In the world of power tools, mastering the intricacies of a cutting apparatus is essential for optimal performance and maintenance. A well-functioning tool relies on its essential elements working in harmony, contributing to efficiency and precision during use.

Each segment of this mechanism plays a crucial role, impacting both the ease of operation and the durability of the device. Recognizing how these individual components interact allows users to make informed decisions regarding upkeep and repairs.

By exploring the structure and function of each element, enthusiasts and professionals alike can enhance their understanding and ensure that their equipment remains reliable over time. A thorough grasp of these fundamentals ultimately leads to improved outcomes in various applications.

Understanding Chainsaw Chain Components

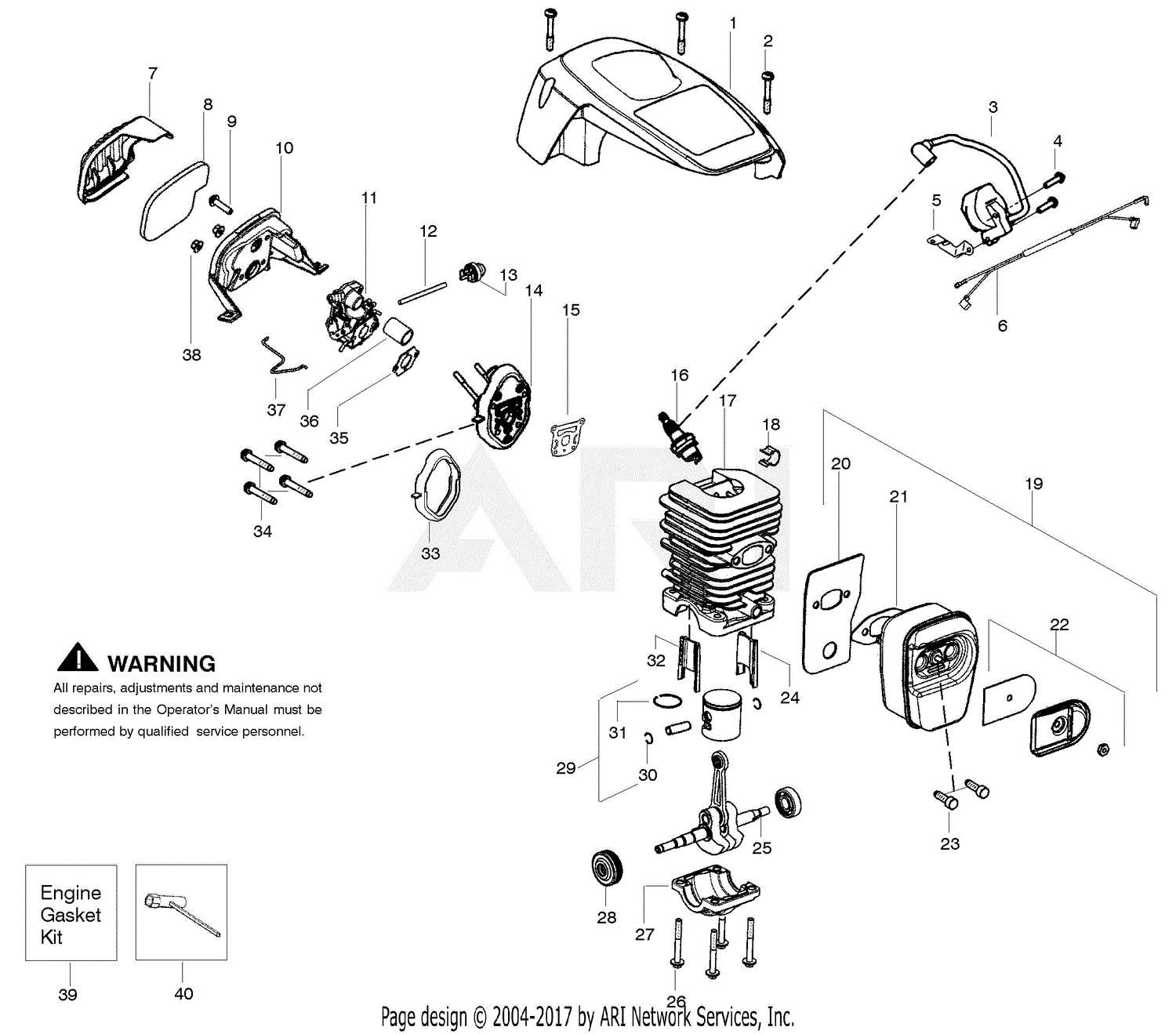

Grasping the intricacies of a cutting tool’s components is essential for optimal performance and maintenance. Each element plays a pivotal role in ensuring efficiency and safety during operation. By examining the various elements, one can appreciate how they work in unison to achieve seamless cutting capabilities.

