For any outdoor enthusiast or maintenance professional, the functionality and longevity of garden machinery are paramount. A thorough understanding of the various components involved in these tools can significantly enhance performance and ensure effective maintenance. This section aims to provide insights into the essential elements that make up these machines, facilitating better usage and care.

When it comes to troubleshooting or upgrading your equipment, having a clear representation of its individual elements is invaluable. Knowing how each component interacts can help in identifying potential issues and understanding how to optimize functionality. This knowledge empowers users to tackle maintenance tasks with confidence and precision.

By familiarizing yourself with the layout and role of each section, you can ensure that your machinery operates at peak efficiency. Whether you are performing routine checks or replacing specific components, this guide will serve as a reliable resource for maintaining your outdoor equipment in excellent working condition.

This segment provides a comprehensive look at a popular outdoor tool designed for managing yard debris. Known for its efficiency and ergonomic design, this equipment is widely used in various settings, from residential lawns to commercial spaces. The section emphasizes its compact structure and user-friendly operation, making it a reliable choice for both beginners and experienced users.

Design and Functionality

The model combines a powerful engine with an intuitive build, ensuring ease of use during extended sessions. Its lightweight form allows for comfortable handling, while the well-balanced structure minimizes strain on the operator. The thoughtful placement of controls makes adjusting speed and flow simple, enhancing the overall experience.

Key Components and Maintenance

Understanding the essential elements of this device can extend its lifespan and maintain peak performance. Regular upkeep, including inspecting filters, cleaning airways, and replacing worn-out components, ensures optimal operation. Each part, from the engine housing to the adjustable nozzle, plays a role in maintaining smooth performance over time.

Key Features of the Model

This equipment is designed for those who value performance and ease of use, offering a range of benefits that make it ideal for both beginners and experienced users. Its thoughtful design combines power with ergonomic elements to provide an efficient and comfortable experience.

The device boasts a high-powered motor that ensures efficient air movement, making it suitable for various outdoor tasks. Despite its robust capabilities, the unit is lightweight, allowing users to handle it with minimal effort over extended periods.

An intuitive control layout allows for simple operation, making it easy to adjust the speed and direction to match the specific needs of the task at hand. Additionally, the model is equipped with vibration-dampening technology, reducing strain during prolonged use and enhancing overall comfort.

Durability is another standout aspect, with a build quality that is made to withstand regular use in different environmental conditions. This makes it a reliable tool for those seeking long-term value without frequent maintenance.

