In the intricate world of fluid dynamics, the efficiency and reliability of machinery heavily depend on the design and arrangement of its essential elements. Each component plays a vital role, contributing to the overall functionality and performance of the system.

To achieve optimal operation, it is crucial to grasp how these integral pieces interact and support one another. By breaking down their configuration and understanding their relationships, we can identify areas for improvement and ensure longevity in performance.

Through a detailed examination, one can delve into the mechanics at play, gaining insights that empower users to make informed decisions regarding maintenance and upgrades. This knowledge ultimately leads to enhanced operational success and reduces the likelihood of unexpected failures.

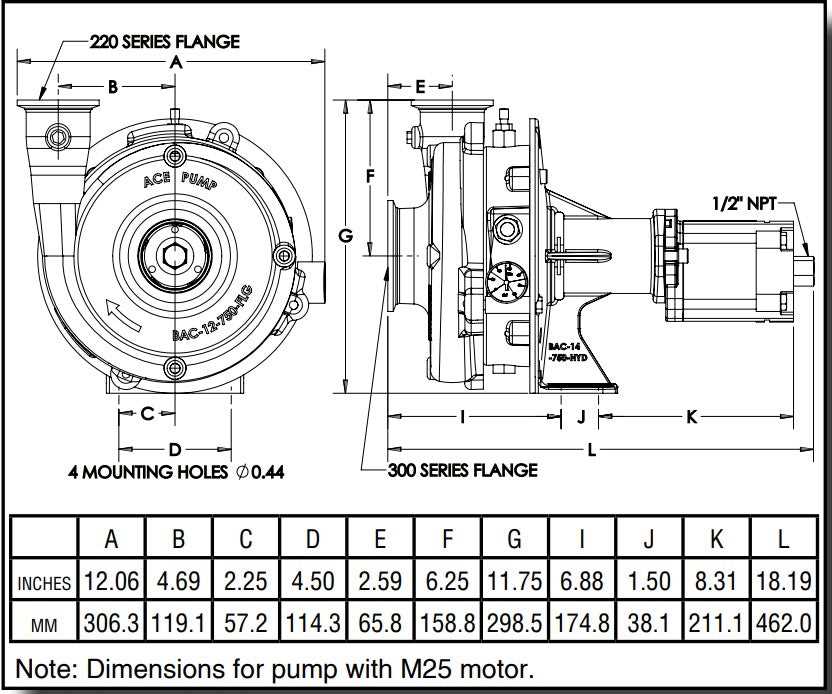

Ace Pump Parts Overview

This section aims to provide a comprehensive understanding of the components involved in fluid transfer systems. Recognizing the various elements can enhance operational efficiency and maintenance practices.

Key Components

Understanding the fundamental elements is essential for effective management. These pieces play a crucial role in ensuring optimal functionality and longevity of the system.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal mechanisms. |

| Rotor | Drives the movement of the fluid through the system. |

| Seals | Prevent leaks and maintain pressure within the assembly. |

| Valves | Regulate the flow direction and pressure. |

Maintenance Tips

Regular checks on these components can lead to improved performance and reduced downtime. Ensuring proper lubrication and timely replacements is key to longevity.

Understanding Pump Functionality

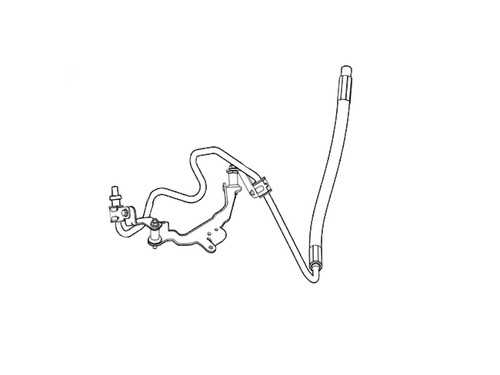

Grasping the mechanics behind fluid movement is crucial for optimizing system efficiency. The interplay of various components determines how effectively a device can transfer liquids, ensuring consistent performance across different applications.

