In the world of outdoor equipment, effective maintenance and repair are essential for ensuring optimal performance. Knowing the various elements that make up a powerful air dispersal device can greatly assist users in troubleshooting and enhancing their machine’s functionality. This knowledge empowers enthusiasts and professionals alike to keep their tools in prime condition, allowing for seamless operation in yard work or landscaping tasks.

The intricate assembly of a high-performance air mover involves numerous parts, each playing a critical role in its efficiency. From the motor to the housing, understanding how these components interact can help in identifying potential issues and making informed decisions about repairs. Moreover, having a clear overview of the layout can simplify the process of reassembly after maintenance.

For those keen on delving deeper, a visual representation of these components can be invaluable. Such illustrations not only clarify the relationship between different elements but also serve as a guide during repairs or replacements. Familiarity with the design of these tools equips users with the confidence to tackle any challenges that may arise, enhancing their overall experience with outdoor maintenance tasks.

Understanding Husqvarna 125B Blower Components

Gaining insight into the individual elements of outdoor equipment is crucial for effective maintenance and performance enhancement. Each component plays a vital role in the overall functionality, contributing to its efficiency and durability. Familiarizing oneself with these parts can simplify troubleshooting and repair processes, ensuring prolonged service life and optimal operation.

Here are the key elements to consider:

- Engine: The heart of the device, responsible for generating power.

- Fan: Essential for directing airflow, impacting speed and volume.