The leading element serves as the front line, guiding the tool through the material. Attached to it are the teeth, which perform the actual cutting action. These are often followed by rivets that connect the segments, allowing for smooth movement. The drive links are critical as they transfer power from the motor, enabling the entire mechanism to function effectively.

Understanding the importance of tensioning mechanisms is also vital, as they maintain the right amount of pressure for optimal operation. Finally, the guide bar plays a significant role in providing stability and precision. Each component’s functionality contributes to the ultimate performance of the entire assembly.

Overview of Chainsaw Chain Functionality

This section delves into the essential mechanics that drive a cutting mechanism, highlighting the critical components that contribute to its efficiency and effectiveness. Understanding these elements is crucial for anyone looking to enhance performance or maintain equipment properly.

The primary function revolves around the interaction between the moving elements and the material being cut. Each component plays a unique role, from ensuring smooth movement to maintaining sharpness and durability. Here’s a closer look at how these features work together:

| Component | Function |

|---|---|

| Drive Links | Transmit power from the motor to the cutting edges. |

| Cutting Teeth | Engage with the material to create clean cuts. |

| Depth Gauges | Regulate the depth of the cut for optimal performance. |

| Rivets | Securely join components, allowing for flexibility and strength. |

Each of these elements contributes to the overall functionality, ensuring that the cutting apparatus operates smoothly and efficiently. Regular maintenance and understanding of these components can significantly enhance performance and prolong the lifespan of the equipment.

