Understanding the structure and the various elements that make up your equipment is essential for effective maintenance and long-lasting performance. This guide provides a detailed look into the main elements of the machine, ensuring you have the knowledge to keep everything running smoothly.

By gaining insight into the assembly and individual elements, you’ll be able to address issues more quickly and with confidence. Each section focuses on vital mechanisms, helping to identify potential concerns and ensuring optimal operation over time.

With a clear understanding of the essential components, you will enhance the lifespan and efficiency of the equipment, avoiding unnecessary downtime and repairs. This approach provides a practical way to manage upkeep and ensure consistent functionality.

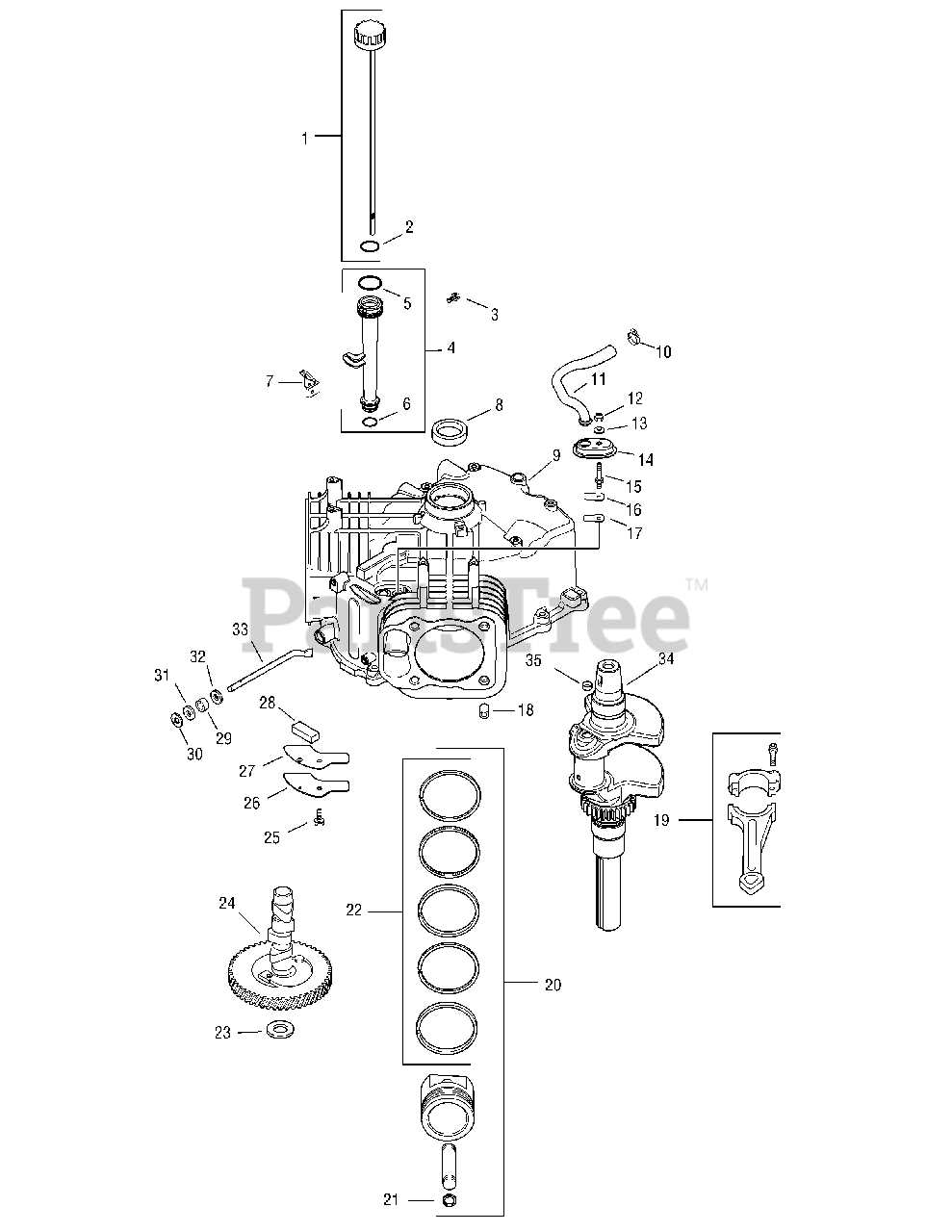

This section provides a clear understanding of the essential mechanical parts that power the vehicle. It covers the vital elements responsible for functionality, efficiency, and performance. Understanding these components helps users maintain and repair their equipment more effectively.

