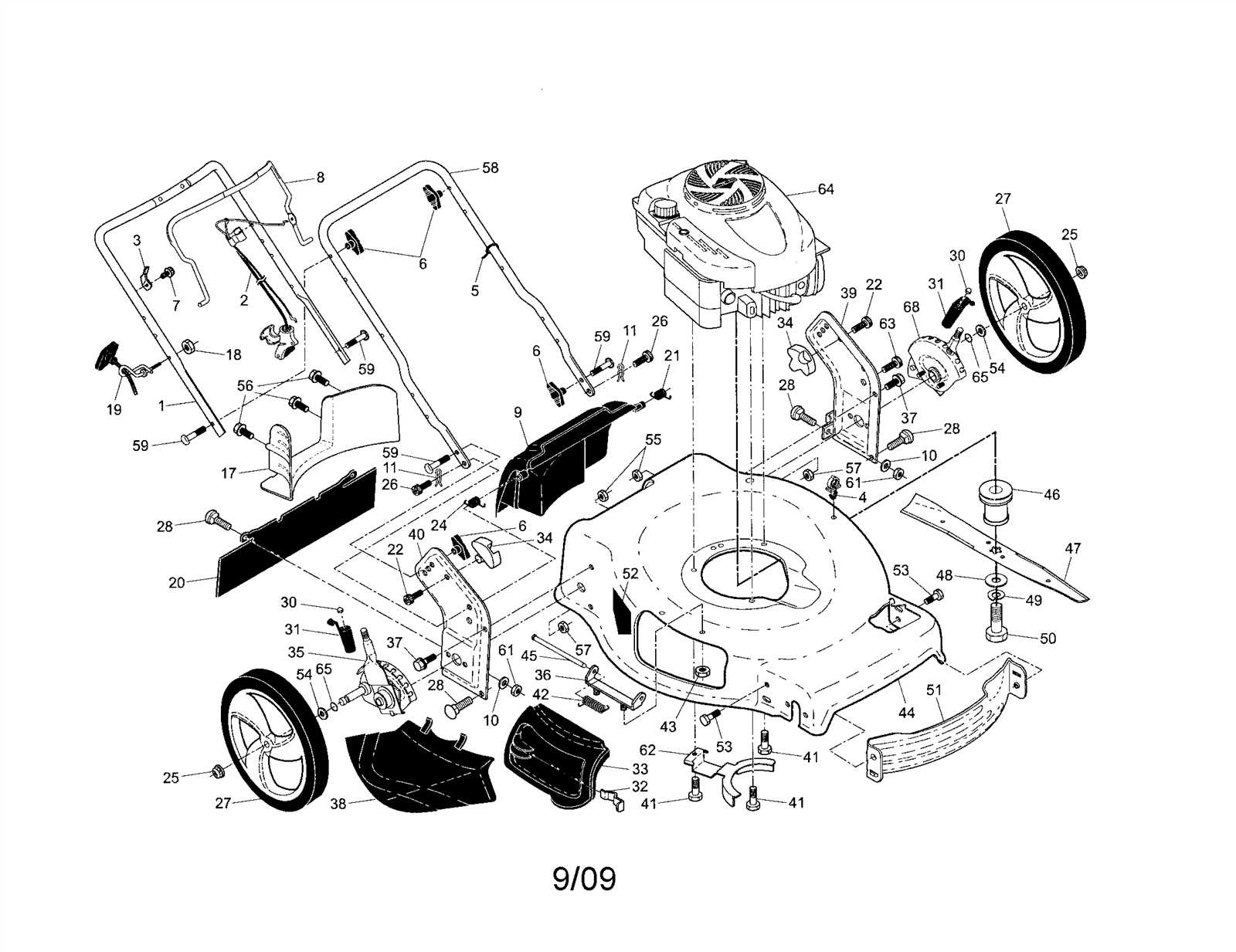

Maintaining machinery requires a clear understanding of its internal structures and elements. Knowledge of how each component fits together not only aids in troubleshooting but also ensures efficient operation. This section provides insights into the arrangement and function of various parts, enabling users to make informed decisions during maintenance or repair tasks.

