Exploring the intricacies of machinery reveals a complex web of essential elements that work in harmony to ensure optimal performance. Each segment plays a crucial role, contributing to the overall functionality of the system. Grasping the arrangement and relationship between these individual parts is vital for anyone seeking to maintain or repair these intricate machines.

In the realm of automotive and industrial equipment, having a clear visual representation of the various components is indispensable. This knowledge enables technicians and enthusiasts alike to delve deeper into their understanding, ensuring they can identify and resolve issues efficiently. The clarity provided by such illustrations is the ultimate resource for effective maintenance and repair strategies.

By familiarizing oneself with these essential layouts, individuals can enhance their skills and confidence when tackling any challenges that arise. This understanding not only fosters a greater appreciation for the machinery but also empowers users to engage in informed decision-making regarding repairs and upgrades.

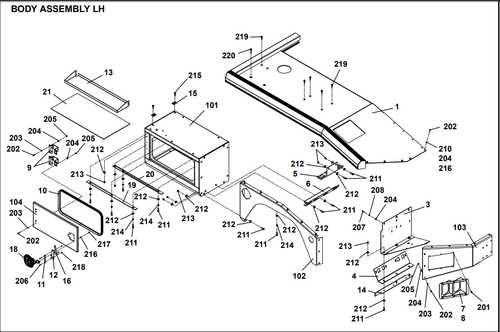

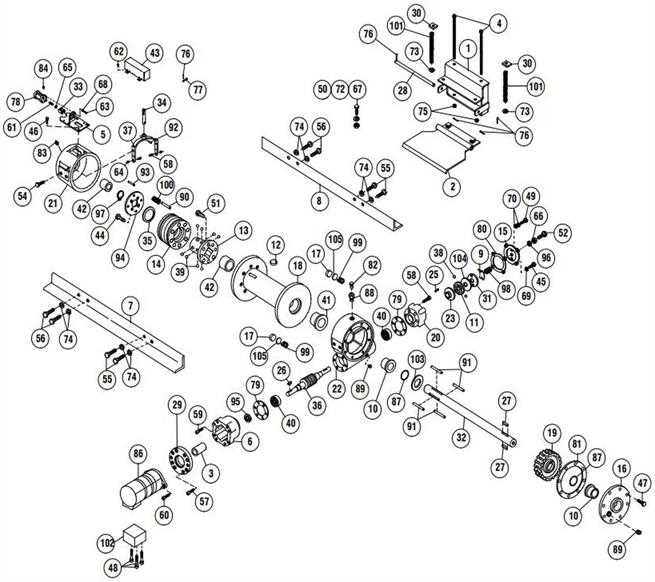

Understanding Jerr-Dan Parts Diagram

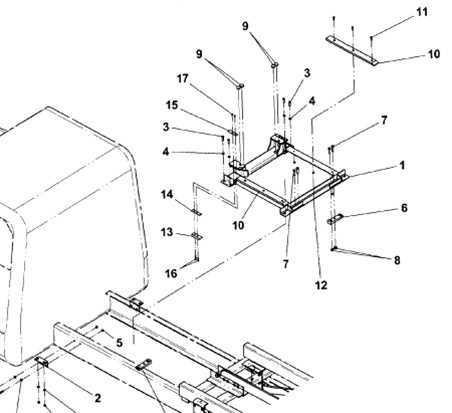

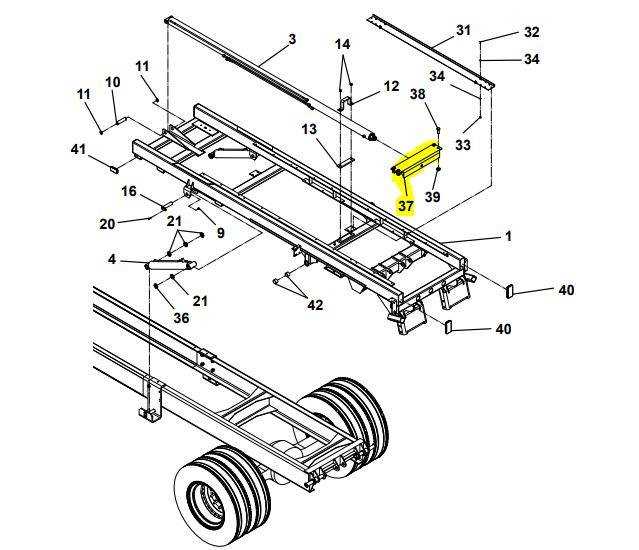

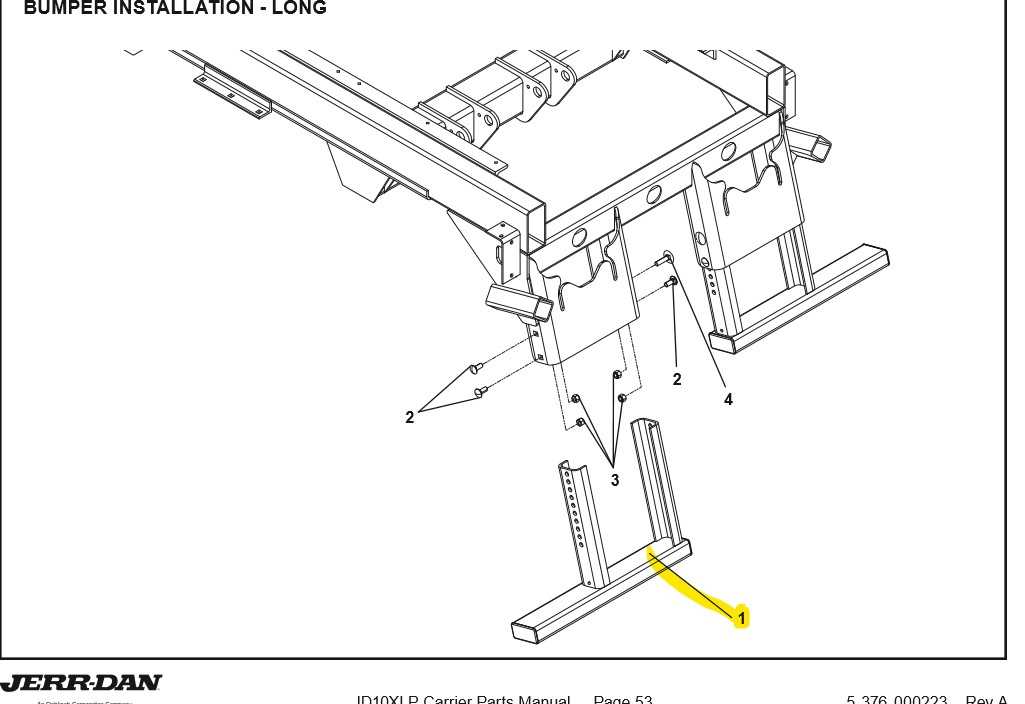

This section aims to shed light on the intricate representations of components utilized in specific machinery. These visual aids serve as essential tools for technicians and operators, providing a clear view of each element’s function and placement within the system. Familiarity with these illustrations enhances the efficiency of repairs and maintenance, ensuring that every piece is correctly identified and handled.

Importance of Component Illustrations

Having access to detailed visual representations is crucial for effective troubleshooting and servicing. These schematics not only delineate the relationship between different elements but also highlight potential issues that may arise during operation. Understanding these visuals fosters a deeper comprehension of the machinery’s design and functionality.

Navigating the Visual Representations

When interpreting these illustrations, attention to detail is paramount. Each segment is meticulously labeled, allowing users to pinpoint specific areas requiring attention. By grasping the layout and interconnections depicted, individuals can approach repairs methodically, minimizing errors and enhancing overall performance.

Importance of Accurate Parts Identification

Precision in recognizing components is crucial for ensuring the smooth operation and longevity of machinery. Misidentification can lead to costly errors, delays, and even safety hazards, emphasizing the necessity of clarity in every detail.