Key elements include the driving force, the mechanisms for creating flow, and the pathways through which the fluid travels. Each component plays a vital role in maintaining pressure and volume, influencing overall effectiveness.

By delving into these elements, one can achieve a deeper appreciation of how to maximize operational capacity and address potential challenges. This understanding is the ultimate foundation for troubleshooting and enhancing performance in diverse environments.

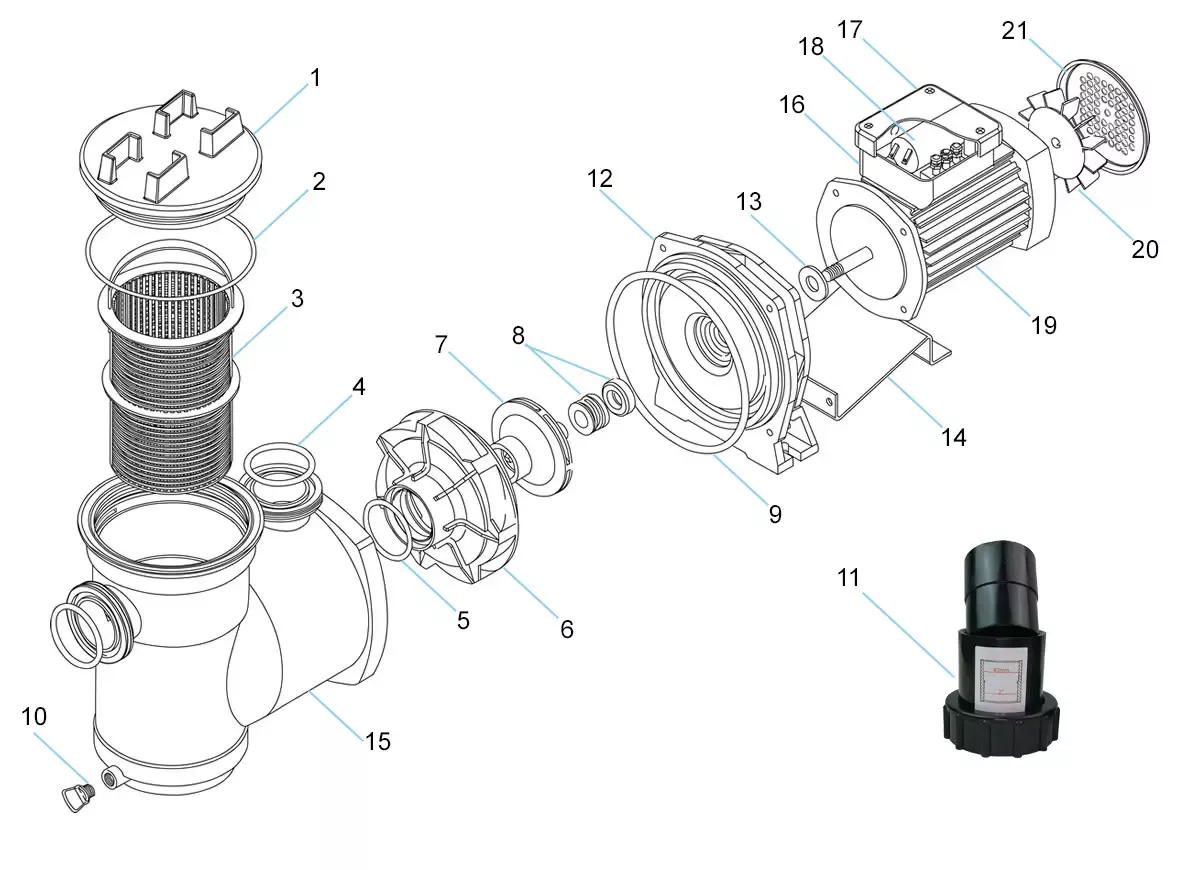

Common Components in Ace Pumps

Understanding the essential elements that make up these mechanisms is crucial for optimal functionality and maintenance. Each component plays a vital role in the overall operation, contributing to efficiency and durability. Familiarity with these integral parts can enhance troubleshooting and repair processes.

