In the world of off-road exploration, the importance of precise control and handling cannot be overstated. Enthusiasts often seek to enhance their vehicles’ performance by delving into the various elements that contribute to their maneuverability and stability on challenging terrains. This article aims to shed light on the intricate assembly that underpins effective navigation in rugged environments.

When examining the intricacies of these assemblies, one can appreciate the careful engineering that ensures optimal functionality. Each segment plays a vital role, from ensuring smooth transitions during sharp turns to maintaining alignment over uneven surfaces. Understanding these components not only aids in effective maintenance but also empowers drivers to make informed modifications tailored to their specific needs.

Whether you are a seasoned off-road veteran or a newcomer eager to explore, familiarizing yourself with the essential components of your vehicle will enhance your driving experience. By gaining insight into the layout and operation of these crucial elements, you can better appreciate the craftsmanship behind every journey into the wild.

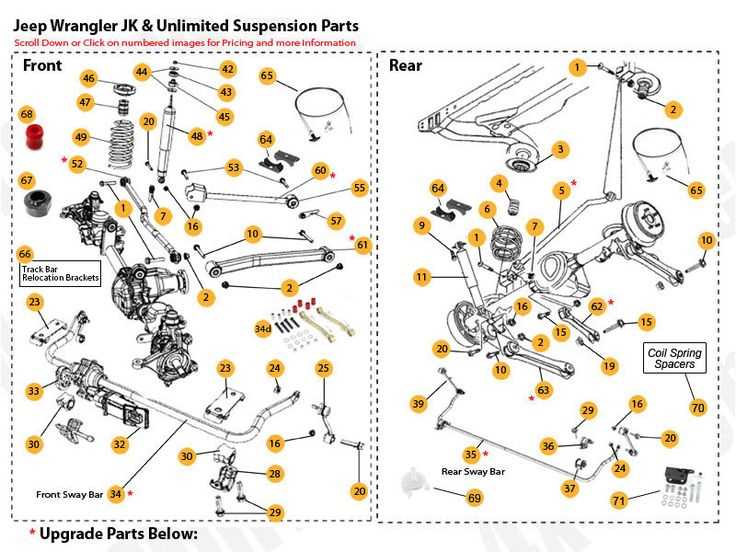

Understanding Jeep Wrangler JK Steering System

The intricate mechanism that guides a vehicle’s direction is vital for ensuring control and safety. This system comprises various components that work together to provide precise handling and responsiveness. A comprehensive understanding of these elements can enhance the experience of driving and maintaining such a vehicle.

Key Components of the Directional System

Each element within this guiding mechanism plays a significant role in its overall functionality. Knowledge of how these components interact can help in diagnosing issues and performing maintenance effectively.

| Component | Function |

|---|---|

| Gearbox | Transforms the rotation from the steering wheel into lateral movement. |

| Linkage | Connects the gearbox to the wheels, facilitating their movement based on the driver’s input. |

| Control Arms | Support the suspension and help maintain proper wheel alignment during movement. |

| Knuckles | Enable the wheels to pivot and turn, allowing for effective cornering. |

Maintenance Tips for Optimal Performance

Regular inspection and upkeep of these components are crucial for ensuring longevity and reliability. Keeping an eye on wear and tear, as well as performing timely replacements, can greatly enhance the performance and safety of the vehicle.