Correct identification streamlines maintenance processes, allowing technicians to efficiently address issues without unnecessary downtime. When each element is properly labeled and understood, repairs can be executed swiftly, enhancing overall productivity.

Moreover, thorough knowledge of each component aids in inventory management, reducing the risk of overstocking or running out of essential items. This balance not only optimizes resource allocation but also supports cost-effectiveness in operations.

Ultimately, investing in precise identification systems fosters trust among users and technicians, reinforcing a culture of reliability and safety in equipment management.

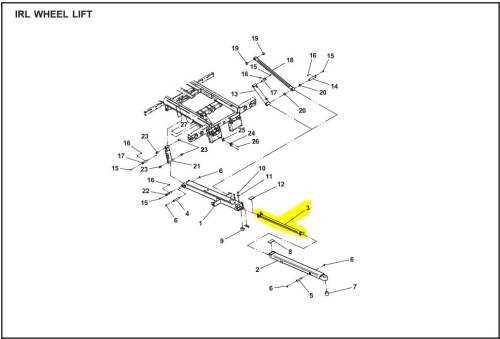

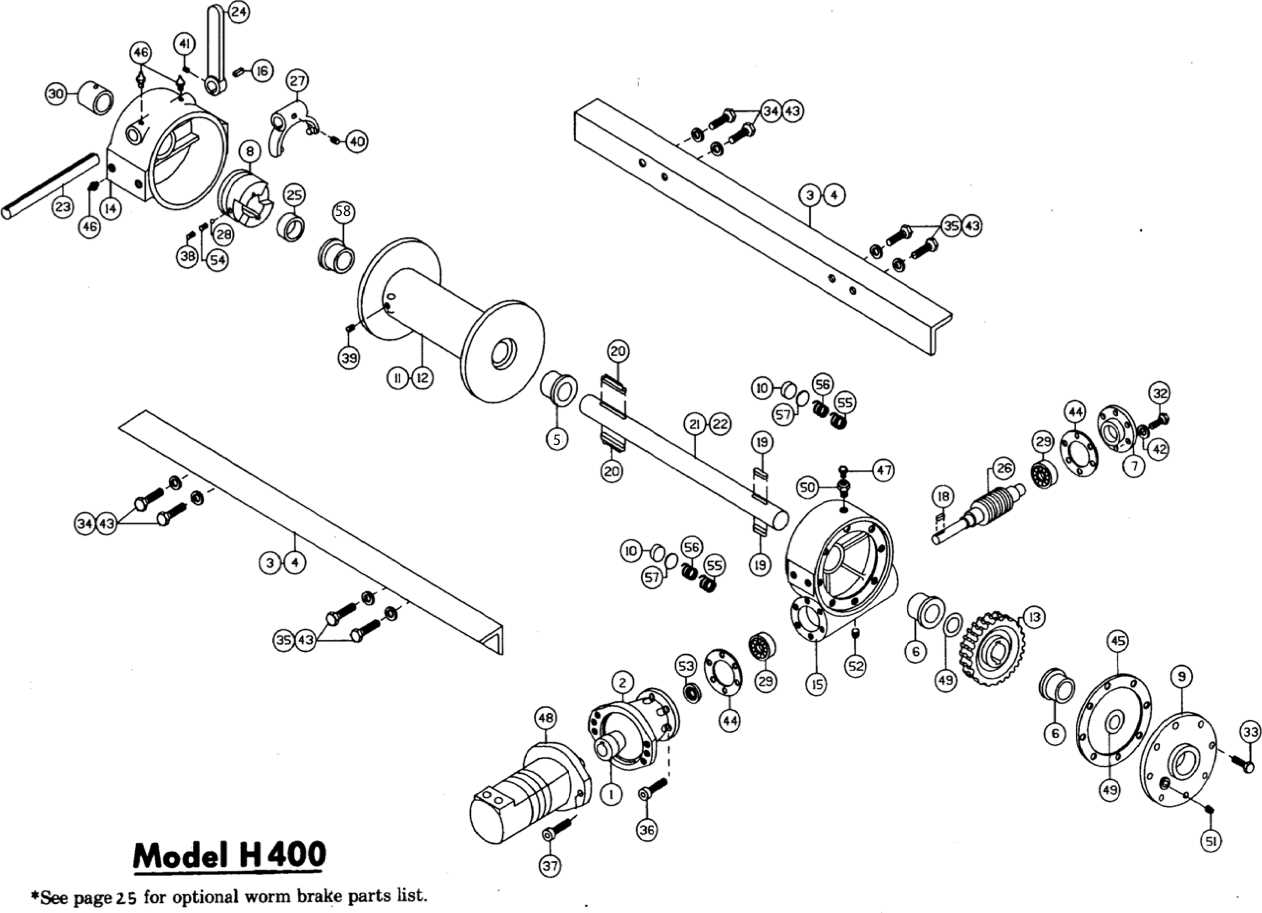

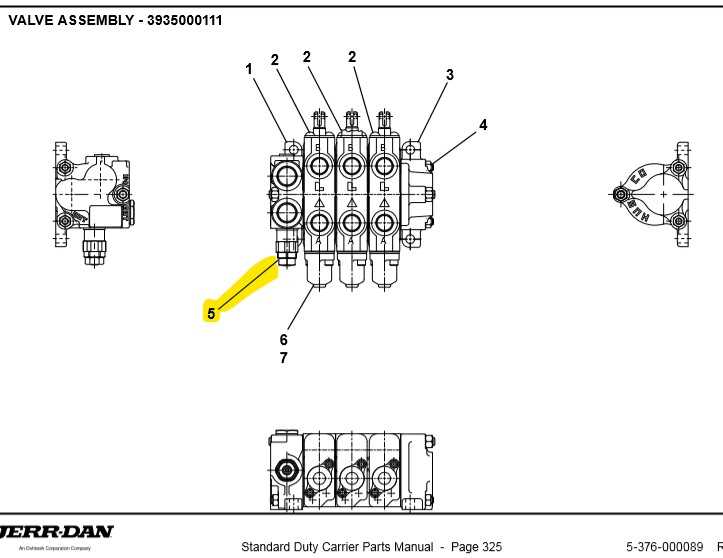

Common Components in Jerr-Dan Models

Understanding the essential elements found in various models is crucial for optimal performance and maintenance. Each unit comprises a range of components that work in harmony to ensure reliability and efficiency. From hydraulic systems to support structures, these features are designed to meet specific operational needs.

One prominent aspect is the hydraulic pump, which plays a vital role in powering the lifting mechanism. Coupled with robust cylinders, it enables smooth operation under heavy loads. Additionally, the chassis provides a sturdy foundation, enhancing stability during use.

Another key element is the control system, allowing operators to manage functions with precision. This includes electronic controls that facilitate quick adjustments and improve overall user experience. Lastly, accessories such as lighting and winches contribute to the versatility and safety of the unit.

How to Access Parts Diagrams Online

Finding the right schematics online can significantly enhance your repair and maintenance processes. With a variety of resources available, it’s crucial to know how to efficiently locate and utilize these visual aids to ensure optimal functionality of your equipment.

Step-by-Step Guide

- Identify the manufacturer and model of your equipment.

- Visit the official website or trusted distributors that provide schematics.

- Navigate to the support or resources section.

- Look for the option to view or download visual representations.

- Utilize search features for quick access by entering specific keywords.

Helpful Tips

- Bookmark reliable sites for future reference.

- Consider joining forums or communities for shared resources.

- Check for updates regularly to access the latest materials.

Tips for Effective Diagram Navigation

Navigating complex visual representations can be challenging. To enhance your experience and ensure you find the information you need quickly, consider implementing these practical strategies.

Utilize Search Functions

Many visual tools come equipped with search capabilities. Using keywords related to your inquiry can significantly reduce the time spent locating specific components.

