The essential components that contribute to a vehicle’s ability to halt safely and effectively are crucial for any enthusiast or owner to comprehend. These mechanisms are not merely functional; they embody a blend of engineering excellence and safety standards designed to ensure optimal performance on the road.

In this section, we will delve into the intricate details of the various elements involved in the stopping process. By understanding their layout and interaction, one can appreciate how these systems work together to deliver the ultimate driving experience.

From the pressure application to the eventual deceleration, grasping these fundamental aspects provides valuable insights for maintenance and enhancement. Equipped with this knowledge, individuals can make informed decisions regarding care and improvements of their vehicles.

Understanding Club Car Braking Systems

The effectiveness of a vehicle’s stopping mechanism is crucial for ensuring safety and performance. A well-designed stopping system plays a vital role in controlling motion and providing the necessary responsiveness. Familiarity with the various components and their functions is essential for maintenance and troubleshooting.

At its core, the system comprises several key elements that work in harmony. These include friction components that generate the necessary force to slow down or halt movement, as well as hydraulic or mechanical systems that facilitate this action. Each element must function optimally to ensure reliable operation.

Regular inspection and maintenance are imperative for longevity and reliability. Over time, wear and tear can affect performance, leading to potential hazards. Understanding how each component interacts within the system allows for proactive care and timely interventions.

In summary, grasping the intricacies of the stopping mechanism enhances both the lifespan of the vehicle and the safety of its operation. With proper knowledge and upkeep, users can ensure a dependable and efficient performance every time.

