In the world of power equipment, a deep comprehension of the various components that contribute to functionality is essential. Each element plays a crucial role in the overall performance, ensuring efficiency and longevity of your device.

Visual aids can significantly enhance the understanding of these individual elements. They provide a clear representation of how parts interconnect, allowing users to identify and address issues with ease.

By exploring these illustrations, one can delve into the intricate workings of the machinery. This knowledge empowers users to maintain their tools effectively, ultimately leading to optimal operation and durability.

Understanding Craftsman CMCST915 Parts Diagram

Grasping the intricate layout of components is crucial for effective maintenance and repair of any equipment. A visual representation helps users identify and locate essential elements, ensuring a smoother experience during servicing. This guide will explore the significance of such visual tools, enhancing overall comprehension and facilitating efficient troubleshooting.

Importance of Visual Aids

Visual aids are instrumental in simplifying complex machinery. They provide clarity, making it easier for users to pinpoint specific segments and understand their functions. By utilizing these resources, individuals can effectively diagnose issues and carry out necessary replacements or repairs.

Key Components Overview

| Component | Description |

|---|---|

| Handle | Provides grip and control for operation. |

| Motor | Powers the device, crucial for performance. |

| Blade | Essential for cutting tasks, needs regular checks. |

| Housing | Encloses components, ensuring safety and durability. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of various machines. They provide a clear layout of individual elements, making it easier for users to understand how each piece fits into the larger assembly. This clarity is essential for effective troubleshooting and efficient replacements.

Furthermore, these illustrations serve as invaluable tools for both novice and experienced technicians. By highlighting the relationship between different components, they simplify complex processes and enhance overall comprehension. This accessibility helps prevent mistakes, saving time and resources during repairs.

Additionally, these visuals facilitate communication among users, manufacturers, and service personnel. When everyone refers to the same representation, discussions become more productive, and issues can be resolved swiftly. Overall, having a detailed visual guide enhances the overall experience of maintaining and servicing equipment.

Key Components of the CMCST915

This section delves into the essential elements that contribute to the functionality and efficiency of the device. Understanding these components is crucial for optimal performance and maintenance.

Essential Elements

- Motor: Powers the equipment and determines its operational capabilities.

- Blade: Responsible for cutting, with various designs suited for different tasks.

- Handle: Provides grip and control, influencing user comfort during operation.

- Battery: Supplies the necessary energy for cordless functionality, affecting runtime and power.

- Chassis: The main body structure that houses and protects the internal components.

Supportive Features

- Safety Mechanisms: Ensure user protection while operating the device.

- Adjustable Settings: Allow customization based on user preferences and task requirements.

- Maintenance Access: Design elements that facilitate easy upkeep and repairs.

