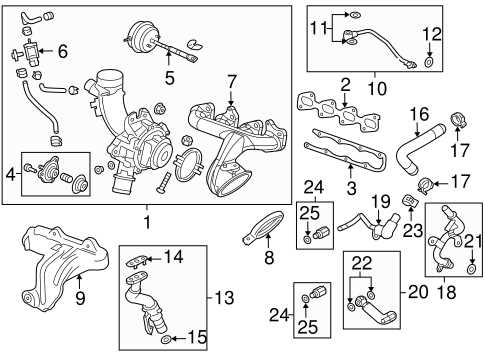

| Thermostat |

Regulates the flow of coolant based on the temperature, ensuring consistent operation. |

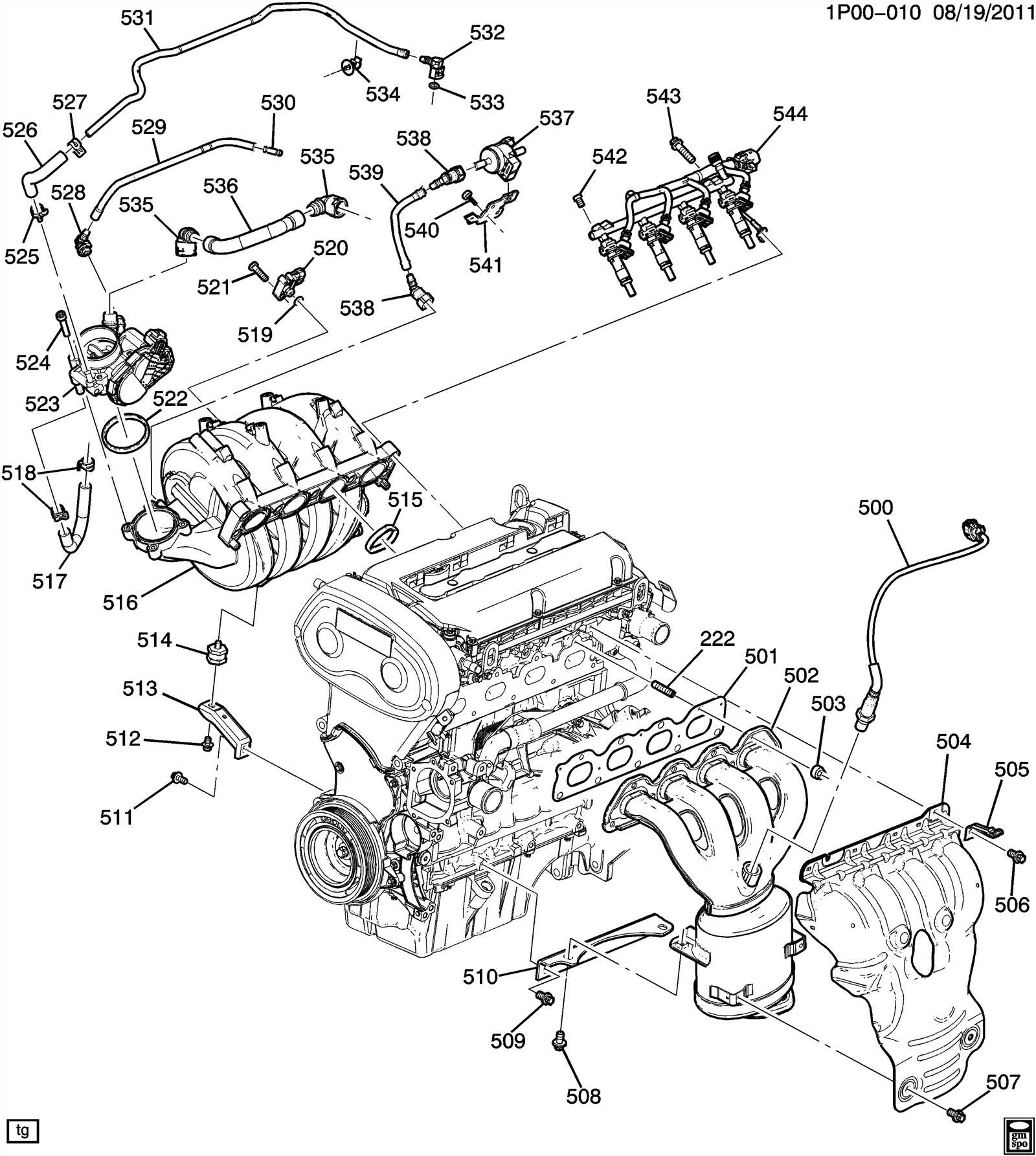

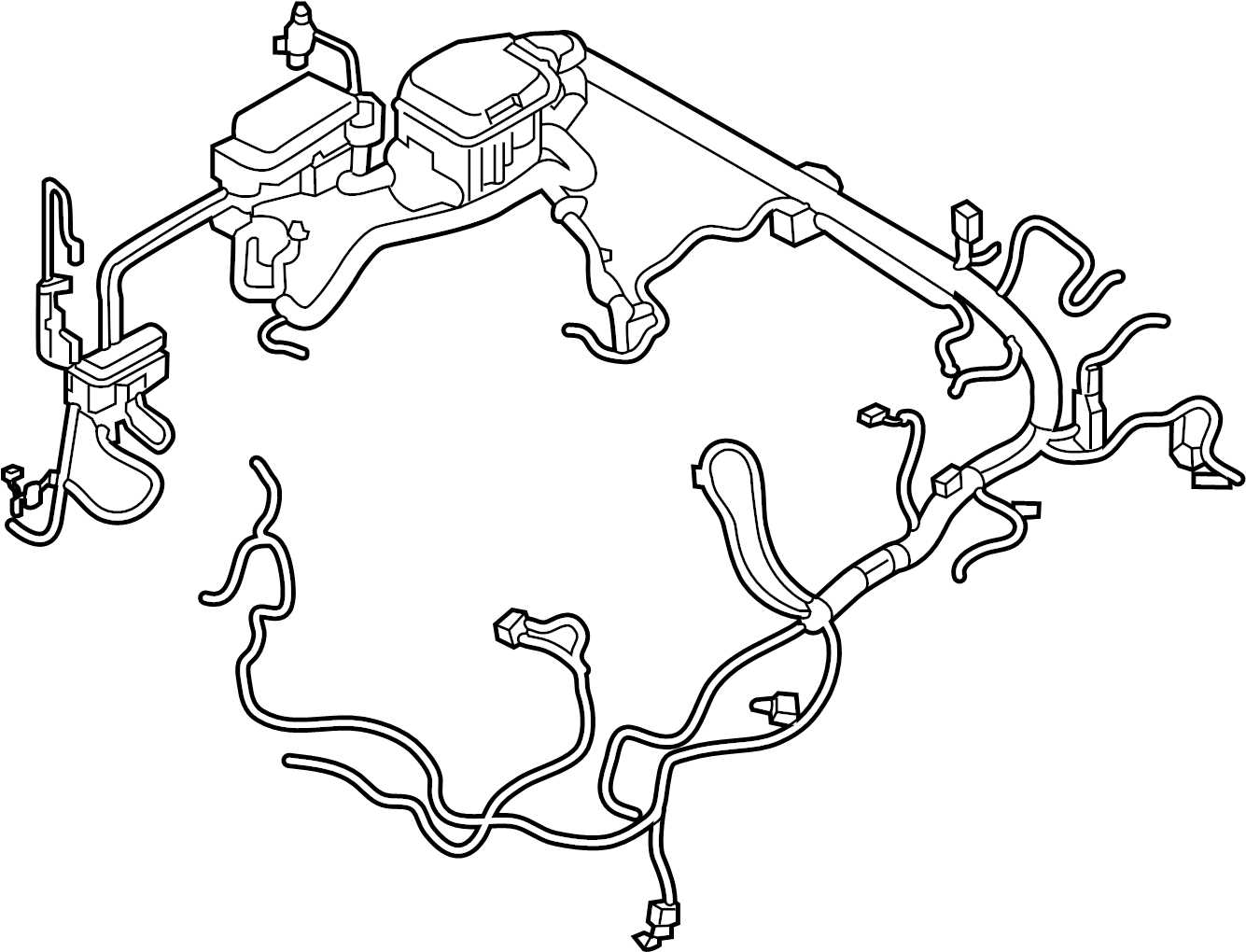