Key Elements

Among the most significant components are the casing, which provides structural integrity, and the impeller, responsible for fluid movement. Additionally, the shaft connects the motor to the impeller, ensuring power is transmitted effectively. Regular inspection of these elements can prevent premature wear and ensure smooth operation.

Supporting Mechanisms

Other noteworthy components include the seals, which prevent leaks and maintain pressure, and the bearings, which reduce friction and support rotating parts. Understanding these supporting mechanisms is essential for maintaining the overall health of the system.

Benefits of Using Quality Parts

Utilizing superior components in machinery ensures optimal performance and longevity. When high-grade materials are employed, users can expect enhanced reliability, leading to reduced downtime and maintenance costs. This approach not only maximizes efficiency but also extends the lifespan of the entire system.

Durability is a key advantage of choosing top-notch components. Quality items are designed to withstand harsh conditions and heavy usage, which diminishes the likelihood of breakdowns. Consequently, this contributes to a smoother operational flow and boosts overall productivity.

Furthermore, investing in reliable elements can lead to cost savings in the long run. Although the initial expenditure may be higher, the reduced frequency of replacements and repairs significantly offsets this cost. Organizations can allocate resources more effectively, focusing on growth rather than maintenance issues.

Additionally, enhanced performance is a notable benefit. Quality components often provide better efficiency and effectiveness, which translates to improved output. By ensuring that each element functions optimally, users can achieve superior results and maintain a competitive edge in their respective fields.

Lastly, the use of premium components promotes safety. High-quality materials are rigorously tested and manufactured to meet strict standards, minimizing the risk of failure. This not only protects the equipment but also safeguards the well-being of operators and surrounding personnel.

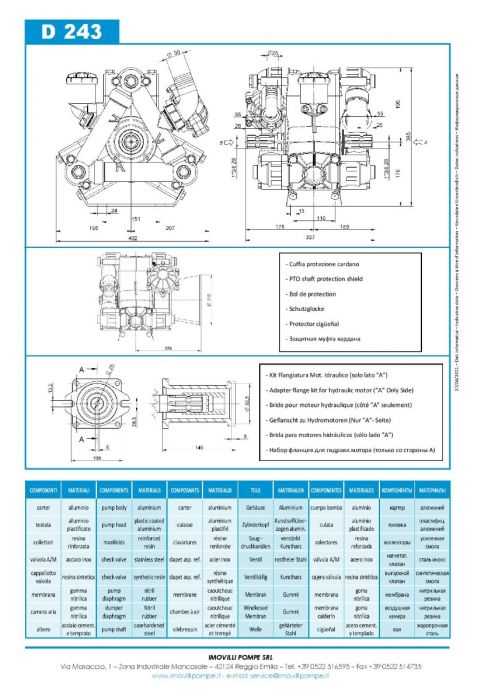

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. Such visuals provide a clear layout of various elements, allowing users to identify and locate each item quickly. Familiarizing yourself with these illustrations enhances your ability to troubleshoot and manage equipment efficiently.

1. Familiarize Yourself with the Legend: Most illustrations come with a legend or key that explains symbols and numbers used throughout. Taking the time to review this section can save you confusion later on.

2. Follow the Flow: Pay attention to the directional arrows and lines connecting different components. This will help you understand how the elements interact and function together within the system.

3. Identify Key Components: Start by locating major parts, often highlighted or labeled prominently. Once you grasp the primary structure, you can delve deeper into the smaller components and their specific roles.

4. Use Reference Numbers: Each item is typically associated with a unique identifier. Use these numbers to cross-reference with catalogs or manuals to find additional details about the components, including specifications and replacement options.

