The design of any reliable power system is complex and involves numerous interconnected elements working in harmony. Each component plays a vital role in ensuring optimal performance, contributing to overall efficiency and durability. Understanding the layout and functionality of these components is crucial for maintaining and troubleshooting the machine effectively.

In this section, we will explore the key elements that form the foundation of such systems. We will break down the structure to provide a clearer view of how different parts are arranged and interact, ensuring seamless operation.

By the end of this overview, you’ll gain a better grasp of the inner workings of the machinery, allowing for a deeper understanding of its maintenance and repair processes.

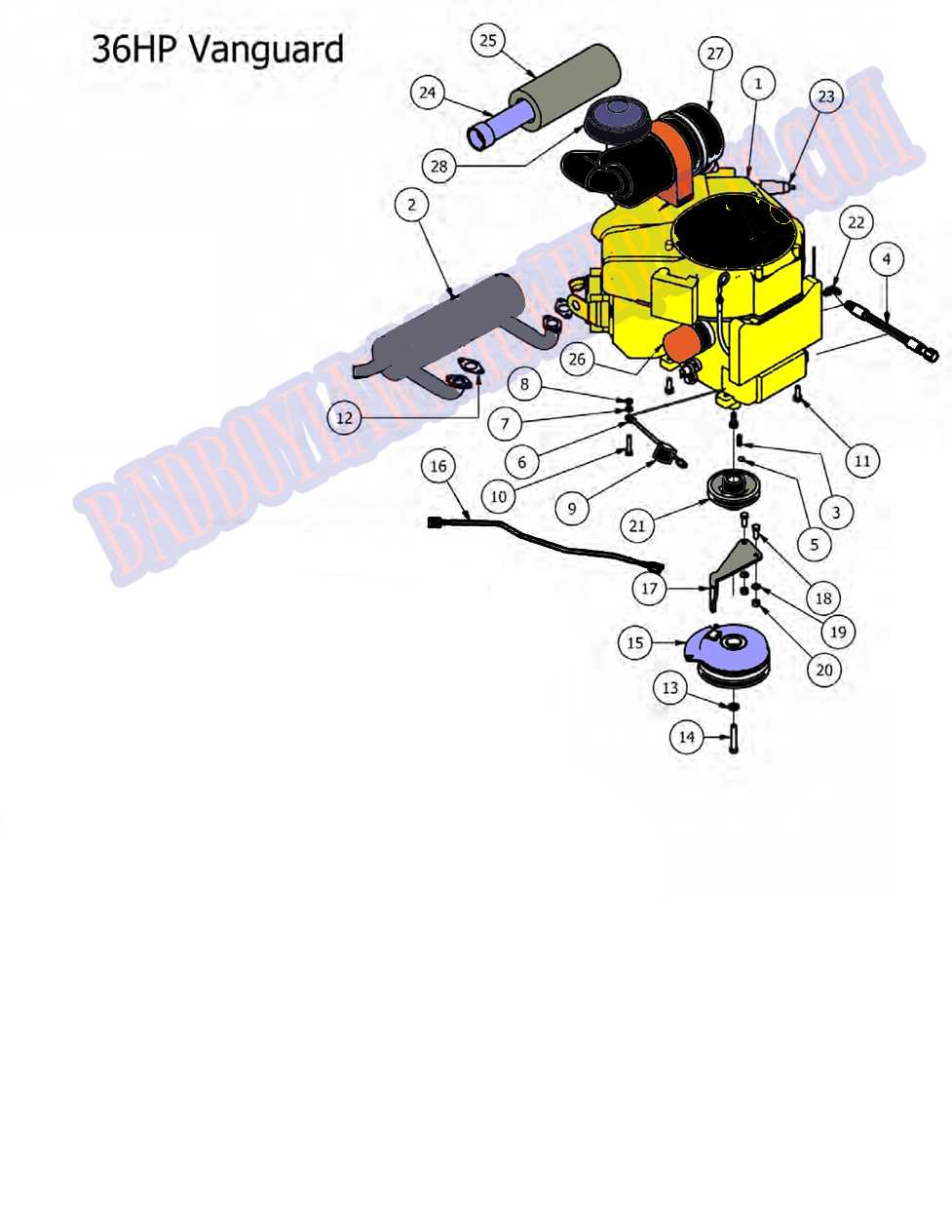

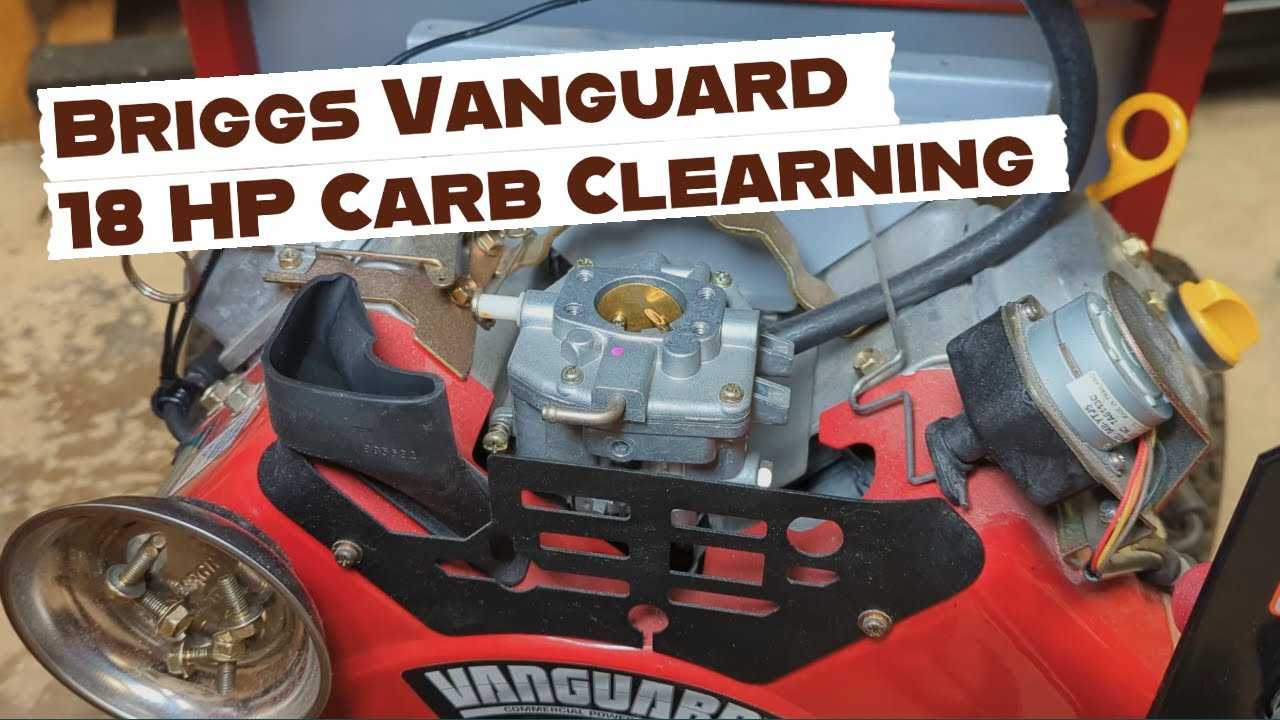

Overview of Vanguard 18 HP Engine Components

The 18 HP model is known for its durability and reliable performance in various applications. This section will explore the main components that contribute to its efficient functionality, ensuring smooth operation under diverse conditions.

Key Mechanical Elements

One of the critical aspects of this machine is its internal structure, which includes moving parts designed to work together seamlessly. The system is built for longevity, with materials chosen for their strength and resilience. Each component plays a specific role in delivering optimal power.

Supportive Systems

Aside from the core mechanical elements, additional systems ensure proper cooling, fuel supply, and exhaust management. These systems maintain balance, protecting the main mechanism from overheating and ensuring fuel is used efficiently. Their role is essential in prolonging the lifespan of the machinery.

Key Features of the 18 HP Vanguard Engine

This powerful 18 HP machine offers impressive characteristics that ensure reliable performance and durability. Designed to meet a variety of operational demands, it combines strength with efficiency to provide smooth functioning in different conditions. Below are the primary aspects that make it a preferred choice for various applications.

Performance and Efficiency

The design ensures high-level output while maintaining fuel efficiency. Its balanced construction reduces vibration, which extends the lifespan of the machine and guarantees smoother operation, even under heavy workloads.

Durability and Maintenance

The materials used in construction are engineered for longevity. Additionally, easy access to maintenance points simplifies routine servicing, ensuring that upkeep is straightforward and cost-effective.

| Feature |

Description |

| Power Output |

Delivers consistent 18 horsepower for demanding tasks |

| Fuel System |

Optimized for efficient fuel consumption, reducing costs |

| Cooling Mechanism |

Advanced cooling technology prevents overheating during extended use |

| Maintenance Access |

Accessible design for easy and quick service |

Common Issues with Vanguard Engine Parts

When working with small machinery, various problems may arise due to wear or poor maintenance. These issues often affect performance, leading to malfunctions or inefficiency in operation. Understanding frequent concerns can help in identifying and solving problems before they escalate.

