In the realm of high-performance machinery, grasping the intricate workings of key elements is crucial for effective maintenance and repair. Each component plays a pivotal role in the overall efficiency and functionality of the system, ensuring optimal performance under various conditions.

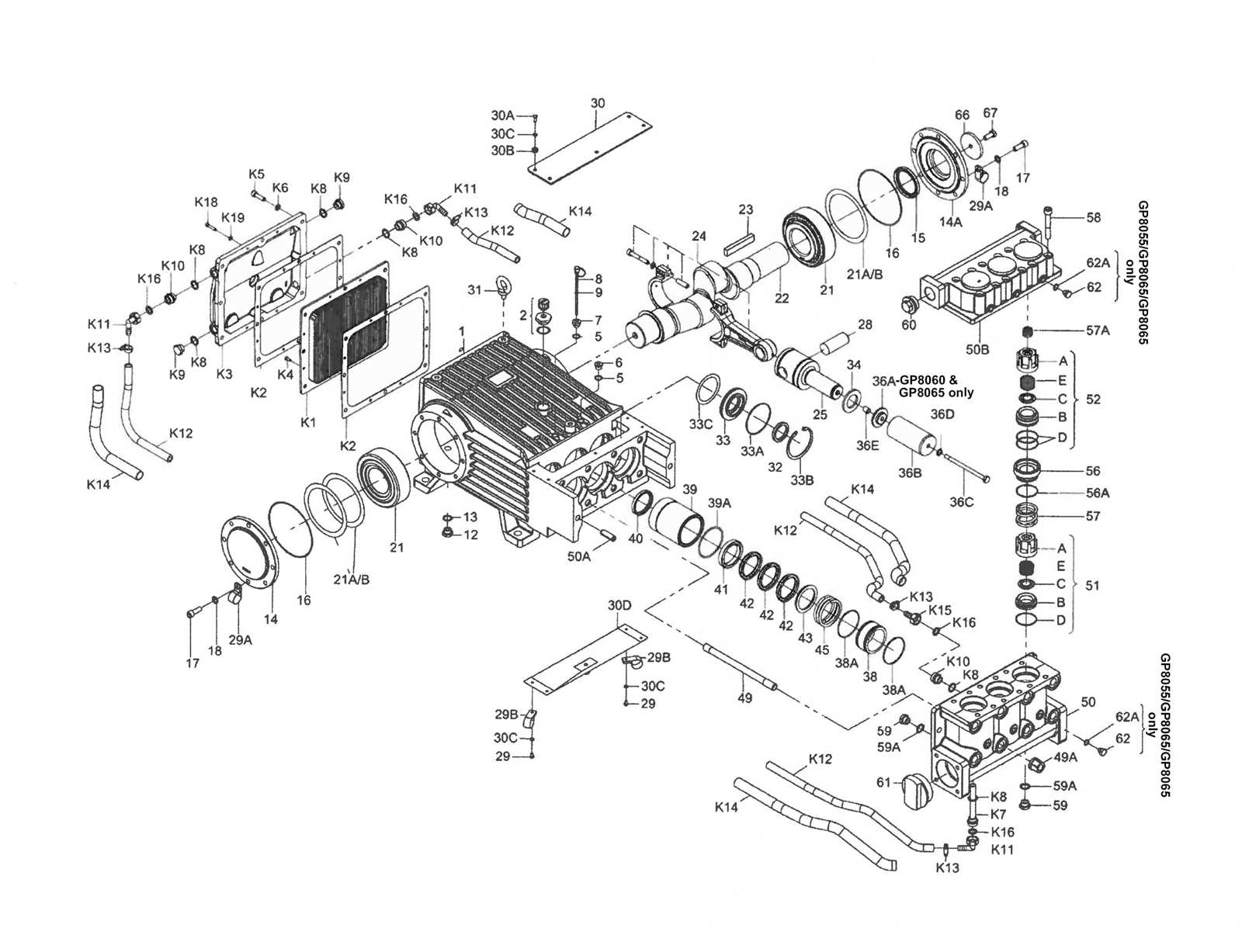

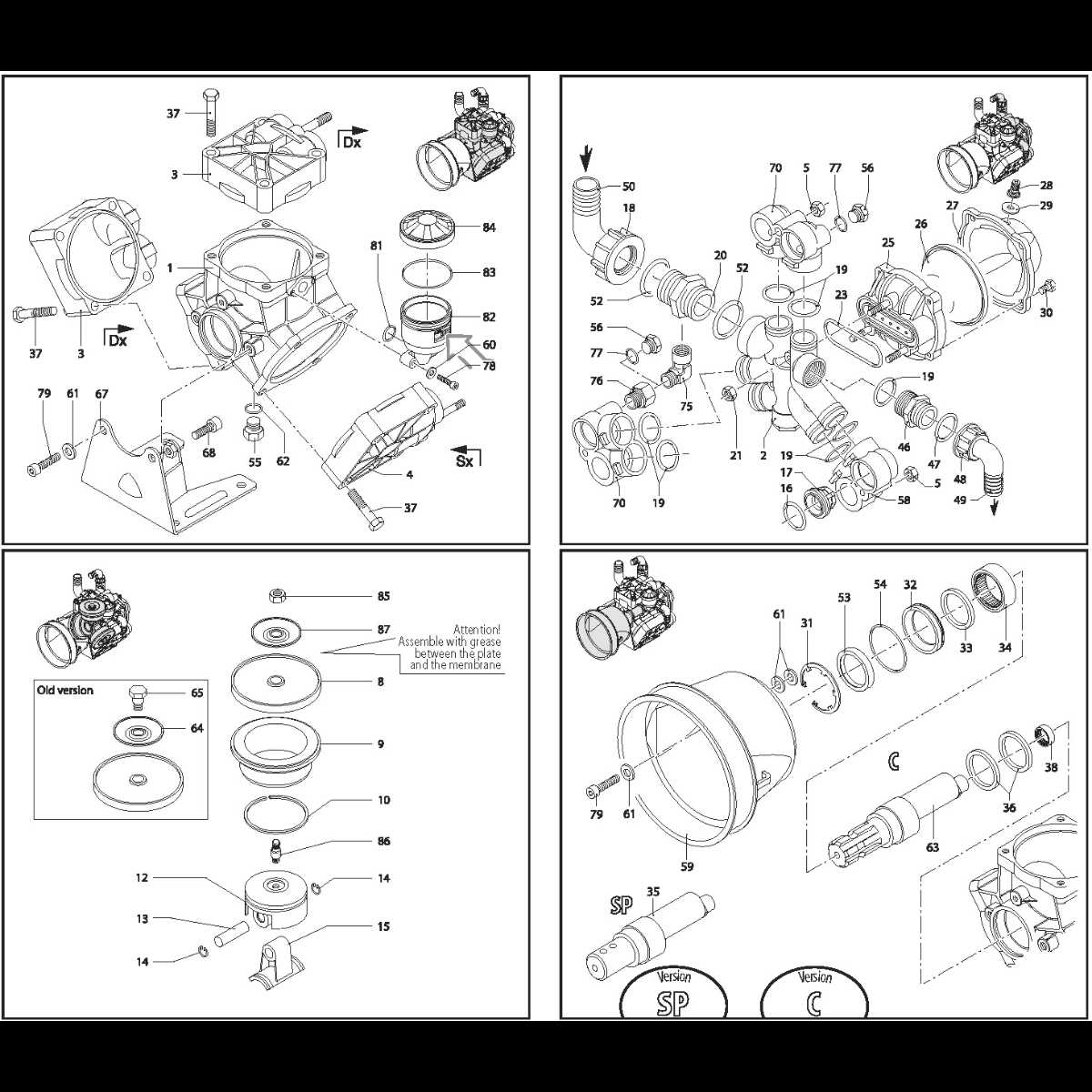