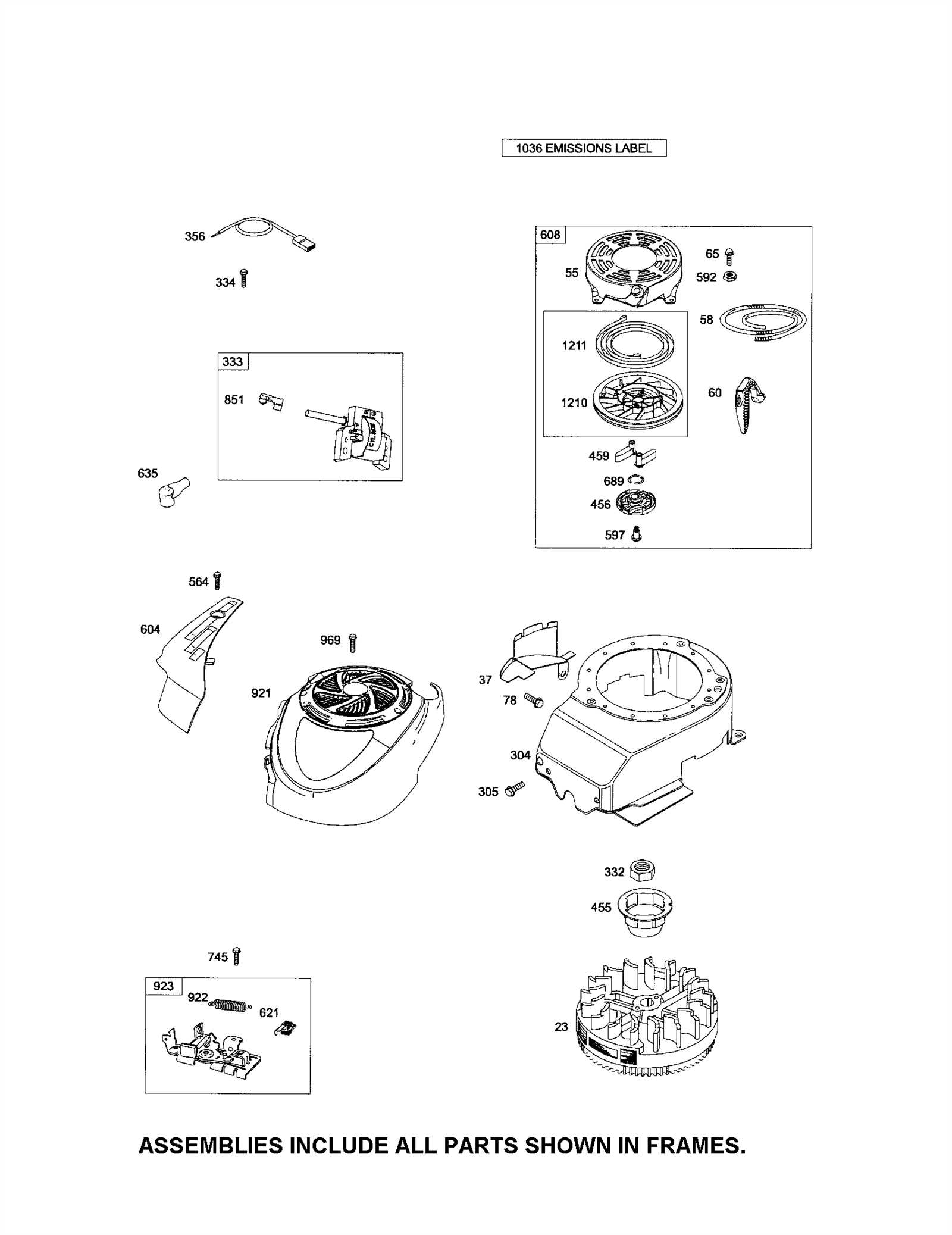

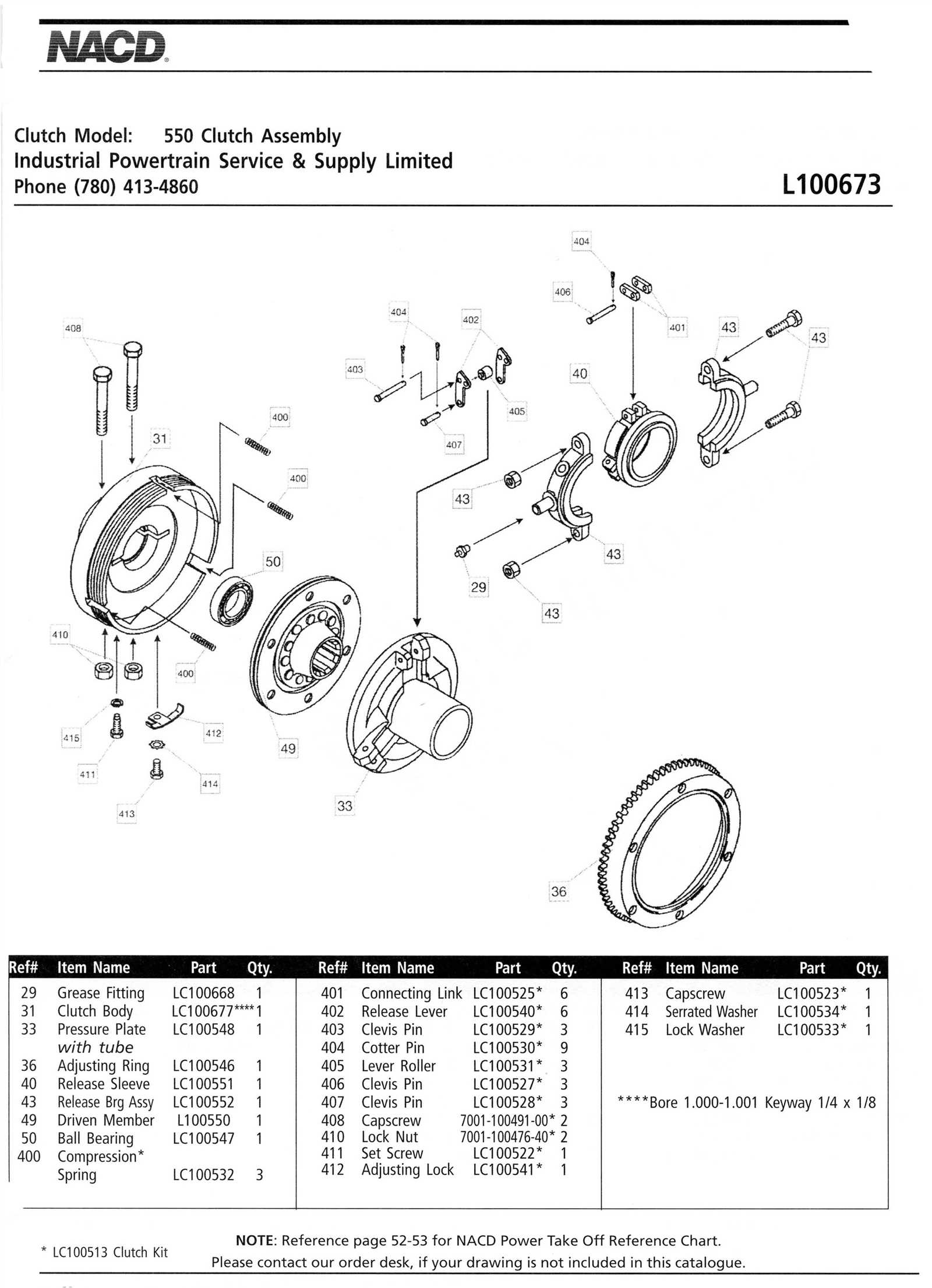

When approaching the complexities of any machine, a detailed visual representation of its assembly can be invaluable. Such illustrations help demystify the connections between different components, allowing users to recognize the importance of each piece within the larger system. By grasping these relationships, one can enhance both performance and longevity.

Moreover, an awareness of the distinct features of each segment empowers users to identify potential issues before they escalate. A well-informed operator can navigate challenges with greater confidence, ensuring that their equipment remains in optimal condition. This section aims to equip you with the essential knowledge necessary for effective maintenance and operational success.