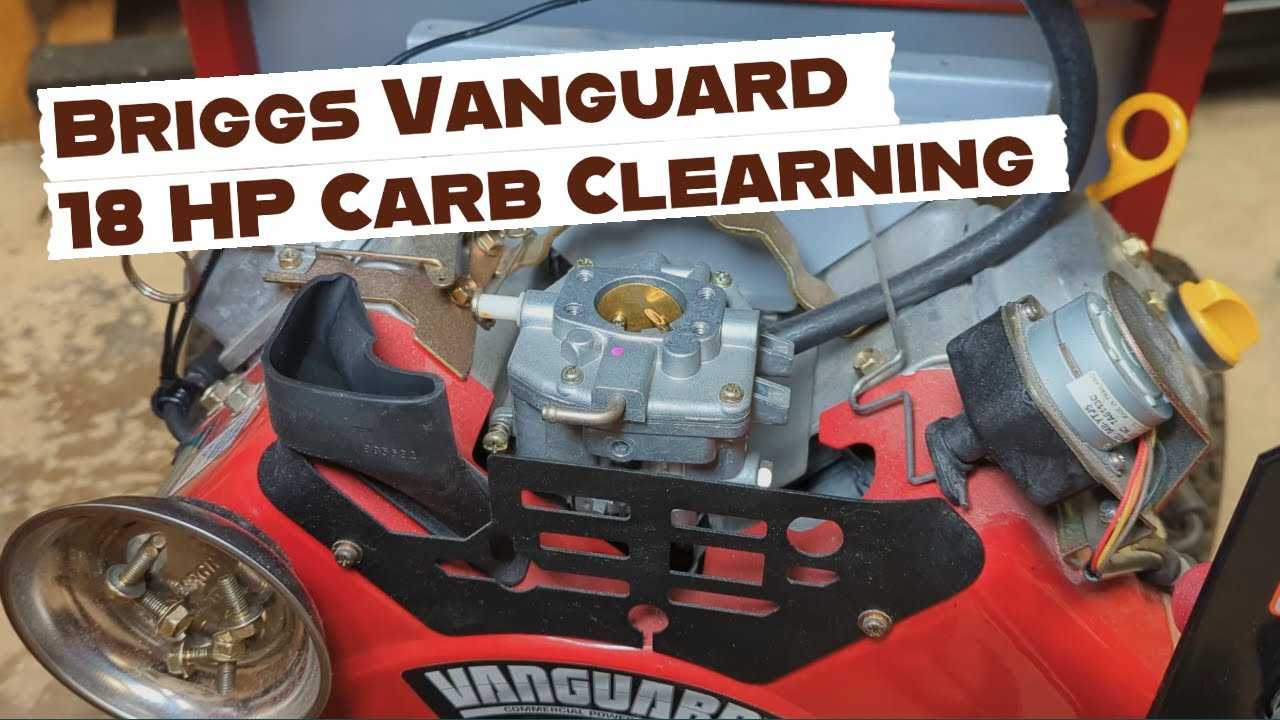

Fuel System Problems

Clogs in the fuel lines or dirty filters are common challenges that cause inconsistent performance. Regular cleaning or replacement of filters and inspecting the fuel lines for blockages are essential to maintain smooth operation. Faulty injectors may also contribute to these troubles.