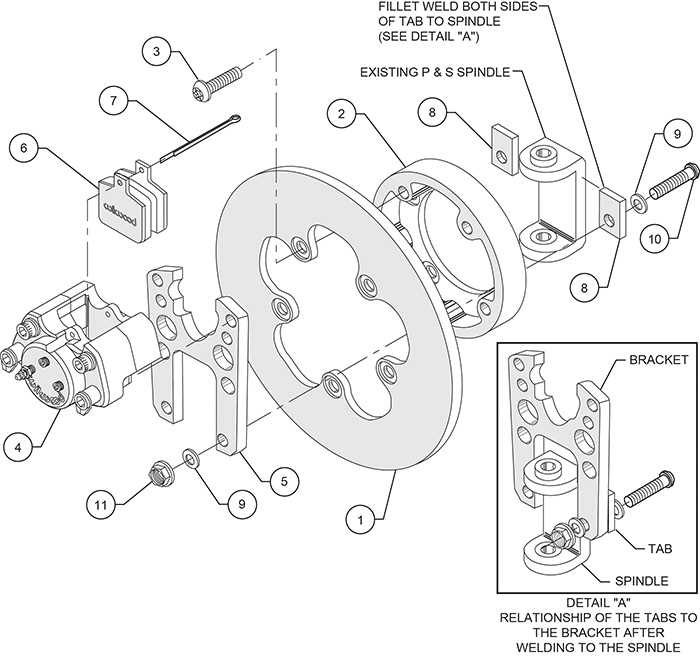

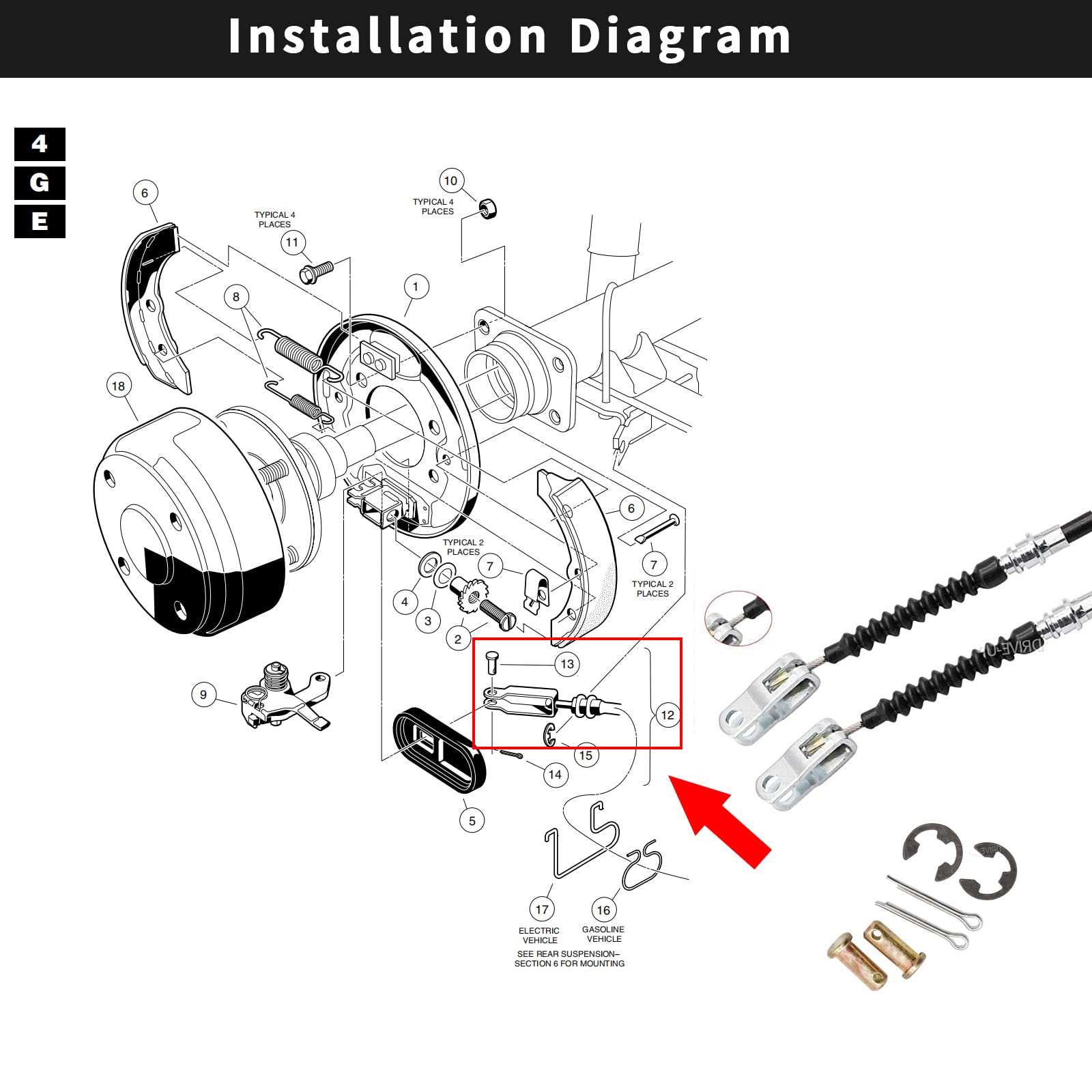

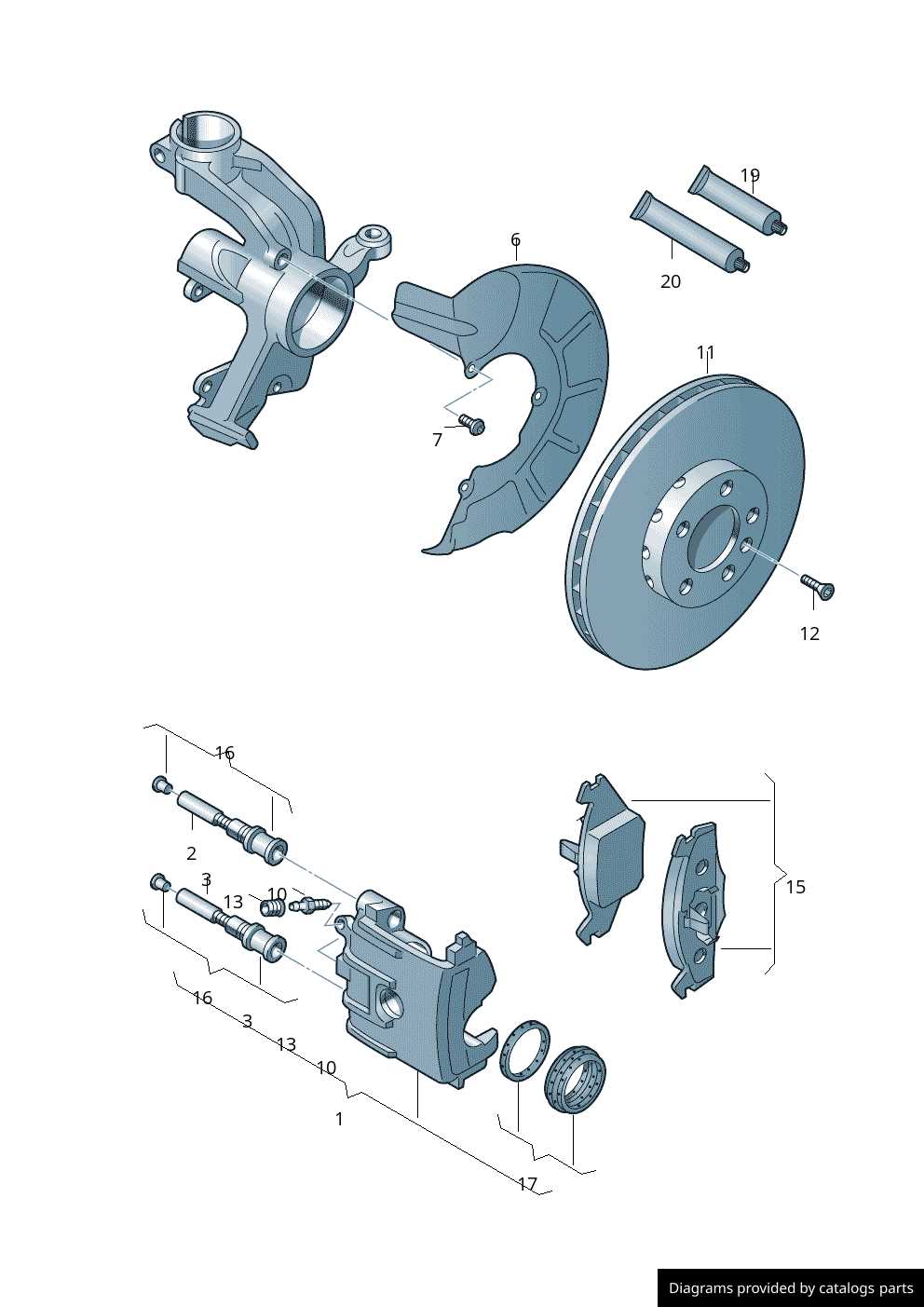

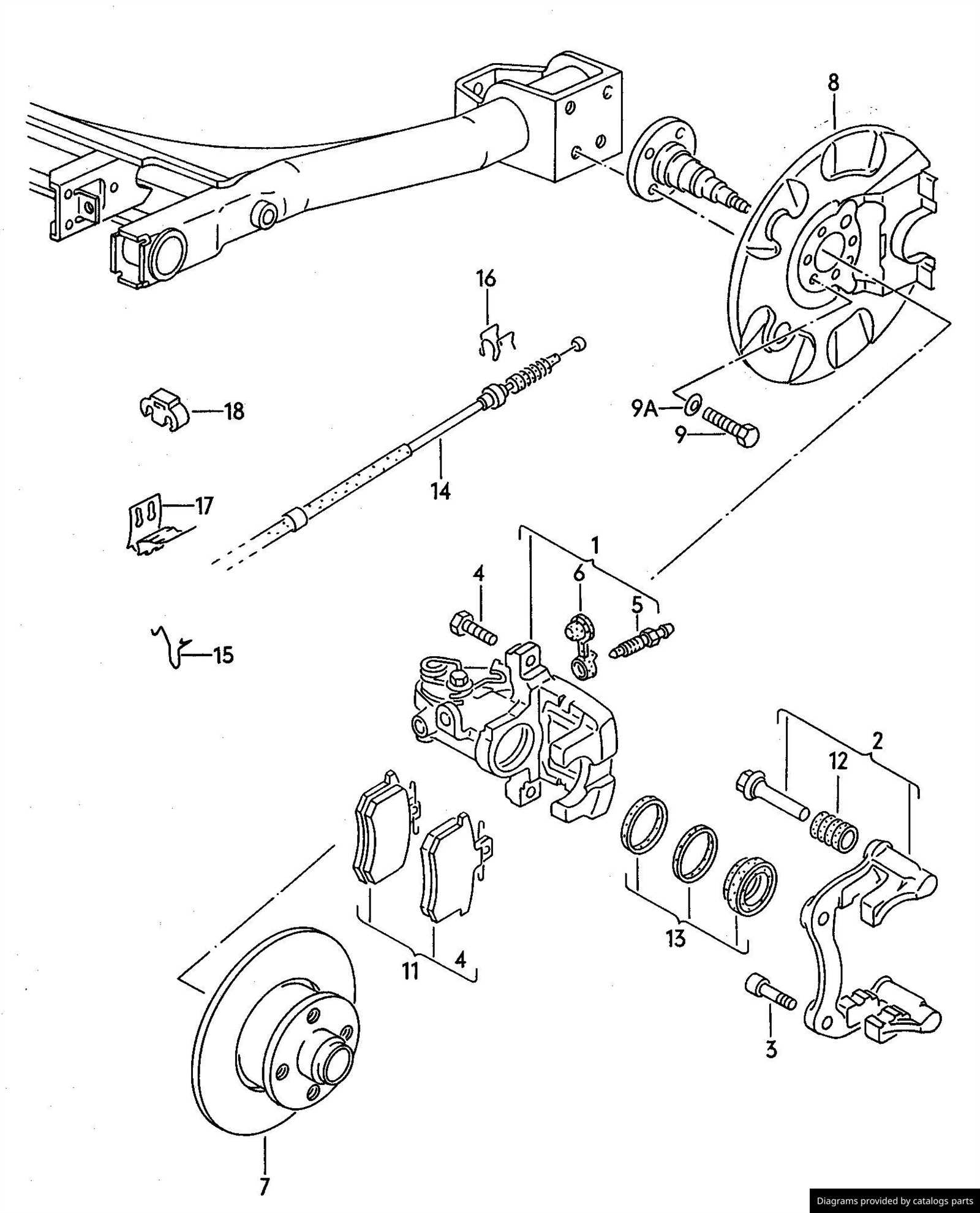

Key Components of Brake Assemblies

Understanding the essential elements that contribute to the functionality of stopping mechanisms is crucial for effective maintenance and performance. These components work in harmony to ensure safety and reliability during operation.

Main Elements

- Piston: This critical piece is responsible for generating the force needed to engage the stopping system.

- Caliper: Housing the piston, this component ensures even pressure distribution across the friction surfaces.

- Friction Material: Attached to the stopping mechanism, it creates the necessary resistance to halt motion.

- Rotors: These circular discs provide a surface for the friction material to act upon, converting kinetic energy into heat.

- Master Cylinder: It converts the force from the pedal into hydraulic pressure, activating the stopping elements.