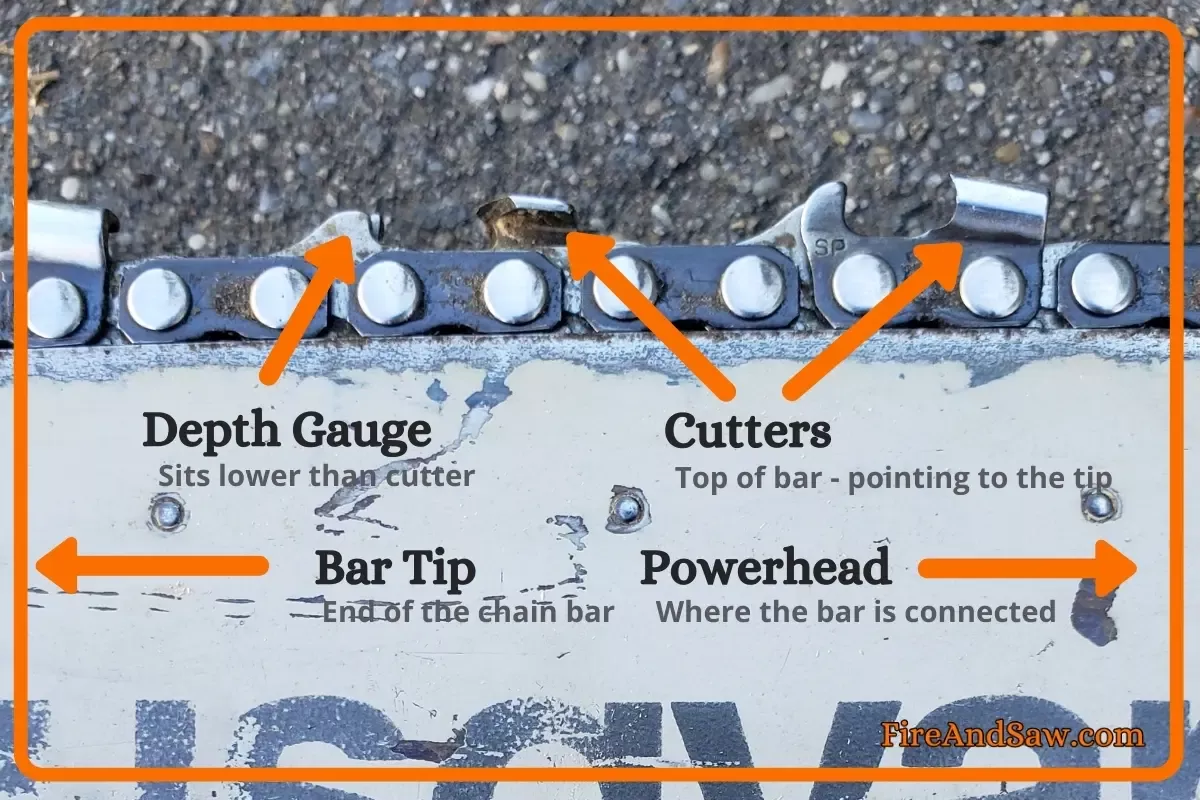

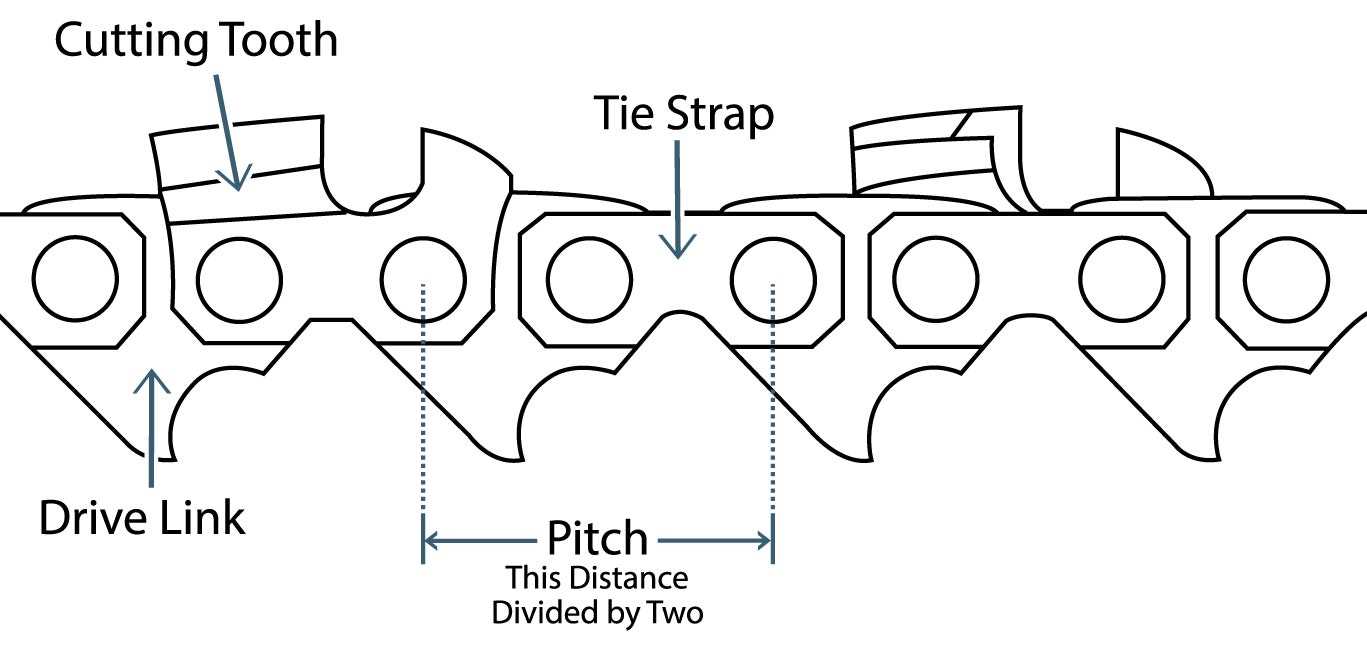

Main Parts of a Chainsaw Chain

The essential components of a cutting loop work together to ensure efficient and precise operation. Understanding these elements is crucial for maintenance and optimal performance during use. Each segment plays a unique role in the overall functionality, contributing to the tool’s effectiveness in various tasks.

Drive Links: These elements are responsible for connecting the loop to the motor. They fit into the guide bar, allowing movement and transferring power effectively.

Cutter Teeth: Positioned at regular intervals, these sharp edges perform the actual cutting. Their design varies depending on the intended application, influencing the speed and smoothness of the cut.

Depth Gauges: Located in front of each cutter, these components control the depth of the cut. Proper adjustment is vital for achieving desired results and preventing damage to the material being worked on.