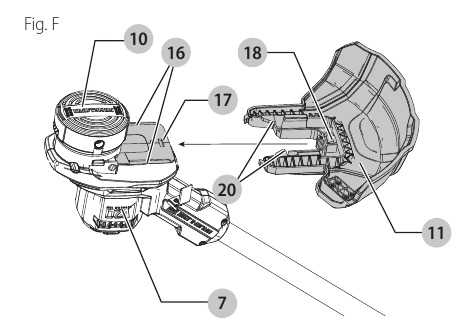

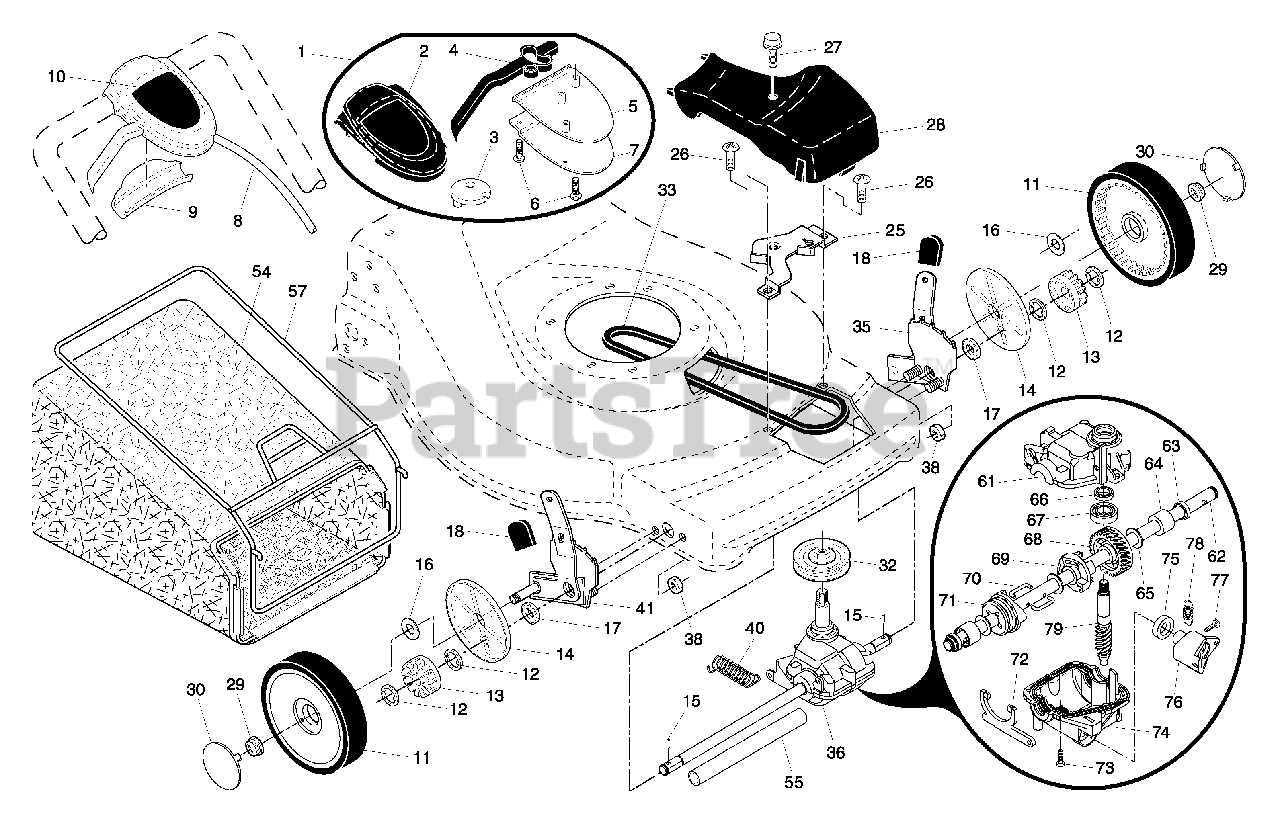

How to Read the Diagram

Understanding the illustration of components is essential for effective maintenance and repair. This guide will help you navigate through the visual representation, ensuring you can identify and locate each part with ease.

To effectively interpret the schematic, follow these key steps:

- Familiarize Yourself with Symbols: Different shapes and lines represent various elements. Take time to learn what each symbol signifies.

- Identify Sections: The layout is often divided into distinct areas, each corresponding to a specific function or assembly. Recognizing these sections can simplify your approach.

- Refer to the Legend: Most illustrations include a legend or key. This reference will clarify any unfamiliar symbols or notations.

- Trace Connections: Follow the lines connecting components. These pathways indicate how parts interact and can reveal potential issues.

- Note Orientation: Pay attention to the orientation of each element. Proper alignment is crucial for optimal performance.

By mastering these techniques, you will enhance your ability to read and understand the visual guide, leading to more efficient repairs and maintenance. With practice, interpreting these illustrations will become second nature.

Common Replacement Parts Explained

When it comes to maintaining your equipment, understanding essential components is crucial for optimal performance. Many of these vital elements can wear out or become damaged over time, requiring attention for effective functionality. By recognizing the most frequently needed replacements, you can ensure your tool operates smoothly.

Blades are among the most critical components. They endure significant stress and can dull or chip, impacting efficiency. Regularly checking and replacing them can enhance cutting performance.