Supporting Components

- Brake Lines: These conduits carry the hydraulic fluid from the master cylinder to the calipers.

- Reservoir: This container holds the hydraulic fluid necessary for operation.

- Hardware: Various clips, bolts, and springs that facilitate assembly and function.

- Heat Shields: Protect surrounding components from excessive heat generated during the stopping process.

Common Brake Issues in Club Cars

Maintaining optimal stopping functionality is crucial for safety and performance in any vehicle. Various factors can lead to performance degradation over time, resulting in unexpected challenges. Understanding these common problems can help in identifying symptoms early and ensuring smooth operation.

| Issue | Description | Possible Solutions |

|---|---|---|

| Fading Response | Decreased responsiveness when applying pressure, often due to overheating. | Allow cooling time, check fluid levels, or replace components as needed. |

| Uneven Wear | Irregular surface wear can lead to poor contact and inefficiency. | Inspect alignment and adjust or replace as necessary. |

| Noisy Operation | Unusual sounds during engagement may indicate wear or debris interference. | Clean surfaces and consider replacing worn items. |

| Leaking Fluid | Fluid loss can lead to a significant reduction in stopping power. | Identify the source of the leak and repair or replace faulty components. |

| Vibration | Shaking during use often suggests issues with balance or wear. | Examine components for damage and ensure proper installation. |

