The efficient operation of lawn machinery heavily relies on the various components that make up its cutting system. Understanding how these elements function together can greatly enhance maintenance efforts and extend the longevity of the equipment. This section delves into the intricate arrangement of the essential pieces that contribute to optimal performance.

By familiarizing oneself with the layout and role of each component, users can identify potential issues and address them proactively. Such knowledge empowers operators to ensure their equipment remains in peak condition, allowing for consistent and effective grass management. Furthermore, comprehending the interconnectedness of these elements promotes informed decision-making when it comes to repairs or replacements.

As we explore the specifics of the various components, attention will be given to their functions and how they interact with one another. This detailed analysis serves as a valuable resource for both novice users and seasoned professionals looking to refine their understanding of lawn care machinery.

This section provides an overview of a specific cutting apparatus designed for lawn maintenance. It highlights its components and functionalities, essential for ensuring optimal performance and longevity. Understanding these elements is crucial for effective operation and maintenance, enhancing the user experience.

Components of the Cutting Apparatus

The cutting mechanism consists of several key elements that contribute to its efficiency. Familiarity with these components is vital for proper upkeep and troubleshooting.

| Component | Description |

|---|---|

| Blades | Essential for cutting grass at desired lengths. |

| Spindle Assembly | Supports and rotates the blades, ensuring smooth operation. |

| Deflector | Directs clippings away from the operator for safety. |

| Frame | Houses all components, providing stability and support. |

Maintenance Tips for Longevity

Regular care and maintenance are crucial for extending the lifespan of this essential lawn equipment. Implementing a maintenance schedule can prevent costly repairs and ensure peak performance.

Key Components of Mower Deck

The essential elements of a cutting platform play a crucial role in its overall performance and efficiency. Understanding these components helps in maintaining the equipment effectively and ensuring optimal functionality during operation.

| Component | Description |

|---|---|

| Cutting Blades | These are responsible for the actual cutting action, providing a clean and even finish to the grass. |

| Spindle Assembly | This component houses the blades and allows them to rotate at high speeds, essential for effective cutting. |

| Height Adjustment Mechanism | This allows the operator to set the desired cutting height, accommodating different grass types and conditions. |

| Chassis | The structural framework that supports all components and ensures stability during operation. |

| Belts and Pulleys | These transmit power from the engine to the blades, crucial for their rotation. |

