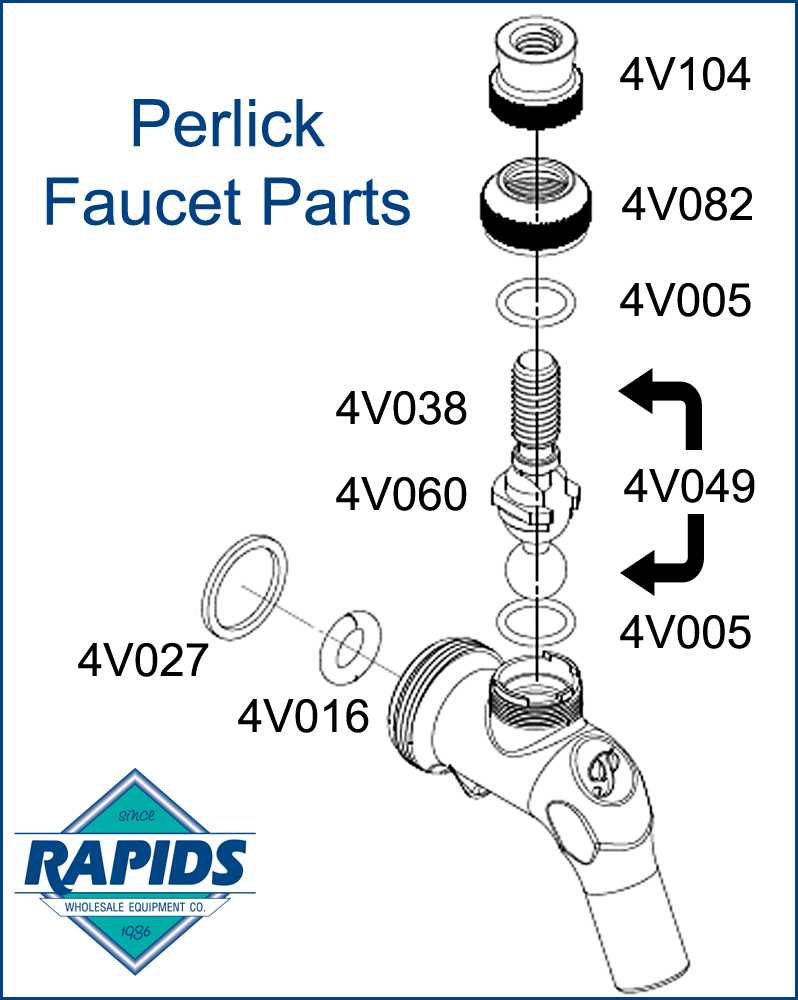

Understanding Beer Faucet Components

To appreciate the mechanics behind serving your favorite brew, it’s essential to explore the various elements that contribute to the overall functionality. Each component plays a significant role in ensuring a smooth and enjoyable pouring experience, enhancing both the flavor and presentation of the beverage.