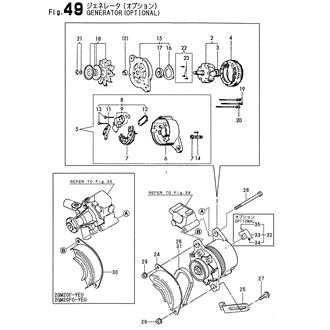

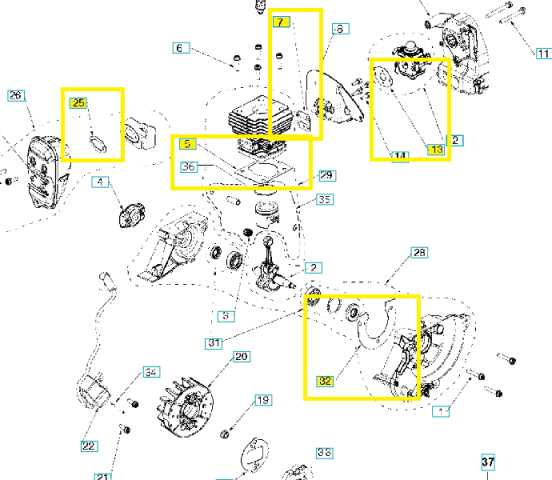

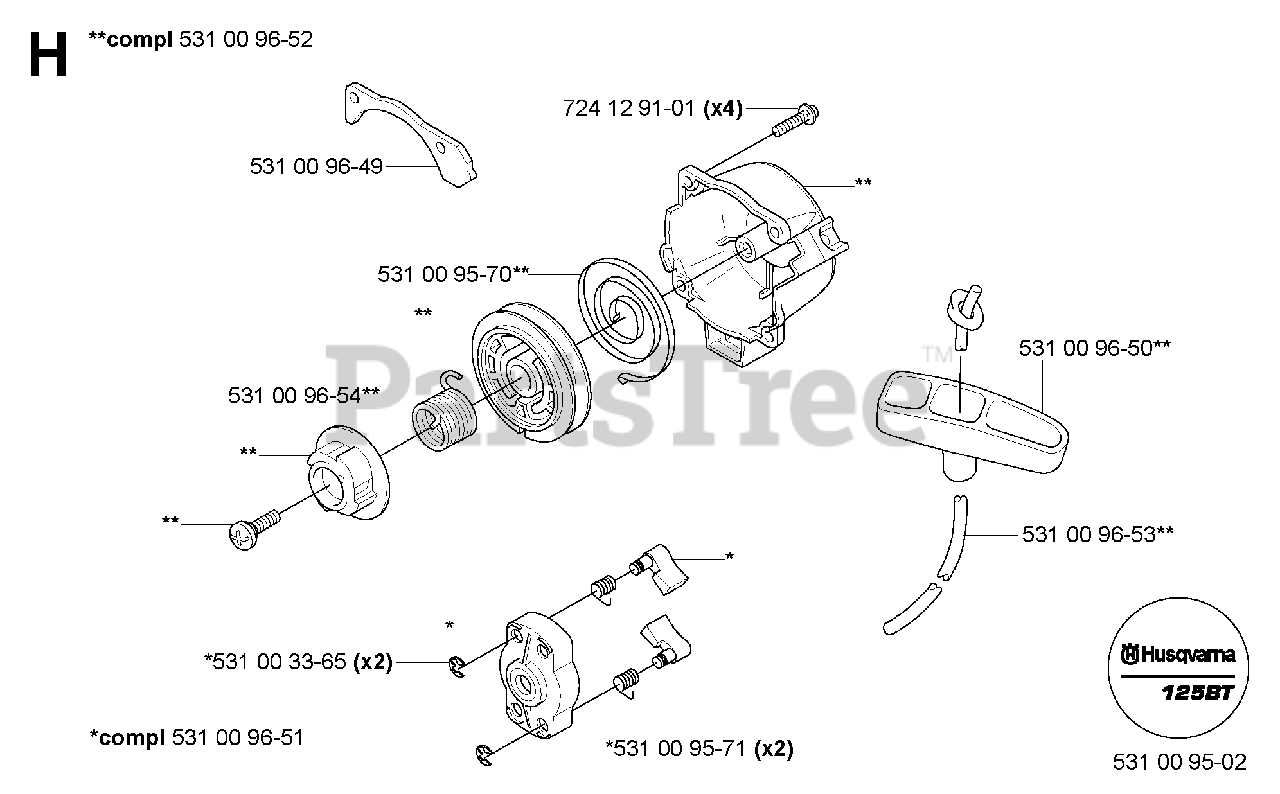

Understanding the Parts Diagram

Exploring the schematic breakdown of the equipment allows users to gain a clearer perspective on the assembly and interconnections of various components. This view simplifies the process of identifying specific elements and understanding their roles within the overall structure.

Main Components Overview

The visual layout typically divides the structure into distinct sections, each representing a crucial area. By analyzing these areas, one can easily distinguish between functional groups and see how each section contributes to the overall operation.

- Engine Assembly: This segment includes the core mechanisms responsible for driving the entire device.

- Air Flow System: Focuses on the mechanisms that facilitate the efficient movement of air through the system.

- Control Interface: This part encompasses the user-interactive elements, ensuring precise regulation during operation.

Connecting the Elements

The diagram helps to visualize how different elements interact. By tracing the connections between various units, users can pinpoint potential points of wear or malfunction, making maintenance more straightforward. Understanding these linkages is key to