- Engine Block: The core part responsible for housing the internal moving elements.

- Pistons and Crankshaft: These components convert fuel combustion into mechanical motion.

- Carburetor: Regulates the mixture of air and fuel, ensuring optimal engine operation.

- Fuel System: Delivers the necessary fuel from the tank to the engine for combustion.

- Cooling System: Prevents the engine from overheating during operation.

- Ignition System: Provides the spark required to ignite the fuel and start the engine.

- Exhaust System:

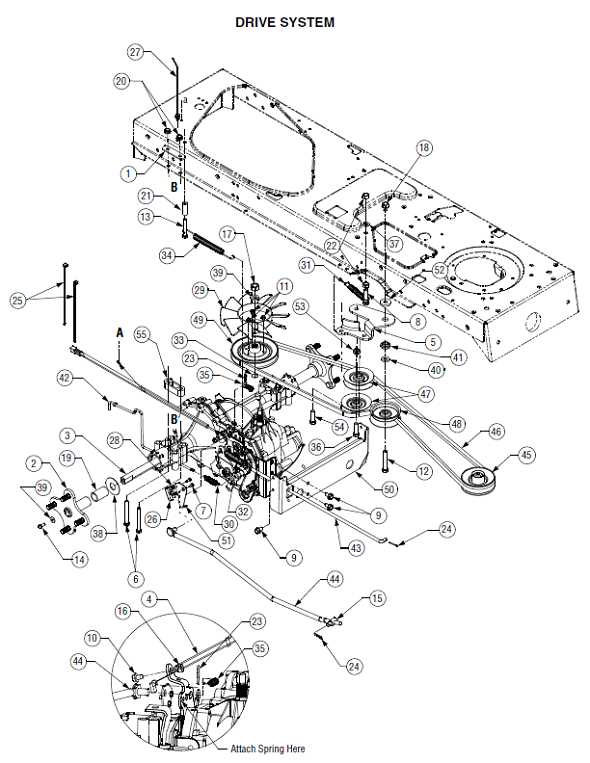

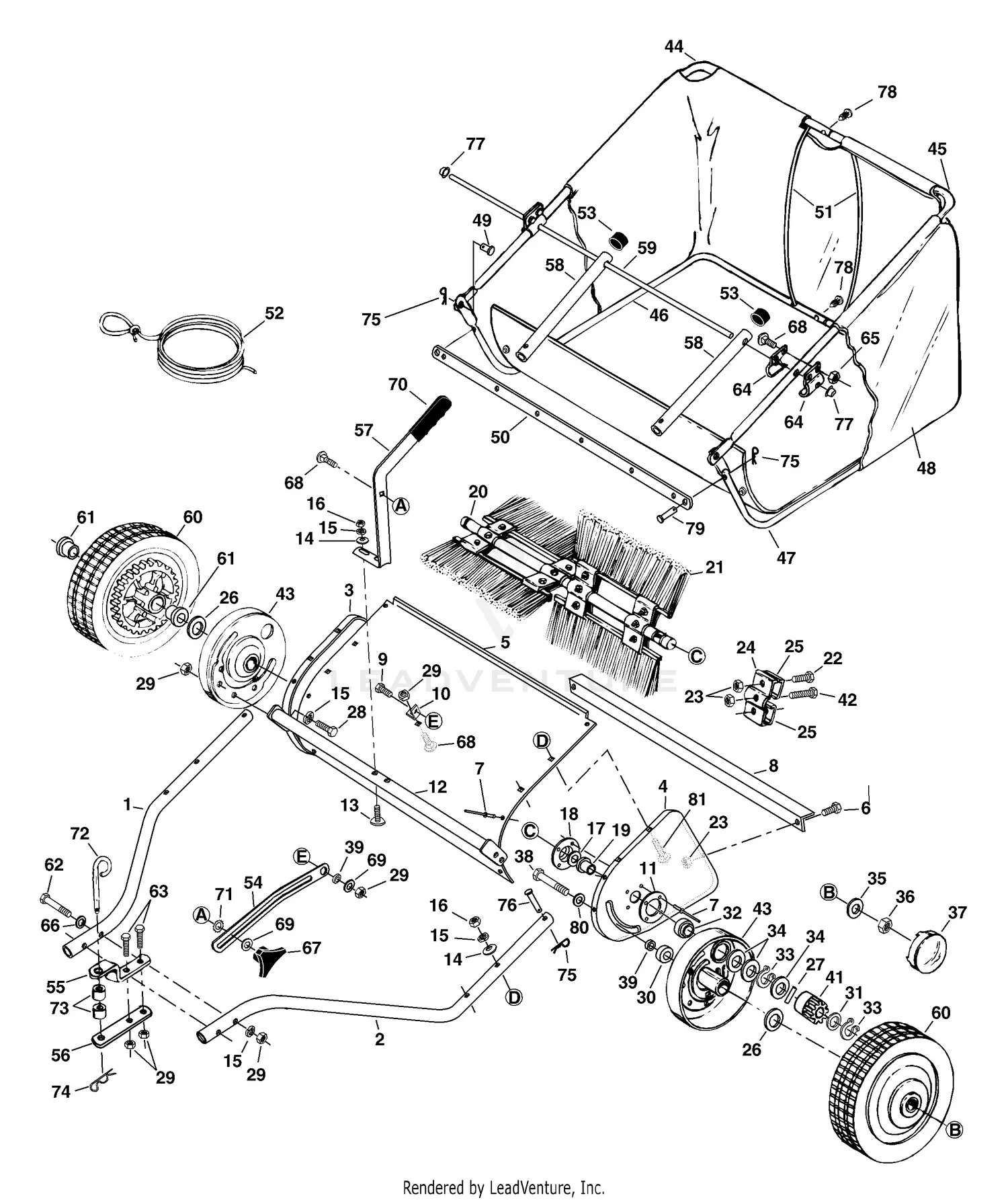

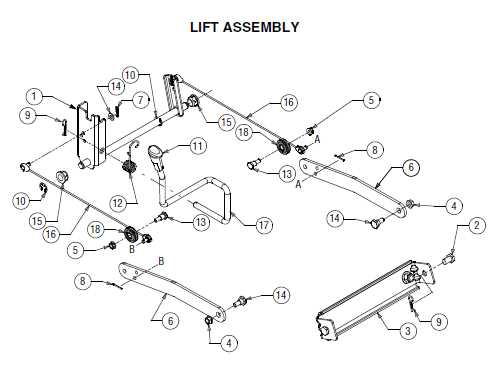

Drive System Parts and Functions

The drive system plays a crucial role in ensuring the smooth operation and movement of the machine. It consists of several interconnected components that work together to transmit power efficiently, allowing the machine to navigate various terrains with ease. Understanding how these elements function is essential for maintaining the system and ensuring long-term performance.

Main Components of the Drive Mechanism

The core of the drive mechanism includes elements responsible for transferring power from the engine to the wheels. This includes transmission systems that regulate speed, gears that adjust torque, and shafts that ensure efficient power delivery. These components are designed to withstand high loads and ensure consistent motion even under demanding conditions.

Role of the Transmission and Axles

The transmission is pivotal in adjusting speed and direction, while the axles serve as the main conduits of motion. Together, they allow for seamless changes in velocity and direction, providing the machine with the necessary control to operate in a wide range of environments.

Steering Mechanism and Linkage Diagram

The steering system plays a vital role in ensuring smooth control and maneuverability. It consists of interconnected components that work together to direct the vehicle. Understanding how these elements function is crucial for maintaining proper alignment and handling.

Key Components of the Steering System

The main components of the steering mechanism include the steering wheel, linkage rods, and pivots, which collaborate to transmit the driver’s input to the wheels. These parts are designed to provide smooth operation and ensure that the vehicle follows the intended path with precision.

