The efficiency and longevity of any water circulation mechanism depend significantly on its individual elements. Understanding these components is crucial for maintenance and effective operation. Each piece plays a vital role in ensuring smooth functionality and optimal performance.

Identifying the various elements involved in such a system allows for better troubleshooting and repair processes. Knowing how each part interacts can lead to improved efficiency and reduced energy consumption. Proper familiarity with these essential components also aids in recognizing signs of wear or malfunction, prompting timely interventions.

In this section, we will explore the key elements that contribute to the successful operation of a water circulation setup. From motor assemblies to filtration units, each aspect will be examined to provide a comprehensive understanding of how they work together seamlessly.

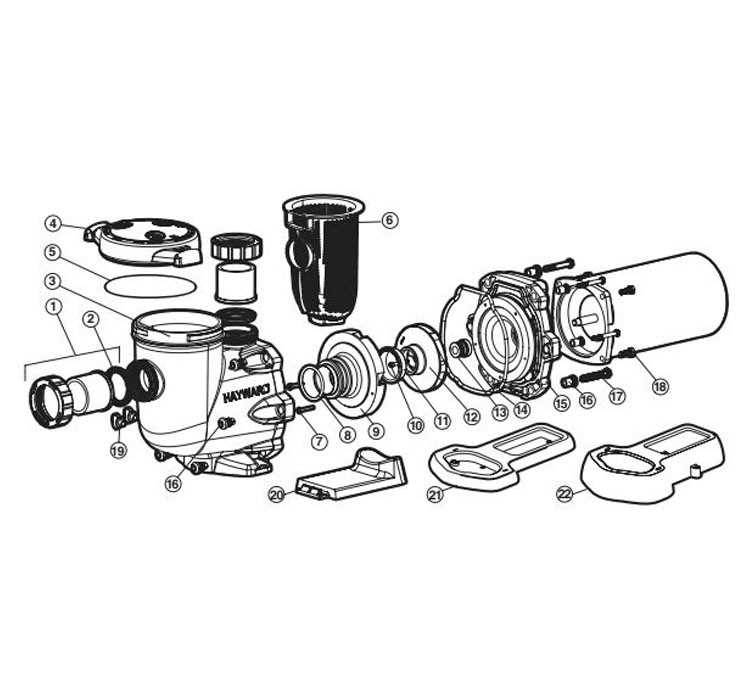

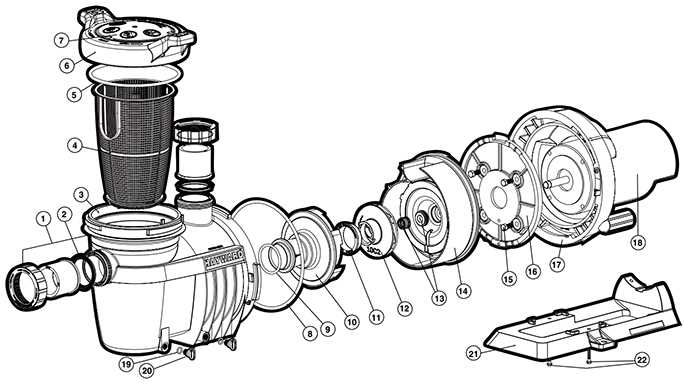

Overview of Hayward Pool Pumps

This section delves into the essential components and functionality of a renowned brand’s circulation systems designed for water management in aquatic environments. These systems play a crucial role in maintaining cleanliness and optimal water conditions, ensuring a refreshing experience for users. Their engineering focuses on efficiency and reliability, making them a preferred choice for many installations.

Key Features

One of the standout characteristics of these circulation units is their powerful motors, which drive the water through the filtration system effectively. Additionally, advanced technology in their design allows for quieter operation and energy efficiency, reducing operational costs over time. Various models offer features such as self-priming capabilities and adjustable flow rates to cater to different needs.