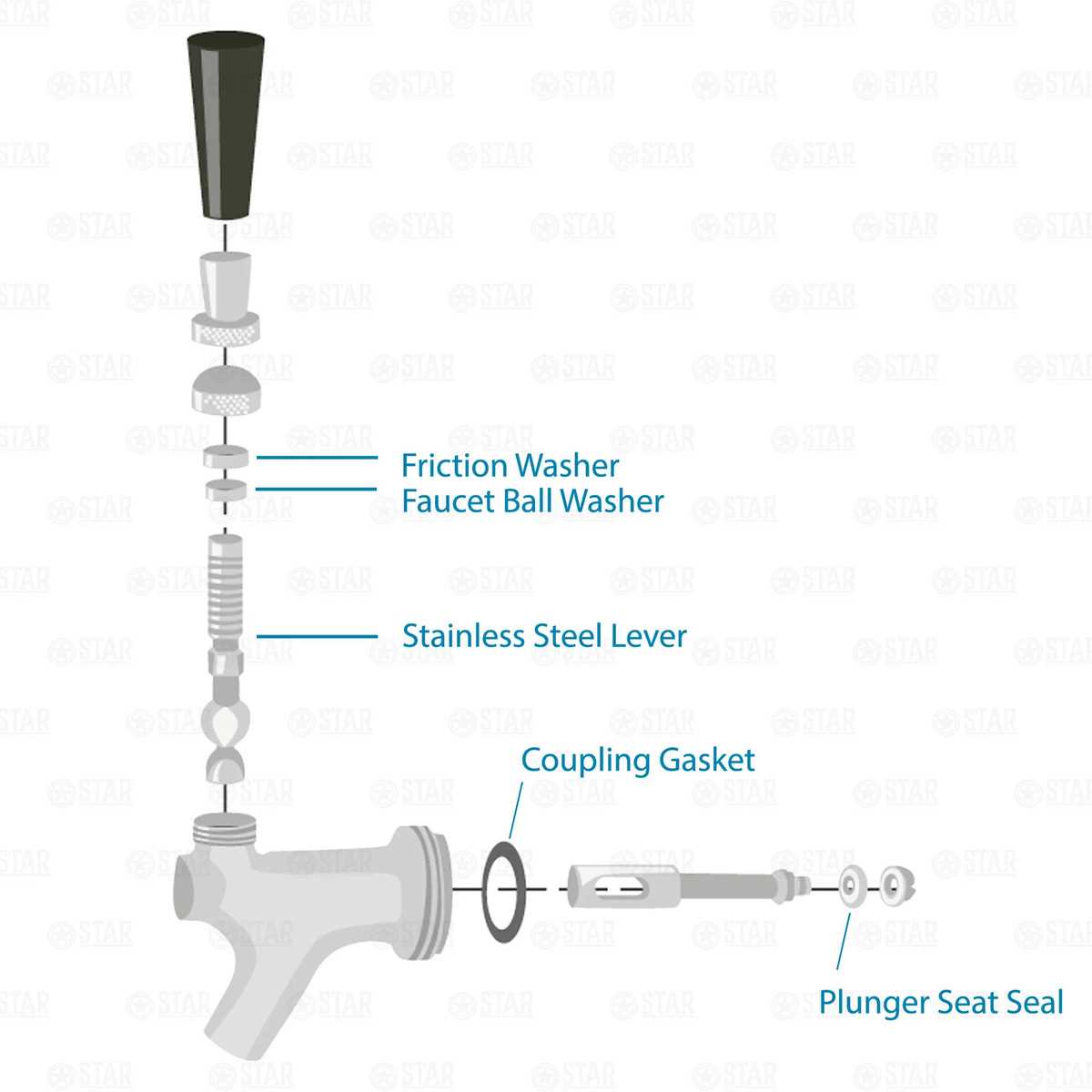

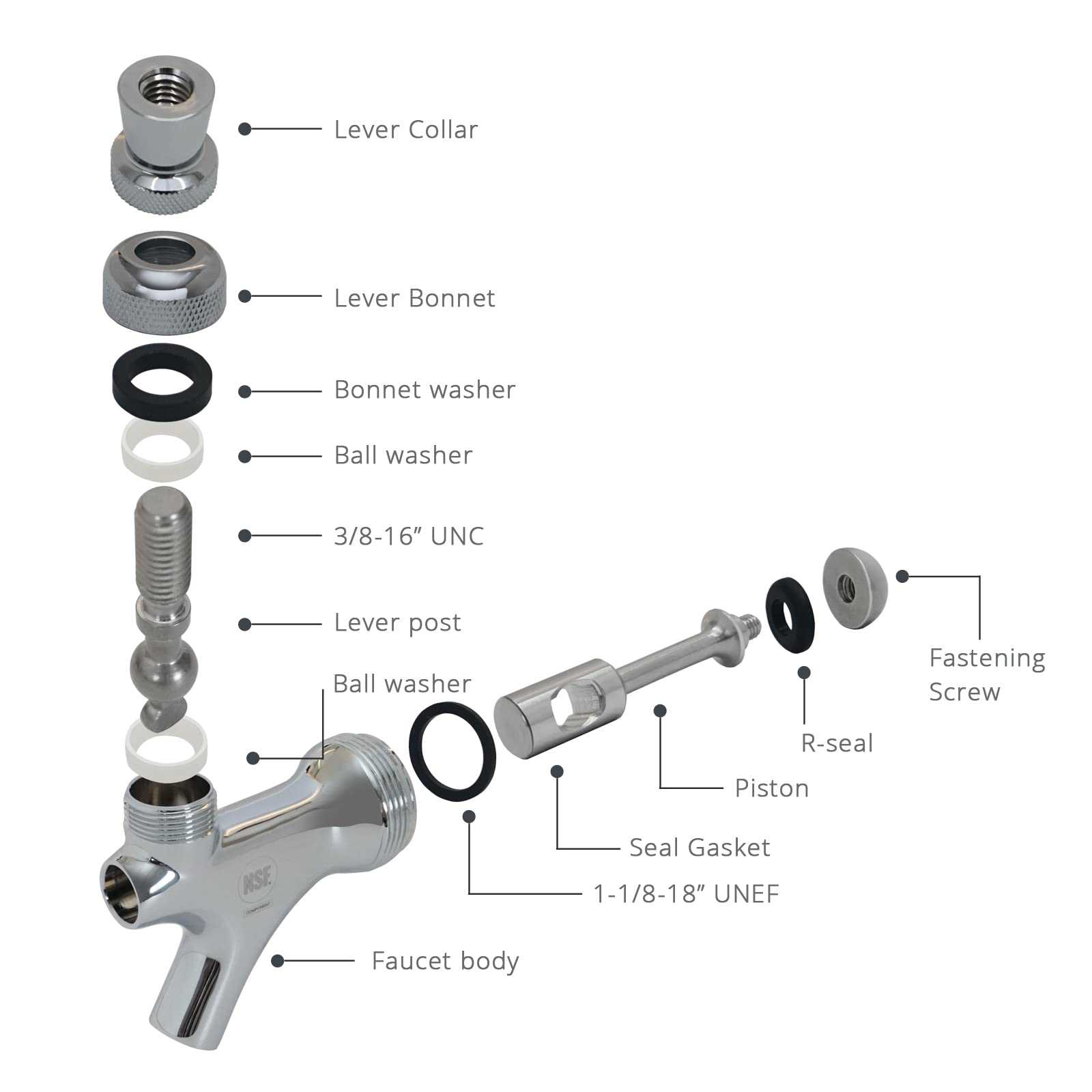

Key Components

- Handle: The lever that initiates the flow, providing control over the pouring process.

- Spout: The opening through which the liquid flows, often designed to create a perfect pour.

- Shank: The connecting piece that links the pouring mechanism to the storage container.

- Gasket: A sealing element that prevents leaks and ensures a tight fit between components.

Additional Elements

- Flow Control: Mechanisms that regulate the speed and volume of the liquid being dispensed.

- Spring: Provides tension to the handle, allowing it to return to its original position after use.

- Nut: A fastening component that holds various elements securely in place.

Understanding these components is vital for anyone interested in maintenance or improvement of their dispensing system, leading to better service and overall satisfaction.