Organize by Sections

Breaking down the visual layout into manageable segments can aid in easier comprehension. This allows you to focus on one area at a time without feeling overwhelmed.

| Tip | Description |

|---|---|

| Zoom In/Out | Adjust your view to focus on details or get a broader perspective. |

| Highlight Key Areas | Use color coding to mark important sections for quick reference. |

| Take Notes | Document your findings to track important information easily. |

Maintenance and Repair Considerations

Ensuring the longevity and efficiency of equipment requires a systematic approach to upkeep and servicing. Regular assessments and prompt attention to any signs of wear can significantly reduce the likelihood of costly breakdowns. A thorough understanding of the various components involved can aid in making informed decisions regarding maintenance and repair strategies.

When planning for maintenance, it’s crucial to establish a routine schedule that incorporates both preventative measures and reactive repairs. This can help in identifying potential issues before they escalate, thus enhancing overall operational reliability.

| Consideration | Description |

|---|---|

| Regular Inspections | Conduct frequent checks to identify any signs of wear or malfunction. |

| Quality Replacement | Use high-quality components to ensure optimal performance and compatibility. |

| Training | Ensure staff are well-trained in proper handling and maintenance procedures. |

| Documentation | Maintain detailed records of maintenance activities and repairs for future reference. |

By prioritizing these considerations, operators can enhance the efficiency and safety of their machinery, ultimately leading to improved operational success.

Upgrading Your Jerr-Dan Equipment

Enhancing your towing and recovery machinery can significantly improve performance and efficiency. Regularly updating components ensures that your equipment operates at its best, allowing for safer and more reliable service. Understanding the available options for enhancement is crucial for maximizing functionality and extending the lifespan of your machinery.

When considering upgrades, it’s essential to evaluate the specific needs of your operations. This may involve integrating advanced technology, improving structural elements, or simply replacing outdated mechanisms. Each modification should be aimed at enhancing capability and ensuring that your machinery meets current industry standards.

Additionally, consulting with professionals who specialize in machinery upgrades can provide valuable insights. They can recommend suitable enhancements tailored to your equipment type, ultimately helping you make informed decisions that align with your operational goals.

Investing in quality upgrades not only boosts performance but also contributes to long-term savings. By reducing maintenance costs and preventing potential breakdowns, you can keep your fleet running smoothly and efficiently. Prioritizing these enhancements is a strategic move that can yield significant benefits for your business.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential to ensure optimal performance and longevity. The marketplace is filled with options, but not all sellers provide high-quality items. It is crucial to identify reliable sources that guarantee the authenticity of the products you purchase.

Authorized Dealers

One of the most reliable ways to obtain genuine items is through authorized dealers. These establishments are recognized by manufacturers and offer a full range of certified products. They often have trained personnel who can assist you in selecting the right components and provide insights into proper maintenance.

Online Retailers

Another convenient option is to explore reputable online retailers. Many websites specialize in providing high-quality components, often with customer reviews and detailed descriptions. Ensure that the platform you choose has a return policy and clear contact information, as this adds an extra layer of trust.

Remember: always verify the authenticity of the components before making a purchase. Choosing genuine items will save you time and resources in the long run.

Frequently Asked Questions About Diagrams

This section aims to address common inquiries regarding visual representations used in technical contexts. Understanding these illustrations can enhance clarity and facilitate better comprehension of complex systems.

What Are the Benefits of Using Visual Representations?

Visual tools simplify complex information, making it easier to understand relationships and functions. They provide a clear overview, aiding both novices and experts in grasping essential concepts quickly.

How Can I Read These Visual Tools Effectively?

To interpret these illustrations effectively, familiarize yourself with common symbols and notations. Additionally, reviewing accompanying legends and descriptions can significantly enhance your understanding.

| Question | Answer |

|---|---|

| What types of illustrations exist? | Various types include flowcharts, schematics, and layouts, each serving distinct purposes. |

| Where can I find these resources? | Resources are often available in manuals, online databases, or manufacturer websites. |

| Can I create my own visuals? | Yes, many software tools allow users to create custom illustrations tailored to their needs. |