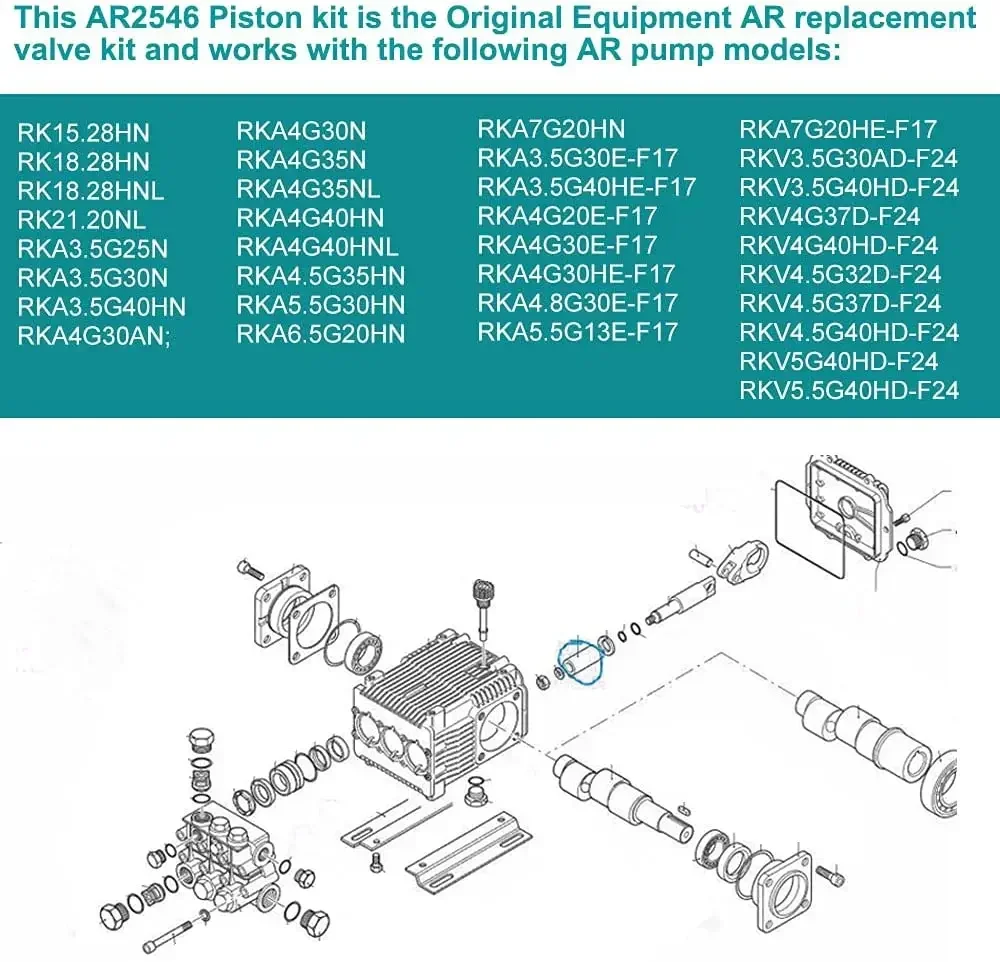

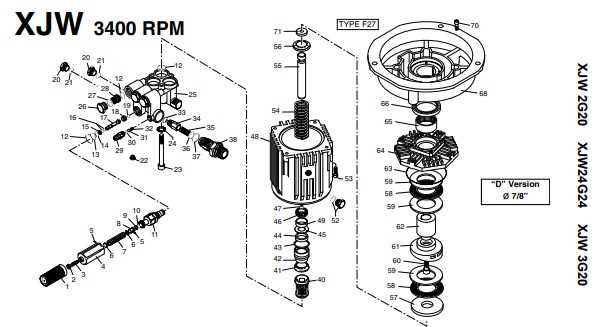

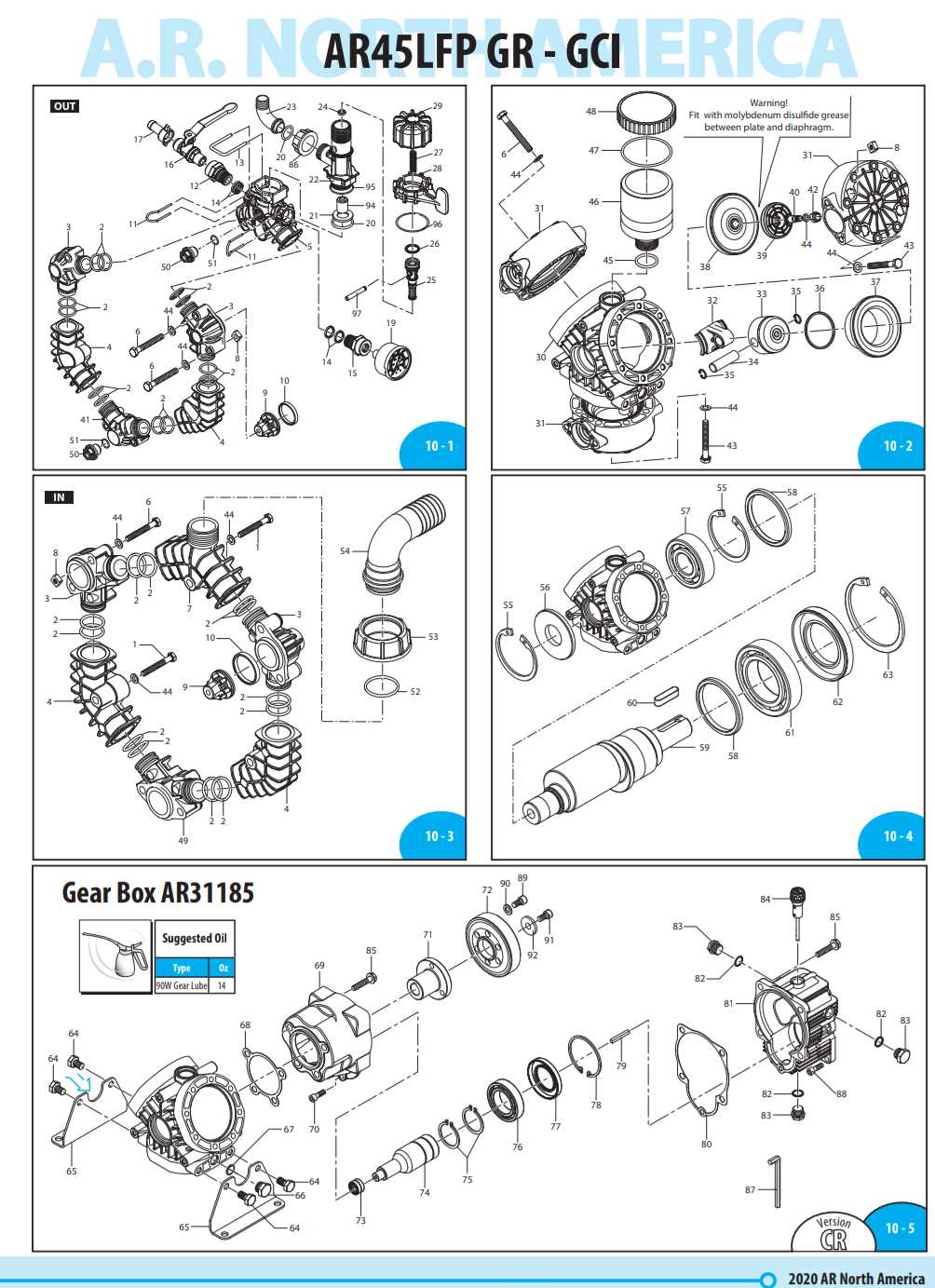

Visual representations of these crucial elements provide invaluable insight, allowing users to easily identify and understand the relationships between each piece. Such illustrations can greatly enhance one’s ability to troubleshoot and execute repairs effectively.