Linkage Connections and Operation

The linkage rods are connected through joints that allow for flexible movement while maintaining stability. This network ensures that the steering commands are transferred effectively, giving the driver full control over the vehicle’s direction.

Component Description Steering Wheel Controls the vehicle’s direction by transmitting inputs to the linkage system. Linkage Rods Transfer steering motion from the wheel to the front tires. Pivots Allow for Deck Assembly Breakdown for SLT1554

The deck assembly is a crucial component for maintaining optimal performance when mowing. Understanding its structure helps in ensuring smoother operation and easier maintenance. The various sections that make up the deck are designed to work together harmoniously, with each part playing an essential role in the machine’s functionality.

The following are the key components of the deck assembly:

- Housing: This forms the main structure of the deck and provides the framework for the other components to attach to.

- Blades: Positioned under the housing, these rotating blades cut the grass to the desired length. They must be sharp and balanced for efficient operation.

- Pulleys: These mechanisms drive the blades and help transfer power from the engine to the deck.

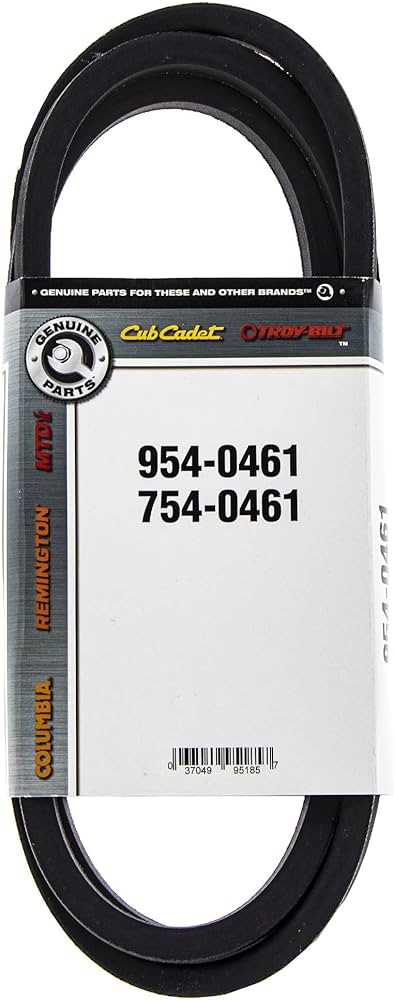

- Belt: The belt works with the pulleys to ensure that power is transferred smoothly, enabling the blades to rotate effectively.

- Spindles: These hold the blades in place and allow them to spin at high speeds, ensuring proper grass cutting performance.

- Adjusters: These allow the user to change the height of the deck, offering flexibility in cutting different types of grass or terrain.

- Washout Port: This feature helps in cleaning the deck after use, ensuring that grass clippings and debris do not build up and affect performance.

Proper assembly and maintenance of each of these components will prolong the life of the deck and contribute to more efficient mowing. Regular inspection is recommended to prevent any wear or damage to these essential parts.

