In the realm of aquatic transport support systems, comprehending the intricate network of components is essential for optimal performance and maintenance. A thorough grasp of each element’s function enhances efficiency and prolongs the lifespan of the entire assembly. This knowledge empowers users to tackle repairs and upgrades with confidence.

Identifying each segment within the assembly allows for better troubleshooting and part replacement. Understanding the relationship between different components facilitates smoother operations and ensures safety on the water. By dissecting the arrangement, individuals can pinpoint potential issues before they escalate into significant problems.

Moreover, familiarizing oneself with the various elements encourages proactive care. Regular inspection and knowledge of how each piece interconnects contribute to a seamless experience. Emphasizing the importance of component awareness ensures that users can enjoy their aquatic endeavors without unexpected disruptions.

Understanding Hewitt Boat Lift Parts

When it comes to the mechanisms that support and secure watercraft, familiarity with their individual components is essential for optimal performance and maintenance. Each element plays a critical role in ensuring the overall functionality and reliability of the system, allowing users to enjoy their time on the water without concerns.

Key Components and Their Functions

Among the most crucial elements are the structural frames, which provide stability and support. Additionally, the buoyancy features are vital for lifting and holding vessels above water levels. Understanding how these parts interact can help in troubleshooting and improving efficiency.

Maintenance Tips for Longevity

Regular inspection and upkeep of these crucial elements can significantly extend their lifespan. Ensuring that all connections are secure and that the buoyancy devices remain intact is essential. Neglecting maintenance can lead to costly repairs or replacements, ultimately impacting your experience.