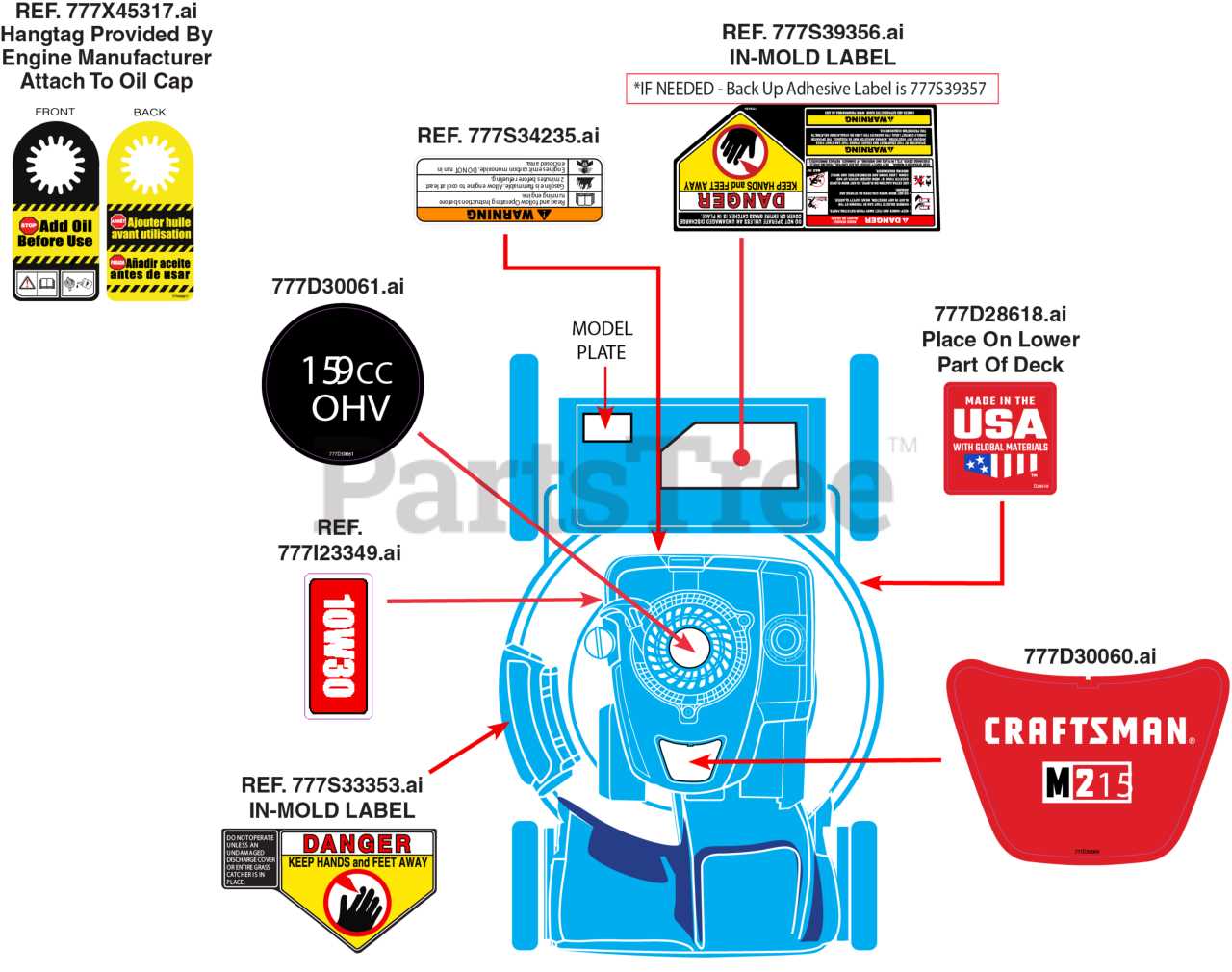

Understanding Craftsman M215 Components

Every machine is composed of various elements that work in harmony to ensure optimal performance. Grasping the function and interaction of these components is essential for effective maintenance and troubleshooting. By familiarizing oneself with each segment, users can enhance the longevity and efficiency of their equipment.

Engine: The heart of the machine, providing the necessary power to drive the entire system. Understanding its workings is crucial for diagnosing issues and ensuring proper functionality.