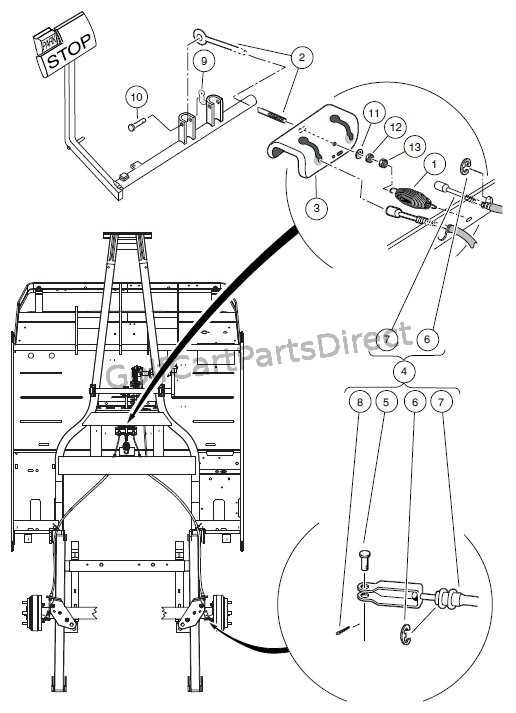

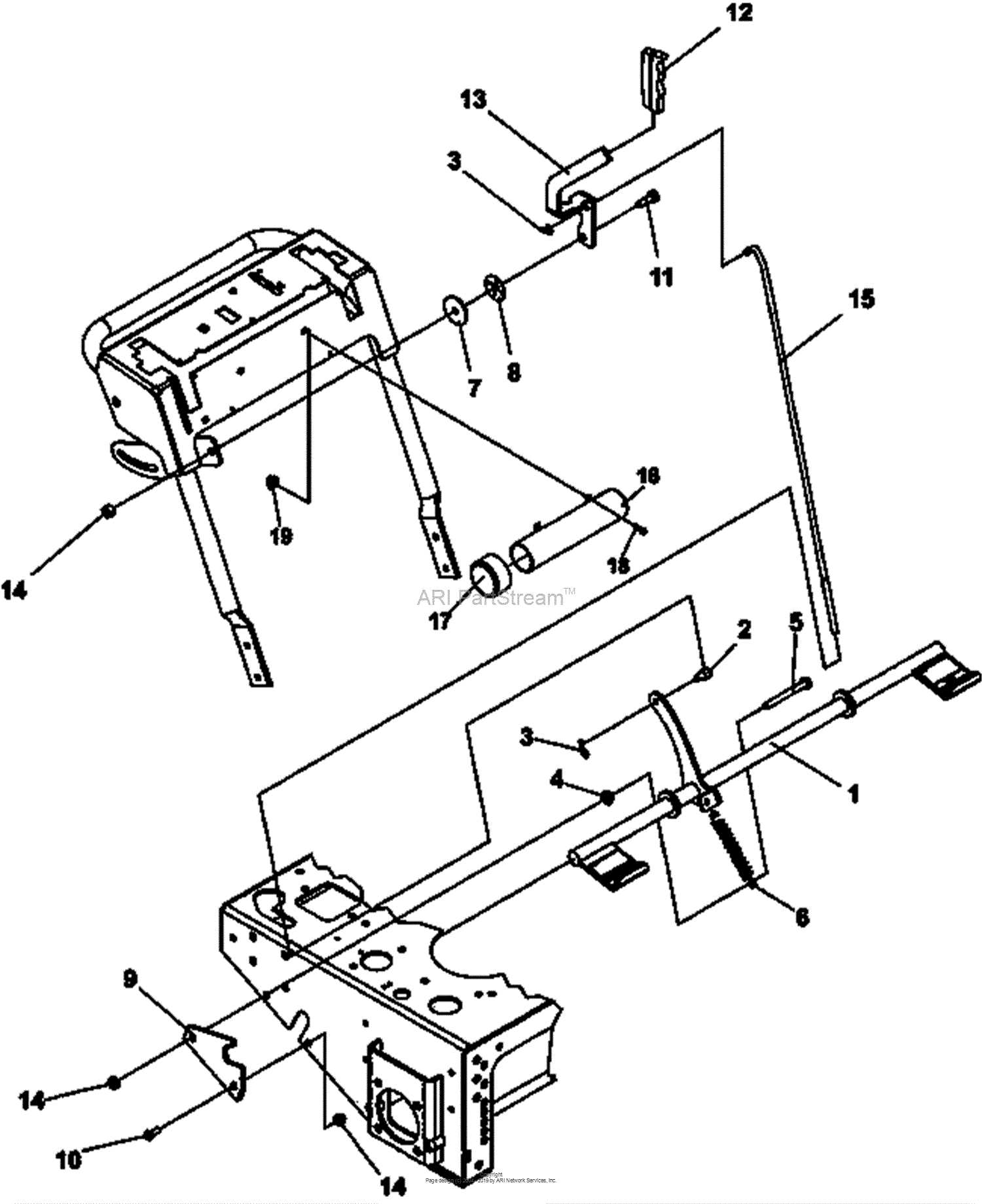

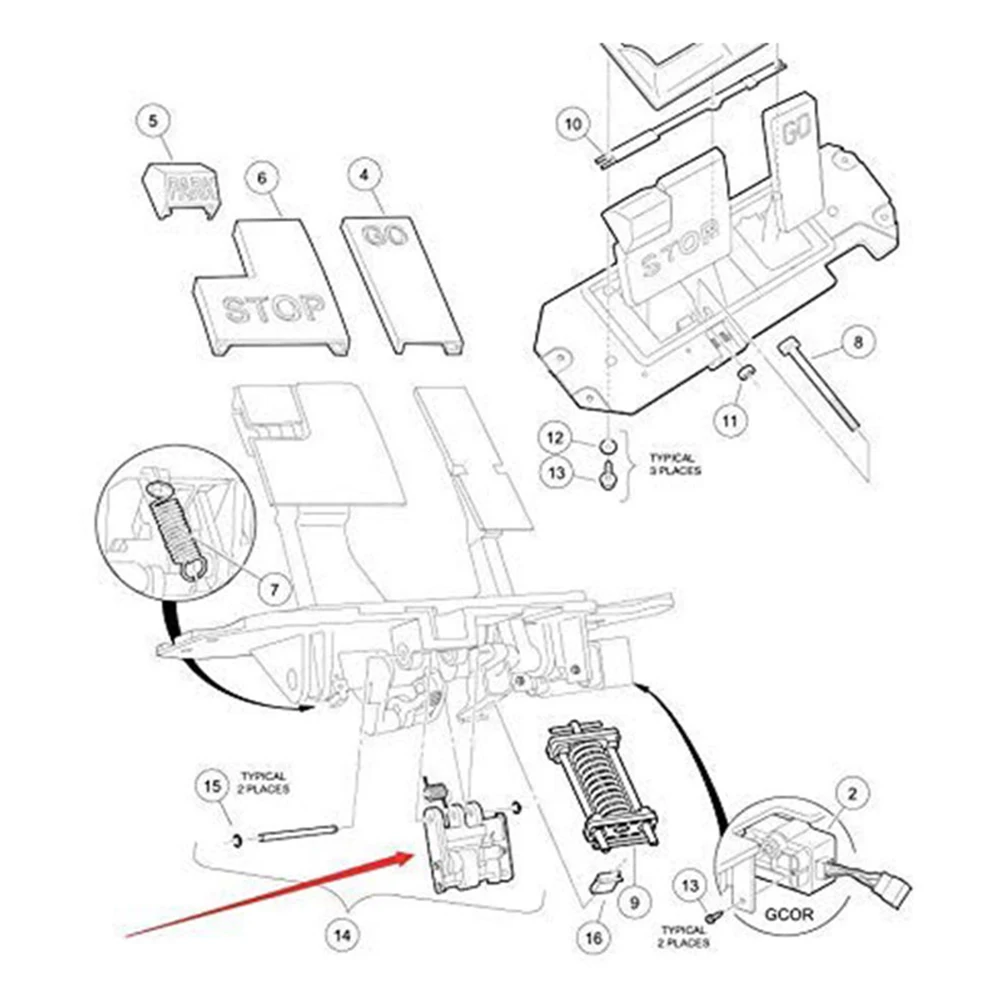

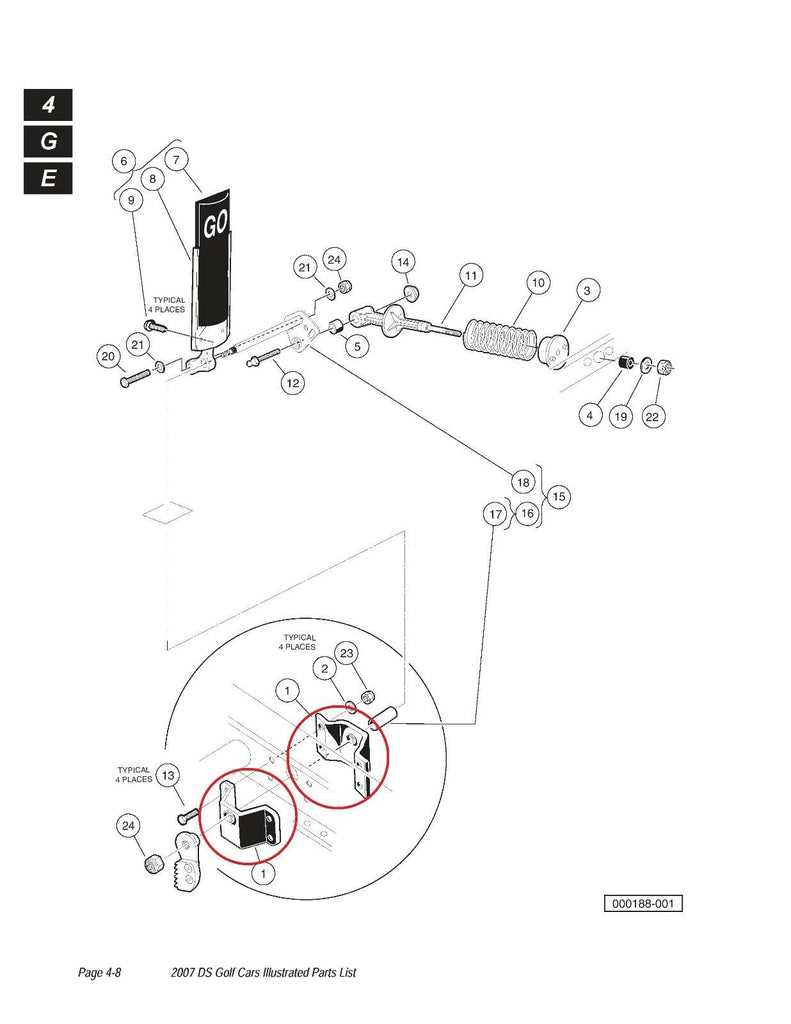

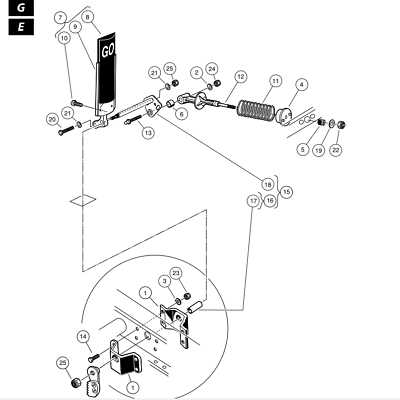