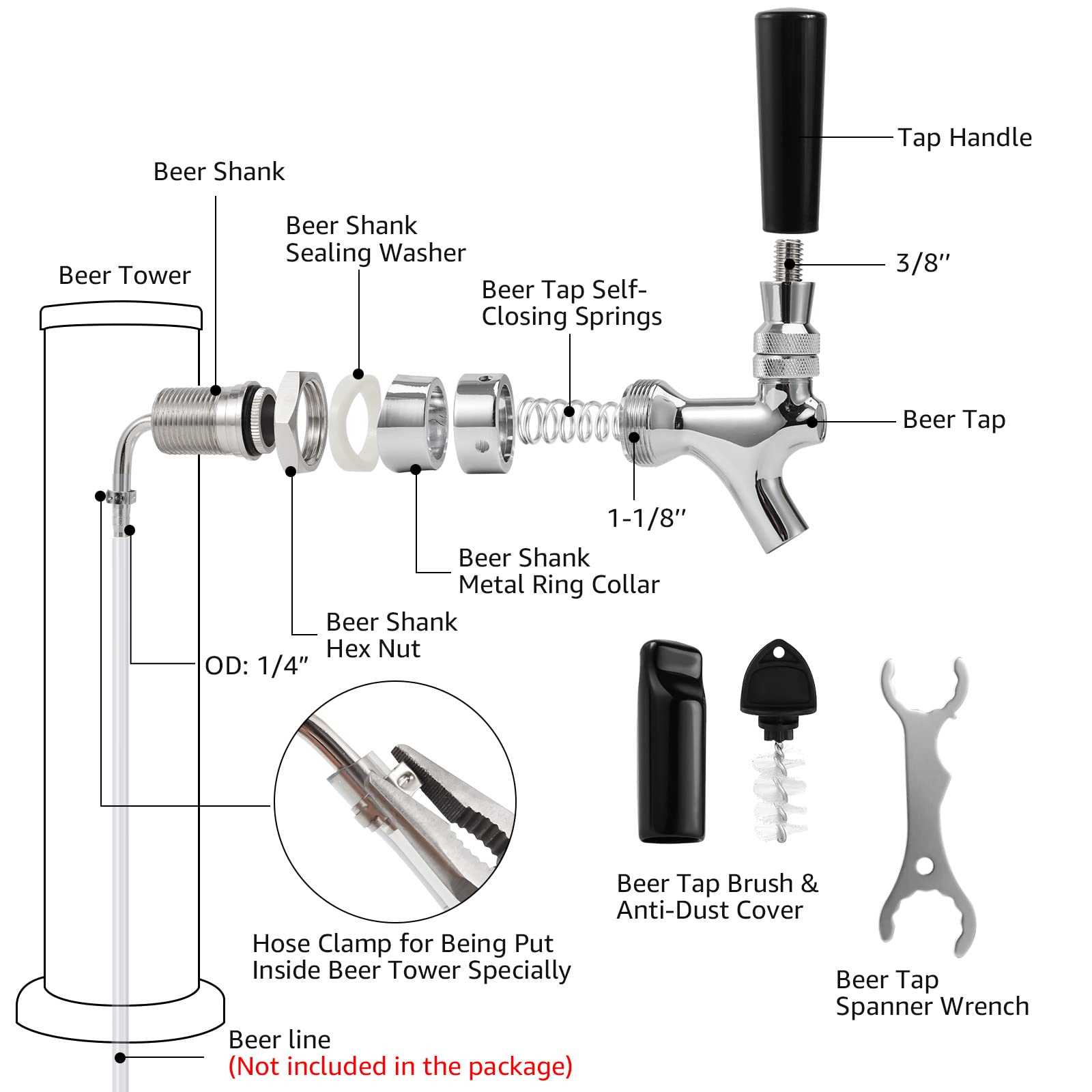

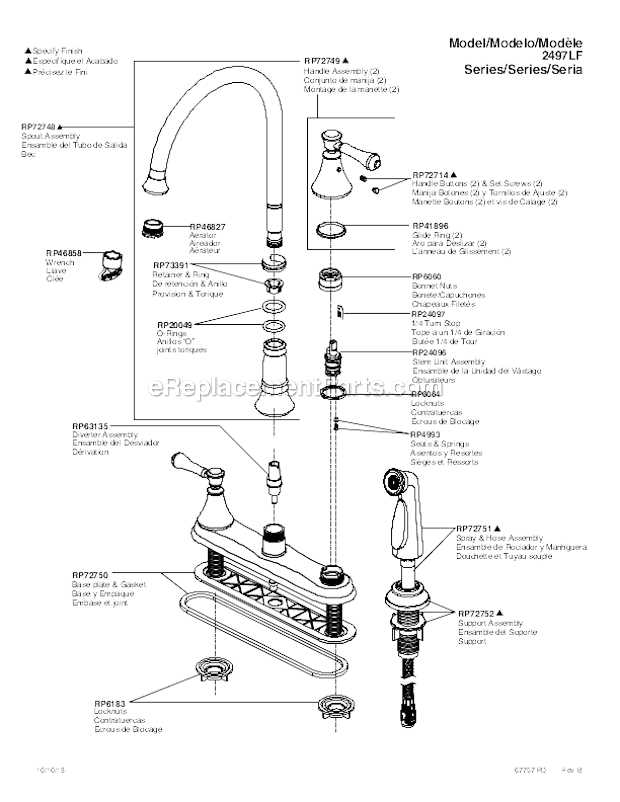

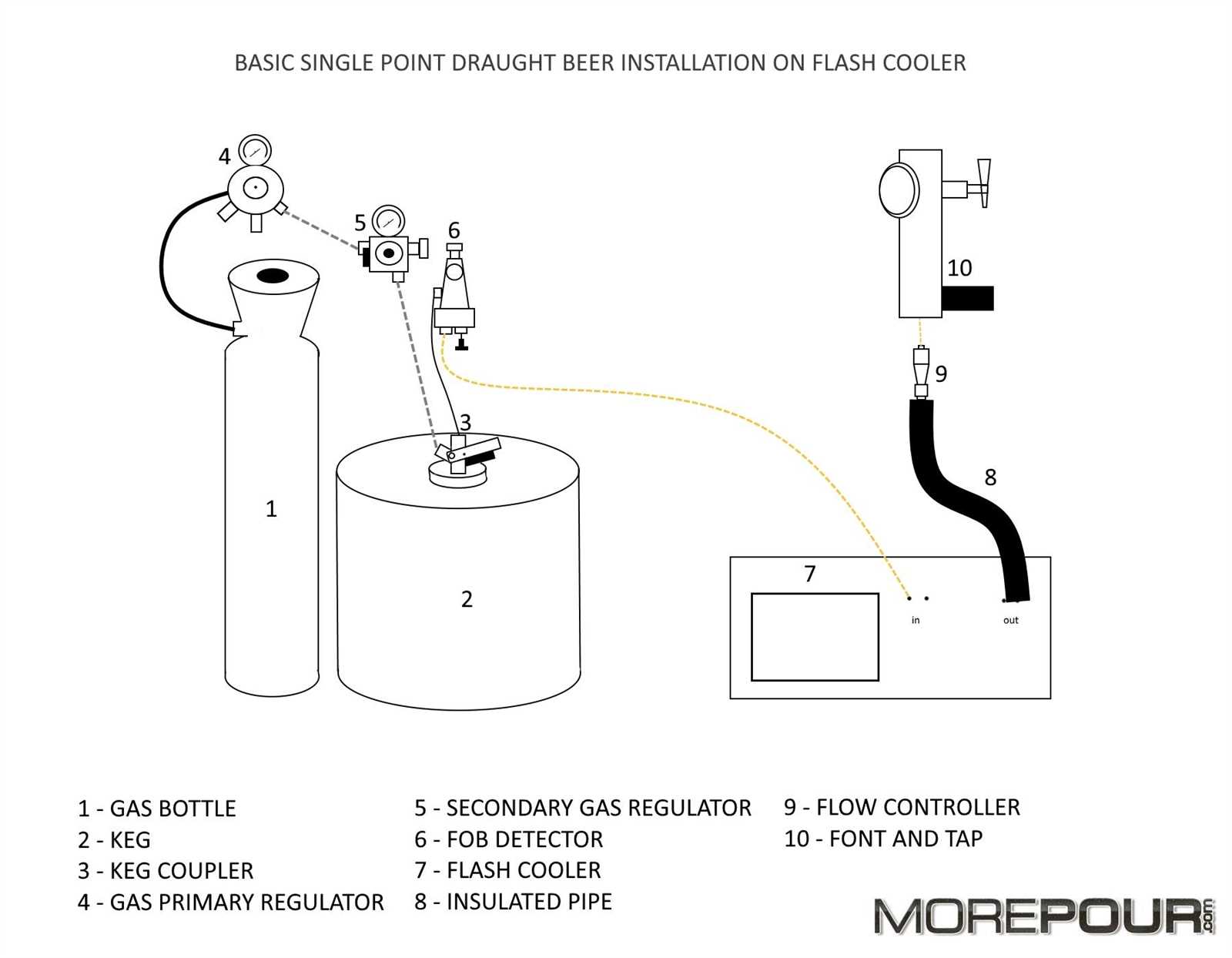

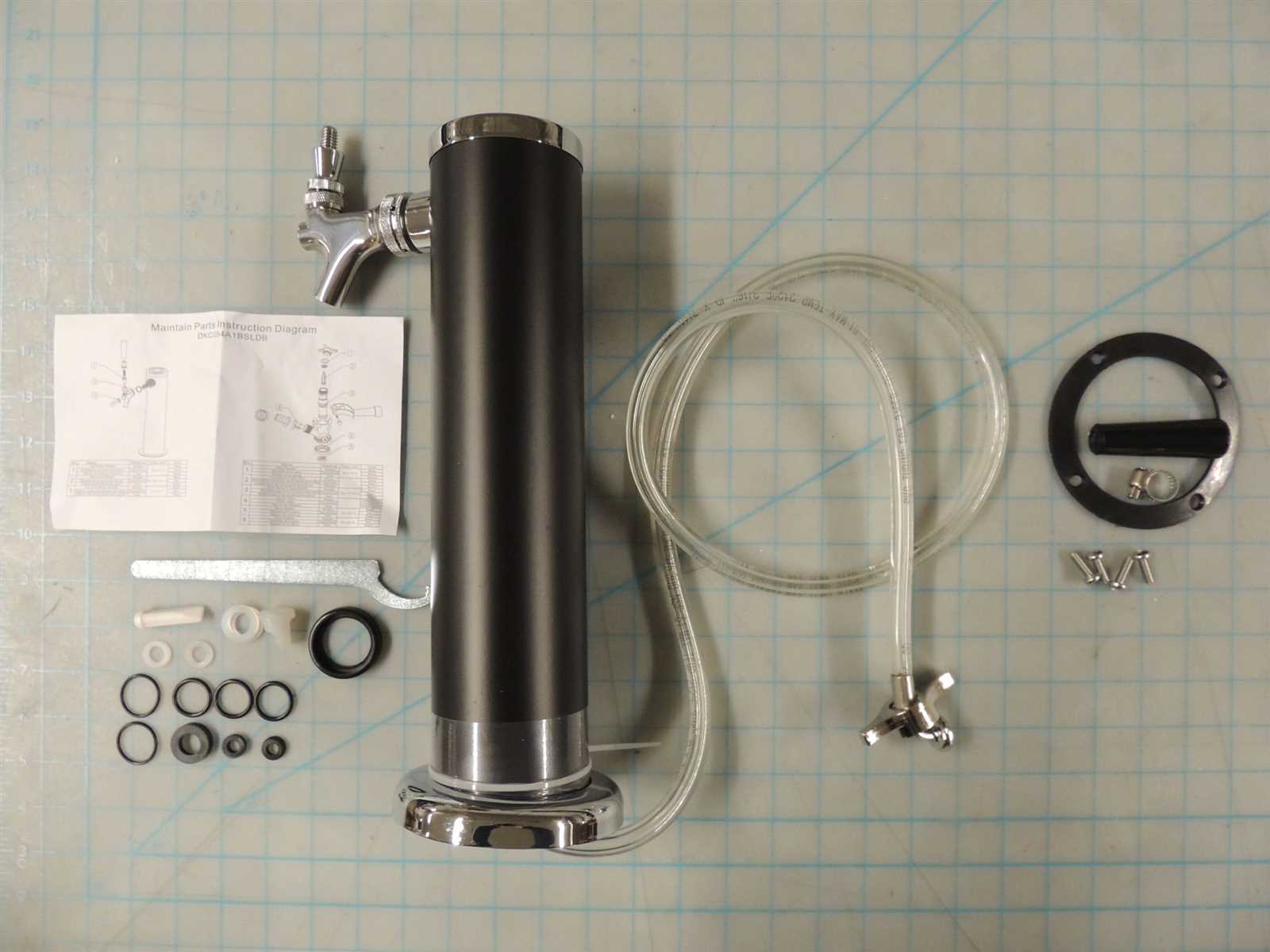

Essential Parts of a Draft System

A well-functioning dispensing setup is crucial for delivering a refreshing and enjoyable experience. Understanding the key components involved in this process can enhance the efficiency and quality of the product being served. Each element plays a significant role in ensuring that the liquid flows smoothly and retains its desired characteristics.

Key Components

At the heart of the system is the tap mechanism, which controls the flow and release of the beverage. Its design ensures that the liquid is dispensed properly, preventing spills and wastage. Another vital element is the keg coupler, which connects the storage vessel to the dispensing system, allowing for a seamless transfer of the product. These components work in tandem to create a reliable and user-friendly experience.

Supporting Elements