Rivet: Serving as a pivot point, this element holds the links together while allowing flexibility. The durability and strength of the rivet are essential for the longevity of the entire assembly.

Side Plates: These parts provide stability and support to the cutting edges. They help maintain the alignment of the loop, ensuring consistent performance during operation.

Understanding these crucial elements enhances the user’s ability to maintain and operate the tool effectively, promoting safety and efficiency in various cutting tasks.

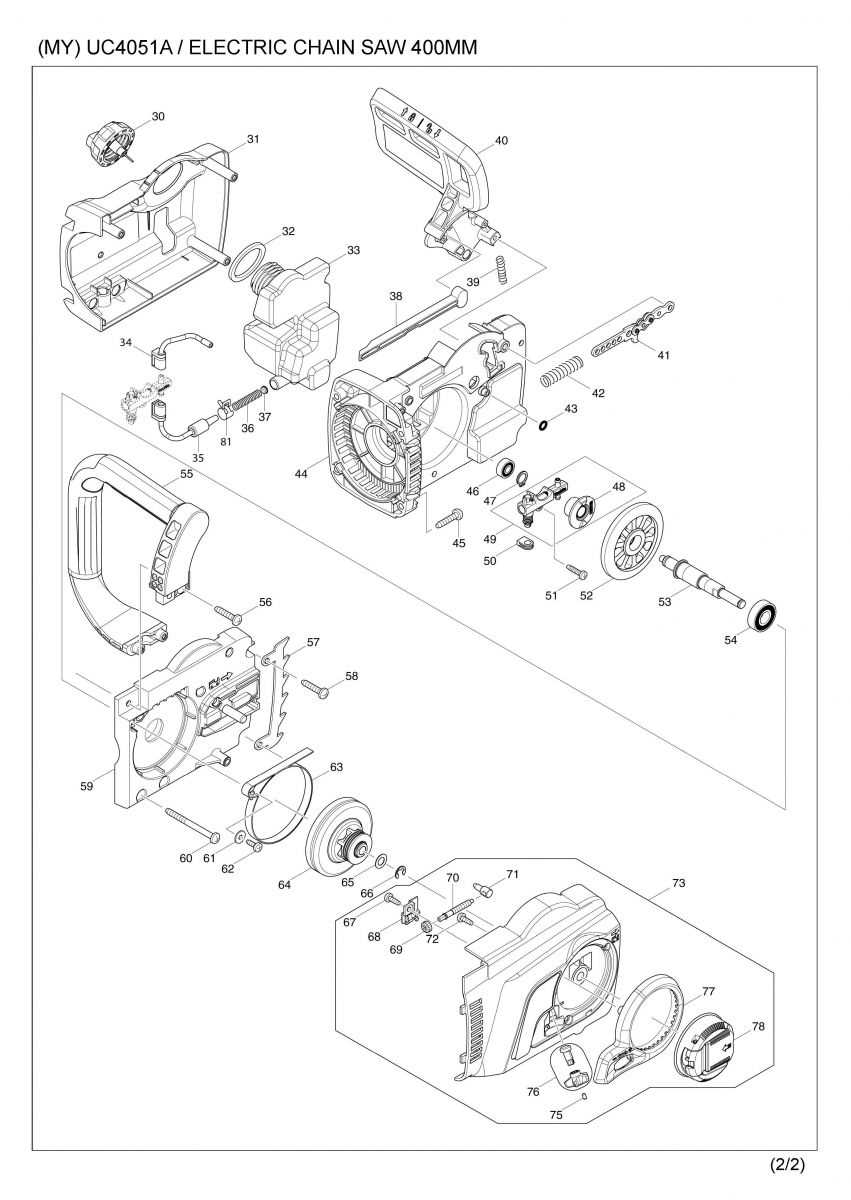

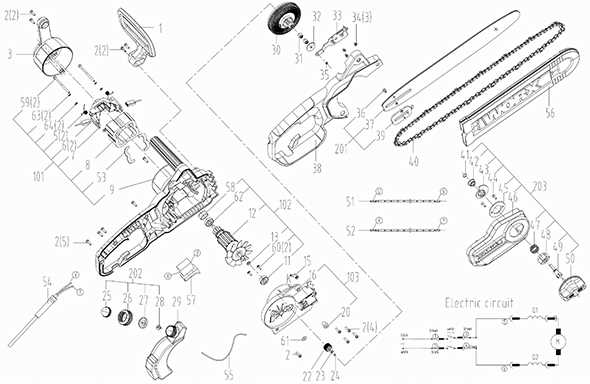

How to Read a Chain Diagram

Understanding the layout of a cutting mechanism is essential for proper maintenance and operation. Familiarity with the components and their functions enhances your ability to troubleshoot and optimize performance. By examining the schematic representation, one can identify various elements and their interconnections, ensuring a comprehensive grasp of the assembly.