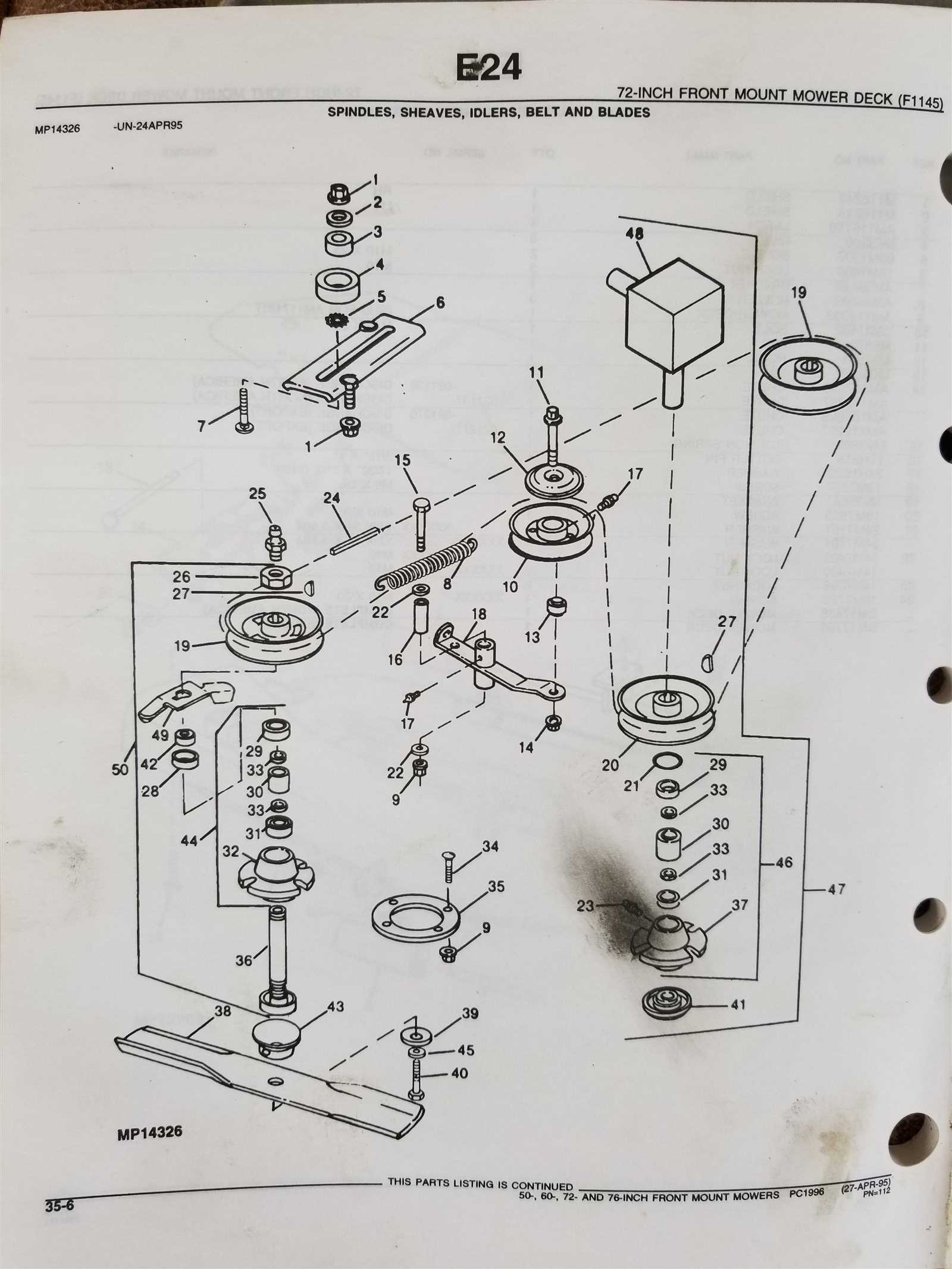

Understanding the Parts Diagram

Comprehending the components layout is essential for effective maintenance and repair of equipment. A clear visual representation aids in identifying each element’s function and location, facilitating smoother assembly and disassembly processes. This knowledge is crucial for ensuring that all pieces work harmoniously together.

Key elements of the layout often include various segments that contribute to the overall functionality. Familiarity with these sections enables users to pinpoint potential issues quickly. Recognizing the significance of each component allows for better troubleshooting and enhances the longevity of the machinery.

In summary, a well-illustrated components layout is invaluable for anyone seeking to optimize equipment performance. It serves as a practical reference that supports informed decision-making during maintenance tasks, ultimately leading to improved operational efficiency.

Maintenance Tips for Mower Deck

Proper upkeep of the cutting assembly is essential for optimal performance and longevity of your lawn equipment. Regular attention to maintenance tasks can significantly enhance the efficiency of the machine while ensuring a clean and even cut. Here are some effective strategies to keep the equipment in excellent condition.

Regular Inspection and Cleaning

Frequent checks and cleaning of the cutting area are crucial. Debris buildup can hinder performance and lead to rust and corrosion. After each use, make it a habit to remove grass clippings and dirt, especially from hard-to-reach spots. Using a soft brush or cloth will help maintain the integrity of the components.

Sharpening and Replacement

Keeping the blades sharp is vital for achieving a precise cut. Dull blades can tear the grass rather than cut it, leading to unhealthy lawns. Regularly inspect the edges for wear and tear, and replace or sharpen them as needed. This simple action can drastically improve the quality of your mowing.

| Maintenance Task | Frequency | Tools Needed |

|---|---|---|

| Inspect and Clean | After each use | Brush, cloth |

| Sharpen Blades | Every 20-25 hours | Wrench, file or sharpener |

| Check Bolts and Screws | Monthly | Screwdriver, wrench |

Common Issues with Mower Parts

Maintaining equipment can be challenging, especially when dealing with various components that can wear out or malfunction over time. Understanding typical problems associated with these components can help users identify issues early and ensure optimal performance.