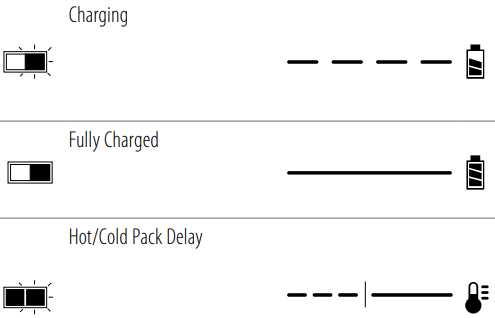

Batteries also play a pivotal role in the operation of cordless tools. As they age, their capacity diminishes, leading to shorter usage times. Replacing old batteries can restore your device’s power and longevity.

Switches are essential for controlling the operation. If you notice any irregularities in responsiveness, replacing the switch can often resolve these issues quickly.

Lastly, motors are fundamental for overall performance. Overheating or mechanical failures can necessitate replacement. Investing in a quality motor ensures reliability and efficiency in your tasks.

Maintenance Tips for Your Tools

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. By following a few simple practices, you can keep your tools in excellent condition, ready for any task at hand.

Routine Cleaning

Cleaning your tools after each use is a fundamental step in maintenance. Remove dirt, debris, and any residues that can lead to corrosion. For metallic components, use a soft cloth or brush. For stubborn grime, a mild detergent mixed with water can be effective. Ensure that all parts are thoroughly dried to prevent rust.

Regular Inspection

Conducting frequent checks on your equipment allows you to identify potential issues early. Look for signs of wear, such as frayed wires, loose screws, or any unusual noises during operation. Addressing these problems promptly can save you time and money in the long run. Additionally, lubricate moving parts regularly to reduce friction and extend the life of your tools.

Remember: A little attention goes a long way in maintaining your equipment. By incorporating these simple tips into your routine, you can ensure that your tools remain reliable and efficient for years to come.

Where to Find Authentic Parts

Ensuring the quality and longevity of your equipment requires sourcing genuine components. Authentic elements not only enhance performance but also guarantee compatibility. Here are several avenues to explore for acquiring these essential items:

- Manufacturer’s Website: Start with the official site, as it often provides direct access to certified goods.

- Authorized Dealers: Visit local distributors who are recognized by the manufacturer for their reliability.

- Online Retailers: Trusted e-commerce platforms frequently offer a selection of verified components.

- Repair Shops: Local repair services may stock or order genuine items and can offer installation assistance.

- Community Forums: Engage with enthusiasts online who may share recommendations for reputable sources.

Utilizing these resources will help ensure that you acquire the necessary elements for optimal functionality and durability.

DIY Repairs Using the Diagram

Understanding the components of your tool is essential for effective maintenance and repairs. By having a visual reference, you can easily identify the parts that may need attention or replacement. This approach not only saves time but also enhances your ability to troubleshoot issues efficiently.

Identifying Common Issues

Start by examining the visual reference to pinpoint typical problems such as wear and tear, misalignment, or damaged components. By recognizing these issues, you can systematically address them, ensuring that your tool functions optimally. This step-by-step method allows for a clear assessment of what needs to be fixed or replaced.

Step-by-Step Repair Process

Once you’ve identified the areas requiring attention, follow a structured repair process. Gather the necessary tools and components, and refer back to the visual guide as you work through each step. This methodical approach not only streamlines the repair but also enhances your understanding of how each part interacts within the system.

FAQs About CMCST915 Parts

This section aims to address common inquiries related to components and accessories for a specific outdoor tool model. Understanding these elements can help users maintain and optimize their equipment efficiently.

| Question | Answer |

|---|---|

| What should I do if a component is damaged? | It’s advisable to replace any damaged parts immediately to ensure safe and effective operation. |

| Where can I find replacement components? | Replacement items can typically be found at local hardware stores or through authorized online retailers. |

| How can I determine which accessory is compatible? | Refer to the user manual or manufacturer’s website for specifications and compatibility details. |

| Is it possible to repair rather than replace? | In some cases, minor repairs can be made, but replacing worn parts is often more effective. |

| What are the signs that I need new components? | Common indicators include reduced performance, unusual noises, or visible wear and tear. |