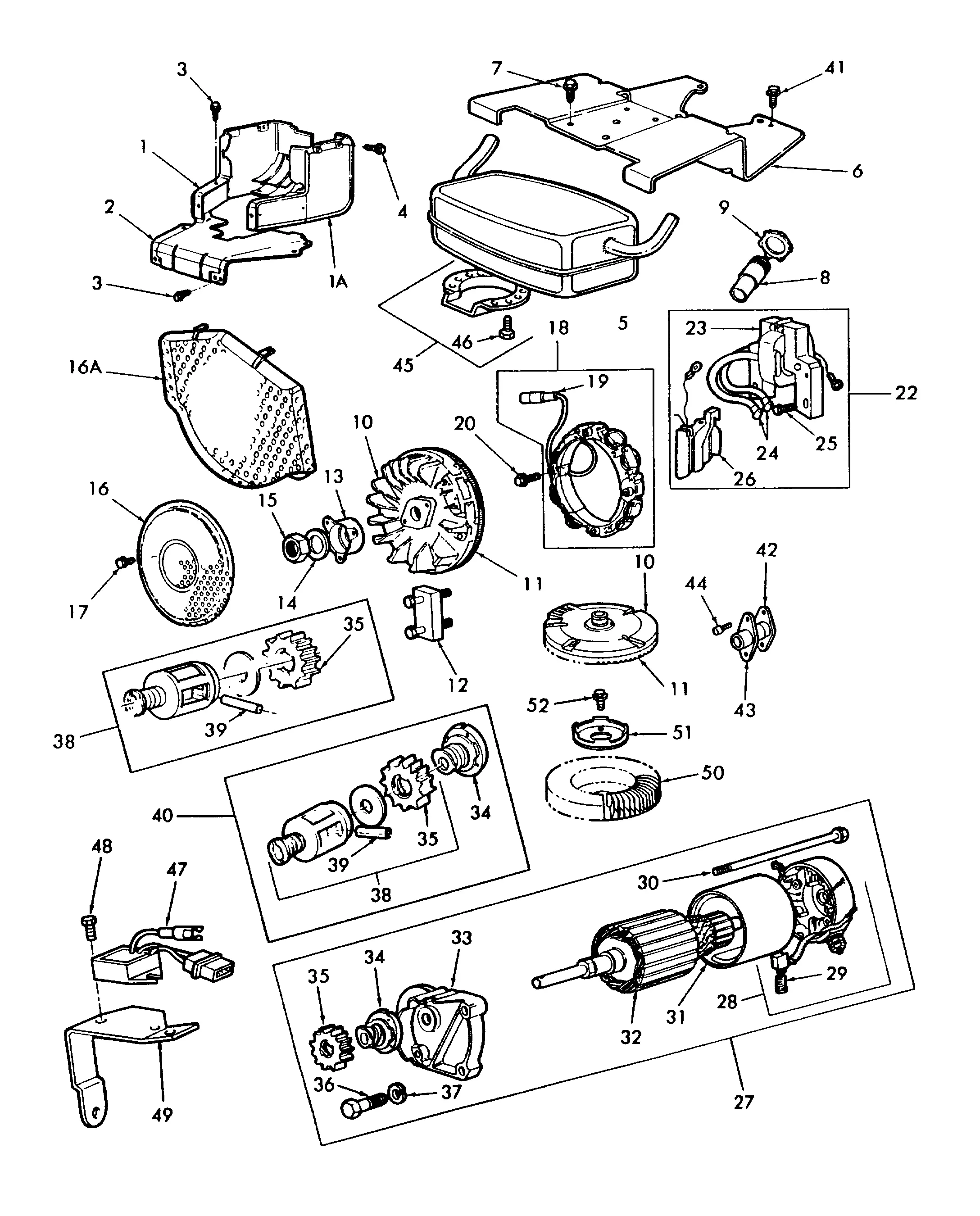

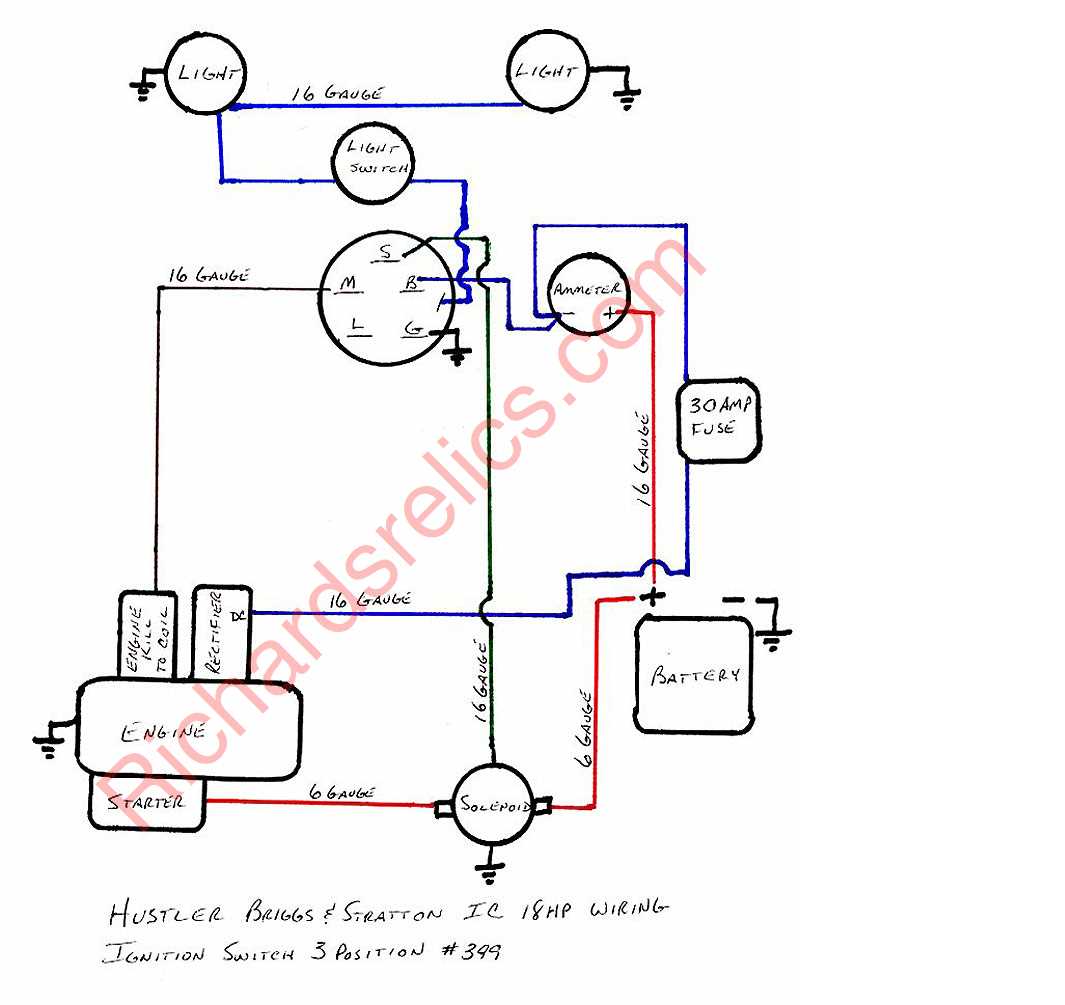

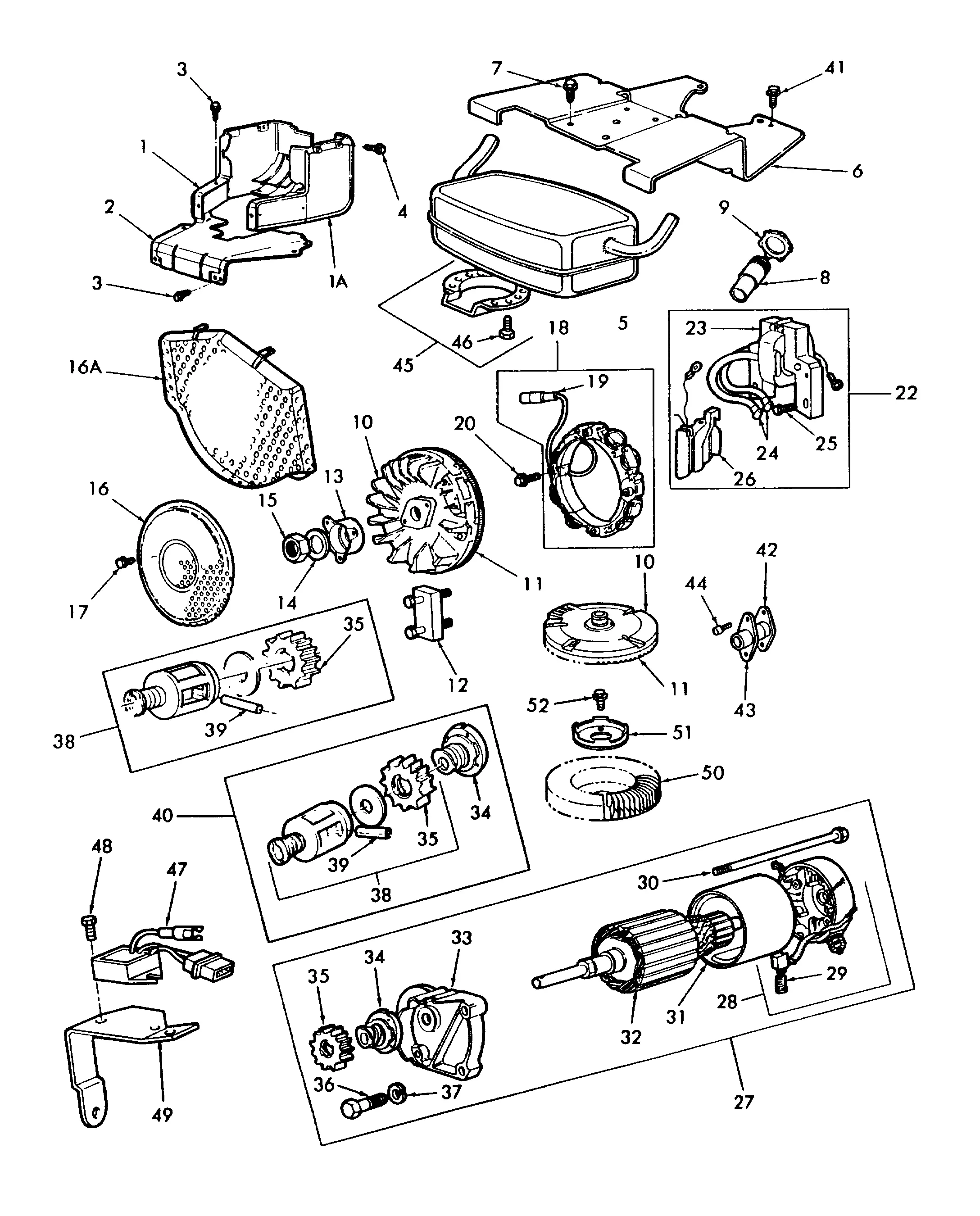

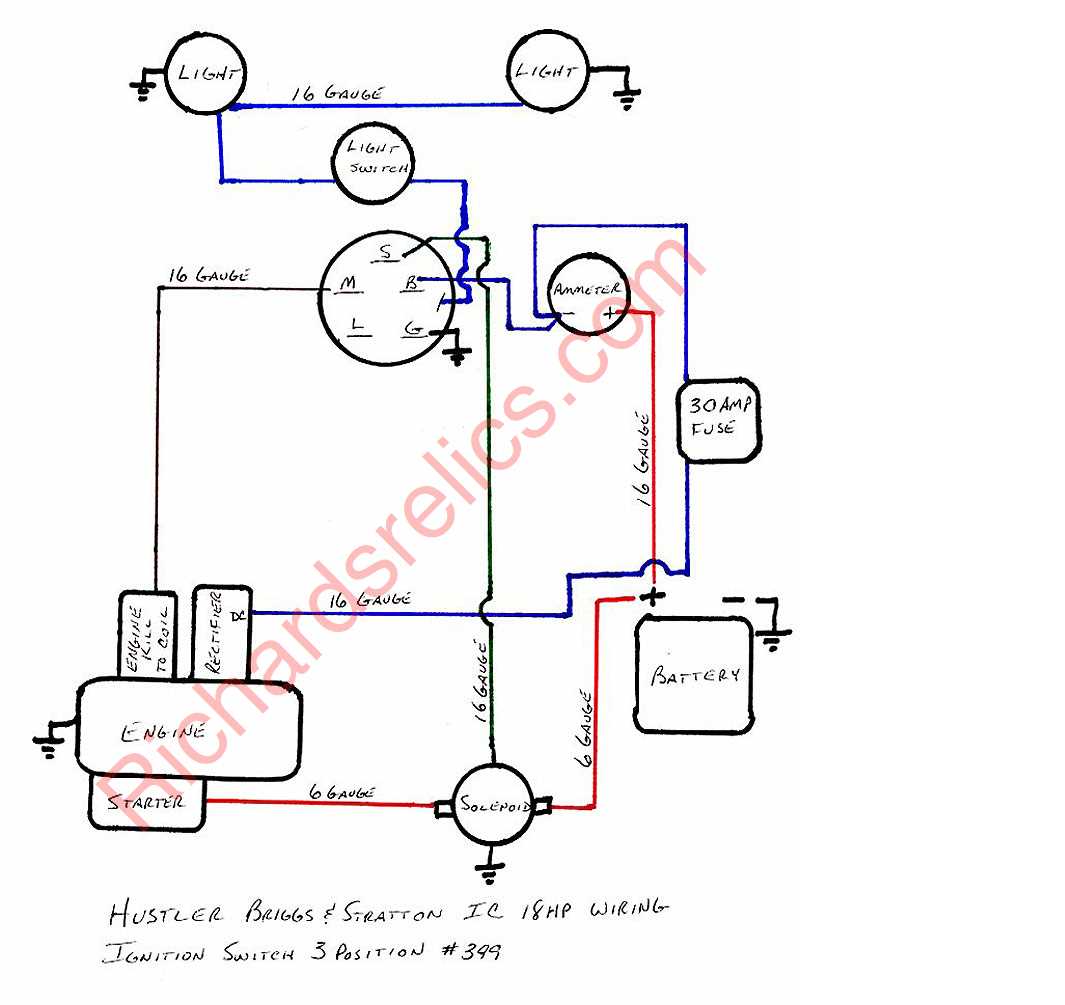

Ignition System Failures

A weak or inconsistent spark is often due to worn spark plugs or faulty wiring. Ensuring proper electrical connections and replacing worn components helps avoid ignition problems. Regular inspection of the ignition system prevents larger issues from occurring.