Start by noting the orientation of the visual aid, as it usually provides a top-down view. Each section is typically labeled with specific terminology, which corresponds to distinct features. Pay attention to symbols and lines, as they illustrate relationships and movement paths between components.

Next, focus on the different segments, understanding their roles in the overall system. Look for annotations that describe each part’s purpose or specifications, such as dimensions and materials. This information is crucial for making informed decisions regarding repairs or replacements.

Finally, practice interpreting various schematics to build confidence. With time, you’ll become adept at quickly recognizing key elements and understanding how they interact, leading to more effective usage and maintenance of your equipment.

Importance of Chain Maintenance

Regular upkeep of your cutting tool’s components is essential for optimal performance and longevity. Proper care ensures efficiency, safety, and a smoother operation, minimizing the risk of unexpected breakdowns and hazards.

Benefits of Routine Care

- Enhances cutting efficiency and speed.

- Reduces wear and tear on components.

- Prevents costly repairs and replacements.

- Increases safety during operation.

Maintenance Practices

- Regularly inspect for damage or wear.

- Keep components clean and lubricated.

- Adjust tension as needed for optimal performance.

- Sharpen edges to maintain cutting effectiveness.

Common Chain Problems and Solutions

In any cutting tool, issues may arise that hinder optimal performance. Understanding these challenges and knowing how to address them is crucial for maintaining efficiency and safety. This section highlights prevalent problems encountered with the cutting loop and offers practical solutions to ensure smooth operation.

Worn Links

Over time, the components can wear down, leading to reduced effectiveness. Regular inspection is essential. If wear is noticeable, consider replacing the affected links or the entire assembly. Keeping the tool well-lubricated can also mitigate wear.

Improper Tension

Incorrect tension can cause slippage or difficulty in cutting. Adjusting the tension is key. Ensure it is snug but not overly tight, allowing for some flexibility. Regular adjustments as needed will prolong the lifespan of the system and enhance cutting performance.