In addition to the primary components, several supporting elements are essential for optimal performance. Gas lines are necessary for maintaining the correct pressure, while temperature controls help keep the beverage at an ideal serving temperature. Together, these features ensure that each pour is consistent and of high quality, elevating the overall enjoyment of the experience.

How a Beer Faucet Works

This section explores the mechanics behind a dispensing system commonly used for pouring refreshing beverages. Understanding its functionality reveals how different components interact to deliver a smooth and enjoyable flow of liquid.

The system operates through a combination of pressure and gravity, allowing the drink to travel from a storage vessel to the serving point. Key elements work together to ensure that the liquid maintains its quality while being poured. Below is a table that outlines the main components involved in this process:

| Component | Function |

|---|---|

| Reservoir | Holds the beverage under pressure, ensuring it is ready for dispensing. |

| Shank | Connects the reservoir to the dispensing mechanism, providing a pathway for the liquid. |

| Handle | Controls the flow, allowing the user to start and stop the dispensing action. |

| Spout | Directs the beverage into the glass, ensuring a clean pour. |

| Seal | Prevents leaks and maintains pressure within the system. |

By coordinating these components, the system achieves an optimal pouring experience, enhancing the enjoyment of the drink served. Proper maintenance and understanding of each element’s role are crucial for consistent performance.

Maintenance Tips for Faucet Longevity

Proper upkeep is essential for ensuring the extended lifespan of your dispensing apparatus. Regular attention not only enhances performance but also prevents costly repairs over time.

Begin with routine cleaning to eliminate residue and buildup, which can impair functionality. Use gentle, non-abrasive cleaners to avoid damaging surfaces. Additionally, regularly inspect for leaks or drips, as these can lead to more significant issues if left unaddressed.

Lubricate moving components with food-safe products to ensure smooth operation and prevent wear. Make it a habit to check and replace washers and seals periodically, as these are often the first points of failure.