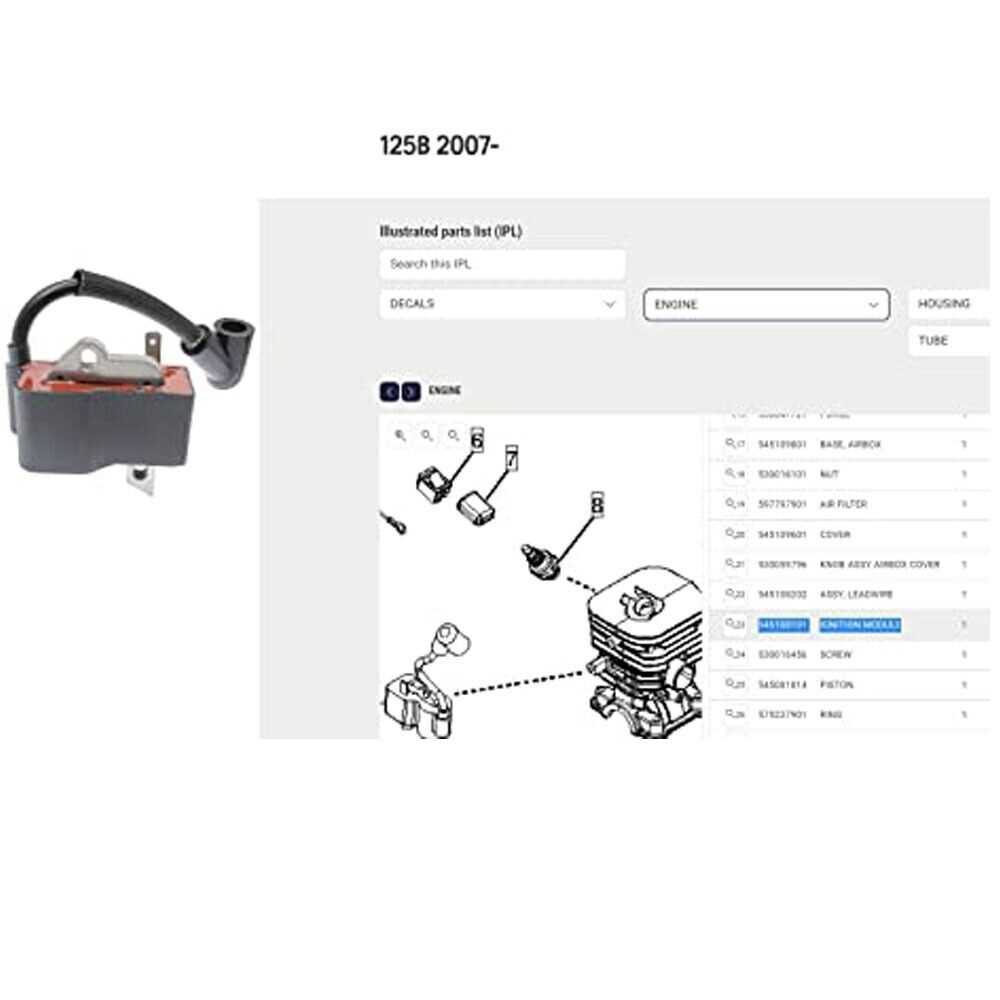

Components Included in the Diagram

The illustration provides a comprehensive overview of the various elements that make up the machinery. Each component plays a crucial role in ensuring smooth operation, contributing to overall performance and efficiency. Understanding these individual elements helps in maintaining, repairing, or replacing them when necessary.

Key Functional Elements

- Engine Unit: The power source that drives the entire system, ensuring efficient energy conversion and output.

- Air Intake Assembly: Facilitates the proper flow of air through the mechanism, aiding in optimal functionality.

- Ignition Module: Responsible for initiating the startup process, creating the spark necessary to begin operation.

- Fuel Tank: Stores the energy source required for continuous operation, designed with durability in mind.

Supporting Structures

- Frame Housing: Encases critical components, providing structural integrity and protection from external factors.

- Control Handles: Offers users a way to manage and direct the operation, ensuring precision during use.

- Maintenance Tips for Longevity

Regular upkeep is key to ensuring reliable operation and extending the lifespan of your equipment. Following a few simple guidelines can help maintain performance over time and prevent common issues that may arise with frequent use.

- Clean the air intake regularly to prevent debris buildup. This helps maintain airflow and ensures the internal components are free from obstructions.

- Inspect the fuel system and replace the filter when needed. A clean fuel filter ensures efficient fuel flow, reducing the chance of engine problems.

- Check and replace the spark plug annually. A fresh spark plug can improve ignition, leading to smoother operation and easier starts.

- Ensure proper lubrication of moving parts. Apply the recommended lubricant to keep mechanisms running smoothly, reducing wear and tear.

- Examine the exhaust system for clogs or damage. A clear exhaust helps maintain optimal power output and prevents overheating.

- Store the device in a dry, sheltered area when not in use.

Common Issues and Solutions

Maintenance challenges often arise during the use of outdoor machinery, leading to various operational disruptions. Understanding these challenges can help extend the service life and ensure reliable performance. Below is a list of typical problems encountered and practical steps to address them.

-

Engine Struggles to Start:

This is a frequent concern and can be linked to fuel quality or spark plug condition. To resolve, inspect the fuel mixture, ensuring it is fresh and properly blended. Replace the spark plug if signs of wear or buildup are evident.

-

Decreased Air Output:

A reduction in airflow may indicate obstructions or a clogged filter. Check for any debris blocking the airflow path and clean the air filter thoroughly. Replacing the filter periodically can prevent this issue from recurring.

-

Engine Overheating:

Prolonged use can lead to elevated temperatures, causing the engine to shut down or perform poorly. Ensure proper ventilation and clean any accumulated dirt from cooling fins. Allow the device to cool down between extended usage sessions.

