Exploring the intricate design of a heavy-duty vehicle’s frontal structure reveals the essential elements that contribute to its performance and durability. Each component plays a vital role in ensuring that the vehicle can withstand various challenges, from rugged terrains to demanding loads. Understanding how these pieces fit together can significantly enhance maintenance and repair efforts.

Within this discussion, we will delve into the various segments that make up the frontal configuration, highlighting their functions and interactions. A well-organized overview of these elements not only aids in visualizing the assembly but also assists vehicle owners and enthusiasts in identifying potential issues and planning for upgrades or replacements.

Moreover, having a clear representation of this assembly can serve as a valuable resource for both amateur mechanics and seasoned professionals. By recognizing the significance of each component, one can better appreciate the engineering that underpins these robust machines, ensuring longevity and reliability on the road.

Understanding Ford F250 Front End Components

The components located at the forefront of a vehicle play a crucial role in its overall performance and safety. A clear comprehension of these elements can aid in maintenance and repairs, ensuring a smoother driving experience. Various elements work together to provide stability, control, and support during operation.

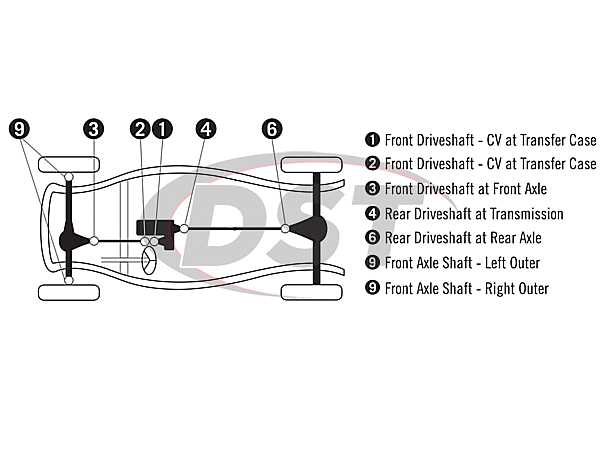

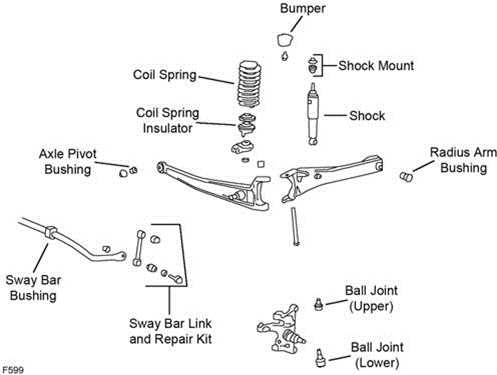

- Suspension System: This assembly is responsible for absorbing shocks and maintaining tire contact with the road, contributing to ride comfort and handling.

- Steering Mechanism: Essential for directing the vehicle, this system includes various linkages and joints that allow for smooth turning and maneuverability.

- Frame Structure: Serving as the backbone, it supports all front components while providing strength and durability.

- Braking System: Crucial for safety, it includes calipers, rotors, and pads, ensuring effective stopping power.

- Wheel Assembly: Comprising tires, rims, and bearings, this unit is fundamental for traction and stability.

Understanding each of these components not only enhances vehicle performance but also aids in early detection of potential issues, ultimately leading to a safer driving experience.

- Regular inspections can identify wear and tear.

- Timely replacements ensure optimal functionality.

- Knowledge of these components empowers informed maintenance decisions.

Familiarity with these fundamental aspects is vital for any vehicle owner or enthusiast, fostering a deeper appreciation for the engineering behind automotive design.

Key Parts of the 2002 F250 Front End

The essential components of a vehicle’s forward section play a crucial role in both functionality and aesthetics. Understanding these elements is vital for maintenance and repair, ensuring optimal performance and safety on the road.

Suspension System

The suspension assembly is integral for ride quality and handling. It includes springs, shock absorbers, and control arms that work together to absorb impacts and stabilize the chassis.