Maintenance and Care

Regular maintenance is vital to ensure the longevity and performance of these systems. Users should conduct routine checks on the motor, seals, and other integral components to prevent any potential issues. Following the manufacturer’s guidelines for care and servicing can significantly enhance the efficiency and lifespan of the equipment, contributing to a consistently pleasant environment.

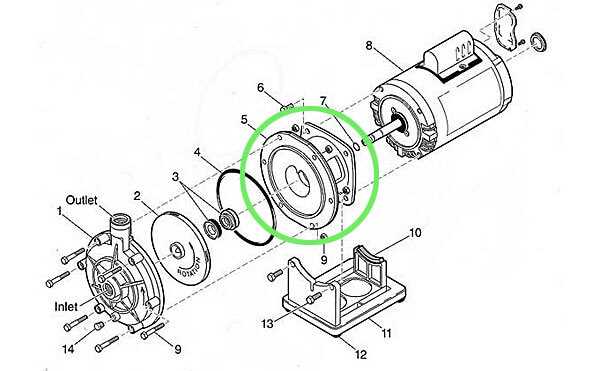

Key Components of a Pool Pump

The functionality of a water circulation system relies on several essential elements that work together to ensure efficient operation. Understanding these components is crucial for maintaining and optimizing the system’s performance.

Motor: The driving force behind the system, the motor converts electrical energy into mechanical energy, enabling the movement of water. It is vital to select a motor with the appropriate power to match the system’s requirements.

Impeller: This rotating component creates the necessary pressure to move water through the system. The design and material of the impeller can significantly affect the efficiency and durability of the circulation process.

Volute: The volute houses the impeller and directs water flow. Its shape is designed to minimize turbulence and maximize efficiency, ensuring that water moves smoothly through the system.

Strainer: Located at the intake, the strainer prevents debris from entering the system, protecting the internal components from damage. Regular cleaning and maintenance of the strainer are essential for optimal performance.

Seal: Seals prevent leaks by maintaining a watertight barrier between different components. Regular inspection and replacement of seals can help avoid potential issues and ensure a long-lasting system.

Control Panel: This component allows users to manage and monitor the system’s operation. Modern control panels may offer features such as timers, speed settings, and diagnostic tools for efficient management.

Understanding 1.5 HP Pump Functionality

This section explores the essential principles underlying the operation of a specific horsepower motor designed for fluid circulation systems. Understanding these principles is crucial for effectively maintaining and troubleshooting the equipment.

The functionality of a motor relies on various components that work together to ensure efficient operation. Each element plays a vital role in the overall performance, contributing to the system’s ability to maintain optimal flow rates and pressure levels.

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical energy to drive the system. |

| Impeller | Moves the liquid through the system, creating flow and pressure. |

| Diffuser | Directs the flow from the impeller to the discharge outlet, improving efficiency. |

| Strainer | Filters debris from the fluid, protecting internal components. |

| Seal | Prevents leakage of the fluid and protects the motor from moisture damage. |

By familiarizing yourself with these components and their functions, you can enhance the longevity and efficiency of your system, ensuring it operates at peak performance.

Common Issues with Pool Pumps

Many individuals encounter various challenges with their aquatic circulation systems, affecting overall performance and efficiency. Recognizing these issues early can help in maintaining optimal function and extending the lifespan of the equipment.

Noise Problems: Unusual sounds such as grinding, humming, or rattling may indicate a malfunctioning component or debris lodged in the mechanism. These noises can disrupt the peaceful environment around your water feature.

Insufficient Flow: A decrease in water movement may result from blockages in the system, worn-out seals, or improper installation. This issue can lead to poor filtration and create an unhealthy environment.

Overheating: Excessive heat can cause significant damage, often resulting from a clogged filter, low water levels, or malfunctioning motor components. Keeping an eye on temperature levels is essential to prevent breakdowns.

Leaks: Water escaping from connections or seals can lead to decreased efficiency and increased energy costs. Identifying the source of leaks promptly is crucial for maintaining system integrity.

Electrical Issues: Faulty wiring or malfunctioning controls may hinder the operation of your equipment. Regular inspections of electrical components can help prevent unexpected shutdowns or safety hazards.