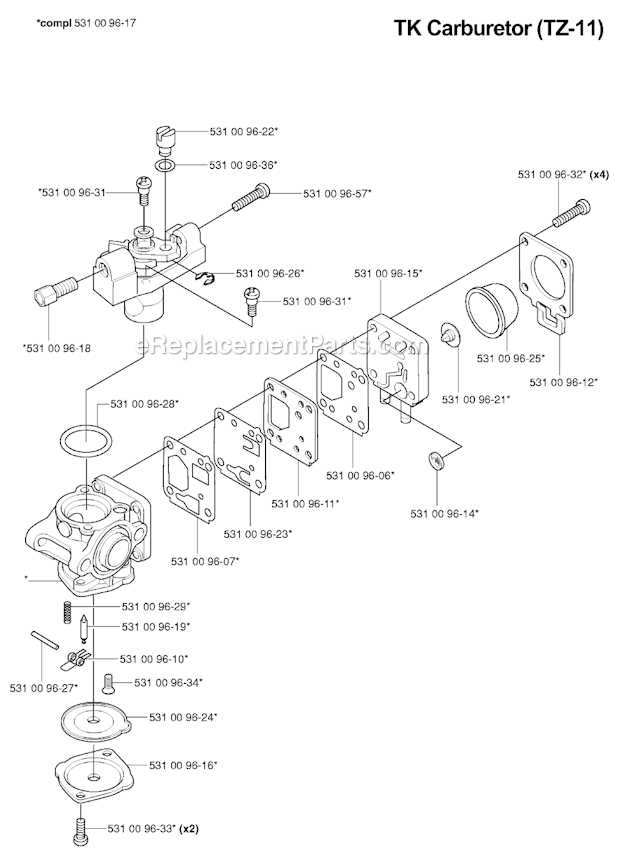

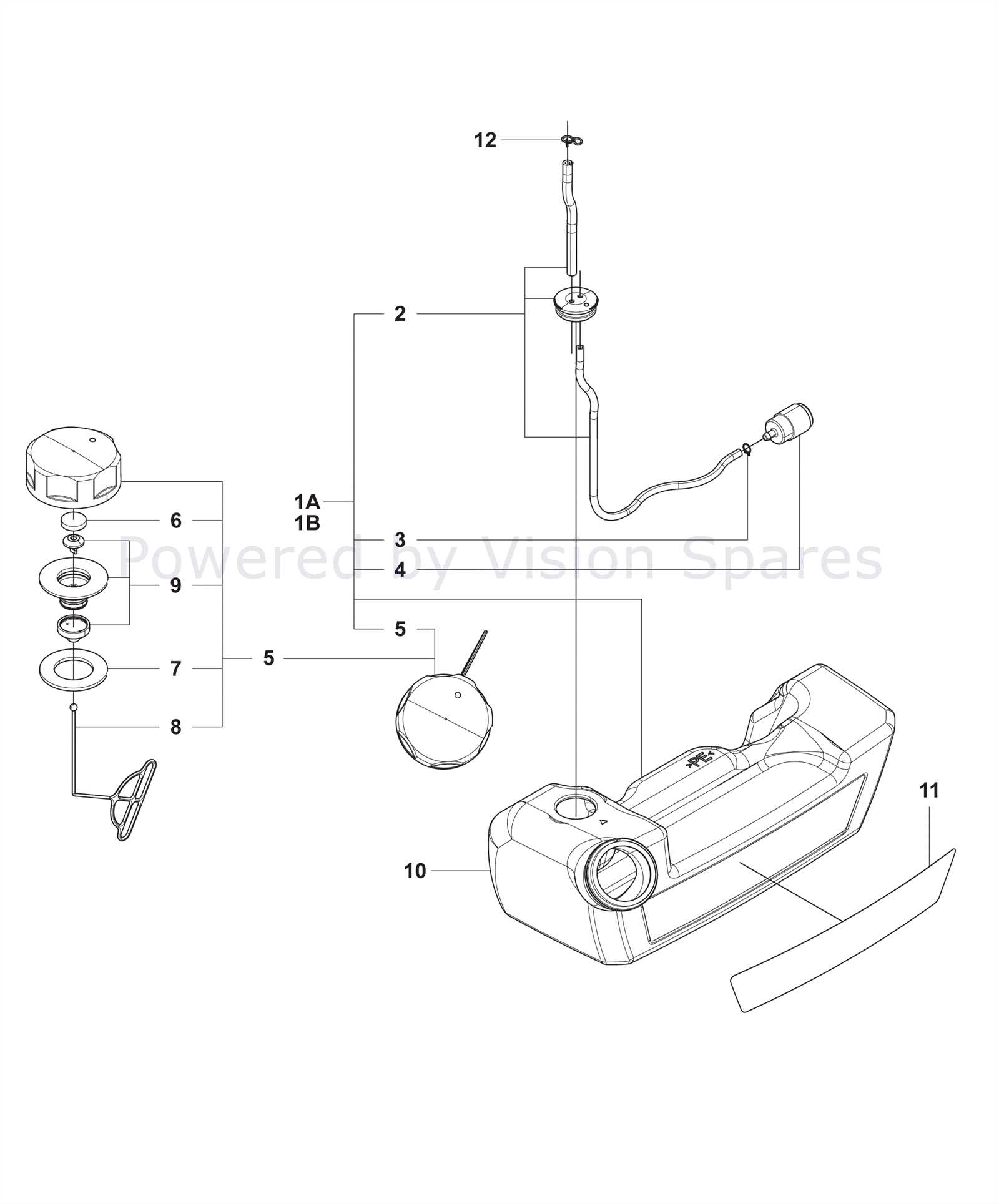

- Fuel System: Includes components such as the tank and filter, crucial for optimal combustion.

- Exhaust System: Manages emissions and helps in maintaining engine performance.

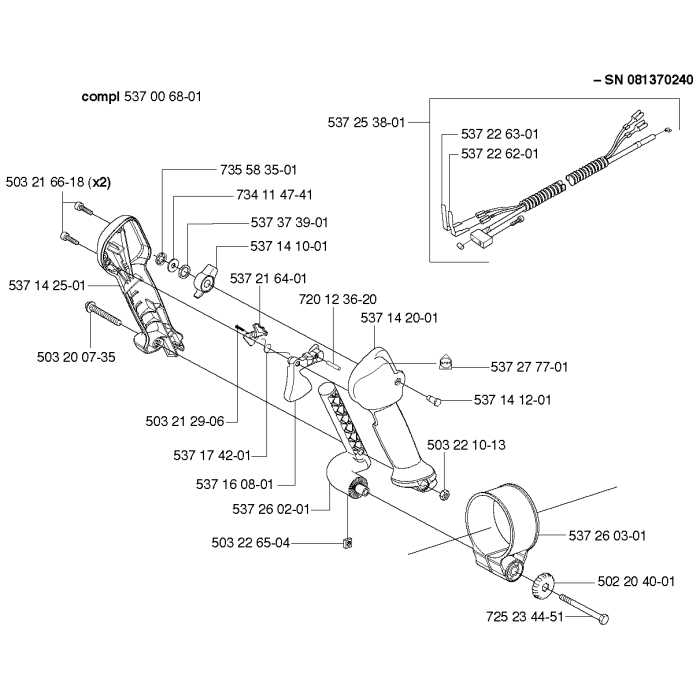

- Controls: User interface that allows for adjustments in speed and direction.