Finally, store your equipment in a dry, cool environment when not in use to protect against corrosion and degradation. Following these practices will ultimately help maintain optimal performance and prolong the lifespan of your dispensing system.

Common Issues with Beer Faucets

When it comes to serving a refreshing drink, certain challenges can arise that affect the overall experience. Understanding these common problems is crucial for ensuring optimal functionality and enjoyment. From flow inconsistencies to leaks, these issues can hinder the perfect pour.

Flow Problems

One frequent issue is inconsistent flow, which can be caused by various factors, including blockages or pressure imbalances. Identifying the root cause is essential for maintaining a smooth operation.

Leakage Issues

Leaks can significantly impact performance, leading to wasted product and frustration. Regular inspections and maintenance can help mitigate this problem.

| Issue | Potential Causes | Solutions |

|---|---|---|

| Inconsistent flow | Blockages, pressure issues | Check for obstructions, adjust pressure |

| Leaks | Worn seals, loose connections | Tighten fittings, replace seals |

Upgrading Your Beer Dispensing Setup

Enhancing your beverage serving arrangement can significantly improve the overall experience for both hosts and guests. By integrating superior components and optimizing functionality, you can achieve a more efficient and enjoyable pouring process. This guide will delve into the various options available for upgrading your system.

Key Components to Consider

When thinking about enhancements, it’s essential to focus on a few critical elements that can elevate your setup. The following table outlines some important upgrades along with their benefits:

| Component | Benefit |

|---|---|

| High-Quality Tap | Provides smoother flow and better control. |

| Cooling System | Maintains optimal temperature for a refreshing pour. |

| Line Cleaning Kit | Ensures cleanliness, improving taste and hygiene. |

| Pressure Regulator | Balances pressure for consistent pouring. |

| Customized Handles | Adds a personal touch and enhances aesthetics. |

Installation Tips

Proper installation is crucial for maximizing the benefits of your new components. Ensure that all connections are secure and that the system is thoroughly tested before use. Regular maintenance checks can also help identify any issues early, ensuring a seamless experience for everyone involved.

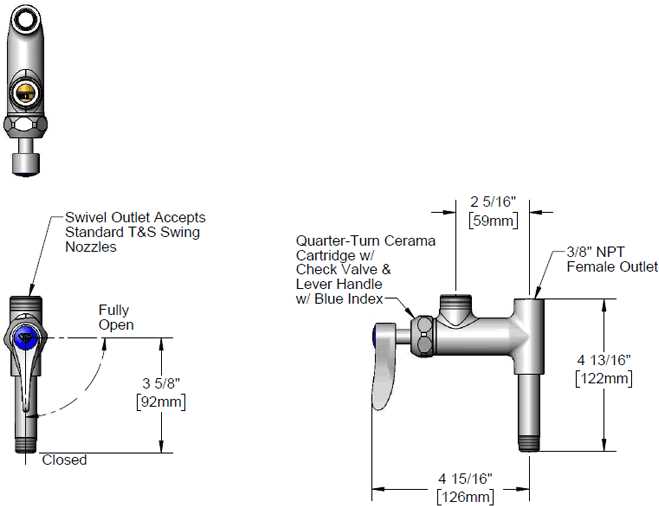

Choosing the Right Faucet Type

Selecting the appropriate dispensing mechanism is crucial for enhancing the overall experience of enjoying your favorite beverages. With various options available, understanding the unique characteristics and functionalities of each type can significantly impact the quality and presentation of the drink served. This decision not only affects the taste but also the aesthetics and convenience of use.

Types of Dispensing Mechanisms

There are several styles to consider, each catering to different preferences and serving environments. Traditional designs offer reliability and simplicity, while more modern variants may provide advanced features such as temperature control or ease of cleaning. It’s essential to assess your specific needs, whether for home use, a bar, or a commercial setting, to determine which design best suits your requirements.

Factors to Consider

When choosing a dispensing solution, consider factors like material, maintenance, and compatibility with your setup. Stainless steel options are popular for their durability and easy upkeep, while plastic alternatives may be lighter and more cost-effective. Additionally, evaluate how the selected model integrates with your existing infrastructure, ensuring a seamless experience for both you and your guests.