Wear and Tear

Over time, components can experience degradation due to constant use. This can lead to:

- Reduced efficiency in operation

- Increased fuel consumption

- Unusual noises during functioning

Improper Maintenance

Lack of regular upkeep can cause several issues, such as:

- Accumulation of debris, leading to blockages

- Rust and corrosion due to exposure to moisture

- Poor performance and uneven cutting results

Replacement Parts for Mower Deck

Maintaining the efficiency and functionality of your equipment requires understanding the essential components that may need to be replaced over time. Ensuring that each element is in optimal condition not only enhances performance but also extends the lifespan of the machinery. Familiarity with various available components is crucial for timely repairs and replacements, contributing to a smooth operation.

Essential Components

Key elements that may require attention include blades, belts, and bearings. Blades are vital for achieving a clean cut, while belts ensure proper movement and power transfer. Additionally, bearings play a significant role in facilitating smooth rotation, reducing friction, and preventing wear. Regular inspection of these components can help identify any signs of damage or wear that necessitate replacement.

Where to Find Quality Components

Finding reliable sources for quality components is essential for maintaining your machinery. Online retailers and specialized local dealers often provide a wide selection of components tailored to specific equipment needs. When purchasing, ensure that the components are compatible with your model and are made from durable materials to guarantee longevity and performance.

Installation Guide for Mower Components

Proper assembly and installation of cutting equipment elements are essential for optimal performance and longevity. This section outlines the necessary steps to ensure that each component is installed correctly, minimizing potential issues during operation.

Step 1: Begin by gathering all necessary tools and components. Ensure that you have a clear workspace to facilitate efficient assembly.

Step 2: Refer to the assembly instructions specific to your model. Each component should be fitted according to the manufacturer’s specifications to maintain functionality and safety.

Step 3: Securely fasten all parts using the appropriate hardware. Check for tightness and alignment to prevent any operational difficulties.

Step 4: Once the installation is complete, conduct a thorough inspection to confirm that everything is in place and functioning correctly. Test the equipment briefly to ensure proper operation before full use.

Step 5: Regular maintenance is crucial for longevity. Follow the recommended service intervals to keep your assembly in optimal condition.

Benefits of Proper Deck Maintenance

Regular upkeep of your lawn equipment’s cutting apparatus is essential for optimal performance and longevity. Consistent care not only enhances efficiency but also ensures a pristine cut, promoting healthy grass growth.

- Improved Cutting Performance: Routine maintenance helps maintain sharp blades, resulting in cleaner cuts and reducing the risk of tearing grass blades.

- Increased Lifespan: Regular inspections and part replacements can extend the operational life of the equipment, saving costs on premature replacements.

- Enhanced Safety: Proper maintenance reduces the likelihood of mechanical failures, minimizing safety hazards during operation.

- Fuel Efficiency: Well-maintained machinery operates more efficiently, leading to lower fuel consumption and reduced operating costs.

- Environmental Benefits: Efficiently functioning equipment minimizes emissions and waste, contributing to a healthier environment.

In conclusion, investing time in proper care of your lawn equipment’s cutting system reaps significant rewards, ensuring effective operation and prolonging its service life.

Where to Find Quality Parts

Locating reliable components for your equipment can significantly enhance its performance and longevity. There are various sources to consider when searching for high-quality replacements that ensure optimal functionality.

- Authorized Dealers: These establishments often carry a wide range of certified components, ensuring compatibility and reliability.

- Online Retailers: Websites specializing in machinery supplies frequently provide detailed specifications and customer reviews, helping you make informed decisions.

- Local Repair Shops: Small businesses focused on equipment repair can offer valuable insights and access to quality parts, often with personalized service.

- Manufacturer’s Website: The official site may provide direct options for purchasing genuine components, often including warranties.

- Forums and Community Groups: Engaging with other users can lead to recommendations for trusted sources and potentially discovering hard-to-find items.

Taking the time to explore these avenues will help ensure you acquire the best components for your machinery needs, leading to improved efficiency and durability.