Understanding these components will facilitate better maintenance practices and enhance the user experience. Regular inspections and knowledge of each element’s function can prevent common issues and extend the lifespan of the equipment.

By keeping these aspects in mind, users can ensure their equipment remains reliable and efficient for all outdoor tasks.

Key Parts of the 125B Blower

This section explores the essential components that contribute to the efficient operation of the air propulsion device. Understanding these elements can enhance maintenance and performance.

- Engine: The heart of the machine, providing the necessary power.

- Fan: Responsible for creating airflow, essential for the unit’s function.

- Air Intake: Allows ambient air to enter, facilitating combustion.

- Fuel Tank: Stores the mixture needed for operation.

- Throttle Control: Enables the user to adjust speed and airflow.

Each component plays a vital role, working in harmony to deliver optimal performance.

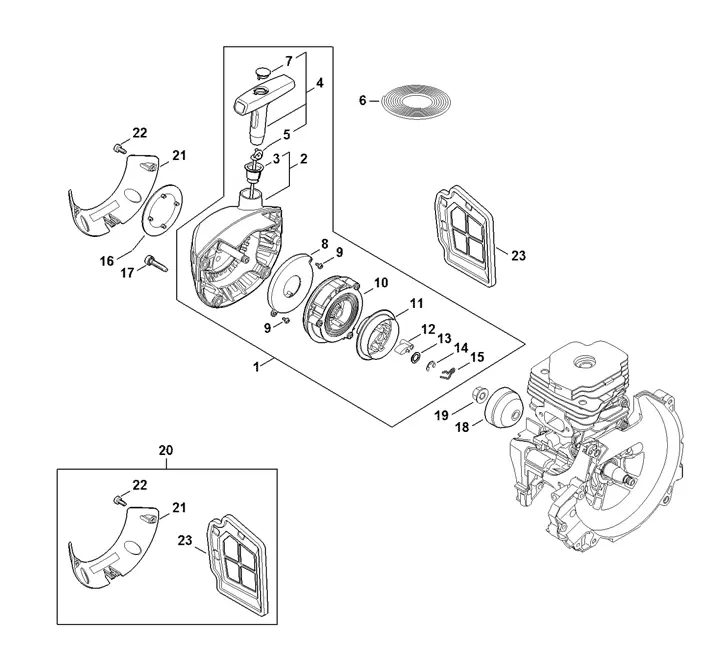

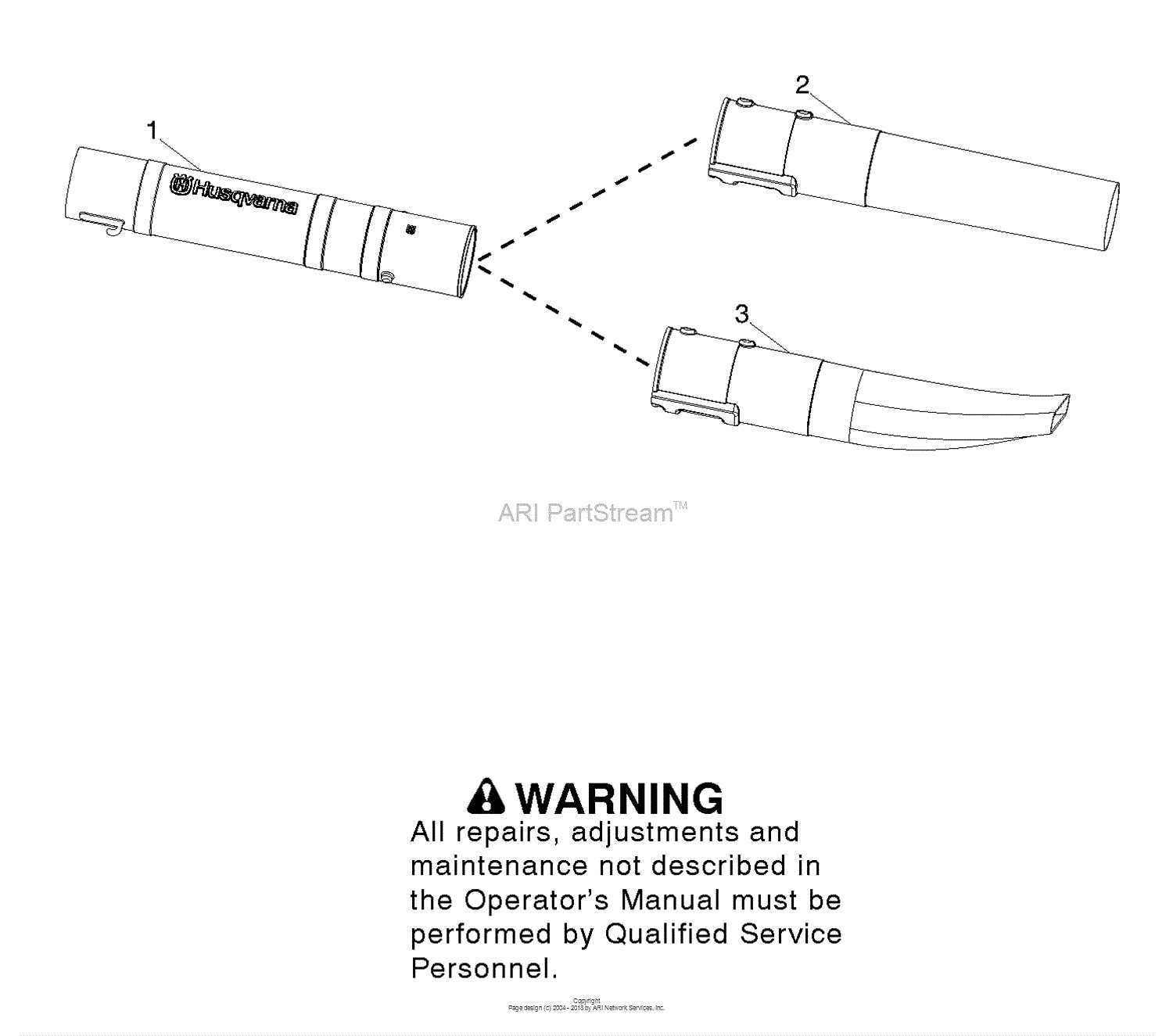

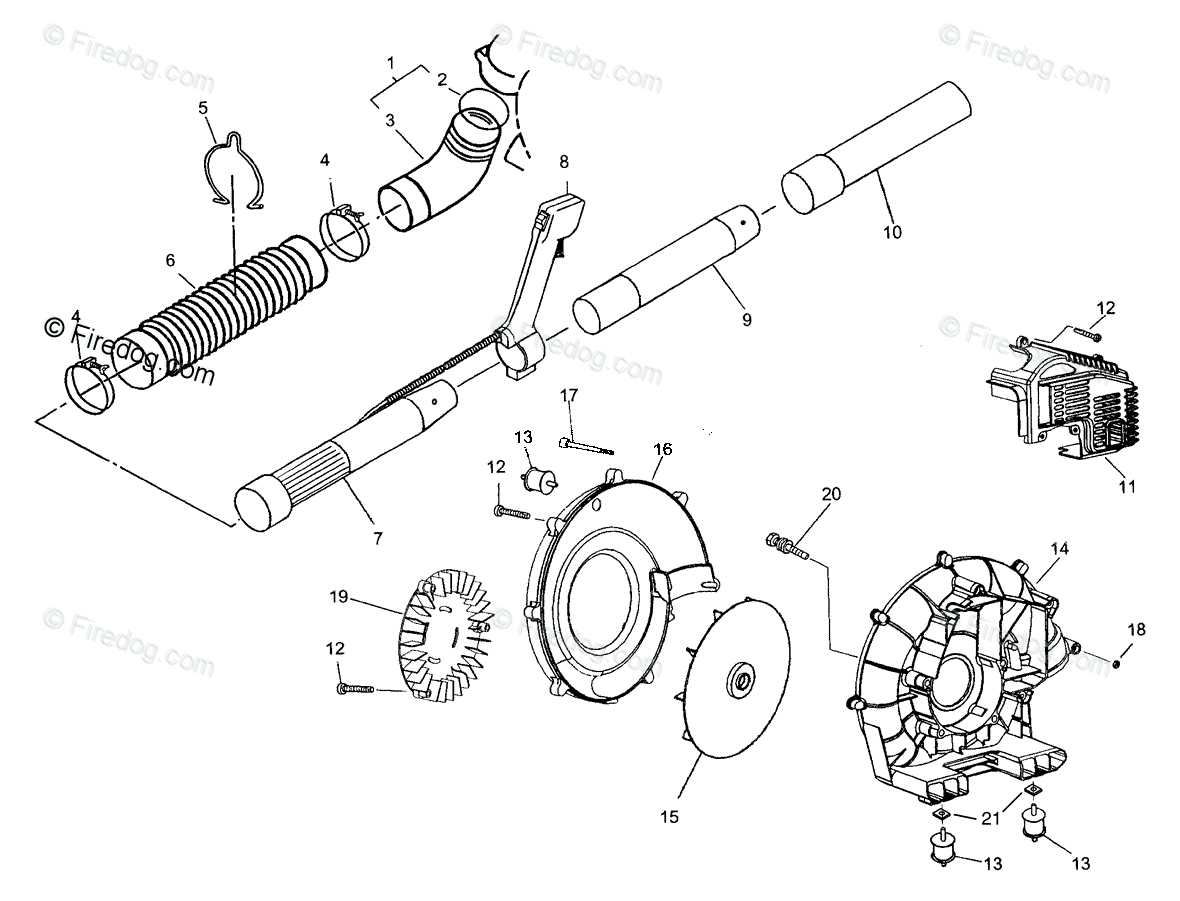

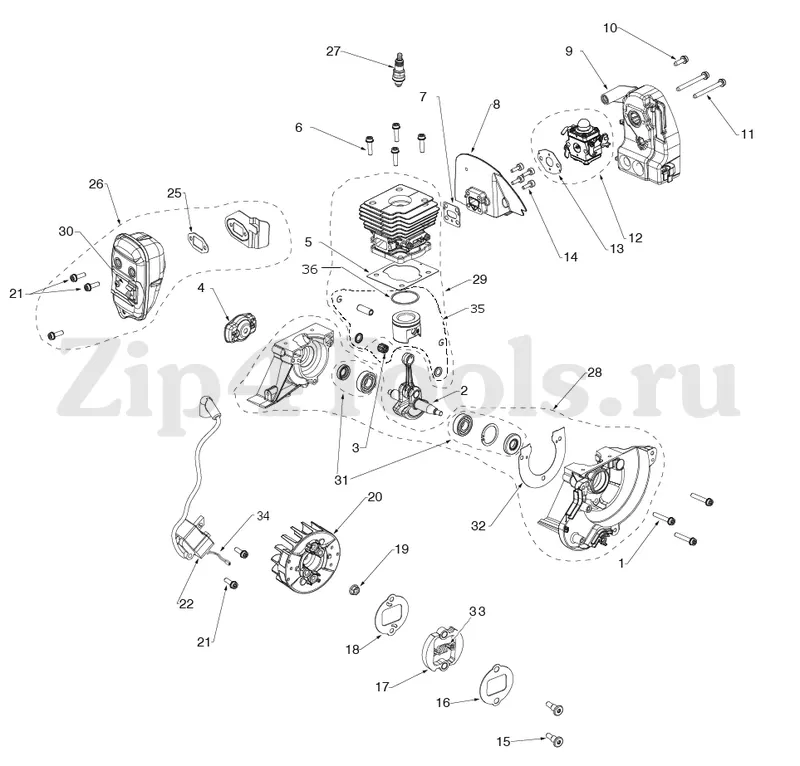

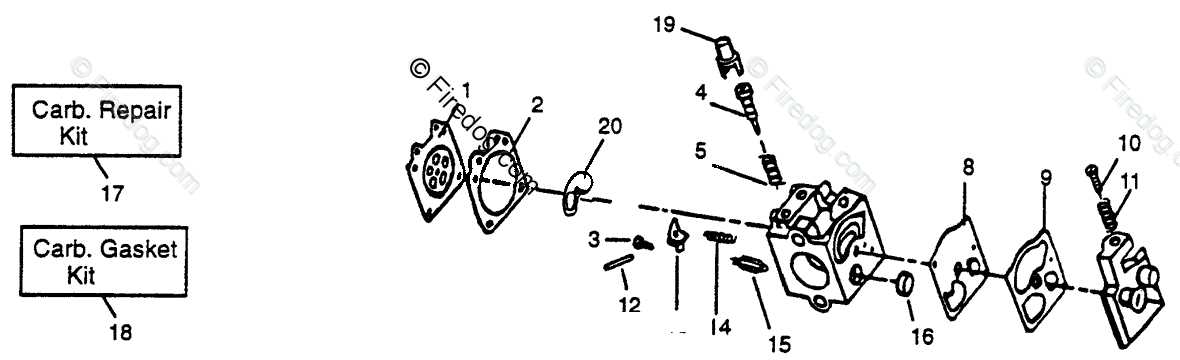

Exploring the Parts Diagram