Essential Elements of the Fuel Injection System

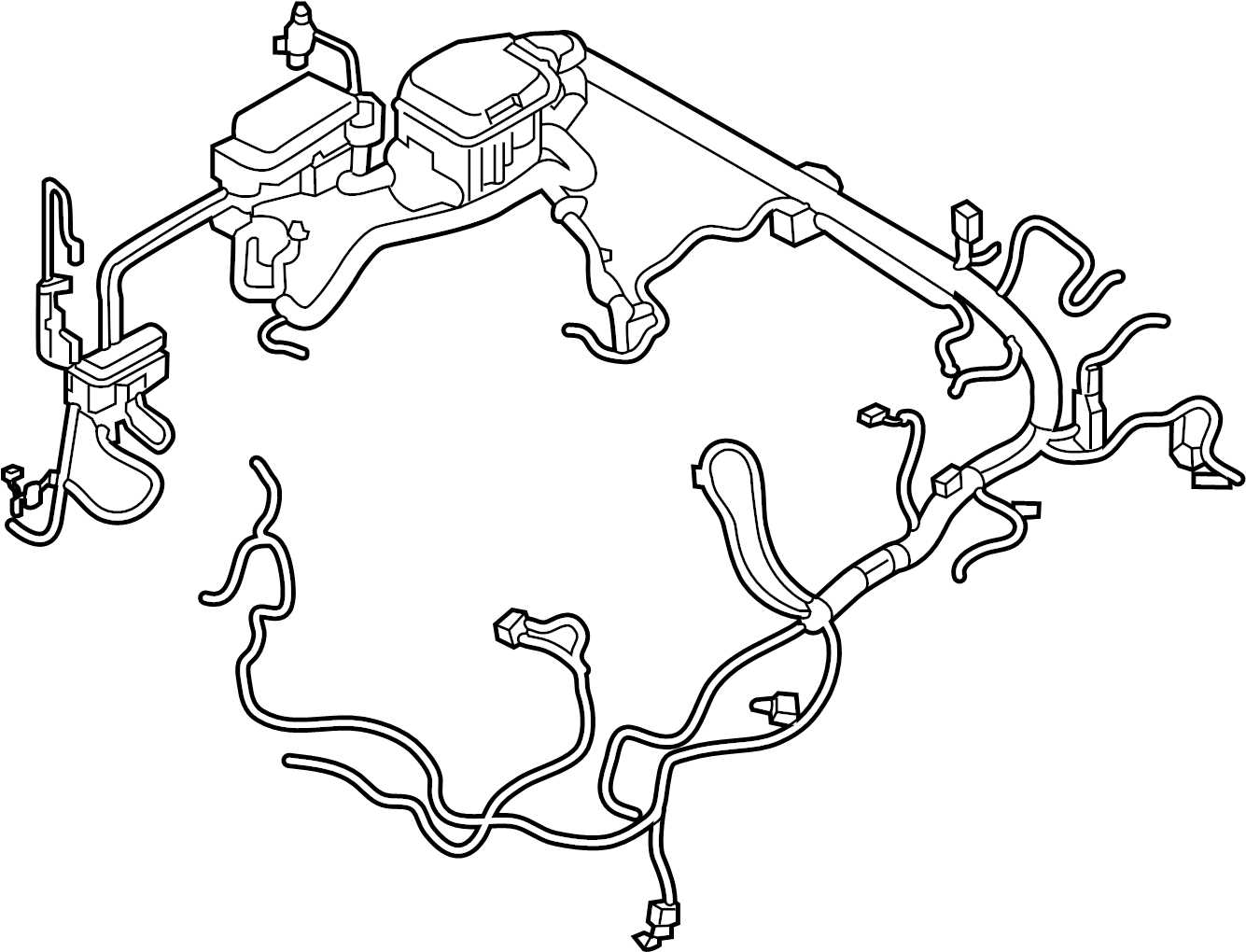

The fuel injection system is a critical component of modern vehicles, responsible for delivering the appropriate amount of fuel to the combustion chamber. This system enhances efficiency, reduces emissions, and optimizes performance. Understanding its fundamental elements is essential for diagnosing issues and ensuring proper functionality.