5. Note Compatibility: Recognize that not all components are interchangeable. Understanding compatibility is crucial, especially when sourcing replacements or upgrades.

By mastering these techniques, you can navigate component illustrations with confidence, ensuring more efficient repairs and improved equipment longevity.

Maintenance Tips for Pump Longevity

Ensuring the durability of your equipment requires a proactive approach to care and upkeep. By following a series of strategic practices, you can significantly enhance the lifespan and efficiency of your machinery. Consistent attention to these factors not only prevents costly breakdowns but also optimizes overall performance.

Regular Inspections: Conduct frequent evaluations to identify any signs of wear or damage. Look for leaks, unusual noises, or vibrations that may indicate underlying issues. Early detection is key to preventing further complications.

Fluid Quality: Utilize high-quality fluids and regularly check their levels and conditions. Contaminants can cause corrosion and reduce efficiency, so ensure that fluids are clean and suitable for your specific application.

Cleaning: Keep components free from debris and buildup. Regular cleaning not only prevents clogs but also allows for better heat dissipation, which is crucial for optimal operation.

Lubrication: Apply the appropriate lubricants to moving parts as recommended. Proper lubrication minimizes friction and wear, leading to a smoother operation and extended life of your equipment.

Monitoring Temperature: Keep an eye on operating temperatures. Excess heat can be detrimental, so ensure that cooling systems are functioning effectively and that heat sinks are clean and unobstructed.

Scheduled Maintenance: Develop and adhere to a maintenance schedule. Regular servicing by qualified professionals can catch issues before they escalate, ensuring your equipment remains in peak condition.

By implementing these practices, you can promote the longevity and reliability of your machinery, ultimately leading to improved efficiency and reduced operational costs.