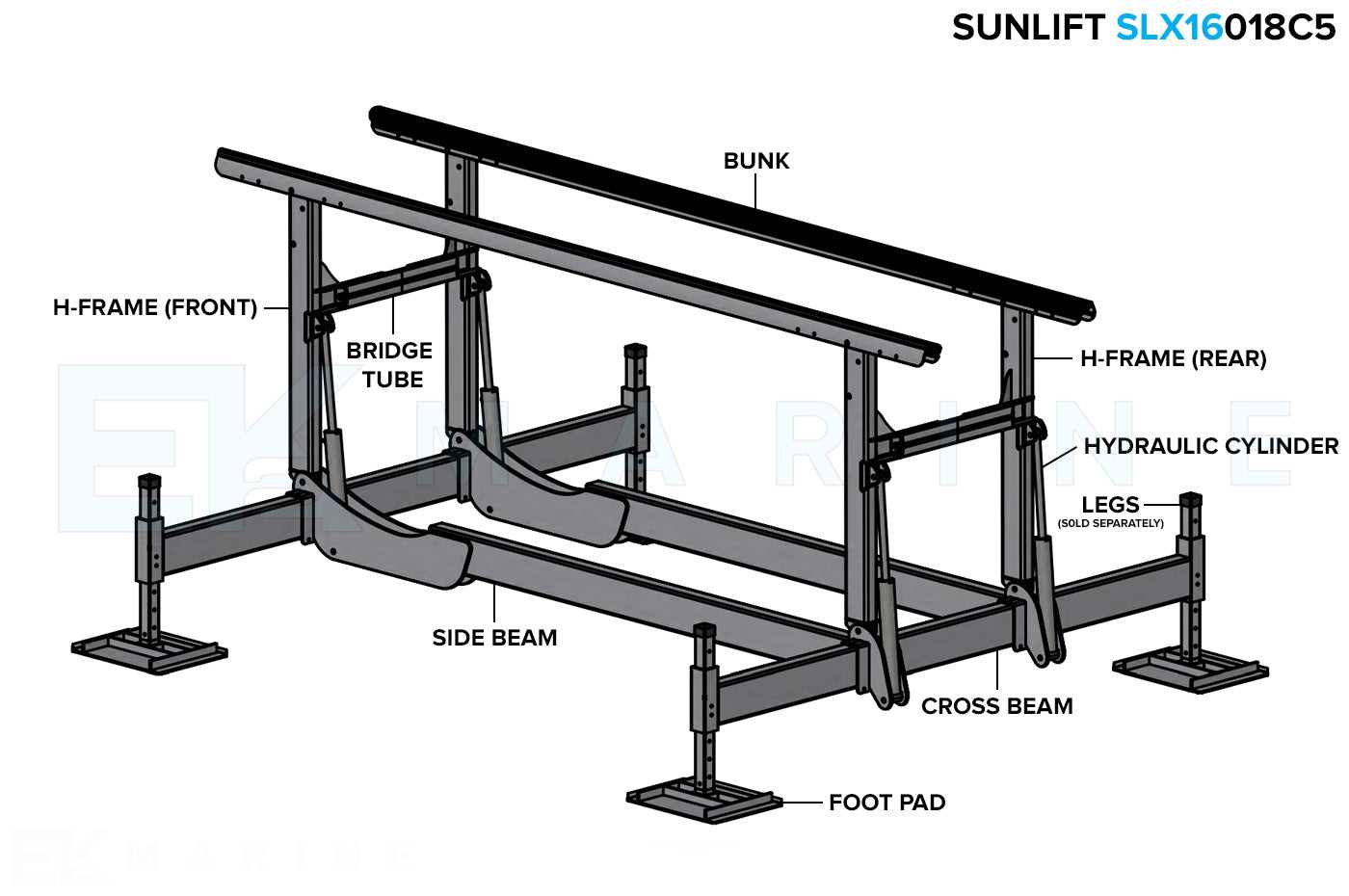

Components of a Hewitt Boat Lift

This section explores the essential elements that contribute to the functionality and efficiency of a marine elevation system. Understanding these components is crucial for proper maintenance and optimal performance.

- Frame: The foundational structure that supports the entire system.

- Cradle: A supportive platform that holds the vessel securely.

- Pulleys: Mechanisms that aid in lifting and lowering operations.

- Ropes: Durable lines that connect to the lifting system for maneuverability.

- Motor: The power source responsible for driving the elevation mechanism.

- Control System: The interface that allows users to operate the mechanism with ease.

- Floatation Devices: Elements that provide buoyancy and stability during operation.

Each of these components plays a vital role in ensuring a smooth and effective lifting experience, making it imperative to maintain them in good condition.