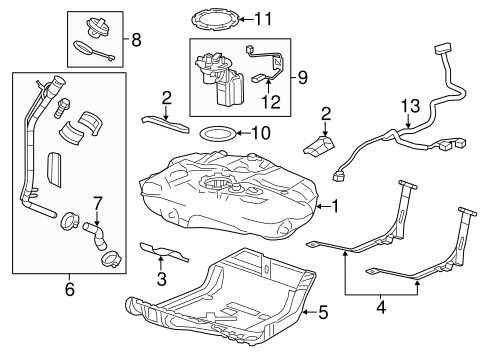

- Fuel Pump: This device draws fuel from the tank and delivers it to the injectors under high pressure.

- Fuel Injectors: These electronic valves spray a fine mist of fuel directly into the intake manifold or combustion chamber, ensuring a precise mixture with air.

- Fuel Rail: This component acts as a conduit for the fuel, distributing it evenly to each injector while maintaining consistent pressure.

- Pressure Regulator: It regulates the fuel pressure within the system, ensuring that injectors receive fuel at the correct pressure for optimal performance.

- ECU (Engine Control Unit): The brain of the system, the ECU calculates the required fuel amount based on various inputs, including engine temperature and throttle position.

Each of these elements plays a vital role in the overall performance and efficiency of the fuel delivery process. Proper maintenance and understanding of these components can lead to enhanced vehicle performance and longevity.

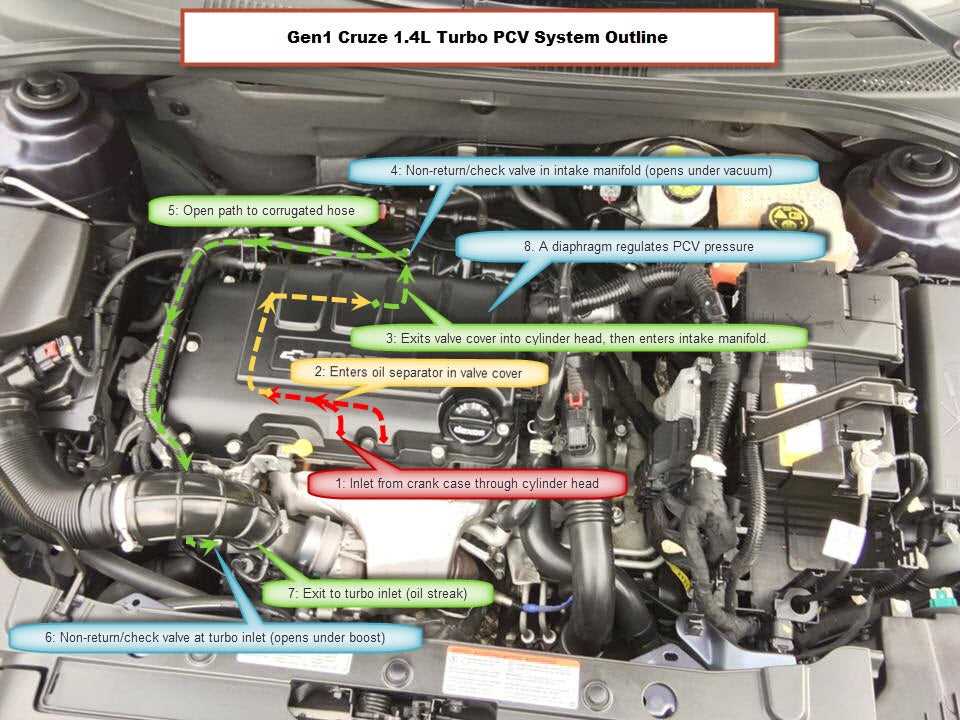

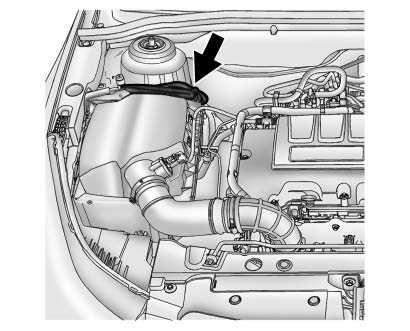

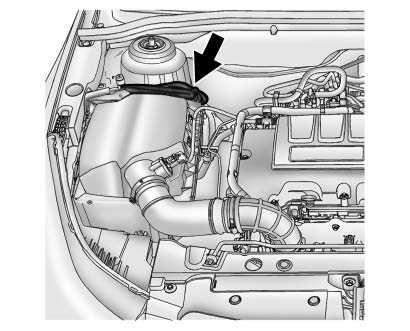

Overview of the Turbocharging Technology

Turbocharging technology has revolutionized the performance and efficiency of modern vehicles. This innovative approach enhances power output while maintaining or even improving fuel economy. By utilizing exhaust gases to drive a turbine, this system forces additional air into the combustion chamber, enabling a denser fuel-air mixture.