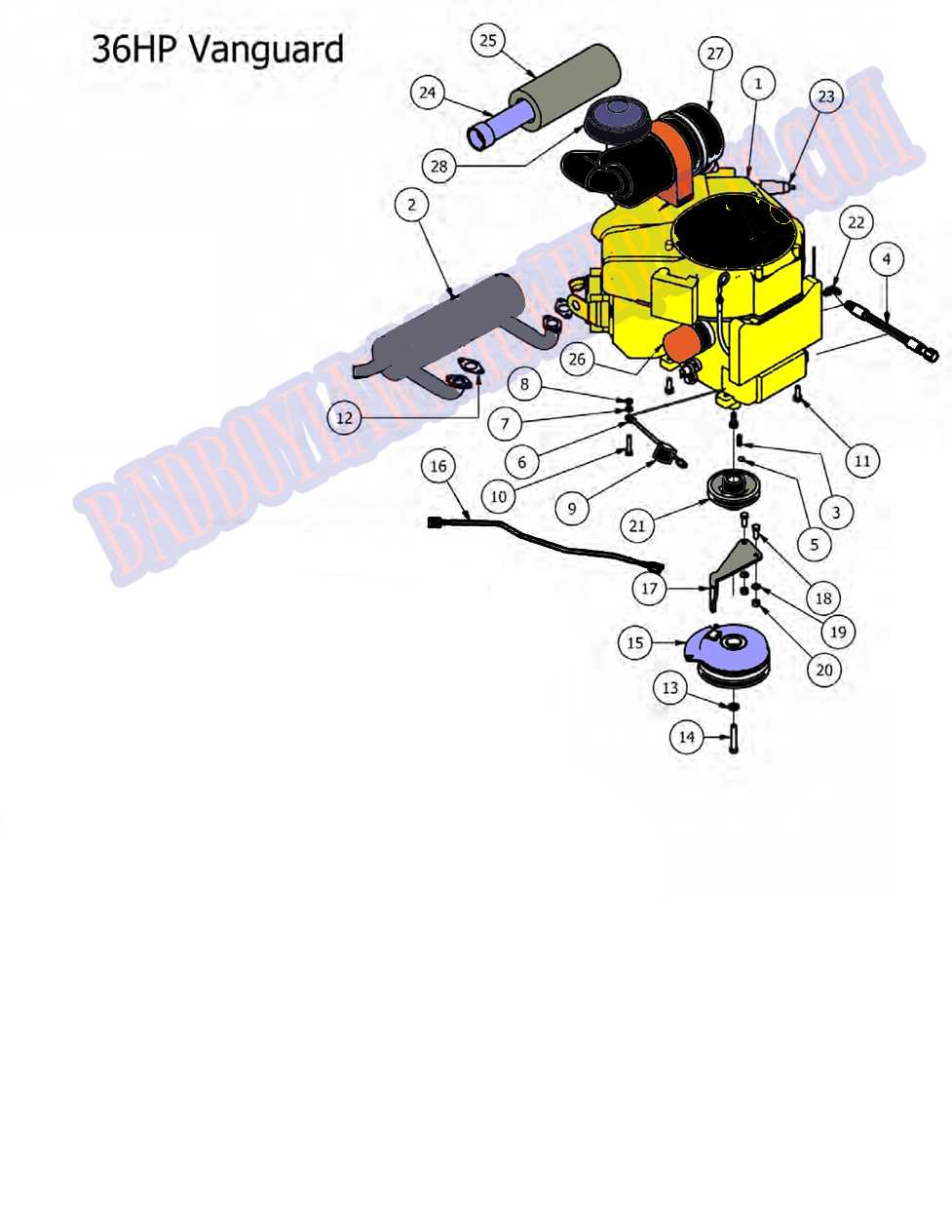

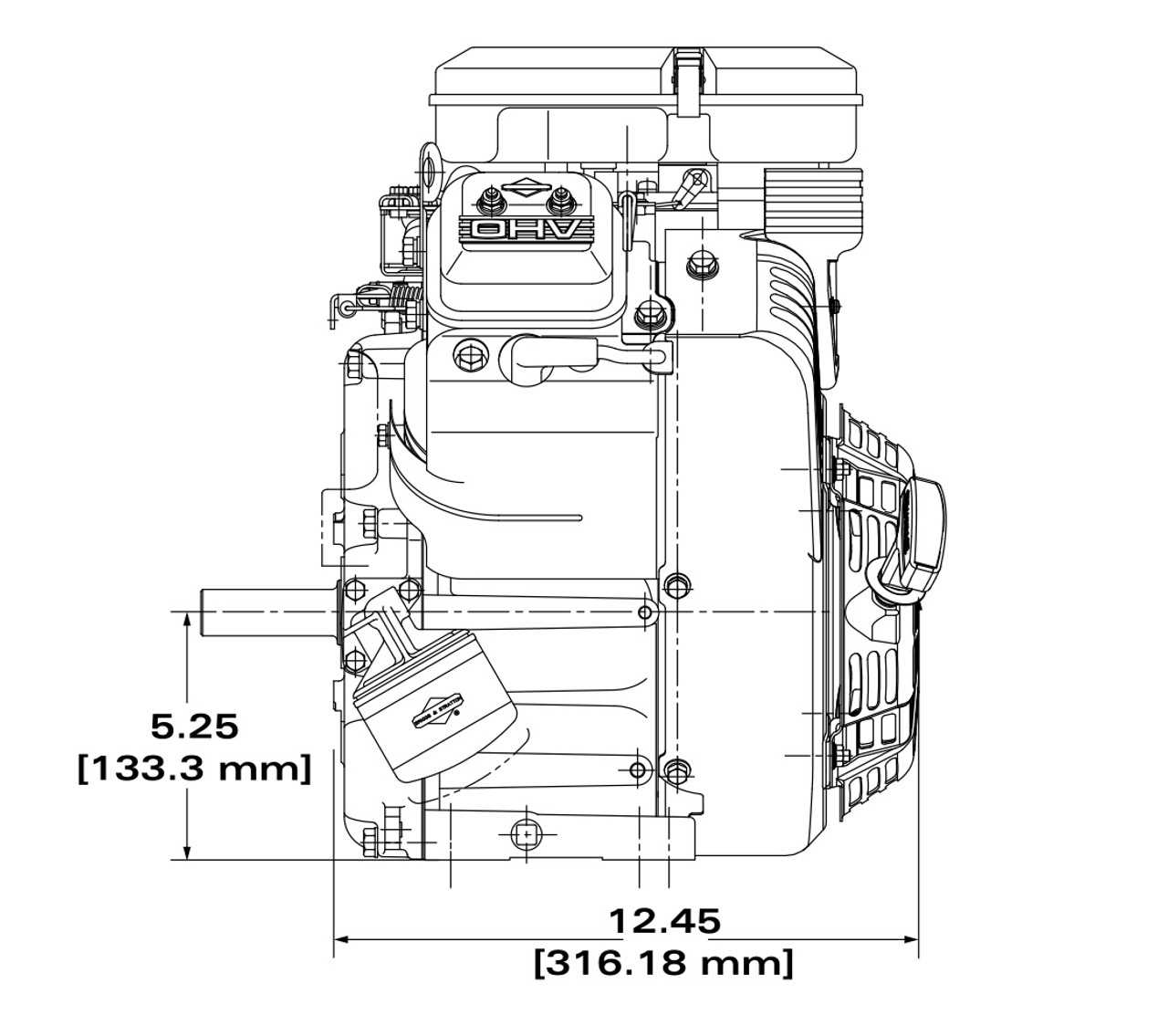

How to Identify Vanguard Engine Components

Understanding the various elements of a mechanical unit is essential for proper maintenance and repair. Recognizing key sections and components can save time and ensure smooth operation.

- Locate the ignition system by identifying where the spark plug is connected. This area is crucial for starting the unit.

- Find the fuel intake by tracing the path from the tank to the carburetor, which controls the mixture of fuel and air.

- Inspect the cooling system, usually marked by fins or a fan, which helps regulate temperature during operation.

- Identify the exhaust outlet, the section responsible for expelling gases produced during combustion.

- Check the lubrication system, typically involving a dipstick or cap, which ensures smooth movement of internal parts.

By examining these areas, you can easily determine the function of each component and keep the machine running efficiently.

Replacement Guide for Vanguard 18 HP Parts

When maintaining or restoring a high-performance 18 HP model, it’s crucial to choose suitable components to ensure longevity and efficient operation. Selecting the correct replacements and understanding the process for swapping out older units can help avoid unnecessary wear and tear while optimizing performance.

Key Components for Maintenance

Regular upkeep requires attention to certain areas that frequently experience stress. These include essential systems responsible for fuel delivery, cooling, and power output. Below is a list of key elements often in need of replacement:

| Component |

Function |

Recommended Check Interval |

| Fuel Filter |

Keeps impurities out of the fuel system |

Every 100 hours |

| Air Filter |

Ensures clean airflow for combustion |

Every 50 hours |

Maintenance Tips for a Vanguard Engine

Regular upkeep of your machinery ensures optimal performance and a longer lifespan. Consistent attention to key components, proper lubrication, and timely replacements prevent malfunctions and extend service life. It is crucial to establish a routine for inspection and care to avoid unexpected breakdowns.

Begin by checking fluid levels frequently. Low or contaminated fluids can lead to significant wear. Ensure that filters are clean and free from blockages to promote efficient operation. Cleanliness is also essential for cooling systems, preventing overheating during use.

Another important step is tightening any loose bolts or fasteners. Vibration from prolonged usage can cause loosening, which may lead to severe damage if not addressed. Regular inspection helps identify such issues early.

Finally, schedule periodic professional tune-ups. Expert assessments can detect underlying problems that may not be obvious during routine checks. Proactive care keeps your machine running smoothly and avoids costly repairs.