-

V

Identifying Replacement Parts

When maintaining equipment, it’s crucial to recognize which components need replacing to ensure optimal performance. Understanding how each element fits within the overall structure allows users to pinpoint what needs attention during repair or upkeep.

Commonly Replaced Components

Some components tend to wear out faster due to frequent use. Recognizing these pieces can save time and reduce frustration during maintenance. Items like filters, gaskets, and control mechanisms often need inspection and periodic swapping.

Reference Chart for Quick Identification

The following chart provides a straightforward way to match commonly required elements with their corresponding identifiers and functions, making it easier to find suitable replacements.

Component Function Replacement Frequency Air Intake Screen Prevents debris from entering the internal chamber Every 6-12 months Fuel Line Transports fuel from the tank to the engine Annually or as needed Car Where to Purchase Genuine Parts

When it comes to maintaining the performance and longevity of your equipment, choosing authentic components is crucial. These items are designed specifically for your model, ensuring compatibility and optimal function. Whether you’re looking to replace worn-out elements or stock up on essentials, finding the right suppliers can make all the difference.

For those who value reliability and quality, there are a few reputable options to consider. Authorized dealers are often the best choice, as they provide products directly from the manufacturer. This guarantees that the items meet the required standards and come with proper warranties. Additionally, these outlets can offer advice tailored to your needs, helping you select the exact component for your device.

Online platforms are another convenient option, offering a wide range of options to suit various requirements. Many certified vendors operate through these marketplaces, offering a seamless way to order the necessary components from the comfort of your home. It’s important, however, to verify the authenticity of the seller before making a purchase to avoid subpar imitations.

Lastly, visiting local hardware shops can be an excellent way to find what you need quickly. Some stores carry a range of authentic replacements, allowing you to inspect the items before buying. This can be particularly useful if you need a part immediately or prefer to support local businesses while ensuring the durability of your equipment.

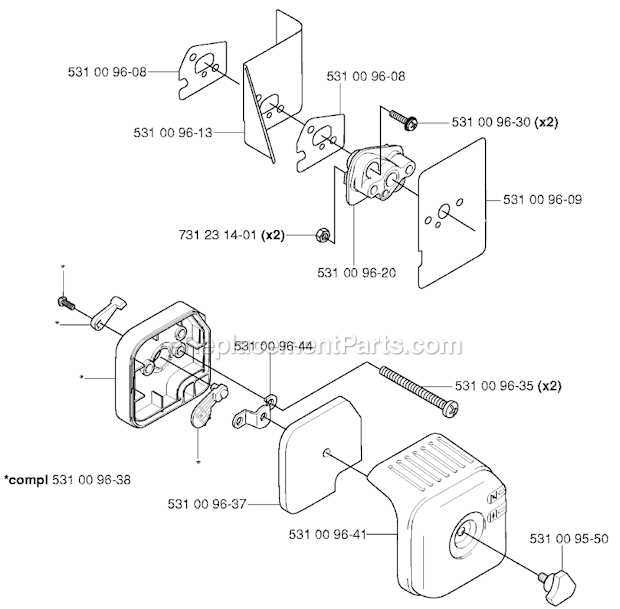

Assembly Instructions for Replacements

Proper assembly of replacement components ensures efficient functionality and extends the lifespan of your equipment. Following the correct sequence and using appropriate tools is crucial for optimal performance. Below is a guide for reassembling various key components, allowing for a smooth installation process.

Component Tools Needed Steps Fan Housing Screwdriver, Wrench Remove old housing by unscrewing bolts, align the new part with the mounting points, and tighten screws securely. Fuel Tank Wrench, Pliers Drain any remaining fluid, disconnect fuel lines, and replace with the new container. Reattach lines and ensure no leaks. Ignition Coil Screwdriver Detach the wiring harness, unscrew the old coil, position the replacement, and reconnect the harness. Air Filter Cover Screwdriver Release the cover latches, remove the old filter, insert the new one, and secure the cover back in place. Ensure

Tools Needed for Disassembly

Before starting the process, having the right equipment is essential for a smooth and efficient breakdown. Using the appropriate items ensures that each step is performed without unnecessary strain, reducing the risk of damaging small components or fasteners. Proper preparation will also help save time during reassembly.

Basic Equipment

The core set of tools required includes a range of screwdrivers and hex keys. These items allow for the removal of various screws and bolts, which hold together different sections. Additionally, pliers are crucial for handling clips and springs, providing a secure grip while working with small or intricate elements.

Specialized Instruments

In addition to the basics, a set of socket wrenches might be needed for specific bolts that require extra torque. A soft mallet can help to gently separate tightly fitted sections without causing damage. A small pick set is also helpful for accessing hard-to-reach areas or carefully prying apart connections.

-