Key Elements in a Volvo Truck Body Parts Diagram

Understanding the structure and components of a large vehicle is essential for maintenance and repair. A detailed overview provides valuable insight into how various sections are interconnected and how each element contributes to the overall functionality. By analyzing the key mechanical systems, one can better comprehend the arrangement of external and internal components.

Main Structural Sections

The overall framework is built from several core segments, each fulfilling a unique role in both support and performance. These include the main chassis, which serves as the foundation for all other components, and the cabin area, which ensures driver safety and comfort. Each section is designed with specific materials and engineering techniques to enhance durability and efficiency.

Vital Mechanical Components

Beyond the structural aspects, the mechanical elements are critical for smooth operation. These include the

How to Read and Interpret Vehicle Structure Schematics

Understanding how to interpret technical schematics for automotive frameworks is crucial for identifying the correct components and ensuring proper maintenance or repairs. These schematics provide a detailed overview of the entire structure, allowing you to see the exact positioning of various elements in relation to each other. By learning the proper way to read these drawings, you can effectively troubleshoot and pinpoint the areas that need attention.

Key Elements in Structural Schematics

Every schematic is organized into sections that represent different areas of the vehicle’s framework. These sections typically include detailed illustrations with labels, showing how each part fits into the overall design. Paying attention to the symbols and numbers provided in these drawings is essential, as they offer valuable information about the size, placement, and function of individual elements.

Interpreting Symbols and Annotations

Symbols and annotations within schematics serve as a guide to understanding how each part connects and interacts with the others. These can indicate assembly instructions, fastener types, or material specifications. Familiarizing yourself with these notations will help you interpret the drawing accurately and make informed decisi

Commonly Replaced Components in Heavy-Duty Vehicles

In the world of large commercial vehicles, certain elements tend to experience more wear and tear than others. These frequently serviced elements are crucial for maintaining overall performance and ensuring safety on the road. Regular upkeep and timely replacements of these components are essential for reducing downtime and prolonging vehicle lifespan.

Brake Systems: The braking system is one of the most critical areas requiring frequent attention. Due to constant use, elements like pads and discs must be regularly inspected and replaced to ensure optimal stopping power.

Suspension Units: The suspension is another key area that often requires maintenance. Elements like shock absorbers and springs undergo significant stress, especially when the vehicle is used for transporting heavy loads.