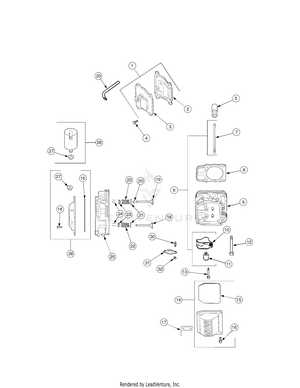

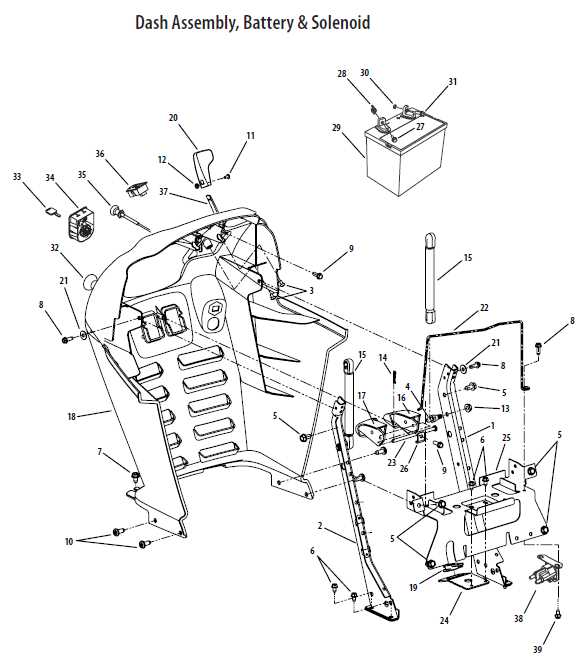

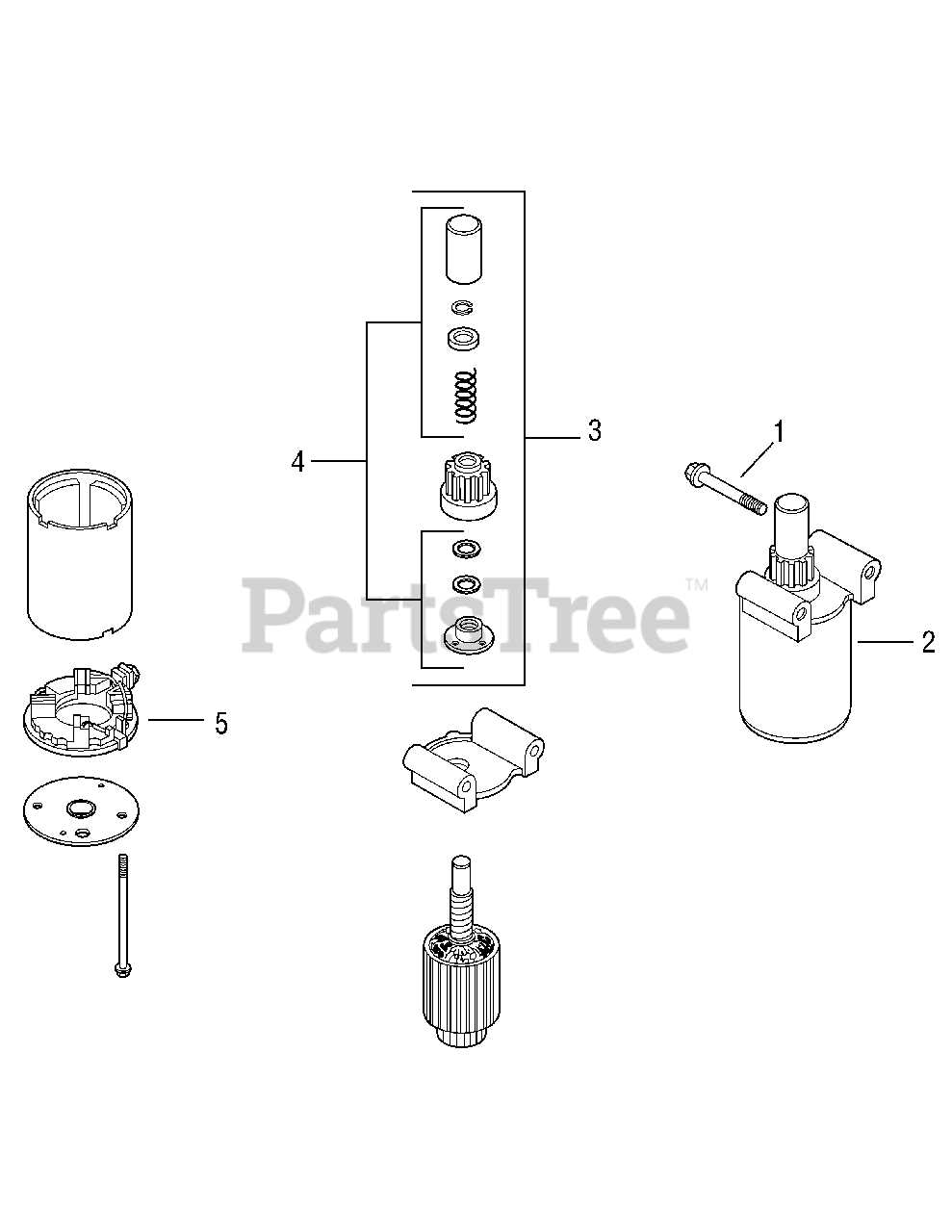

Electrical System Parts and Connections

The electrical system is a vital component that ensures the seamless operation of machinery, providing the necessary power and control for various functions. Understanding the key elements and their interconnections is crucial for effective troubleshooting and maintenance.