By exploring these essential components in detail, one can ultimately achieve a deeper comprehension of the system’s operations. This knowledge empowers users to maintain equipment with confidence, ensuring longevity and reliability in performance.

Understanding Annovi Reverberi Pumps

This section aims to provide insight into the functioning and design of high-performance fluid transfer systems. These devices are essential in various applications, from industrial uses to home cleaning solutions, where reliable and efficient operation is crucial.

At the core of these systems is a sophisticated mechanism designed to generate pressure and facilitate the movement of liquids. Understanding the components and their interactions is vital for anyone looking to maintain or troubleshoot these machines effectively.

Each unit typically comprises several key elements, including the motor, which drives the mechanism, and the housing that protects the internal workings. The integration of these components ensures optimal performance and longevity, making knowledge of their functions important for users.

Regular maintenance and awareness of potential issues can greatly enhance the lifespan of these systems. Familiarity with the assembly and operation principles allows users to perform necessary repairs and adjustments, ensuring consistent efficiency over time.

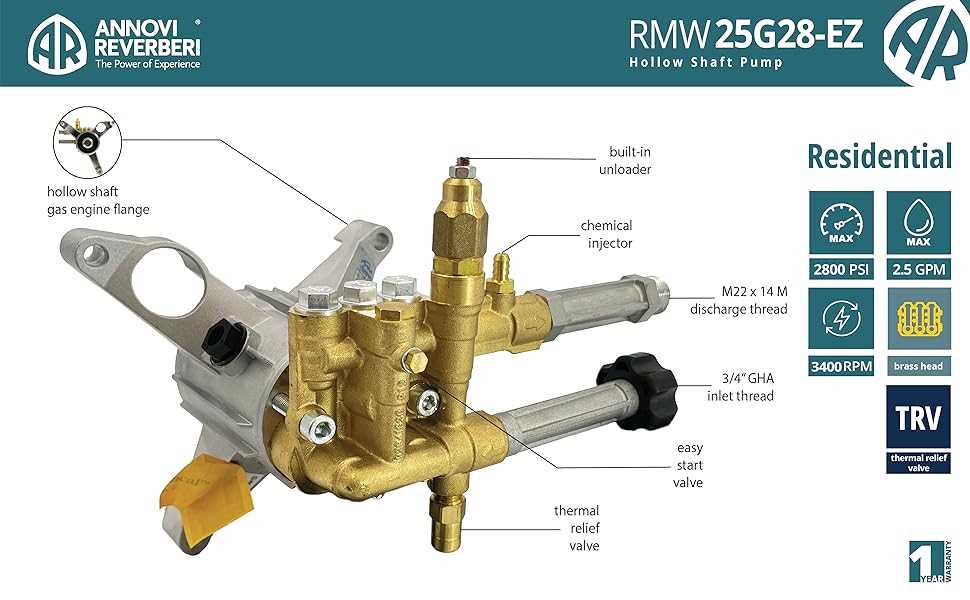

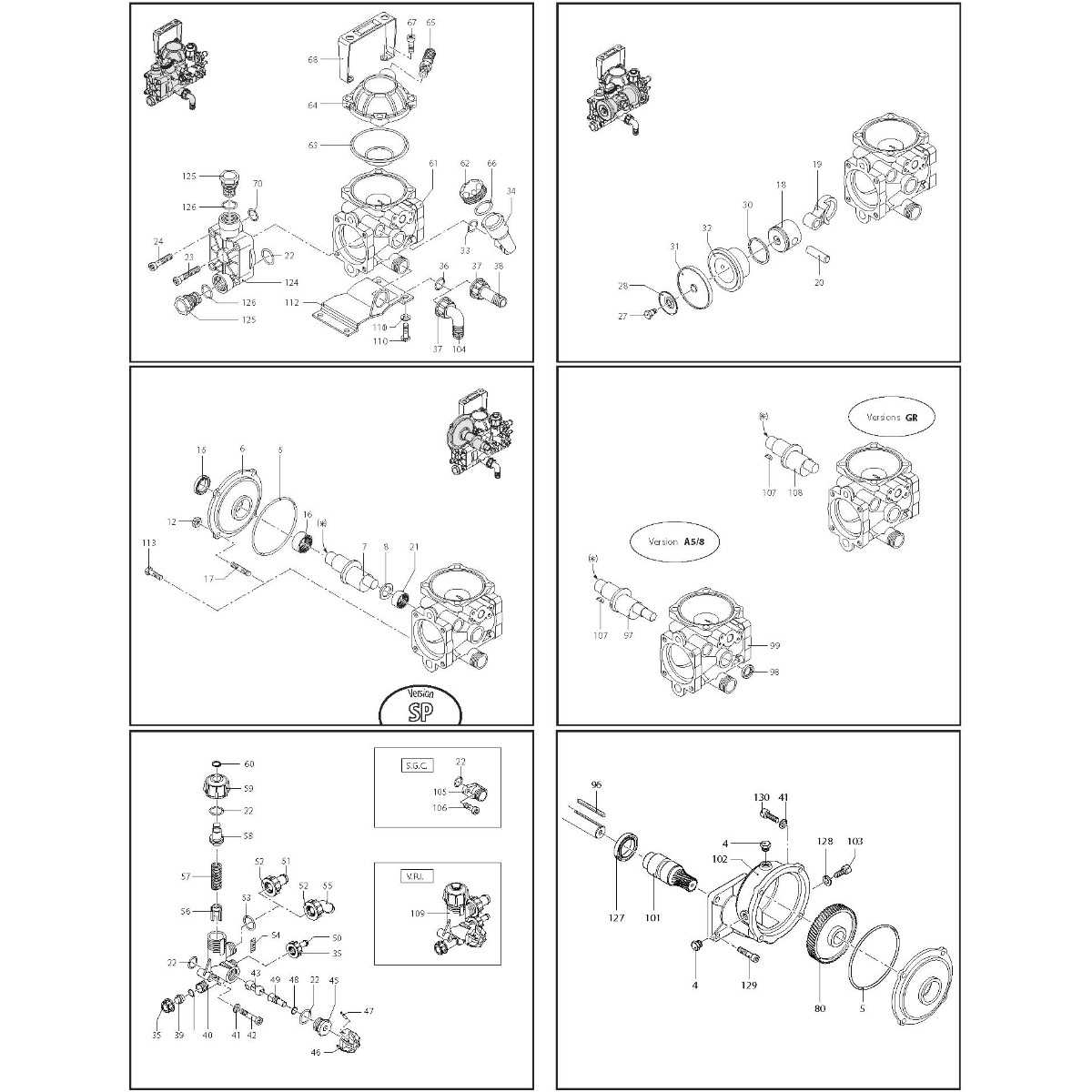

Key Components of Annovi Reverberi Pumps

Understanding the essential elements of these high-pressure devices is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring the overall functionality and durability of the equipment.

Cylinders serve as the heart of the system, where fluid is compressed and directed. The quality of the materials used in their construction directly influences performance and longevity.

Valves regulate the flow of liquids, ensuring optimal pressure management. These mechanisms must be both durable and precise to prevent leaks and ensure consistent operation.

Pistons are responsible for converting mechanical energy into hydraulic energy, making their design vital for effective fluid movement. Their compatibility with the surrounding components is key to achieving desired pressure levels.

Seals maintain the integrity of the system by preventing leaks and protecting internal parts from contamination. Regular inspection and replacement of seals are essential for maintaining efficiency.