Addressing these common problems with diligence can ensure the longevity and effectiveness of your circulation system, allowing for a more enjoyable and safe aquatic experience.

Maintenance Tips for Pool Owners

Proper upkeep is essential for any water feature to ensure its longevity and optimal performance. Regular attention not only enhances the enjoyment of your aquatic space but also prevents costly repairs in the future. By following a few straightforward guidelines, you can maintain a clean and inviting environment for relaxation and recreation.

Regular Cleaning: Keeping the surface and walls free from debris is vital. Use a net or skimmer to remove leaves and dirt frequently. Vacuuming the bottom helps eliminate stubborn particles that settle over time.

Check Water Chemistry: Balancing pH levels, alkalinity, and chlorine content is crucial for maintaining clear water and protecting equipment. Test the water regularly using a quality testing kit and adjust the chemicals as needed.

Inspect Equipment: Regularly examine all components for signs of wear or damage. Look for leaks, unusual noises, or vibrations that might indicate a problem. Timely repairs can prevent larger issues down the line.

Monitor Water Levels: Ensure that the water is at the appropriate level for efficient operation. Evaporation and usage can lower the levels, so refill as necessary to avoid strain on the system.

Winterization: If applicable, prepare your setup for colder months by properly draining and storing equipment to prevent freezing damage. Use appropriate covers to protect against the elements during the off-season.

Implementing these practices can significantly enhance your enjoyment and minimize future issues. A well-maintained aquatic environment provides a refreshing escape for everyone.

Replacement Parts for Hayward Pumps

When maintaining a filtration system, having access to the right components is essential for optimal performance. This section provides an overview of essential replacements that can help ensure longevity and efficiency in your system.

Common components that may require replacement include:

- Seals and O-rings: Vital for preventing leaks and maintaining pressure.

- Filters: Essential for trapping debris and keeping the water clean.

- Impellers: Responsible for moving water efficiently; wear over time can affect flow rates.

- Motors: Key for the operation of the entire system; signs of wear may necessitate a replacement.

- Housings: Protect internal components; cracks or damage can lead to malfunction.

When selecting replacements, consider the following:

- Compatibility with your system model.

- Quality of the components, as higher quality often leads to better durability.

- Manufacturer recommendations to ensure proper fit and function.

By ensuring you have the correct replacements, you can enhance the performance and lifespan of your filtration system.

Identifying Pump Part Numbers

Understanding the unique identifiers for various components is essential for maintenance and repairs. Each element within the system is designated a specific code that allows for easy reference when ordering replacements or consulting documentation. Familiarity with these codes can streamline the process of identifying and acquiring the necessary components, ensuring that your equipment operates efficiently.

These identifiers are typically found on the components themselves or in the manufacturer’s literature. Properly recognizing these numbers not only aids in quick replacements but also enhances the overall reliability of the entire system.

| Component Description | Part Number |

|---|---|

| Motor Assembly | MP-12345 |

| Sealing Gasket | SG-67890 |

| Impeller | IM-54321 |

| Strainer Basket | SB-98765 |

| Diffuser | DF-13579 |

Safety Precautions When Repairing Pumps

When undertaking maintenance or repairs on mechanical devices, it is essential to prioritize safety. Proper precautions can prevent accidents and ensure a smooth workflow. Understanding the inherent risks and following established safety protocols are vital steps in the repair process.

Here are some key safety measures to consider:

- Always disconnect the device from its power source before beginning any repair work.

- Use appropriate personal protective equipment (PPE), such as gloves, safety goggles, and steel-toed boots.

- Ensure your workspace is clean and organized to avoid tripping hazards and misplaced tools.

Moreover, consider the following recommendations:

- Read the manufacturer’s instructions and guidelines thoroughly before starting repairs.

- Have a first-aid kit readily available in case of minor injuries.

- Be aware of your surroundings and avoid distractions while working.

By adhering to these precautions, you can significantly reduce the risk of injury and ensure a successful repair process.