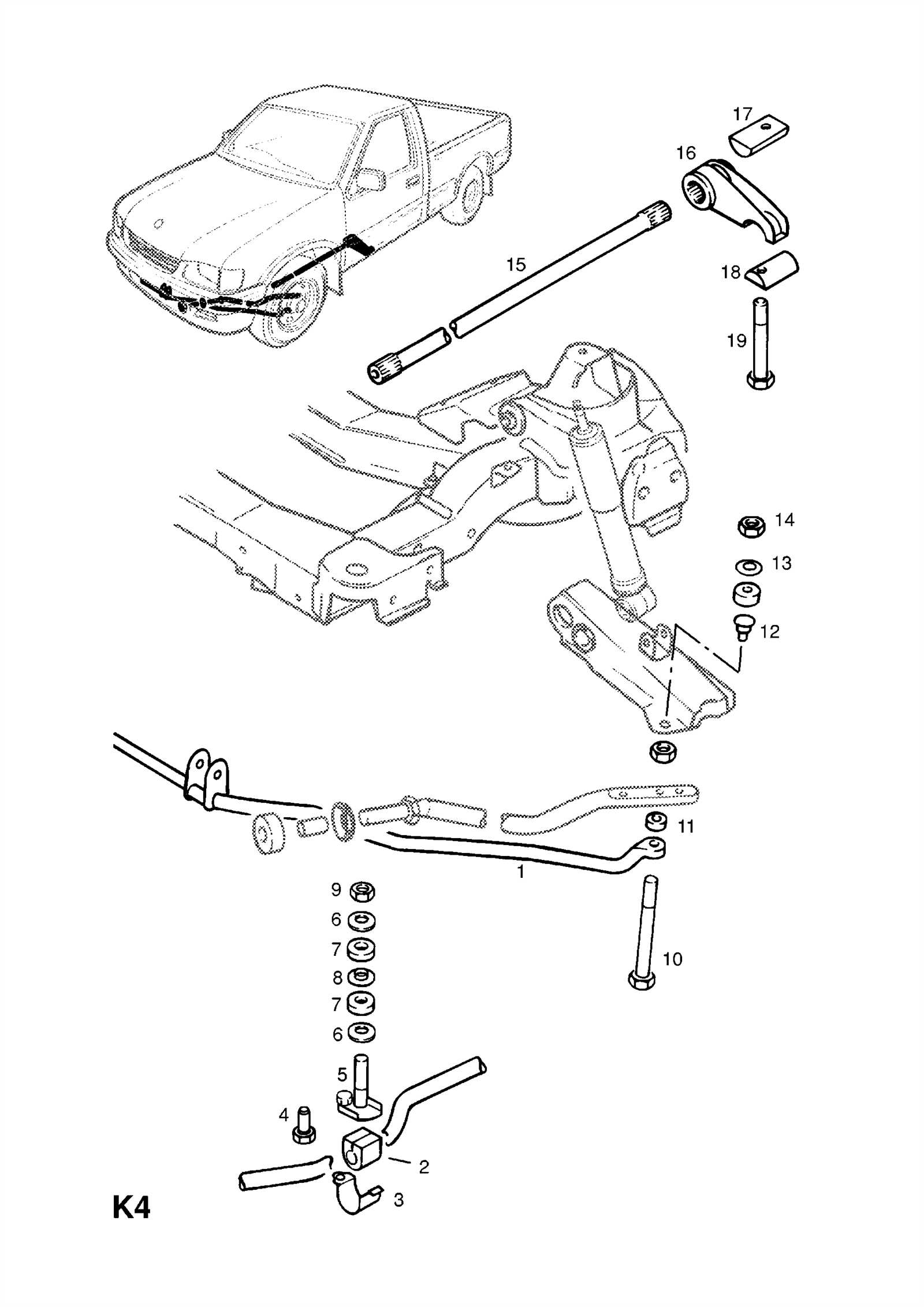

Steering Mechanism

The steering setup allows for precise maneuverability. Key elements like the steering box and linkage connect the driver’s input to the wheels, ensuring a responsive driving experience.

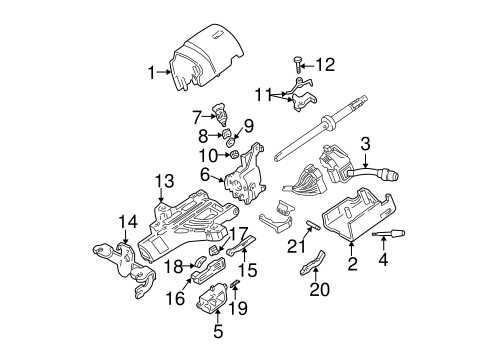

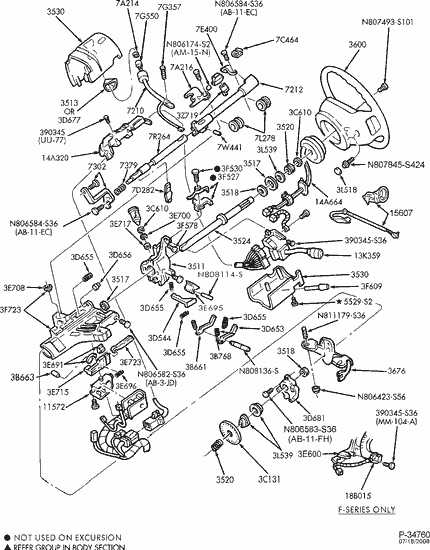

Visual Guide to F250 Diagrams

This section provides an insightful overview of schematic representations related to vehicle components. Understanding these visuals can significantly enhance your knowledge of mechanical assemblies and aid in maintenance or modifications. Each illustration serves as a crucial tool for enthusiasts and professionals alike.

Understanding Component Relationships

Visual representations help clarify how individual elements interact within the assembly. By exploring these connections, users can grasp the ultimate functionality of the entire system, making troubleshooting and upgrades more accessible.

Utilizing Illustrations for Repairs

When tackling repairs, referencing these schematics can streamline the process. They not only show the layout but also indicate specific locations for components, ensuring that replacements or adjustments are made accurately. Knowledge is power in automotive maintenance.