Connecting rods link the pistons to the motor, transferring force and enabling the cyclic motion that drives fluid through the system. Their strength and flexibility are crucial for reliable performance.

By recognizing the importance of each of these elements, users can enhance the longevity and efficiency of their equipment, ensuring optimal performance for a variety of applications.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of machinery relies heavily on regular upkeep. Neglecting maintenance can lead to performance issues, increased wear and tear, and ultimately costly repairs. A systematic approach to care not only enhances the functionality of the equipment but also maximizes its lifespan.

Routine checks and timely replacements of essential components are crucial in preventing minor problems from escalating into major failures. This proactive strategy helps in maintaining optimal performance, reduces downtime, and ensures that the equipment operates safely and reliably. Additionally, proper maintenance can lead to significant savings in operational costs, as efficient machines consume less energy and require fewer resources.

Moreover, a well-maintained system fosters confidence among users and stakeholders. When equipment functions at peak efficiency, it enhances productivity and contributes to a smoother workflow. Investing in regular maintenance is not merely a choice but a necessity for anyone aiming to achieve sustained success in their operations.

Common Issues and Solutions

In the realm of high-pressure fluid devices, users may encounter various challenges that can hinder performance. Identifying these issues and implementing effective solutions is crucial for maintaining optimal functionality. This section outlines frequent problems along with practical remedies to enhance reliability.

Frequent Problems

| Issue | Description |

|---|---|

| Low Pressure | This can occur due to blockages or leaks within the system, leading to insufficient output. |

| Unusual Noises | Strange sounds may indicate mechanical wear or misalignment, which could compromise efficiency. |

| Overheating | Excessive heat often results from inadequate lubrication or prolonged operation without rest. |

Effective Solutions

| Problem | Recommended Action |

|---|---|

| Low Pressure | Check for obstructions in hoses and fittings; replace any damaged components. |

| Unusual Noises | Inspect and tighten all fasteners; replace worn parts as necessary. |

| Overheating | Ensure adequate lubrication is applied; allow for regular breaks during operation. |

