The functionality of agricultural machinery relies heavily on its individual elements and their seamless integration. Understanding the various components of such equipment is essential for optimal performance and maintenance. This section aims to provide insights into the essential parts that contribute to the efficient operation of a specific type of agricultural implement.

Each component serves a unique purpose, contributing to the overall effectiveness and reliability of the equipment. Recognizing how these elements interact can enhance the user’s ability to troubleshoot and perform necessary repairs. Moreover, familiarizing oneself with these components can facilitate better decision-making regarding upgrades and replacements.

In summary, a thorough comprehension of the various elements that comprise this equipment is crucial for anyone involved in its operation or upkeep. By exploring the intricate relationships among these parts, operators can ensure their machinery remains in peak condition and ready for use.

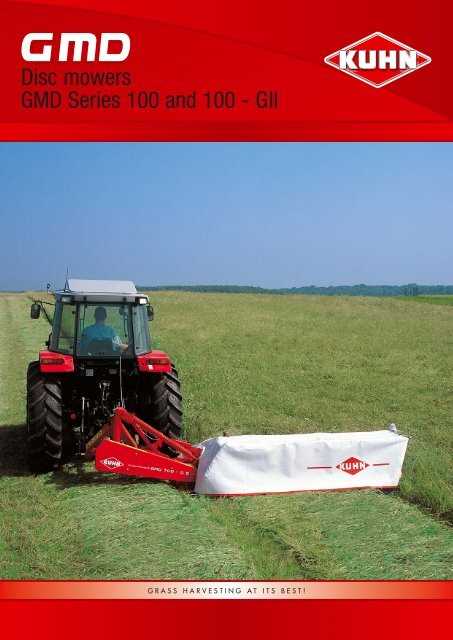

This section explores the fundamental elements of a specific agricultural implement designed for cutting and processing vegetation. Each component plays a vital role in ensuring efficient operation, contributing to overall productivity. Gaining a deeper understanding of these elements aids in the maintenance and optimal use of the equipment.

| Component | Description |

|---|---|

| Cutter Bar | The primary element responsible for the actual cutting action, designed to provide a clean and precise cut. |

| Gearbox | Essential for transferring power from the machine’s engine to the cutter bar, allowing for effective operation. |

| Frame | The sturdy structure that supports all components and maintains stability during operation. |

| Hitch | A mechanism that connects the implement to a towing vehicle, enabling easy maneuverability. |

| Blade Assembly | Consists of sharp blades that rotate to cut through plant material efficiently. |

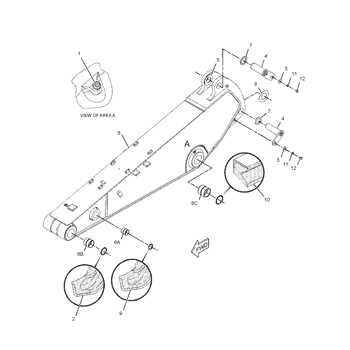

Exploring the Assembly Diagram

Understanding the construction and layout of agricultural equipment is essential for maintenance and efficient operation. This section focuses on a visual representation that outlines the various components and their interconnections. By examining this illustration, operators can gain insights into how each element interacts, ensuring effective troubleshooting and repairs.

Key Components Overview

The illustration showcases essential elements that contribute to the overall functionality of the machinery. Each part is strategically positioned, highlighting its role in the machine’s performance. Familiarizing oneself with these components can significantly enhance the user experience and prolong the equipment’s lifespan.

Maintenance Insights

Regular examination of the layout can aid in identifying wear and tear, allowing for timely interventions. Understanding the placement of components facilitates easier access during servicing, ensuring that operators can perform necessary checks and replacements without difficulty. This proactive approach to maintenance is vital for optimal operation.

Maintenance Tips for GMD 700 Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By adhering to a systematic maintenance routine, you can prevent wear and tear, reduce the likelihood of breakdowns, and enhance the efficiency of your machinery. This section offers practical suggestions to help you maintain the various components effectively.

Routine Inspections

Conducting frequent inspections is crucial for identifying potential issues early. Check for signs of wear, rust, or damage on all components. Ensure that fasteners are secure and replace any that are worn or broken. Keeping an eye on these details can save you from costly repairs in the future.

Lubrication and Cleaning

Proper lubrication is vital for smooth operation. Use the recommended lubricants for each part, and ensure that all moving elements are adequately greased. Additionally, regular cleaning helps remove debris and contaminants that can impede functionality. Make it a habit to clean the equipment after each use to maintain its performance.

Best Practices for Part Cleaning

Proper maintenance of machinery components is crucial for ensuring longevity and optimal performance. Cleaning these elements not only removes dirt and debris but also helps to identify potential issues before they escalate. Following the right techniques can significantly improve the efficiency and reliability of your equipment.

1. Use Appropriate Cleaning Solutions

Choosing the right cleaning agents is essential. Utilize solvents that are specifically designed for the materials you are working with to avoid damage. For instance, mild detergents can be effective for softer surfaces, while more robust cleaners may be required for tougher residues. Always follow the manufacturer’s recommendations to ensure compatibility.