Main Components

This section includes the battery, starter motor, ignition switch, and wiring harness. Each element plays a specific role, working together to facilitate the machine’s performance. Proper functioning of these components is essential for reliability and efficiency.

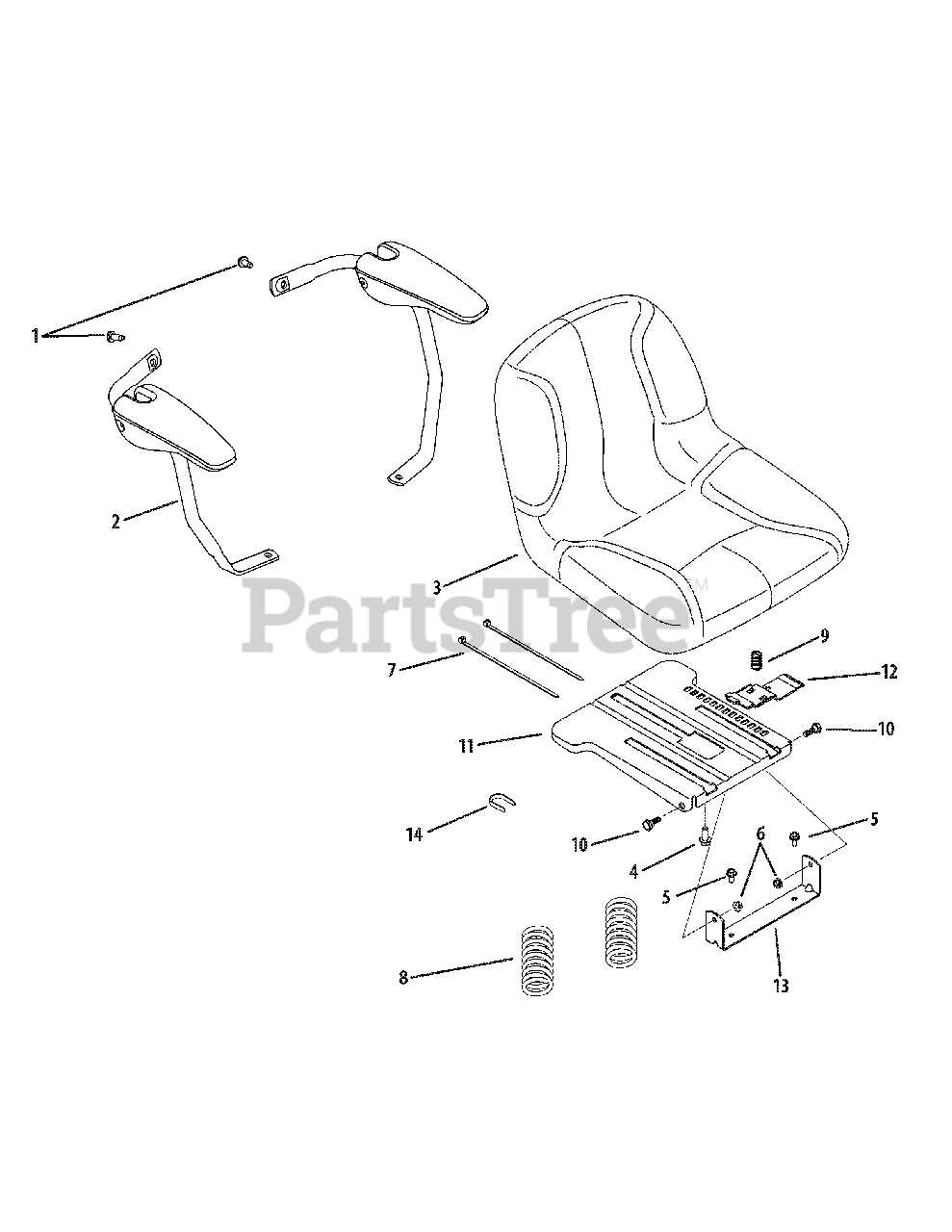

Chassis and Frame Structural Components

The structural integrity of any lawn tractor relies heavily on its chassis and frame, which serve as the foundation for all major components. These elements provide stability, support, and durability under various operating conditions. Understanding the key structural parts ensures proper maintenance and safe operation, as they are crucial in distributing forces during use and protecting internal systems from external damage.