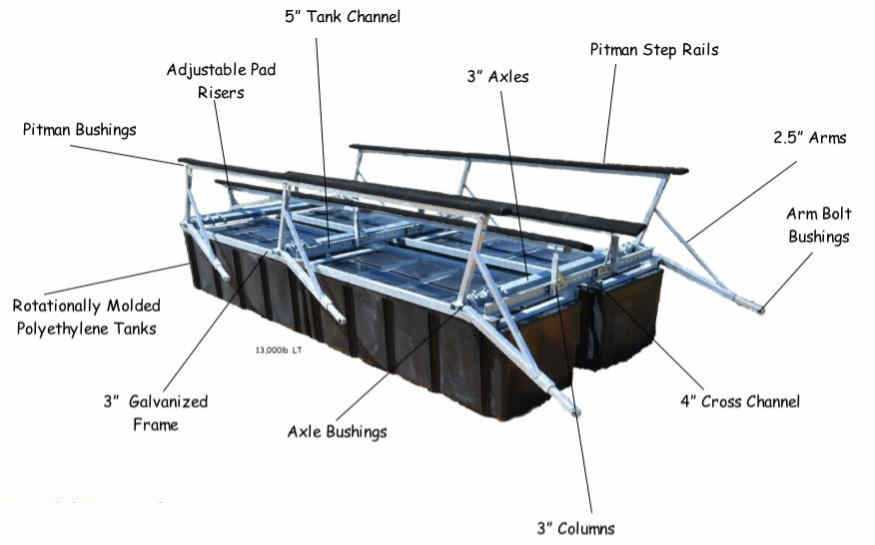

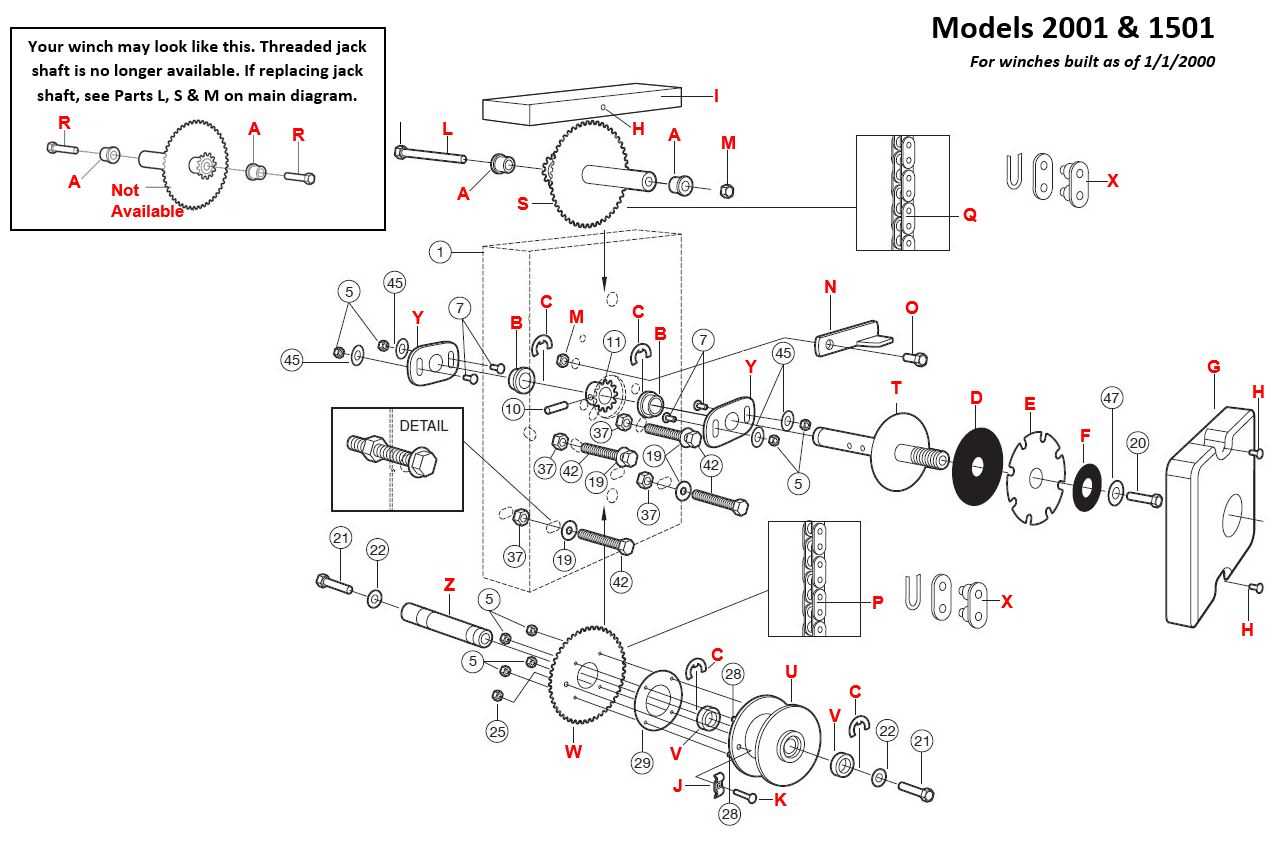

How to Read the Parts Diagram

Understanding a visual representation of components is essential for effective assembly and maintenance. These illustrations provide crucial information about the individual elements, their arrangement, and how they interact with one another. Mastering this skill can significantly enhance your troubleshooting and repair capabilities.

Identifying Key Components

Start by familiarizing yourself with the symbols and labels used in the illustration. Each part is typically marked with a unique identifier, which can be cross-referenced in accompanying documentation. Pay close attention to any annotations that indicate dimensions or specifications.

Understanding the Relationships

Next, focus on the connections between the elements. Understanding how each piece relates to others will help you grasp the overall function. Note any directional arrows or lines that suggest movement or alignment, as these are vital for proper assembly and operation.

Common Issues with Boat Lifts

Managing aquatic platforms can sometimes present challenges that require attention and maintenance. Understanding these common problems is essential for ensuring longevity and optimal performance. Below are some frequent issues encountered by users and potential solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Mechanical Failure | Wear and tear on components can lead to breakdowns. | Regular inspection and timely replacement of worn parts. |

| Corrosion | Exposure to water can cause rust and deterioration of materials. | Use of marine-grade materials and applying protective coatings. |

| Electrical Issues | Faulty wiring or connections can disrupt functionality. | Routine checks and repairs of electrical systems. |

| Improper Installation | Incorrect setup may lead to instability or operational failure. | Follow manufacturer guidelines and seek professional installation. |

| Environmental Factors | Debris and water levels can affect performance. | Regular cleaning and monitoring of surrounding conditions. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adopting a consistent maintenance routine will help identify potential issues before they escalate, ensuring seamless operation throughout the year.