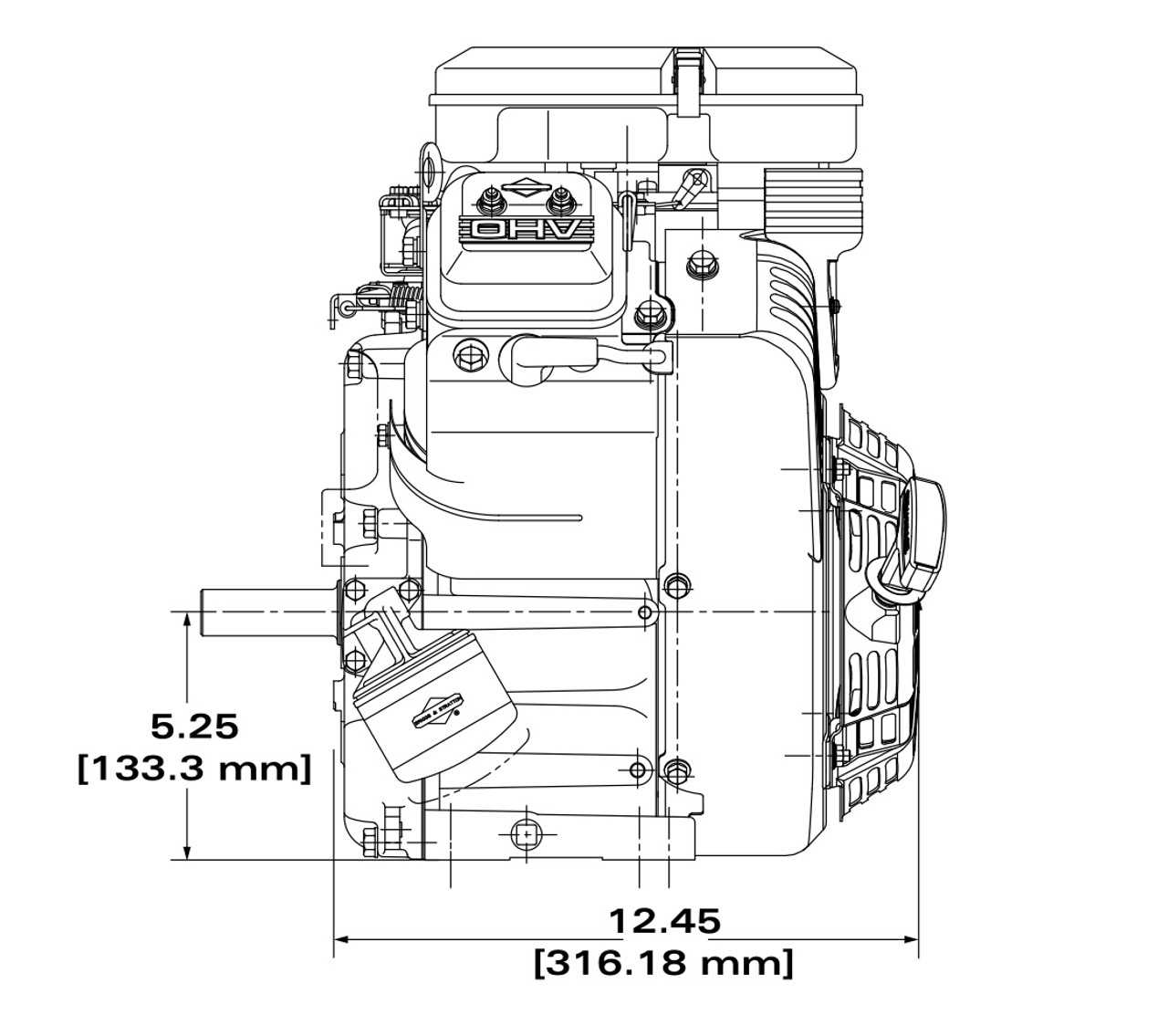

Understanding the Vanguard Engine’s Cooling System

The cooling mechanism plays a crucial role in maintaining optimal operating temperatures, ensuring efficient performance and longevity of the machinery. This system prevents overheating by effectively dissipating heat generated during operation. Understanding its components and functions is essential for effective maintenance and troubleshooting.

Key Components of the Cooling Mechanism

The primary elements include a radiator, coolant, and a water pump. The radiator facilitates heat exchange, allowing the coolant to absorb excess heat before it circulates back to the engine. The water pump ensures the consistent flow of the coolant, maintaining circulation throughout the system.

Importance of Regular Maintenance

Regular inspection and maintenance of the cooling system are vital to prevent potential failures. Checking coolant levels, ensuring the radiator is free of obstructions, and examining hoses for leaks contribute to the overall efficiency and reliability of the machinery.

Benefits of Using Genuine Vanguard Parts

Utilizing authentic components offers numerous advantages for maintenance and performance. These elements are specifically designed to fit and function seamlessly within your machinery, ensuring optimal operation and longevity.

Enhanced Reliability

Using original components significantly boosts the reliability of your equipment. Each piece is manufactured to exacting standards, which helps prevent premature failures and reduces the likelihood of unexpected breakdowns.

Improved Performance

Authentic components contribute to better overall performance. They are engineered to work together efficiently, maximizing power output and ensuring smooth operation. This results in higher productivity and less downtime for repairs.

Upgrading Your Vanguard Engine for Better Performance

Enhancing the capabilities of your small machinery can lead to significant improvements in efficiency and power. Upgrading various components can optimize overall functionality, resulting in smoother operation and increased output. Understanding how different modifications can impact performance is essential for achieving desired results.

Choosing the Right Components

Selecting high-quality elements is crucial for maximizing performance. Focus on parts that provide durability and reliability. Consider options such as advanced air filters, efficient exhaust systems, and high-performance fuel injectors. These upgrades can contribute to a noticeable boost in operational efficiency.

Tuning and Maintenance

Regular tuning and proper maintenance are vital to ensure your upgrades function as intended. Keep an eye on wear and tear, and replace any worn components promptly. Additionally, regular checks and adjustments can enhance performance and extend the lifespan of your machinery.