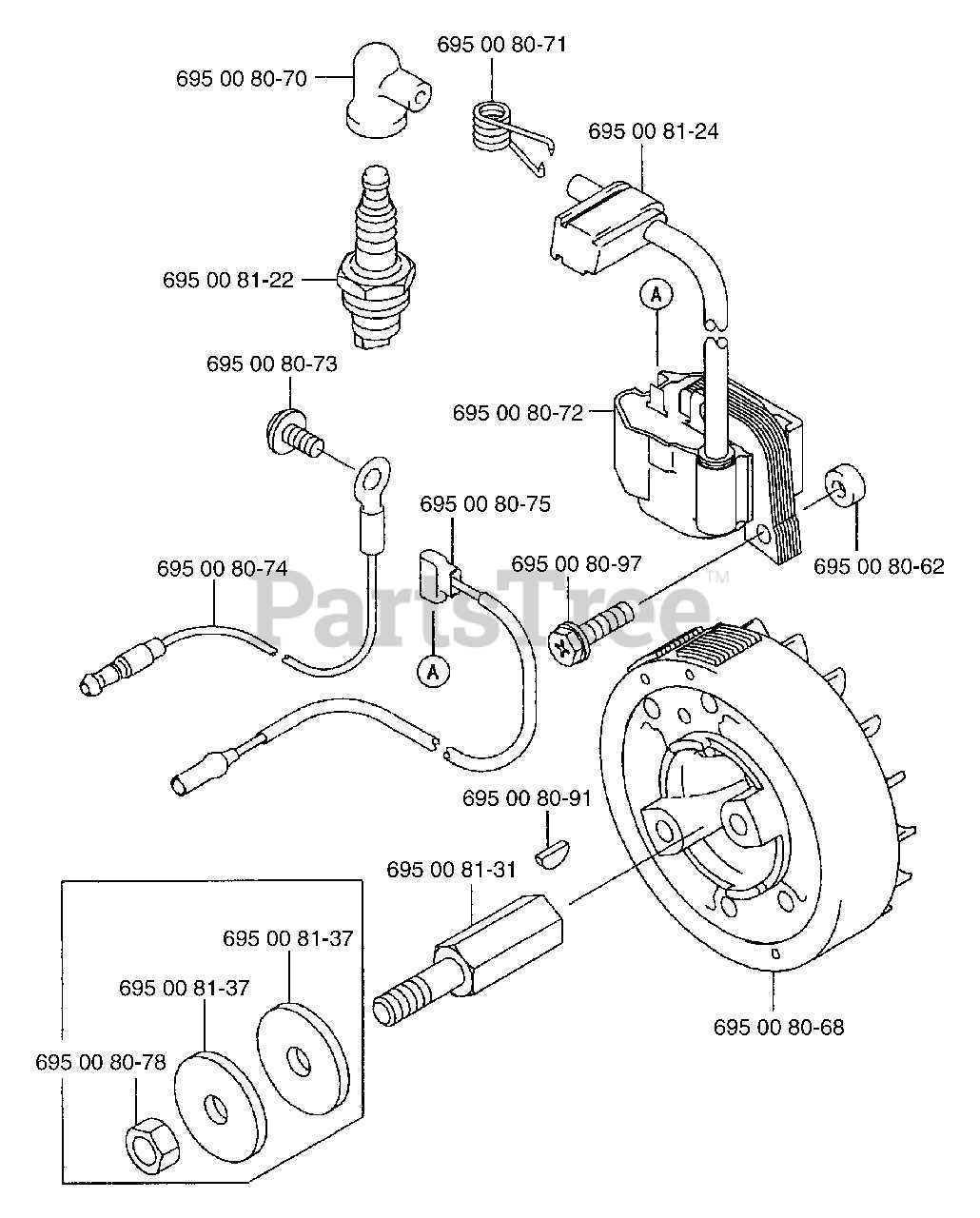

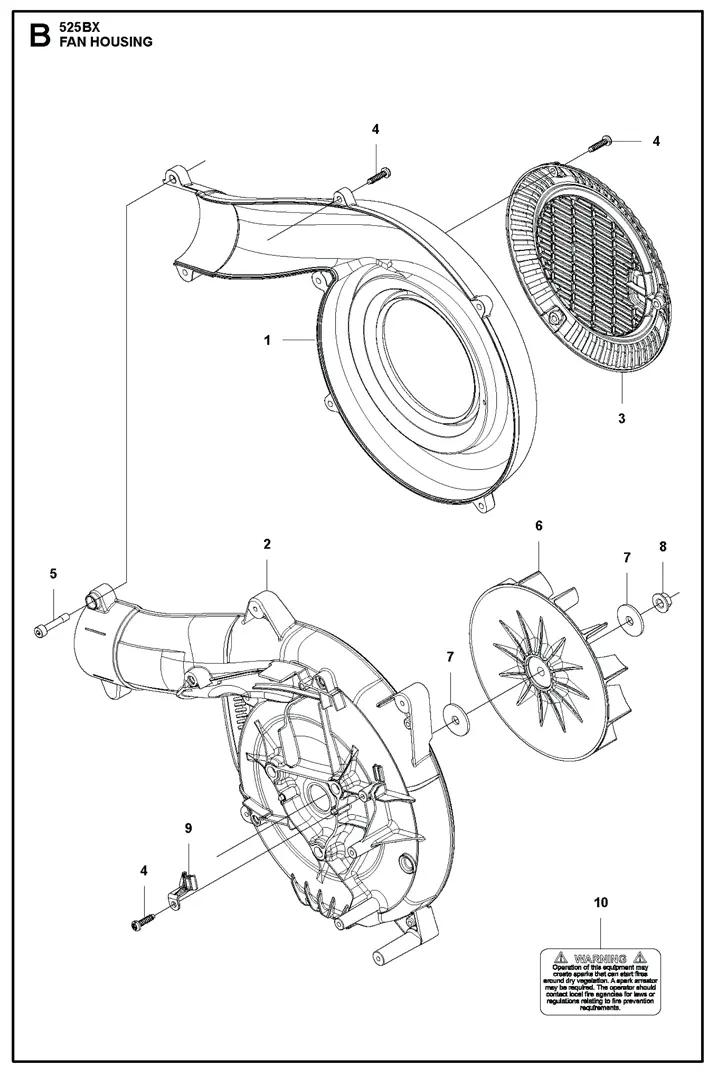

Understanding the intricacies of equipment components is essential for maintenance and repair. This section delves into the visual representation that showcases various elements and their relationships within the machine. By analyzing this illustration, users can identify each segment’s function and enhance their operational knowledge.

Detailed illustrations play a crucial role in simplifying complex structures, making it easier to locate specific components. Each label serves as a guide, offering insight into how different parts interact and contribute to overall performance. This knowledge is ultimately beneficial for troubleshooting and ensuring longevity.

Familiarity with the layout not only aids in efficient repairs but also empowers users to perform routine maintenance effectively. Recognizing the significance of each element promotes a deeper appreciation of the machinery, ultimately leading to better care and improved functionality.

Importance of Each Component

Understanding the significance of each individual piece within a mechanical system is crucial for optimal performance and longevity. Every element contributes to the overall functionality, and neglecting any part can lead to inefficiencies or failures.

Functionality and Efficiency

Each element plays a specific role that enhances the efficiency of the entire apparatus. From the intake to the exhaust, every component is designed to ensure smooth operation, preventing potential breakdowns and maximizing output.

Maintenance and Repair

Recognizing the function of each part aids in effective maintenance and troubleshooting. When users can identify which component is underperforming, they can address issues promptly, ultimately extending the lifespan of the equipment.