2. Employ Correct Cleaning Tools

Utilizing the right tools can make a significant difference in the cleaning process. Soft brushes, microfiber cloths, and non-abrasive sponges are ideal for removing grime without scratching surfaces. High-pressure air can also be used to blow out dirt from intricate areas. Always assess the condition of the components and choose tools that will not cause further wear.

Inspecting Wear and Tear Signs

Regular examination of equipment is crucial to ensure optimal performance and longevity. Identifying indicators of degradation can prevent unexpected breakdowns and costly repairs. This section discusses the key aspects to consider when assessing the condition of your machinery.

Common Indicators of Wear

- Blades: Check for chipping or dullness, which can affect cutting efficiency.

- Belts: Look for fraying or cracks that may lead to slippage or failure.

- Bearings: Listen for unusual noises or vibrations that suggest wear or damage.

- Hydraulic Hoses: Inspect for leaks or signs of abrasion that can compromise functionality.

Routine Maintenance Tips

- Conduct regular visual inspections before and after use.

- Clean components to remove debris that may cause wear.

- Lubricate moving parts as recommended to minimize friction.

- Replace any worn parts promptly to maintain efficiency.

By staying vigilant and addressing wear signs early, you can enhance the reliability of your equipment and extend its service life.

Replacing Parts on the GMD 700

Maintaining agricultural machinery is essential for optimal performance and longevity. When components wear out or malfunction, timely replacement is crucial to ensure the equipment operates efficiently. Understanding the process of swapping out various elements can significantly enhance the overall functionality of your machinery.

Identifying Worn Components

Before initiating the replacement process, it is vital to accurately identify which elements require attention. Regular inspections can help spot signs of wear, such as cracks, excessive rust, or unusual noises during operation. Once identified, securing the correct replacements is necessary to restore performance.

Steps for Effective Replacement

To effectively replace the worn components, begin by ensuring the machine is powered down and safely positioned. Gather the necessary tools, including wrenches and pliers. Carefully remove the faulty part, following the manufacturer’s guidelines to avoid damaging surrounding areas. Install the new element by aligning it properly and securing it tightly. Finally, conduct a thorough test to verify the machine’s functionality.

Step-by-Step Replacement Guide

This section provides a comprehensive guide to the process of replacing essential components in a specific agricultural implement. Following these detailed instructions will help ensure that the replacement is conducted efficiently and effectively, minimizing downtime and maintaining optimal performance.

Preparation and Safety

Before starting the replacement process, it is crucial to gather all necessary tools and equipment. Ensure that the machine is turned off and securely parked on a flat surface. Always wear appropriate safety gear, such as gloves and protective eyewear, to prevent injuries during the procedure.

Replacement Procedure

Begin by removing the cover or protective casing of the implement to access the internal components. Carefully disconnect any electrical connections and detach any bolts or fasteners holding the old component in place. Once removed, compare the old part with the new one to confirm compatibility.

Next, install the new component by reversing the removal steps. Make sure to secure all connections tightly and check for any potential obstructions that might interfere with operation. After the installation, reattach the cover and conduct a thorough inspection to ensure everything is in place before starting the implement.

Choosing Genuine Replacement Parts

Selecting authentic replacement components is crucial for ensuring the optimal performance and longevity of agricultural equipment. Genuine parts are designed to meet specific manufacturer standards, providing reliability and efficiency. Using original components minimizes the risk of malfunctions and enhances the overall functionality of the machine.

Benefits of Using Authentic Components

Authentic replacements offer numerous advantages, including precise fit and compatibility with existing systems. They are manufactured with high-quality materials, ensuring durability and reducing the likelihood of wear and tear. Moreover, genuine components often come with warranties, providing additional peace of mind for users.

How to Identify Genuine Components

When sourcing replacements, it is essential to verify the authenticity of the components. Purchase from authorized dealers or reputable suppliers to ensure you receive genuine items. Checking for certification marks and product codes can also help in distinguishing original components from counterfeit alternatives.

Troubleshooting Common Issues

When operating machinery, encountering issues is a common occurrence. Understanding how to diagnose and address these problems can enhance performance and prolong the lifespan of the equipment. This section provides insights into typical challenges faced by operators and effective solutions to rectify them.

Identifying Symptoms

Recognizing the signs of malfunction is crucial for timely intervention. Below are some common indicators:

- Unusual noises during operation

- Inconsistent cutting performance

- Excessive vibrations

- Difficulty in starting

Common Solutions

Once symptoms are identified, the following steps can be taken to resolve the issues:

- Check for loose or damaged components and tighten or replace as necessary.

- Inspect the blades for dullness or damage, sharpening or replacing them if needed.

- Ensure that all lubricants are at the correct levels to prevent friction.

- Verify that all safety mechanisms are functioning correctly to ensure safe operation.