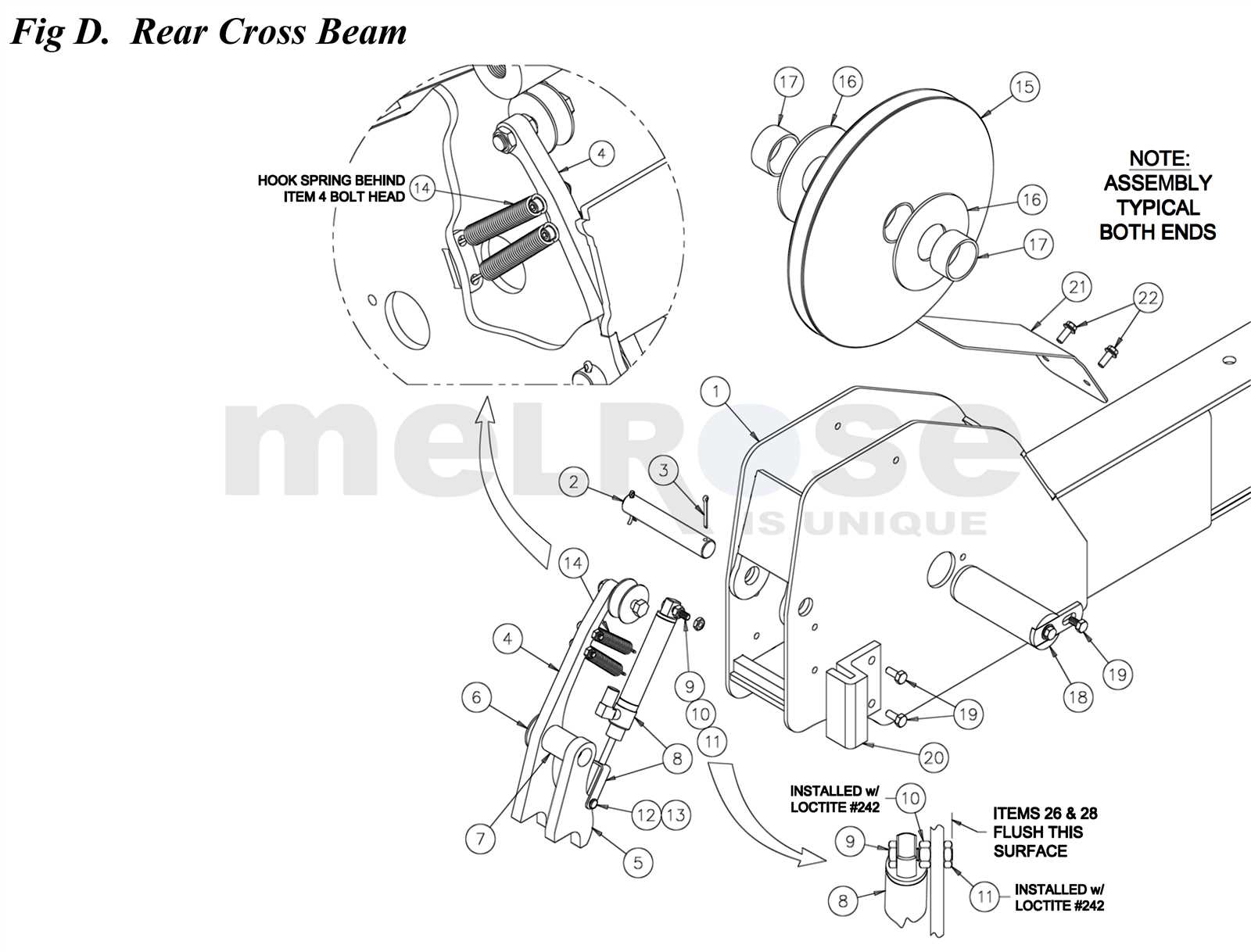

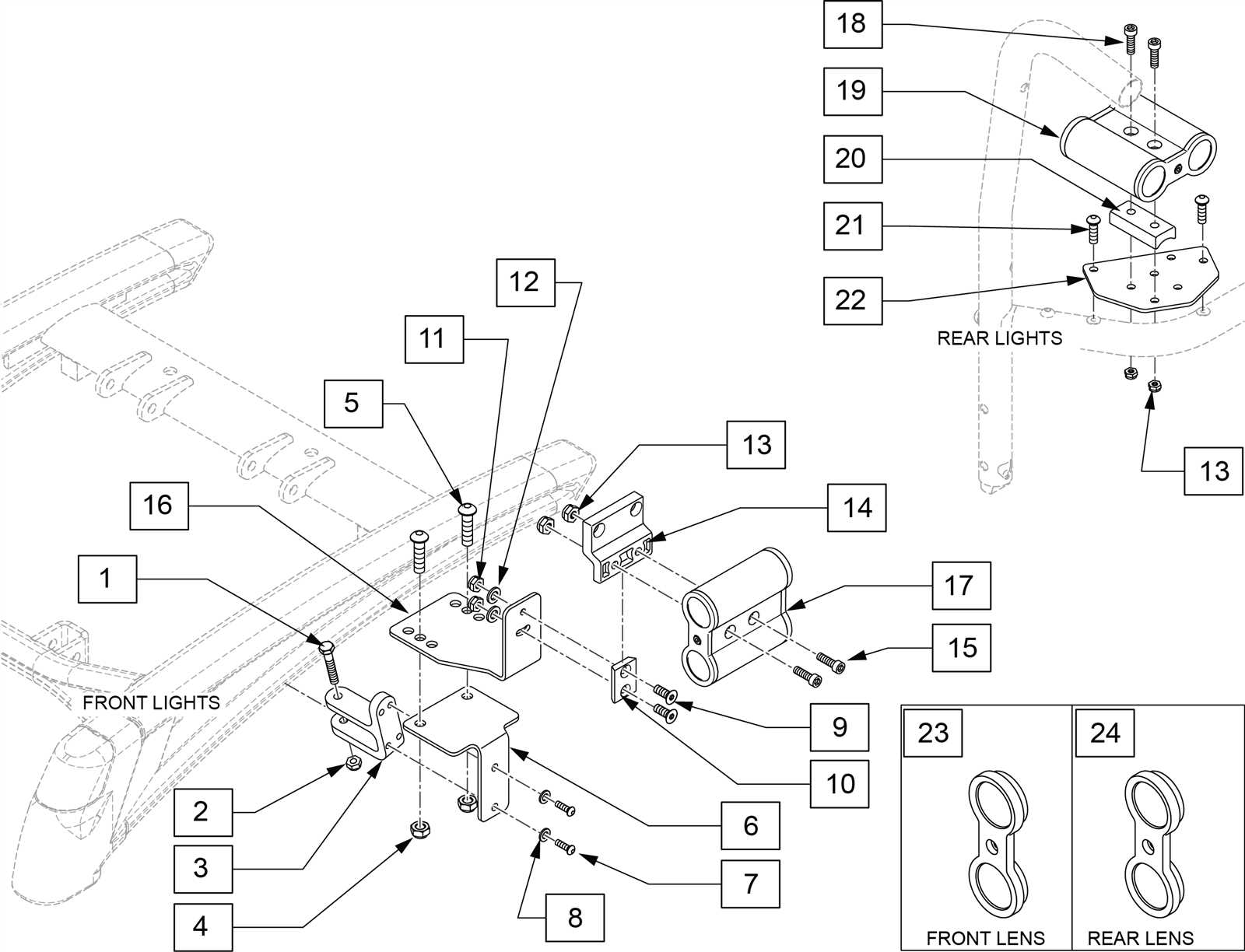

Visual Guide to Brake Diagrams

This section provides an insightful exploration into the intricate layouts associated with stopping mechanisms, essential for understanding functionality and maintenance. By examining various illustrations, readers can better appreciate the interconnectivity of components and their roles in ensuring safety.