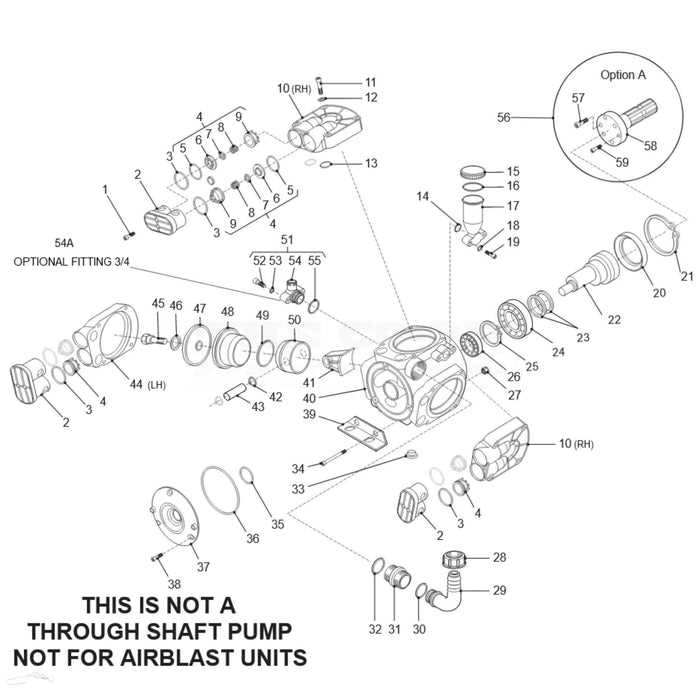

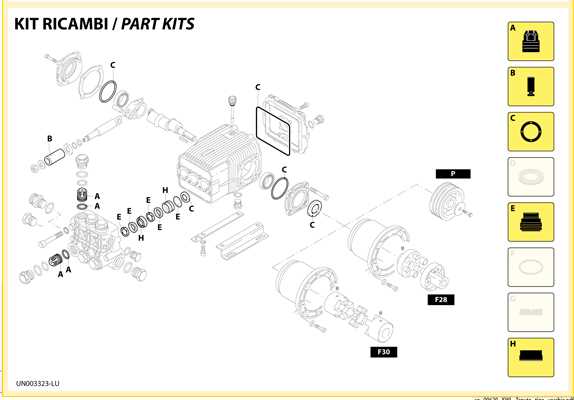

How to Identify Pump Parts

Understanding the components of a hydraulic system is crucial for effective maintenance and repair. Familiarizing yourself with the various elements enables you to troubleshoot issues efficiently and ensures optimal performance.

Common Components

Begin by recognizing the typical elements you will encounter. These often include the motor, casing, and seals. Each has a specific function that contributes to the overall operation, and being able to pinpoint them is essential for any technician.

Identifying Specific Elements

Utilize diagrams and manuals as reference tools. Look for unique markings or numbers on each component. Labeling can also aid in distinguishing between similar parts. Pay attention to size and shape variations that can help you identify the correct components swiftly.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring the functionality of your equipment, ensuring you can effectively address common issues. By following these steps, you will gain insight into troubleshooting and replacing essential components for optimal performance.

| Step | Description |

|---|---|

| 1 | Gather necessary tools and safety gear to ensure a safe working environment. |

| 2 | Disconnect the unit from the power source and remove any hoses or attachments. |

| 3 | Inspect the internal mechanisms for wear or damage; take notes for reference. |

| 4 | Replace any damaged components with new, compatible alternatives. |

| 5 | Reassemble the unit carefully, ensuring all connections are secure. |

| 6 | Reconnect to the power source and perform a thorough test to verify functionality. |

Benefits of Using Quality Parts

Utilizing high-grade components significantly enhances performance and longevity, ensuring reliability and efficiency in operations. Premium materials contribute to reduced wear and tear, minimizing the frequency of replacements and maintenance efforts.

| Advantage | Description |

|---|---|

| Durability | Quality components withstand stress better, extending the lifespan of the equipment. |

| Efficiency | Superior materials lead to optimal functionality, resulting in better overall performance. |

| Cost-Effectiveness | Investing in reliable parts reduces the long-term costs associated with frequent replacements. |

| Safety | High-quality items enhance safety, reducing the risk of malfunctions that could lead to accidents. |

Where to Purchase Replacement Parts

Finding high-quality components for your equipment is essential for maintaining optimal performance. Numerous sources are available to ensure you can easily access the necessary replacements for any repairs or upgrades. Here’s a guide to help you navigate your options.

Online Retailers

The internet offers a wide array of platforms where you can find the required components. Here are some popular choices:

| Retailer | Specialty | Website |

|---|---|---|

| Amazon | General supplies | www.amazon.com |

| eBay | New and used options | www.ebay.com |

| Home Depot | Home improvement | www.homedepot.com |

Local Suppliers

Visiting local shops can provide immediate access to necessary components and expert advice. Many retailers specialize in equipment and maintenance supplies.

Tips for Efficient Pump Operation

Optimizing the functionality of your liquid-moving device not only enhances performance but also prolongs its lifespan. Implementing a few strategic practices can lead to significant improvements in efficiency, reducing downtime and maintenance costs.

Regular Maintenance Checks

Consistent upkeep is crucial for ensuring smooth operation. Consider the following actions:

- Inspect seals and gaskets for wear.

- Clean filters to prevent clogs.

- Check for leaks in hoses and connections.

- Monitor fluid levels and quality regularly.

Optimal Operating Conditions

Understanding and maintaining ideal working conditions can prevent potential issues. Follow these guidelines:

- Maintain the correct temperature for the fluid being handled.

- Ensure the suction and discharge lines are properly sized.

- Avoid running the device dry to prevent damage.

- Calibrate pressure settings according to the manufacturer’s recommendations.