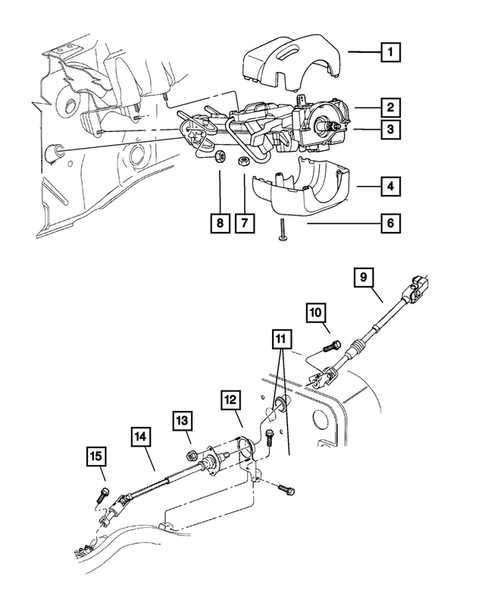

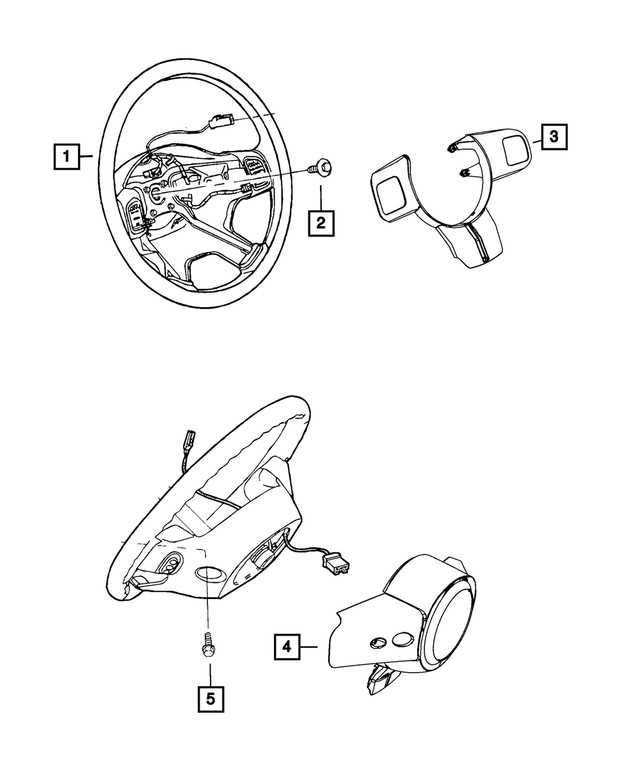

Key Components of the Steering Assembly

The functionality of a vehicle’s control system relies on several essential elements that work in harmony to ensure precise handling and maneuverability. Understanding these components can enhance the appreciation of automotive design and performance.

| Component | Description |

|---|---|

| Rack and Pinion | This mechanism converts rotational motion into linear motion, allowing for responsive turning. |

| Linkages | These rods and connectors transmit movement from the control wheel to the wheels, ensuring coordinated action. |

| Column | The vertical shaft connects the control mechanism to the rack, providing stability and support. |

| Bearings | These reduce friction between moving parts, facilitating smooth operation and enhancing durability. |

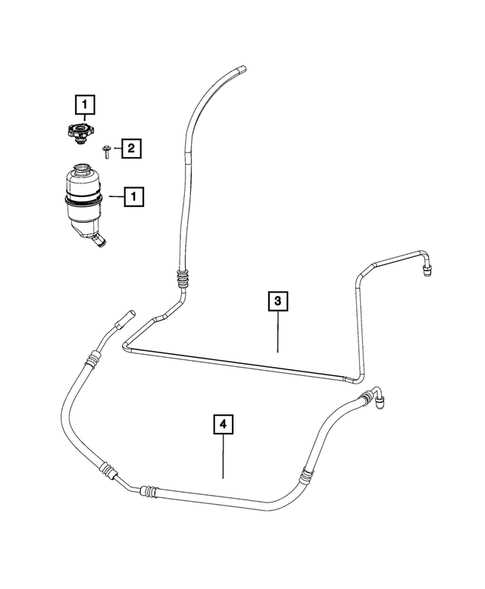

| Power Assist | This feature amplifies the driver’s input, making handling easier and more efficient, especially at low speeds. |

Common Issues in Steering Parts

Understanding the frequent challenges associated with the maneuvering system is crucial for maintaining optimal performance. Drivers often encounter various malfunctions that can affect handling and safety, making awareness of these problems essential for vehicle longevity.

Worn Components

Age and wear can lead to deterioration of essential components, resulting in reduced responsiveness and precision. Regular inspections are vital to identify signs of wear before they escalate into more serious issues.

Alignment Problems

Misalignment can arise from impacts or regular use, causing uneven tire wear and unpredictable handling. Addressing alignment swiftly can prevent further damage and ensure a smooth driving experience.

Benefits of Upgrading Steering Components

Enhancing the control mechanisms of a vehicle can lead to significant improvements in performance and safety. Upgraded elements not only provide a more responsive driving experience but also contribute to overall vehicle longevity. Here are some of the key advantages associated with such enhancements.

Improved Handling and Responsiveness

- Greater precision in maneuvering, especially during challenging terrains.

- Reduced play in the control system, allowing for sharper turns.

- Increased stability, leading to a more confident driving experience.

Enhanced Durability and Longevity

- Use of higher-quality materials that withstand wear and tear better.

- Lower likelihood of premature failure, reducing maintenance costs.

- Improved resistance to environmental factors such as corrosion and extreme temperatures.

Investing in upgraded components can lead to a more enjoyable and secure driving experience, making it a worthwhile consideration for any vehicle owner.