Routine Inspections

Conducting thorough assessments of all components at regular intervals can prevent unexpected breakdowns. Check for wear and tear on critical elements, ensuring everything is functioning as intended.

Lubrication and Cleaning

Keeping moving parts well-lubricated reduces friction and enhances performance. Additionally, cleaning surfaces from debris and grime will promote optimal functioning and extend the lifespan of your system.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often feel overwhelming, especially when faced with various options and technical specifications. Understanding how to navigate the search process effectively can save you time and ensure that you obtain the right items for your needs.

Start by identifying the specific components required for your system. Referencing the original user manual or any available resources can provide valuable insights into the necessary specifications and compatibility. Make a list of the items you need, which will streamline your search.

Utilizing online marketplaces and specialized retailers can significantly enhance your chances of finding the right components. Many platforms offer advanced search filters, allowing you to narrow down results based on size, material, or brand. Additionally, user reviews and ratings can guide you toward reliable options.

Consider joining online forums or communities where enthusiasts and professionals share their experiences. These platforms often feature discussions about common replacements and reliable sources, helping you make informed decisions.

Finally, keep an eye on local suppliers and distributors. Establishing a relationship with nearby businesses can lead to quick access to components and personalized assistance, making the entire process much more efficient.

Importance of Regular Inspections

Conducting frequent evaluations of equipment is crucial for ensuring optimal performance and longevity. Neglecting this practice can lead to unforeseen issues that not only compromise functionality but also pose safety risks. Regular assessments allow for the early detection of wear and tear, helping to maintain operational efficiency.

Benefits of Routine Evaluations

- Enhanced Safety: Regular checks minimize the likelihood of accidents caused by malfunctioning components.

- Cost Savings: Identifying problems early can reduce repair costs and prevent extensive damage.

- Improved Efficiency: Well-maintained systems operate more effectively, ensuring smooth functionality.

- Extended Lifespan: Consistent upkeep contributes to the durability of equipment, prolonging its useful life.

Key Aspects to Inspect

- Mechanical Components: Ensure all moving parts are functioning correctly and are lubricated as needed.

- Structural Integrity: Check for any signs of wear, rust, or damage to support structures.

- Control Systems: Verify that all operational controls are responsive and free of defects.

- Electrical Connections: Inspect wiring and connections for signs of corrosion or wear.

In summary, maintaining a routine inspection schedule is essential for the reliable operation of equipment. Proactive measures not only enhance safety but also optimize performance and extend the lifespan of critical systems.

Safety Features of Hewitt Lifts

When it comes to ensuring user security and preventing accidents, innovative mechanisms play a vital role in aquatic equipment. These features are designed to enhance stability, reliability, and overall safety during operation.

- Emergency Stop Mechanism: Allows for immediate cessation of movement in case of an unexpected situation.

- Load Monitoring Systems: Alerts users if weight exceeds safe limits, reducing the risk of failure.

- Anti-Tip Design: Prevents the structure from tipping over, ensuring balance and safety.

- Corrosion-Resistant Materials: Enhances longevity and reduces hazards associated with wear and tear.

Implementing these safety attributes is crucial for providing peace of mind and promoting a secure experience on the water.

Upgrading Your Boat Lift System

Enhancing your aquatic elevation mechanism can significantly improve functionality and longevity. Whether you’re seeking better performance, increased capacity, or advanced features, upgrading your system can offer numerous benefits.

Here are some key considerations for a successful upgrade:

- Evaluate Current Condition: Assess the existing setup for wear and tear. Identify components that may need replacement or enhancement.

- Capacity Requirements: Determine the weight and size of the vessels you intend to support. This will guide your selection of stronger, more robust components.

- Technology Integration: Consider modern solutions such as remote controls or automated systems that provide ease of use and convenience.

When planning your upgrade, it’s crucial to focus on the following aspects:

- Quality of Materials: Invest in durable materials that can withstand harsh marine environments.

- Installation: Ensure proper installation by hiring professionals or following detailed guidelines if you choose a DIY approach.

- Maintenance: Incorporate a regular maintenance schedule to prolong the lifespan of your upgraded system.

By considering these factors, you can effectively enhance your aquatic elevation mechanism, ensuring reliable operation and increased enjoyment on the water.