Common Issues with Blower Parts

When operating outdoor equipment designed for airflow, several challenges may arise over time. Understanding these typical complications can aid in proper maintenance and enhance the overall lifespan of the machinery. From performance issues to physical wear, addressing these concerns promptly is essential for efficient functionality.

Performance Degradation

One of the most frequent problems is a noticeable drop in efficiency. This can manifest as reduced airflow or inconsistent operation. Factors contributing to this include clogged filters and damaged impellers. Regular inspection and cleaning can often rectify these issues, ensuring optimal performance.

Physical Wear and Tear

Components such as seals, gaskets, and housing can suffer from deterioration due to exposure to various elements. Cracks and breakages not only affect the aesthetic appeal but can also lead to leaks and further mechanical failures. Timely replacement of worn parts is crucial to maintaining equipment integrity and functionality.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires consistent care and attention. By following a few key practices, you can significantly extend the lifespan of your tools, enhancing their performance and reliability.

Regularly clean the exterior and any accessible components to prevent debris build-up, which can lead to overheating and malfunctions. Additionally, routinely inspect the device for any signs of wear or damage, addressing issues promptly to avoid more extensive repairs later.

Keep all moving parts adequately lubricated to reduce friction and wear. This simple step can improve efficiency and ensure smooth operation. Furthermore, store your equipment in a dry, sheltered location to protect it from the elements and maintain its condition.

Lastly, follow the manufacturer’s guidelines for routine maintenance, including filter changes and seasonal checks, to keep your machinery in optimal working order. Adopting these habits will help you achieve the ultimate performance from your investment.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing the right components is essential for optimal performance. Fortunately, there are several reliable avenues to explore when looking for specific items needed for repairs or upgrades.

- Official Retailers: Many manufacturers offer a network of authorized dealers. Visiting these stores ensures you receive genuine components that fit perfectly and function as intended.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized equipment shops often have a wide selection of items. It’s wise to check customer reviews to ensure quality before making a purchase.

- Local Repair Shops: Neighborhood repair services not only fix equipment but frequently stock essential components. Consulting with a technician can also provide valuable advice on what to buy.

- Manufacturer’s Website: Many brands provide an online catalog where you can search for specific items by model number. This can save time and ensure compatibility.

By exploring these options, you can easily locate the necessary components to keep your equipment running smoothly.

Assembly Process Explained

The assembly process of outdoor equipment requires careful attention to detail and a systematic approach. Each component plays a crucial role in ensuring optimal performance and longevity. Understanding how these elements fit together can greatly enhance efficiency and functionality.

Step-by-step instructions are essential for assembling the unit correctly. Begin by organizing all components and tools needed for the task. This preparation helps to minimize errors and facilitates a smoother workflow.

Next, follow the manufacturer’s guidelines closely. These instructions typically include diagrams and specifications that clarify how each part interacts with others. Pay special attention to the orientation of components, as incorrect positioning can lead to operational issues.

Once the main body is assembled, it’s important to secure all fasteners and ensure that connections are tight. This step is vital for preventing any potential leaks or malfunctions during use. Additionally, perform a final check to confirm that all parts are properly aligned and functioning as intended.

In conclusion, understanding the assembly process not only aids in constructing the equipment correctly but also contributes to its overall performance and reliability in the field.

Upgrading Your Blower’s Performance

Enhancing the efficiency of your outdoor tool can lead to a more productive experience and improved results in your yard work. Various modifications can be made to increase power, reduce weight, and optimize airflow, allowing for better handling and effectiveness in clearing debris.

One of the first steps in boosting performance is to evaluate the air intake and exhaust systems. Ensuring that these components are clean and unobstructed can significantly impact airflow, resulting in increased power output. Additionally, consider replacing the spark plug with a high-performance option to improve ignition efficiency, which can lead to a smoother operation.

Upgrading to a lightweight battery or a more powerful engine can also make a noticeable difference. Lighter models allow for easier maneuverability, while a stronger engine provides enhanced capabilities for tackling tougher jobs. Moreover, using higher quality fuel can improve combustion and efficiency, contributing to overall performance gains.

Finally, regular maintenance plays a crucial role in ensuring optimal function. Regularly checking and replacing filters, as well as keeping the tool clean and free from debris, will help maintain high performance over time. By taking these steps, you can maximize the potential of your outdoor equipment, making your tasks easier and more effective.