How to Read a Steering Diagram

Understanding the layout of a control mechanism is crucial for effective maintenance and troubleshooting. This guide will help you navigate the various components represented in a schematic, making it easier to identify and address any issues that may arise.

First, familiarize yourself with the symbols commonly used in such representations. Each symbol corresponds to a specific element, often with standardized meanings. Recognizing these symbols will provide insight into how each component interacts within the system.

Next, pay attention to the connections illustrated in the layout. Lines typically represent links between elements, showing how forces are transmitted through the system. These connections can indicate the flow of motion and help identify potential points of failure.

| Symbol | Description |

|---|---|

| Circle | Indicates a pivot point or joint |

| Arrow | Shows the direction of movement |

| Dashed Line | Represents an auxiliary connection |

| Square | Denotes a fixed point or anchor |

Lastly, it’s essential to analyze the layout in its entirety. Consider the sequence of operations and how each component contributes to the overall functionality. This comprehensive understanding will enable you to make informed decisions when working on repairs or enhancements.

DIY Maintenance Tips for Jeep Owners

Performing regular upkeep on your off-road vehicle can enhance performance, extend lifespan, and ensure safety on rugged terrain. This guide provides essential suggestions to keep your machine in optimal condition without professional assistance.

Essential Checks

Regular inspections can prevent minor issues from escalating. Focus on fluid levels, tire pressure, and brake functionality. Keeping a checklist can streamline this process.

Common Maintenance Tasks

| Task | Frequency |

|---|---|

| Oil Change | Every 3,000 miles |

| Filter Replacement | Every 12,000 miles |

| Tire Rotation | Every 5,000 miles |

| Battery Check | Every 6 months |

Staying proactive with these practices can ultimately enhance your driving experience and ensure reliability on every adventure.

Popular Aftermarket Steering Options

Upgrading your vehicle’s handling components can significantly enhance performance and driving experience. Many enthusiasts explore various aftermarket solutions to improve responsiveness, durability, and overall feel. Here are some popular choices that drivers often consider.

- Enhanced Control Arms: These components offer improved articulation and better alignment, ensuring a more stable ride over rough terrain.

- Heavy-Duty Tie Rods: Designed to withstand tougher conditions, these rods provide added strength and reliability, reducing the risk of failure during intense use.

- Adjustable Track Bars: Allowing for fine-tuning of suspension alignment, these bars help maintain proper geometry, especially after lifting modifications.

- Performance Bushings: Upgrading to high-quality bushings can reduce play and enhance feedback, resulting in a more connected driving experience.

When choosing modifications, consider factors such as driving style, terrain, and desired performance improvements. Each option offers unique benefits, contributing to a more tailored setup for your vehicle.

Step-by-Step Installation Guide

This section provides a comprehensive approach to the installation of essential components for enhancing the handling and control of your vehicle. By following this structured guide, you will ensure that every element is fitted correctly, leading to improved performance and safety on the road.

Preparation and Tools Required

Before starting the installation, gather all necessary tools and components. You will typically need a socket set, wrenches, and a torque wrench. It’s also advisable to have a service manual handy for specific torque specifications and additional details regarding your vehicle’s configuration. Ensure you work in a well-ventilated area and wear appropriate safety gear.

Installation Steps

1. Lift the Vehicle: Begin by safely lifting the vehicle using a jack and securing it with jack stands. This will provide adequate clearance for easy access to the undercarriage.

2. Remove Old Components: Carefully detach the existing elements. Take your time to avoid damaging any surrounding parts. Labeling components as you remove them can assist with reassembly.

3. Install New Elements: Position the new components according to the specifications outlined in your service manual. Ensure that each piece aligns correctly before securing it in place.

4. Tighten Fasteners: Using the torque wrench, tighten all fasteners to the manufacturer’s recommended specifications. This step is crucial for ensuring longevity and reliability.

5. Lower the Vehicle: Once everything is securely in place, carefully lower the vehicle back to the ground.

6. Test Drive: Conduct a short test drive to check for any unusual noises or handling issues. If everything feels right, you’ve successfully completed the installation!

Following these steps will lead to a successful enhancement of your vehicle’s functionality, making your driving experience safer and more enjoyable.

Maintaining Proper Alignment and Safety

Ensuring optimal directional control and safety is crucial for any vehicle. Misalignment can lead to uneven tire wear, decreased handling, and compromised stability. Regular checks and adjustments are essential for maintaining performance and safety.

- Regularly inspect tire pressure and tread depth.

- Monitor suspension components for wear and damage.

- Check for any vibrations or pulling to one side while driving.

By addressing these factors, drivers can enhance both vehicle longevity and safety on the road.