Importance of Regular Front End Maintenance

Consistent upkeep of the vehicle’s steering and suspension components is crucial for ensuring optimal performance and safety on the road. Neglecting these elements can lead to a range of issues that not only affect drivability but also compromise the overall safety of the vehicle and its occupants.

Enhancing Safety

Regular inspections and maintenance of the steering and suspension systems help identify potential problems before they escalate. Worn or damaged components can result in reduced control and increased stopping distances, posing a significant risk during driving. Ensuring these systems are in good condition enhances the safety of both the driver and passengers.

Improving Vehicle Longevity

Routine maintenance contributes to the longevity of the vehicle. By addressing wear and tear promptly, vehicle owners can prevent costly repairs down the line. This proactive approach not only preserves the performance but also maintains the value of the vehicle over time, making it a wise investment for any driver.

Common Issues with Front End Parts

When it comes to vehicle suspension and steering systems, various challenges can arise over time. These components play a crucial role in maintaining stability and handling. Understanding the typical problems associated with these mechanisms can help owners identify and address issues promptly, ensuring a safer driving experience.

Worn Bushings and Joints

One of the most frequent problems involves the deterioration of rubber bushings and ball joints. Worn components can lead to a noticeable decrease in responsiveness and may cause uneven tire wear. Owners may experience clunking noises during turns, which is often indicative of failing joints.

Alignment Issues

Misalignment can occur due to various factors, including hitting potholes or curb impacts. This condition affects steering precision and can result in increased tire wear. Regular inspections and adjustments can mitigate these effects and enhance overall vehicle performance.

Upgrading Your F250 Front End

Enhancing the performance and aesthetics of your vehicle’s front assembly can lead to a more enjoyable driving experience. Whether you aim for improved handling, increased load capacity, or a sportier look, there are several modifications to consider. This section explores various options to elevate your vehicle’s capabilities.

Performance Enhancements

To achieve superior handling, consider installing upgraded shock absorbers and springs. These components can significantly improve ride quality and stability, especially under heavy loads. Additionally, performance steering systems can provide better responsiveness, allowing for more precise control.

Aesthetic Improvements

For a more striking appearance, aftermarket grilles and bumper upgrades can transform the overall look. Consider integrating LED lighting for both style and visibility. These modifications not only enhance aesthetics but also increase functionality, making your vehicle stand out on and off the road.

Tools Needed for Front End Repairs

When undertaking maintenance or restoration work on the suspension and steering components of a vehicle, having the right tools is essential for efficiency and safety. Proper equipment not only ensures that tasks are completed accurately but also reduces the risk of injury and damage to the vehicle.

Essential Tools

- Socket Set: A comprehensive socket set is vital for loosening and tightening various fasteners.

- Wrenches: Both standard and adjustable wrenches are necessary for reaching tight spots.

- Torque Wrench: This tool is crucial for applying the correct amount of force to fasteners.

- Pry Bar: Useful for separating components that are tightly fitted together.

- Jack and Jack Stands: Safety is paramount; using a reliable jack system ensures safe access to the undercarriage.

Specialized Equipment

- Ball Joint Separator: A dedicated tool for removing ball joints without damage.

- Alignment Tools: Essential for ensuring proper vehicle alignment after adjustments.

- Steering Wheel Puller: Needed for removing steering components when necessary.

- Brake Line Wrench: Prevents damage to brake lines during repairs.

Gathering these tools before starting any project can save time and effort, enabling smoother and more successful repairs.

Where to Find Quality Replacement Parts

Finding reliable components for your vehicle can significantly impact its performance and longevity. The right sources will ensure that you receive high-quality items that meet or exceed original specifications.

| Source | Description |

|---|---|

| OEM Suppliers | Original manufacturers provide authentic components designed specifically for your vehicle. |

| Aftermarket Retailers | These offer a variety of options that can often be more affordable while still maintaining good quality. |

| Online Marketplaces | Websites that specialize in automotive goods frequently have competitive prices and a broad selection. |

| Local Auto Parts Stores | Convenient for immediate needs, these shops often have knowledgeable staff to assist with your choices. |

Tips for DIY Front End Projects

Taking on a project to enhance the front suspension and steering components of your vehicle can be rewarding. With the right approach and preparation, you can achieve satisfactory results while saving time and money. Here are some practical suggestions to help you navigate your DIY endeavors effectively.

Preparation is Key

- Research Thoroughly: Understand the components and their functions before starting.

- Gather Tools: Ensure you have all necessary tools at hand, including wrenches, jacks, and safety gear.

- Check Your Workspace: Create a clean and organized area to work, minimizing distractions and hazards.

Execution and Safety

- Follow Instructions: Use reliable guides or manuals specific to your vehicle model.

- Take Your Time: Avoid rushing through tasks to prevent mistakes or accidents.

- Safety First: Always wear protective gear and ensure the vehicle is securely supported when working underneath.

By following these guidelines, you can enhance your chances of a successful project while enjoying the process of working on your vehicle.