Illustrations serve as valuable tools, offering clarity that words alone often cannot convey. Through detailed visuals, users can delve into each element’s purpose, ultimately enhancing their comprehension and ability to address any issues effectively.

Whether for repairs or upgrades, having access to these graphical representations simplifies the learning process, making it easier to identify necessary actions and components.

Maintenance Tips for Brake Parts

Ensuring optimal performance and safety requires regular attention to critical components. By following some simple guidelines, you can prolong the lifespan and functionality of these essential elements.

Regular Inspections

- Check for wear and tear regularly.

- Look for signs of corrosion or damage.

- Ensure all connections are secure.

Proper Cleaning

- Use appropriate cleaning solutions to remove dirt and grime.

- Avoid abrasive materials that may cause scratches.

- Ensure all components are dry before reassembly.

Upgrading Your Club Car Brakes

Enhancing the stopping system of your vehicle can significantly improve its performance and safety. This process often involves replacing outdated components with advanced alternatives, resulting in smoother operation and greater reliability. By making informed upgrades, you ensure that your ride remains both efficient and enjoyable.

Before embarking on this enhancement journey, it’s crucial to evaluate the current setup. Identifying which elements need improvement can guide your choices, leading to effective modifications. Upgrading involves not just replacing old pieces, but also considering new technologies and materials that enhance overall functionality.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Friction Material | High-performance pads | Improved stopping power and heat resistance |

| Hydraulic System | Premium fluid | Enhanced response and reduced fade |

| Support Mechanism | Stainless steel calipers | Increased durability and resistance to corrosion |

| Lines | Braided stainless steel | Better pressure retention and less expansion |

Upgrading these elements can transform your vehicle’s stopping capabilities, providing not only peace of mind but also a more enjoyable driving experience. Invest time in researching options and consult with experts to make the best choices for your specific needs.

Signs of Worn Brake Components

Identifying the deterioration of essential stopping mechanisms is crucial for maintaining safety and performance. Recognizing early indicators can prevent further damage and ensure reliable functionality. Various symptoms can signal that these vital elements require attention or replacement.

One of the most noticeable signs is a decrease in responsiveness when engaging the stopping system. If the response feels sluggish or requires more effort, it may indicate wear. Additionally, unusual noises, such as squeaking or grinding, can suggest that the components have reached a critical state. Vibrations during operation can also be a warning sign of imbalance or degradation.

Visual inspection can reveal other important clues. Look for uneven wear patterns or excessive thickness reduction. Accumulation of dust or debris around the area can indicate neglect, which might contribute to component failure. Finally, any warning lights on the dashboard should not be ignored, as they often relate to these systems.

How to Replace Brake Parts

Replacing essential components of your vehicle’s stopping system is a crucial maintenance task that ensures safety and optimal performance. This guide outlines the steps to effectively swap out these vital elements, enhancing your vehicle’s reliability.

Preparation is key before starting any replacement work. Gather the necessary tools, including wrenches, sockets, and a jack, as well as the new components. Ensure you have a clean and well-lit workspace to facilitate the process.

Begin by lifting the vehicle securely, using jack stands to prevent accidents. Once elevated, remove the wheels to access the components that need replacing. Carefully detach the old parts, taking note of their configuration, as this will aid in correctly installing the new ones.

Before installing the replacements, inspect all related components for wear and damage. If anything else shows signs of deterioration, consider replacing it as well. When ready, mount the new items, ensuring they are positioned correctly and securely fastened.

Finally, lower the vehicle and test the system before hitting the road. This ensures everything functions as intended and contributes to the overall safety of your vehicle. Regular maintenance like this not only extends the life of your vehicle but also provides peace of mind during your travels.

Safety Considerations for Brake Systems

Ensuring the reliability and efficiency of stopping mechanisms is crucial for the overall safety of any moving vehicle. Proper maintenance and understanding of these systems can prevent accidents and enhance performance. It is essential to recognize the potential risks and take appropriate measures to mitigate them.

Regular Inspections: Frequent checks are vital to identify wear and tear on components. Timely detection of issues can significantly reduce the risk of failure during operation.

Quality Components: Utilizing high-quality materials and replacements ensures that the system operates effectively. Substandard components can compromise safety and lead to hazardous situations.

Environmental Factors: Be mindful of external conditions that may impact functionality. Elements such as moisture, extreme temperatures, and debris can adversely affect performance.

Training and Awareness: Educating operators about the proper use and potential pitfalls of these systems is essential. Awareness can foster safer practices and prompt immediate attention to emerging problems.

In conclusion, prioritizing safety through diligent maintenance and informed practices is key to preventing malfunctions and ensuring a secure driving experience.