Chassis: This framework supports all other components, contributing to the overall stability. A solid chassis is vital for durability during operation.

Cutting Mechanism: Central to the machine’s purpose, this element requires regular inspection to maintain sharpness and effectiveness. Proper care can greatly affect performance.

Wheels: These parts allow for mobility and ease of use. Their condition directly impacts maneuverability, making regular checks essential.

Controls: User interfaces that allow for operation adjustments. Familiarity with these features can lead to more efficient usage and improved results.

By delving into the intricacies of these components, users can achieve an ultimate understanding that fosters better care and optimal operation of their machines.

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools for identifying each element’s function and placement within a device. They provide a clear overview that enhances comprehension and efficiency during troubleshooting.

Firstly, these illustrations help users quickly locate specific elements, facilitating timely interventions when issues arise. By having a visual guide, individuals can save significant amounts of time that would otherwise be spent searching for components or trying to decipher complex assemblies.

Additionally, these visuals foster a deeper understanding of how different parts interact with one another. This knowledge is crucial for both novice and experienced technicians, as it aids in diagnosing problems accurately and ensuring proper reassembly after servicing.

Moreover, utilizing these representations minimizes the risk of errors. When a user has a clear map of the device’s layout, the chances of misplacing or incorrectly installing components decrease significantly, leading to improved performance and longevity of the machinery.

In conclusion, visual aids are not merely helpful but essential in the realm of equipment management. They streamline processes, enhance knowledge, and promote accuracy, making them indispensable resources for anyone involved in the upkeep of mechanical systems.

Common Issues with M215 Parts

When working with various tools and machinery, users often encounter a range of challenges related to components. Understanding these common problems can significantly enhance maintenance and performance, ensuring longevity and efficiency in operation.

Wear and Tear: One frequent issue involves the gradual degradation of specific elements due to regular use. Components can become less effective over time, necessitating replacement to maintain optimal functionality.

Improper Assembly: Incorrect installation of parts can lead to malfunctions. Ensuring that each component is fitted correctly is crucial for smooth operation and preventing damage to the overall system.

Material Fatigue: Exposure to varying environmental conditions may cause certain materials to weaken. Regular inspections can help identify signs of fatigue, allowing for timely interventions before failures occur.

Incompatibility: Occasionally, users may mistakenly use non-compatible elements, resulting in performance issues. It is vital to verify compatibility to avoid unnecessary complications and ensure seamless functionality.

Lubrication Issues: Insufficient lubrication can lead to friction-related problems, causing parts to overheat or seize. Regular maintenance checks should include ensuring that all moving components are adequately lubricated.

By being aware of these prevalent issues, users can proactively address potential problems, leading to a more reliable and efficient experience with their equipment.

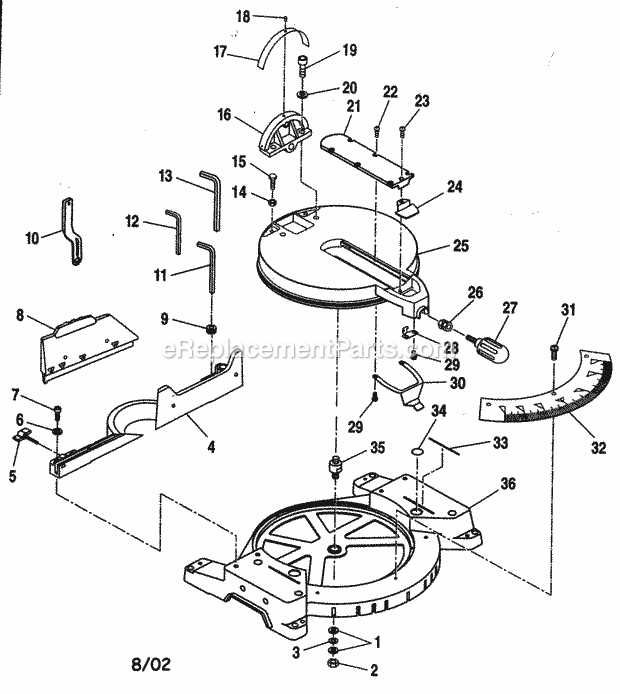

Step-by-Step Repair Guide

This section offers a comprehensive approach to fixing common issues with your equipment. Following these organized steps will ensure a successful restoration process, allowing you to return to optimal functionality quickly.

- Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Replacement parts

- Cleaning materials

- Safety First:

Disconnect power sources and wear protective gear to prevent accidents.

- Disassemble the Unit:

Carefully take apart the components, noting their arrangement for reassembly.

- Inspect Parts:

Check each piece for wear or damage, identifying any that require replacement.

- Clean Components:

Remove dirt and debris from all parts to ensure smooth operation.

- Replace Damaged Parts:

Install new components as needed, ensuring they fit properly.

- Reassemble the Equipment:

Carefully put everything back together, following the order noted during disassembly.

- Test Functionality:

Reconnect power and run a test to confirm that everything operates correctly.

By following these steps, you can effectively address common issues and maintain the longevity of your machinery.

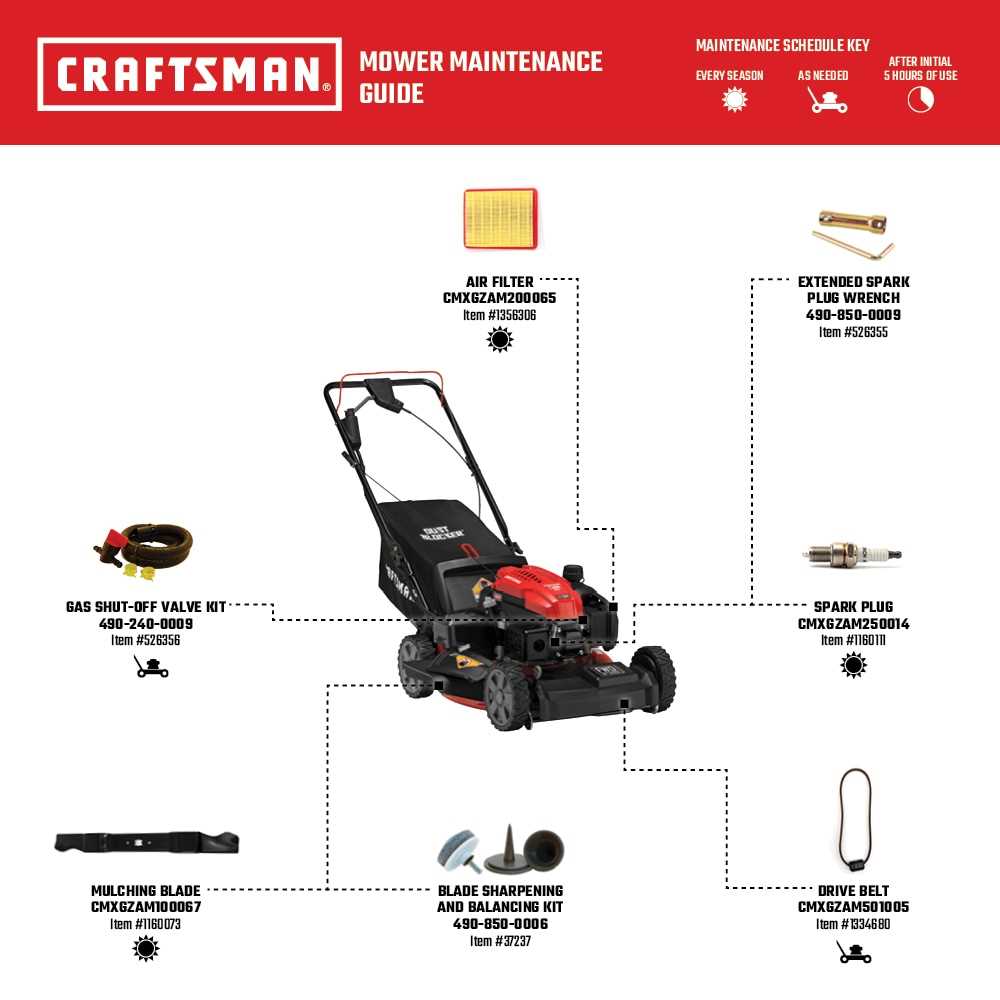

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its performance and longevity. Various sources are available for sourcing these essentials, ensuring you have the right items at your disposal.