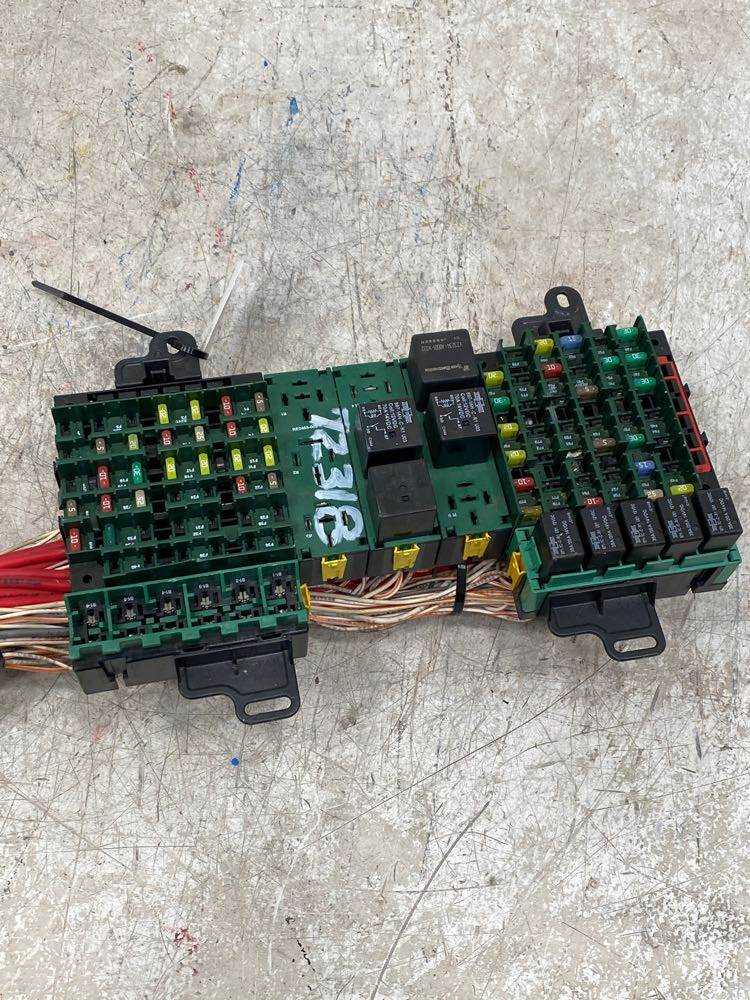

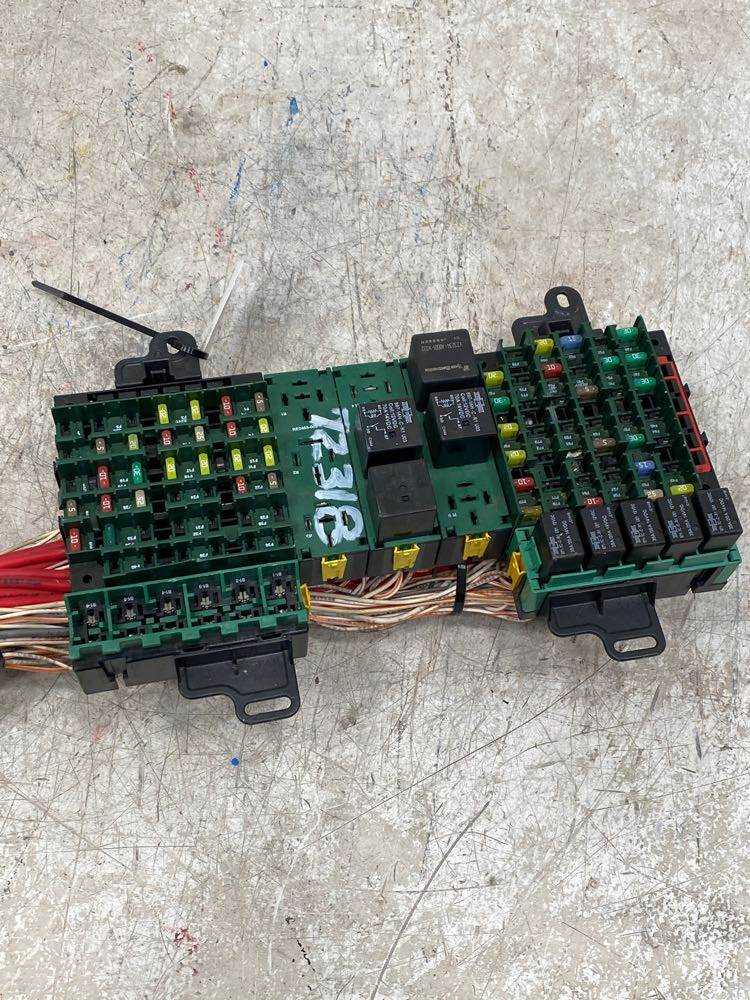

Lighting and Electricals: Lights and electrical components are subject to exposure to the elements, making them prone to malfunction. Regular checks and replacements of headlights, indicators, and wiring ensure compliance

Benefits of Using Genuine Vehicle Components

Opting for original manufacturer components provides numerous advantages, ensuring that your vehicle remains reliable and efficient. These elements are specifically designed and tested to meet the highest standards, guaranteeing seamless compatibility and performance.

Enhanced Durability: Genuine components are built to last longer, minimizing the need for frequent replacements. This not only saves time but also reduces long-term maintenance costs.

Optimal Performance: When using authentic parts, you maintain the original specifications of your vehicle, ensuring smooth operation and peak efficiency. Each part is crafted to fit perfectly, avoiding potential issues caused by ill-fitting alternatives.

Safety Assurance: Authentic components undergo rigorous testing to meet safety regulations, offering peace of mind on the road. They are designed to protect both the vehicle and its occupants, providing a higher level of security.

Where to Find Reliable Volvo Truck Parts Diagrams

Locating accurate schematics for vehicle components can be crucial when working on maintenance or repairs. Whether you’re a mechanic or a DIY enthusiast, having access to well-structured technical illustrations ensures proper assembly and functionality of the entire system. These resources often serve as a roadmap, providing detailed layouts for various assemblies and systems.

Online platforms offer a variety of these technical blueprints, often in digital format for easy access. Many professional websites and automotive databases allow users to search by model or specific system, helping you quickly find the exact illustration needed for your task. Be sure to rely on trusted resources that prioritize accuracy and precision in their documentation.

Another option is to visit official service centers or authorized distributors, where technical experts can provide both hard copies and digital versions of the diagrams. These centers usually have access to the latest updates, ensuring the diagrams match the most current design specifications.

Tips for Maintaining Vehicle Exterior Components

Regular care and upkeep of exterior elements ensure the longevity and durability of any heavy-duty machine. By performing routine inspections and promptly addressing issues such as wear or damage, you can extend the operational life of these crucial elements.

Cleanliness is Key: Consistent washing removes harmful debris, such as salt or dirt, which can cause corrosion. Use appropriate cleaning agents and ensure thorough rinsing to prevent chemical buildup.

Rust Prevention: Applying anti-corrosion treatments is vital for protecting metal surfaces from oxidation. Ensure that all areas, especially those prone to rust, are treated regularly to minimize deterioration.

Proper Alignment and Fastening: Loose or misaligned components can lead to increased wear and tear. Regularly check for secure fittings and proper alignment to prevent unnecessary damage.

Timely replacement and preventive care are the foundation of a well-maintained machine, ensuring smooth operation and a longer service life for all external structures.