The core of turbocharging lies in its ability to extract energy from the exhaust that would otherwise be wasted. This process allows for smaller engines to produce the power of larger ones, contributing to reduced emissions and better fuel efficiency. Moreover, the incorporation of advanced materials and precision engineering in turbochargers has led to significant improvements in durability and responsiveness.

As a result, turbocharging has become increasingly popular in various types of vehicles, from compact cars to high-performance models. This technology not only enhances acceleration and overall driving experience but also aligns with the growing demand for sustainable and efficient automotive solutions.

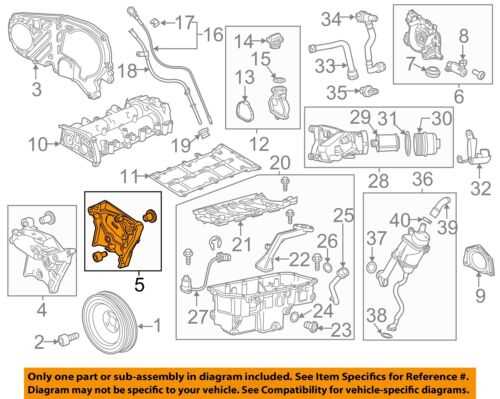

Critical Components of the Exhaust System

The exhaust system is vital for the efficient operation of a vehicle, playing a crucial role in managing emissions and noise. Understanding its key elements helps in diagnosing issues and ensuring optimal performance.

- Exhaust Manifold: This component collects exhaust gases from the cylinders and directs them into the system. It is typically made from cast iron or stainless steel for durability.

- Catalytic Converter: Essential for reducing harmful emissions, this part converts toxic gases into less harmful substances before they exit the vehicle.

- Muffler: Responsible for minimizing noise produced by the engine’s exhaust, the muffler allows for a quieter ride by dissipating sound waves.

- Exhaust Pipes: These pipes transport exhaust gases from the manifold through the system to the rear of the vehicle, ensuring proper flow and reducing backpressure.

- Oxygen Sensors: Positioned in various locations within the exhaust system, these sensors monitor oxygen levels to optimize fuel efficiency and emissions control.

Maintaining these components is essential for achieving emissions compliance and ensuring a smooth driving experience. Regular inspections can help identify potential issues before they escalate, ensuring the system operates efficiently.