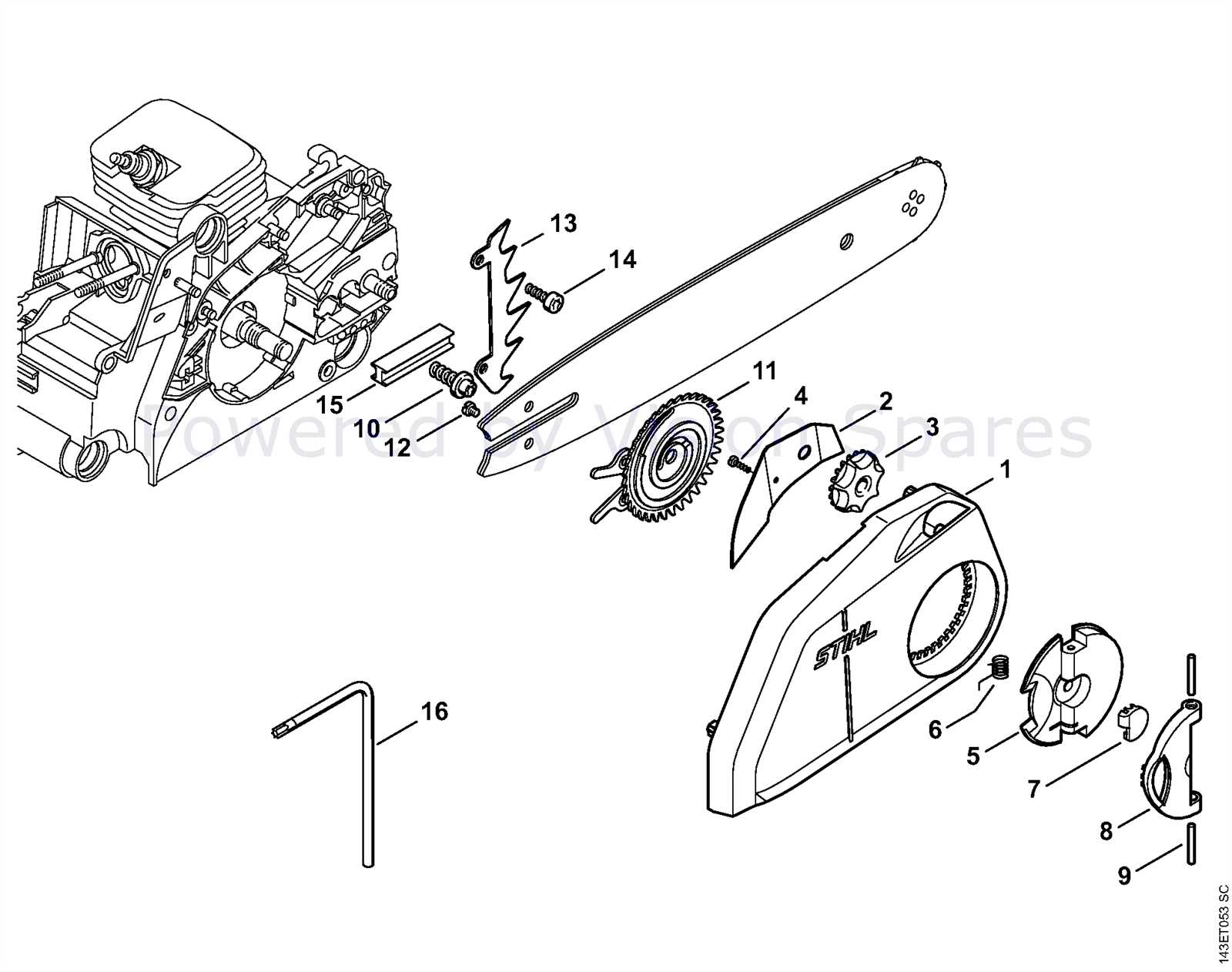

Choosing the Right Chain for Your Saw

Selecting the appropriate cutting loop for your tool is crucial for achieving optimal performance and efficiency. The right choice can enhance your cutting experience, ensuring safety and durability. Here are some key factors to consider when making your decision:

- Type of Wood: Consider the type of materials you will be working with. Softer woods may require a different cutting configuration than hardwoods.

- Bar Length: Ensure that the cutting loop matches the length of your tool’s guide bar. Compatibility is vital for effective operation.

- Pitch: Look for the correct pitch size, as it affects the distance between the links and influences cutting speed.

- Gauge: The gauge refers to the thickness of the drive links. Choosing the right gauge ensures a snug fit within the guide bar.

- Number of Links: The number of links impacts the overall length of the loop. Ensure it corresponds with your tool’s specifications.

- Teeth Configuration: Different configurations provide varying levels of aggressiveness in cutting. Choose one that suits your specific tasks.

By considering these aspects, you can select the most suitable cutting loop for your needs, enhancing performance and ensuring safety during operation.