Online Retailers

- Dedicated websites specializing in outdoor tools.

- General e-commerce platforms offering a wide range of options.

- Manufacturer’s official websites for authentic items.

Local Stores

- Hardware shops that stock a variety of tools and accessories.

- Home improvement centers with dedicated sections for outdoor equipment.

- Specialty stores focused on repair and maintenance supplies.

By exploring these avenues, you can ensure your equipment remains in optimal condition for all your projects.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your equipment. By implementing a few simple practices, you can significantly enhance its performance and reliability.

Regular Cleaning

- Remove debris and dirt after each use.

- Use a soft brush to clean hard-to-reach areas.

- Check filters and replace them as necessary.

Routine Inspections

- Inspect components for wear and tear periodically.

- Look for loose screws or connections.

- Ensure all moving parts are lubricated appropriately.

By following these maintenance tips, you can delve deeper into achieving optimal functionality and prolonging the life of your tools.

Comparing M215 to Similar Models

When evaluating various models in the same category, it’s essential to analyze their specifications, features, and overall performance. This comparison can highlight the strengths and weaknesses of each option, providing insights into which model may better suit specific needs and preferences.

One significant aspect to consider is the engine power and efficiency, which can greatly influence operational effectiveness. Additionally, design elements such as cutting width and height adjustments can differentiate user experiences and impact usability in diverse conditions.

Another critical factor is durability and maintenance requirements. Models with robust construction and easy-to-access components typically offer better longevity and require less frequent servicing, making them appealing choices for users seeking reliability over time.

Lastly, assessing user feedback and expert reviews can provide valuable perspectives on real-world performance. This information can be instrumental in making an informed decision, ensuring that the selected model aligns with individual requirements and expectations.

DIY Modifications and Upgrades

Enhancing your equipment can significantly improve its performance and longevity. By implementing simple modifications and upgrades, you can tailor your tools to better suit your specific needs, making tasks easier and more efficient. This guide will explore various ways to personalize your device through creative enhancements.

Common Upgrades

Many users opt for upgrades that improve functionality and ease of use. Here are some popular options:

| Upgrade | Description |

|---|---|

| Enhanced Blades | Switching to high-quality or specialized blades can result in cleaner cuts and increased durability. |

| Ergonomic Handles | Replacing standard handles with ergonomic ones can reduce strain and improve comfort during prolonged use. |

| Performance Filters | Installing advanced filters can help maintain engine efficiency and reduce emissions. |

| Upgraded Wheels | Using larger or sturdier wheels can enhance maneuverability on various terrains. |

Customization Tips

For those looking to add a personal touch, customization can be a rewarding process. Consider the following tips:

- Experiment with paint or decals to give your tool a unique look.

- Integrate LED lighting for improved visibility during use.

- Add storage solutions for accessories and tools to enhance organization.

With these modifications and upgrades, you can create a more efficient and personalized experience, allowing your equipment to perform at its best while reflecting your individual style.

Resources for Troubleshooting Problems

When faced with mechanical issues, having access to reliable resources can make all the difference in effectively diagnosing and resolving problems. A variety of guides, manuals, and online forums can provide valuable insights, helping users understand their equipment and pinpoint any faults. This section will outline some essential resources that can assist in troubleshooting common challenges.

User Manuals

User manuals are often the first point of reference for troubleshooting. They typically include detailed information about the machinery, including specifications, maintenance tips, and common troubleshooting steps. Ensuring you have the latest version can provide insights into any updates or modifications made to the model.

Online Forums and Communities

Participating in online communities can offer a wealth of knowledge from fellow users who have encountered similar issues. These platforms allow for the exchange of tips, tricks, and personal experiences that can lead to effective solutions.

| Resource Type | Description | Example |

|---|---|---|

| User Manuals | Official documentation that includes specifications and troubleshooting tips. | Manufacturer’s website |

| Online Forums | Community-driven platforms for sharing experiences and solutions. | Reddit, specialized forums |

| Video Tutorials | Step-by-step guides that visually demonstrate repairs and maintenance. | YouTube channels |

| Customer Support | Direct assistance from professionals to resolve specific issues. | Manufacturer’s support line |