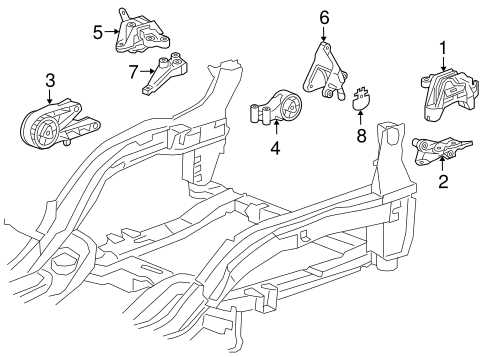

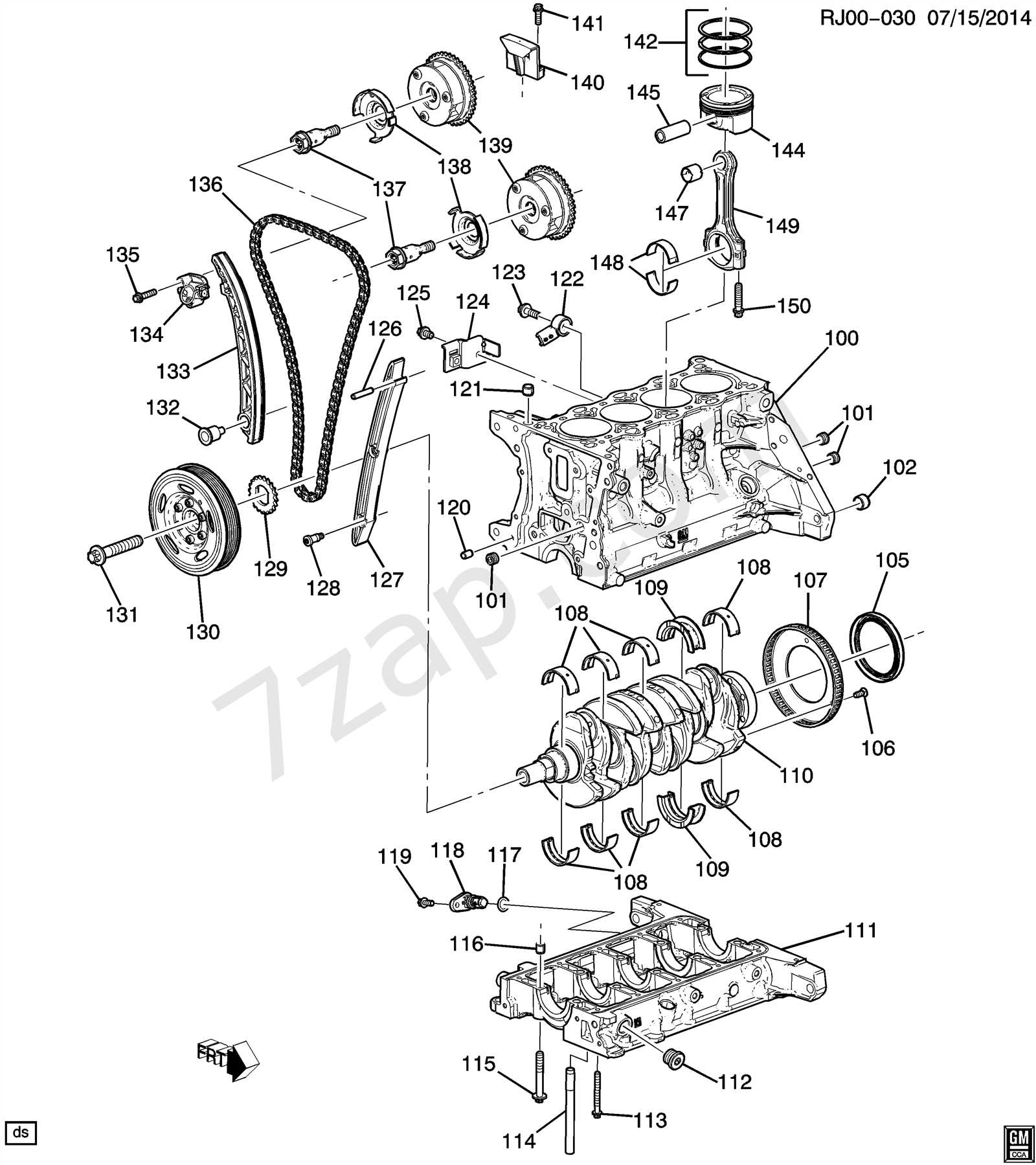

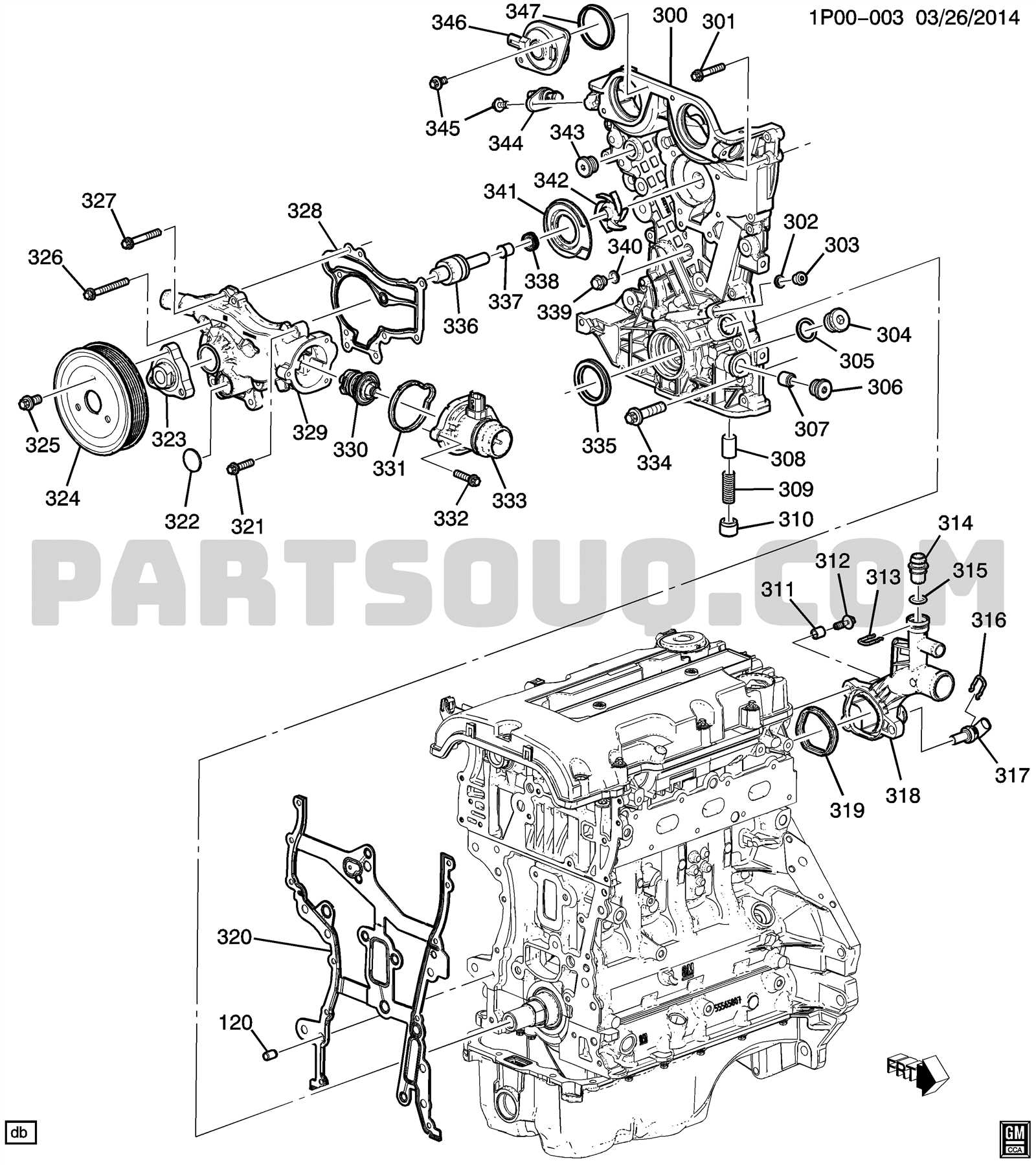

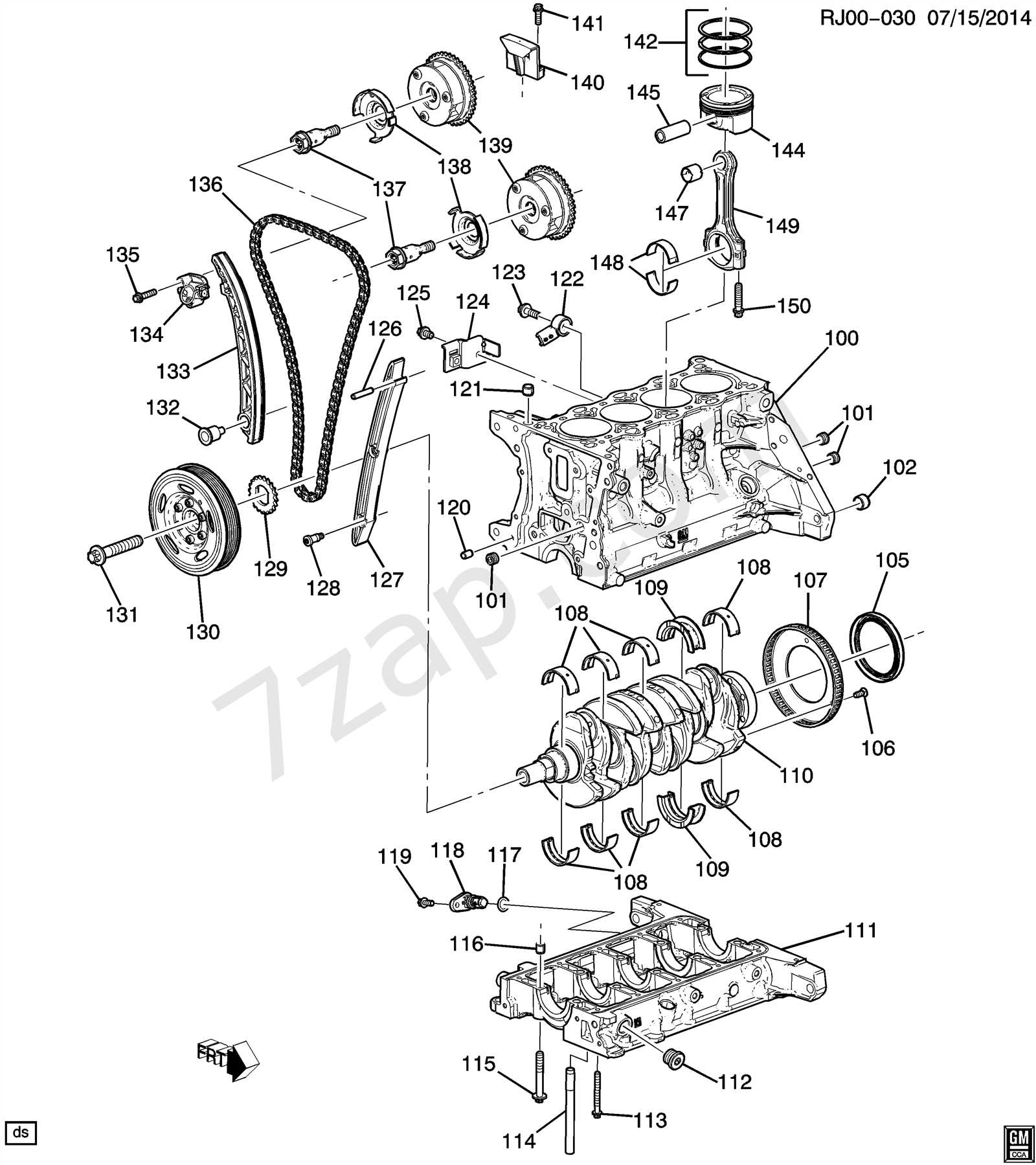

Maintenance and Common Issues with Engine Components

Proper upkeep of automotive machinery is essential for optimal performance and longevity. Regular servicing helps identify potential problems before they escalate, ensuring the vehicle operates smoothly. It is crucial to familiarize oneself with common challenges that may arise within these