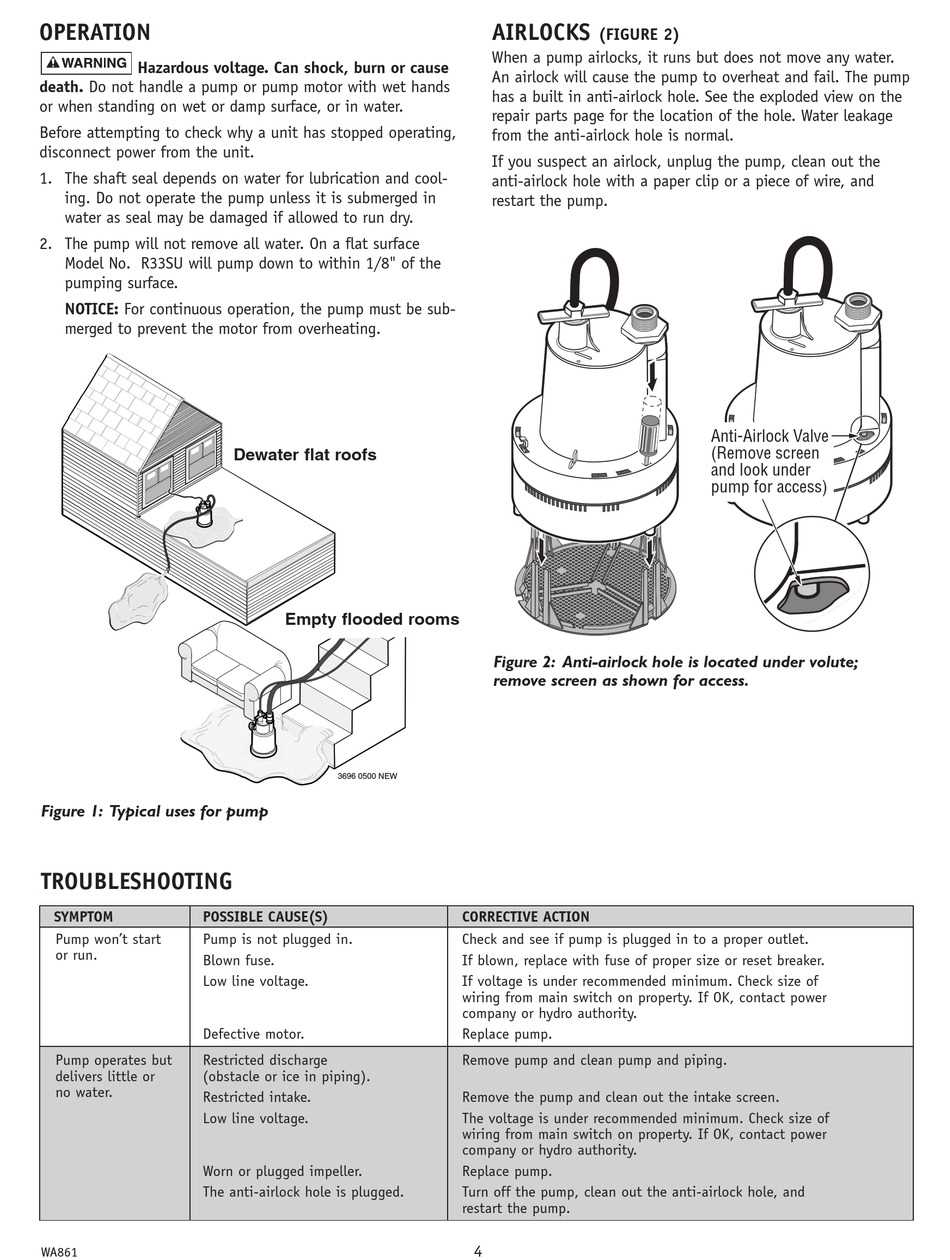

Troubleshooting Common Issues

In any mechanical system, encountering challenges is not uncommon. Identifying and resolving these problems promptly can prevent further complications and ensure optimal performance. This section outlines some frequent difficulties users may face, along with practical solutions to address them effectively.

Identifying Problems

Understanding the symptoms of an issue is crucial for effective resolution. Here are some common indicators that may suggest underlying problems:

- Unusual noises during operation

- Decreased efficiency or performance

- Unexpected leaks or drips

- Inconsistent flow or pressure

Common Solutions

When facing any of the above symptoms, consider the following troubleshooting steps:

- Check for visible damage or wear on components.

- Ensure all connections are secure and free from leaks.

- Inspect filters and screens for clogs or blockages.

- Review operating conditions to verify they align with specifications.

By following these guidelines, users can effectively diagnose and address common challenges, enhancing the longevity and reliability of their equipment.

Comparative Analysis of Pump Models

This section provides an in-depth look at various models in the fluid transfer industry, examining their design features, efficiency, and suitability for different applications. Understanding the nuances between these alternatives can aid in making informed decisions for specific operational needs.

Key Features to Consider

- Flow Rate: Essential for determining the volume of fluid moved.

- Pressure Capacity: Influences the effectiveness in high-resistance environments.

- Energy Efficiency: Important for reducing operational costs.

- Durability: Impacts long-term performance and maintenance frequency.

Model Comparison

-

Model A:

- High flow rate with moderate pressure capacity.

- Best suited for large-scale applications.

-

Model B:

- Excellent energy efficiency and compact design.

- Ideal for residential or small business use.

-

Model C:

- Robust construction with high durability.

- Designed for harsh environmental conditions.

Where to Source Replacement Parts

Finding the right components for machinery maintenance is essential for optimal performance. Reliable sources ensure quality and compatibility, ultimately extending the life of your equipment. Whether for repairs or upgrades, knowing where to look can save time and resources.

Authorized Dealers

One of the best options is to purchase from authorized distributors. These suppliers guarantee genuine components that meet industry standards. They often provide expert advice, helping you choose the right items for your specific needs.

Online Marketplaces

Another effective approach is to explore online platforms. Numerous websites specialize in industrial components, offering a wide range of products at competitive prices. User reviews and ratings can help assess the reliability of sellers, ensuring you make informed choices.