The chassis is designed to hold the engine, transmission, and other essential machinery, while the frame reinforces this structure to withstand the stresses of movement and load-bearing. Together, they form a cohesive unit that ensures smooth performance and longevity of the vehicle.

Component Description Main Frame The core structure that supports all key components such as the engine, transmission, and wheels. Front Axle Part of the chassis that connects the front wheels, allowing for steering and stability during turns. Rear Axle Supports the rear wheels and is responsible for driving the rear end of the vehicle. Steering Column The component that connects the front axle to the steering wheel, facilitating direction control. Footrest Plate Provides a platform for the operator’s feet while offering support and protection for the lower part of the vehicle. Fuel System Parts and Flow Diagram

The fuel system is essential for optimal engine performance, ensuring that the right amount of fuel is delivered efficiently. Understanding its components and the flow of fuel can help in diagnosing issues and maintaining the system effectively.

- Fuel Tank: Stores the fuel required for operation.

- Fuel Pump: Moves fuel from the tank to the engine.

- Fuel Filter: Cleans the fuel before it reaches the engine.

- Carburetor or Fuel Injector: Mixes fuel with air for combustion.

- Fuel Lines: Transport fuel between components.

Each element plays a critical role in the overall functionality, ensuring smooth operation and longevity of the engine.

- Fuel enters the tank.

- The fuel pump activates, drawing fuel from the tank.

- Fuel passes through the filter for purification.

- Clean fuel reaches the carburetor or injector.

- The fuel-air mixture is prepared for combustion.

By grasping the layout and function of each component, operators can ensure efficient fuel flow and address potential issues proactively.

Maintenance Tips for SLT1554 Components

Regular maintenance is key to ensuring the optimal performance and longevity of your garden tractor. Keeping the mechanical and electrical elements in good condition not only improves functionality but also helps to avoid costly repairs down the line. To keep the machine running smoothly, it is important to address key components systematically, following best practices for upkeep.

Engine and Transmission Care

The heart of any riding mower is the engine, and regular maintenance of this component is crucial. Proper care ensures efficient operation and extends its lifespan. Here are some essential maintenance tips for the engine and transmission:

- Change the oil regularly, according to the manufacturer’s guidelines. This helps maintain smooth engine operation and prevents overheating.

- Inspect the air filter regularly and clean or replace it as needed to ensure proper air circulation and engine performance.

- Check the spark plugs and replace them periodically to maintain consistent ignition.

- Keep the transmission fluid levels in check, as this will prevent wear and tear on the transmission system.

Deck and Blade Maintenance

The cutting deck and blades are subject to regular wear and tear due to their frequent use. To keep the mowing performance sharp and effective, follow these tips:

- Sharpen the mower blades at least once per season to ensure a clean and efficient cut.

- Inspect the deck for any debris buildup after each use and clean it to prevent clogging, which can reduce cutting efficiency.

- Check for any loose bolts or fasteners on the deck and tighten them as necessary to ensure stability during operation.

- Lubricate the deck components regularly to prevent rust and ensure smooth operation of the moving parts.

Battery and Electrical System

The electrical system, including the battery, plays an important role in ensuring smooth starting and operation. Here are some tips to maintain this crucial system:

- Keep the battery terminals clean and free of corrosion. Use a wire brush to remove any buildup that may affect performance.

- Check the battery charge regularly and replace it if it begins to show signs of weakness, such as slow starting or difficulty holding a charge.

- Inspect all wiring connections for any signs of wear or damage, and repair or replace faulty wires as needed.

By following these maintenance guidelines, you can ensure that your machine operates at peak efficiency for many seasons to come. Regular attention to the key components will help you avoid costly repairs and maintain a clean, well-maintained garden environment.