crucial mechanisms, as early detection can prevent costly repairs and enhance reliability.

Routine Maintenance Practices

To maintain the functionality of these systems, it is important to adhere to a consistent maintenance schedule. This includes regular checks of fluid levels, filters, and belts. Additionally, timely replacements of worn-out items are necessary to avoid unexpected breakdowns. Inspections should be performed frequently, focusing on signs of wear, leaks, or unusual noises that may indicate underlying issues.

Frequent Challenges and Solutions

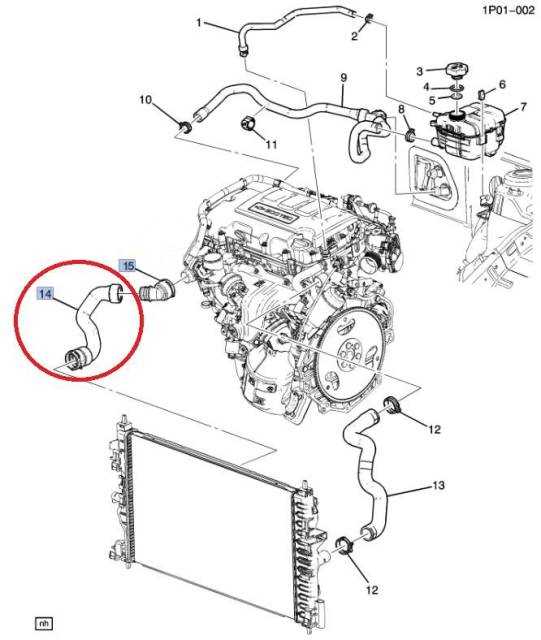

Vehicles may encounter various issues related to their operational mechanisms. Among the most common are overheating, unusual vibrations, and decreased performance. Overheating can often be traced back to coolant leaks or radiator failures, while vibrations may suggest imbalances or alignment problems. Addressing these matters promptly not only enhances safety but also improves the overall driving experience.