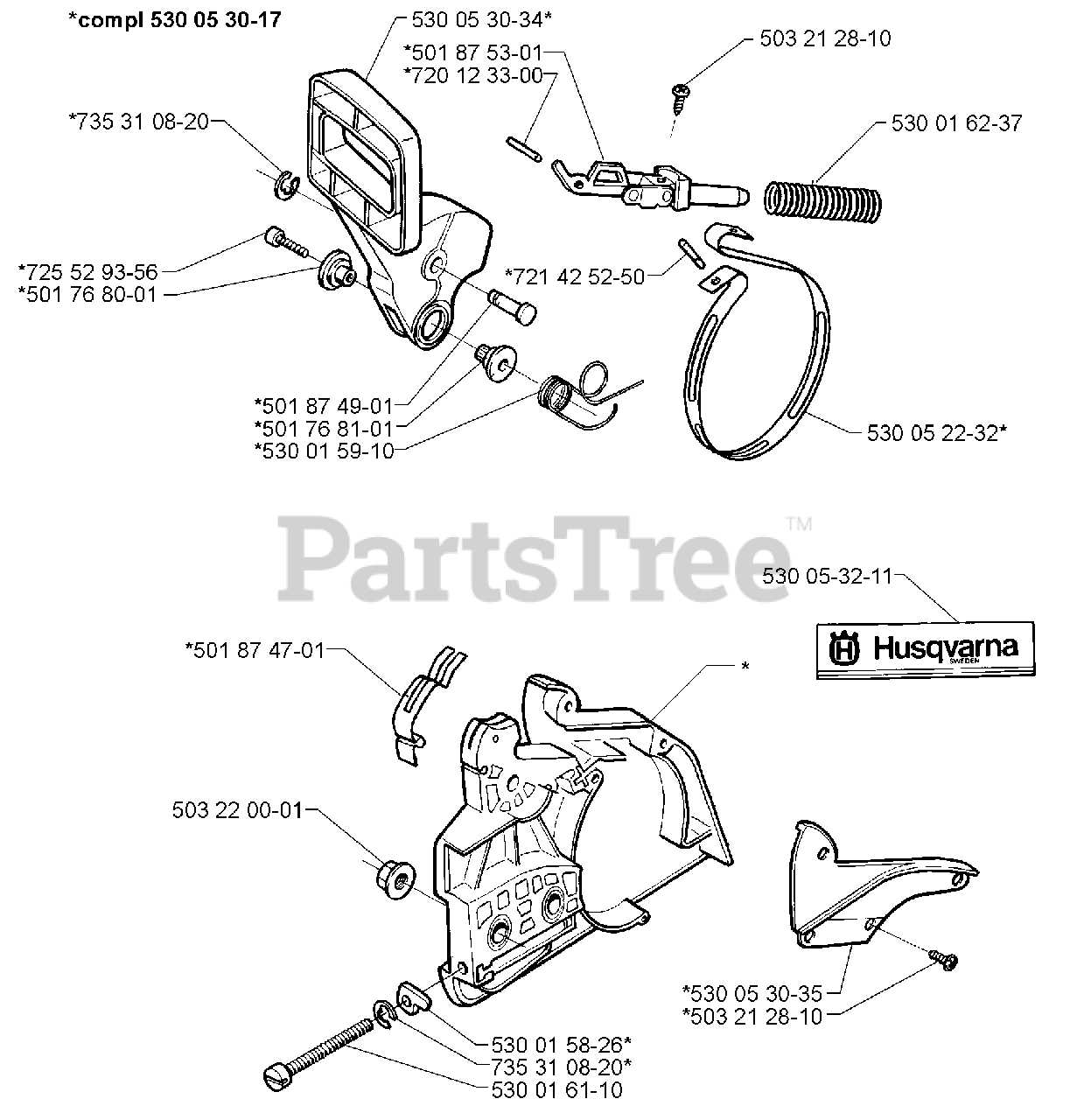

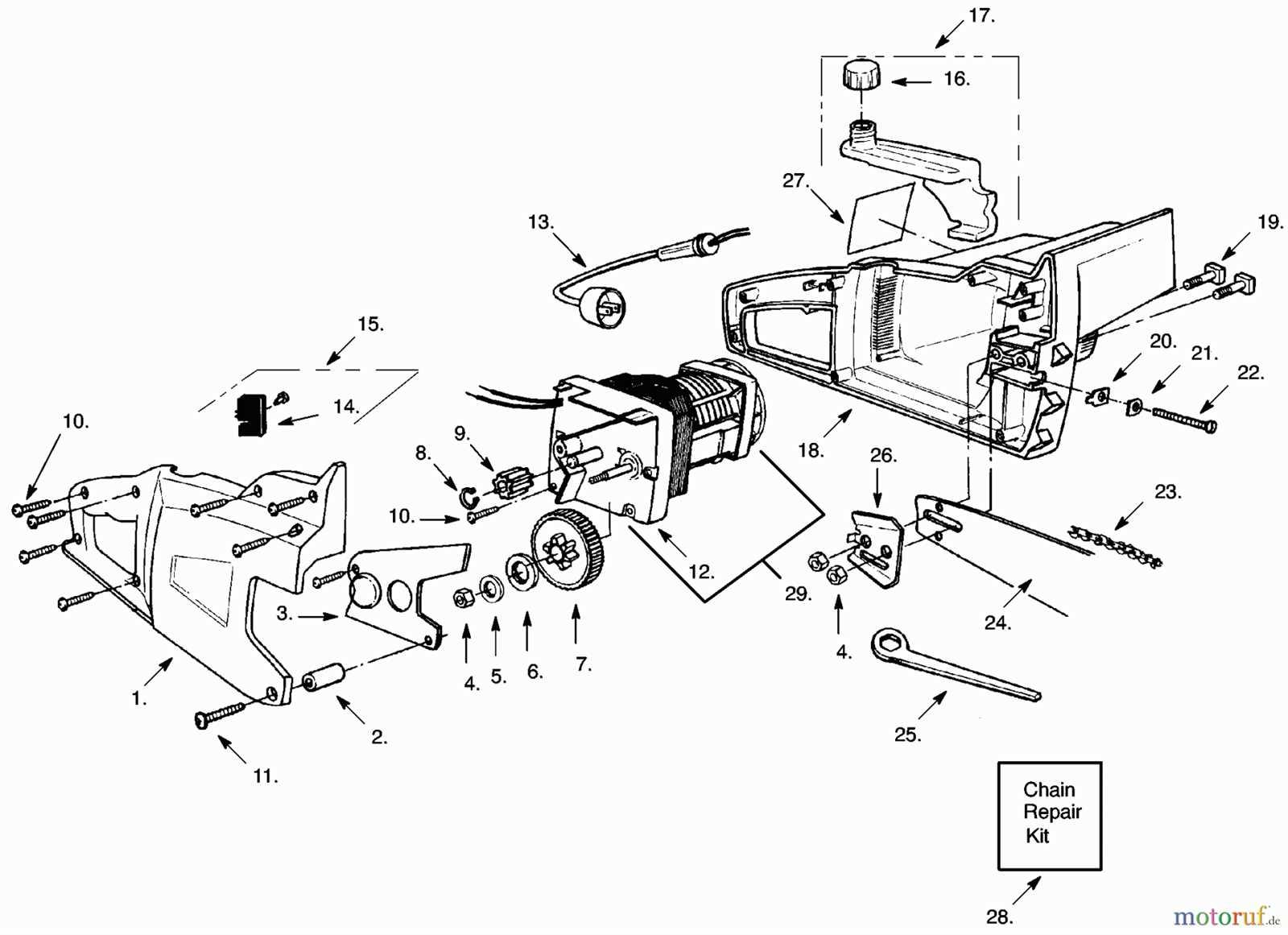

Chain Replacement: Step-by-Step Guide

Replacing the cutting mechanism of your equipment is essential for maintaining optimal performance and safety. This process, though straightforward, requires careful attention to detail to ensure everything functions correctly. Follow these steps to execute a successful replacement efficiently.

Tools and Preparation

Before you begin, gather the necessary tools: a suitable wrench, safety gloves, and protective eyewear. Ensure your equipment is turned off and disconnected from any power source. Lay out your new cutting element and inspect it for any defects. Familiarize yourself with the specific model you are working on, as designs may vary slightly.

Step-by-Step Replacement Process

Start by loosening the tensioning mechanism to relieve any strain on the component. Carefully remove the old item by unscrewing any fasteners holding it in place. Pay attention to the orientation for proper installation of the new element. Position the new piece correctly, ensuring it fits snugly against the guide. Reattach any screws or fasteners securely, then adjust the tensioning system to the manufacturer’s specifications. Finally, perform a visual inspection to confirm everything is in place and tight.

Tip: Always consult your equipment’s manual for specific instructions and safety recommendations.

Once completed, conduct a test run to verify that the replacement operates smoothly. Regular maintenance checks will prolong the lifespan of your tools and enhance their efficiency.

Safety Tips When Working with Chains

Engaging with cutting equipment requires vigilance and adherence to safety protocols. Understanding the inherent risks and following precautionary measures can prevent accidents and ensure a smoother operation. Here are essential guidelines to keep in mind.

Personal Protective Equipment

Always equip yourself with the appropriate protective gear. This includes gloves to shield your hands, eye protection to guard against debris, and hearing protection to minimize noise exposure. Wearing sturdy footwear can also prevent injuries from falling objects or slips.

Proper Handling Techniques

Familiarize yourself with the correct handling methods. Maintain a firm grip and keep your hands away from any moving components. When operating, always ensure a clear workspace, free from obstacles. It’s also vital to maintain focus and avoid distractions during use.

By prioritizing safety and following these recommendations, you can significantly reduce the risks associated with cutting tools and enhance your overall experience.