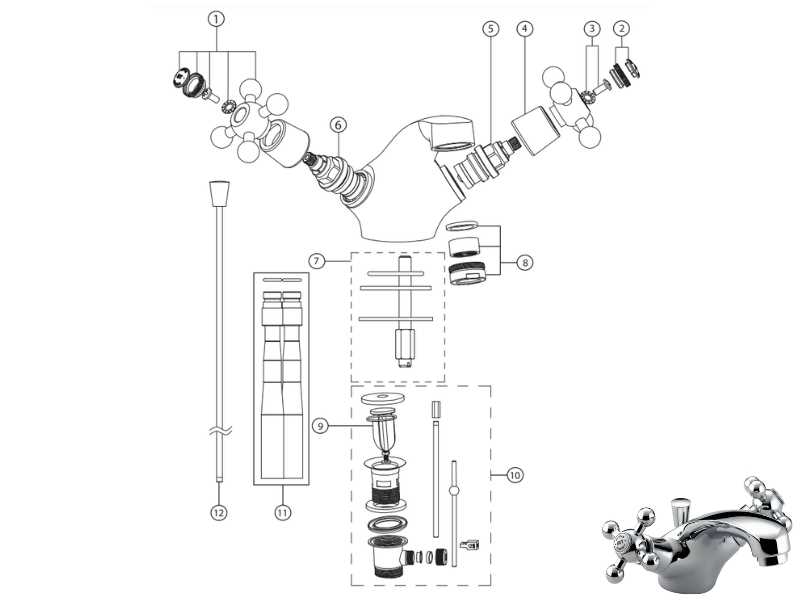

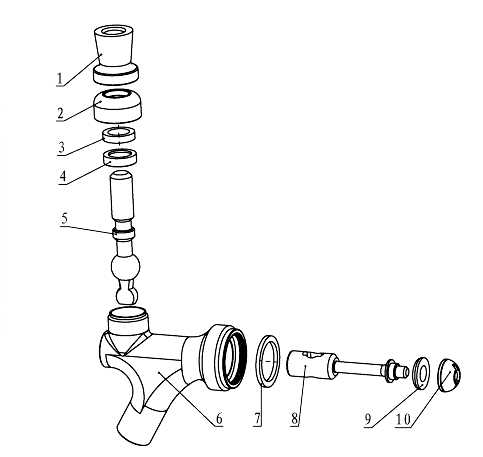

Cleaning Procedures for Beer Faucets

Maintaining cleanliness in your dispensing system is essential for ensuring optimal performance and taste quality. Regular sanitation helps prevent the buildup of residue, which can affect flavor and hygiene. This section outlines effective methods for keeping your dispensing apparatus in top condition.

Step 1: Gather Your Supplies

Before beginning the cleaning process, collect all necessary materials. You will need a suitable cleaning solution, brushes designed for intricate components, and a clean cloth. Ensure that all items are free from contaminants.

Step 2: Disassemble the System

Carefully remove the components that require cleaning. Pay attention to the order of disassembly to facilitate easy reassembly later. This step is crucial for accessing hard-to-reach areas where residue may accumulate.

Step 3: Soak Components

Submerge the removed elements in a cleaning solution for the recommended duration. This allows the solution to penetrate and loosen any stubborn deposits. Ensure that the solution is compatible with the materials to avoid damage.

Step 4: Scrub Thoroughly

Using the brushes, scrub each component to remove remaining debris. Focus on crevices and joints where buildup is most likely to occur. Rinse thoroughly with clean water after scrubbing to eliminate any cleaning agent residue.

Step 5: Reassemble and Sanitize

Once all parts are dry, carefully reassemble the system. After reassembly, perform a sanitation process to ensure that all surfaces are free from harmful microorganisms. This step is vital for maintaining a safe and enjoyable experience.

Step 6: Regular Maintenance

Establish a routine cleaning schedule to keep your dispensing system in excellent condition. Regular maintenance not only enhances performance but also prolongs the lifespan of the equipment.

Benefits of High-Quality Faucets

Investing in superior dispensing mechanisms offers numerous advantages that enhance the overall experience for both users and establishments. Quality craftsmanship ensures longevity, reliability, and satisfaction, making it a smart choice for anyone looking to optimize their serving solutions.

Durability and Longevity

High-end dispensing solutions are built to withstand the rigors of frequent use. Here are some key points regarding their durability:

- Resistant to wear and tear from regular operation.

- Less prone to leaks, reducing maintenance needs.

- Manufactured with premium materials that enhance lifespan.

Enhanced User Experience

Quality mechanisms contribute significantly to the overall user satisfaction. Consider the following benefits:

- Consistent flow rates ensure optimal serving conditions.

- Smooth operation minimizes user frustration.

- Appealing design enhances the aesthetic of any setting.

In summary, selecting superior dispensing equipment not only boosts efficiency but also elevates the overall quality of service provided.