In the realm of horticultural tools, a reliable machine can make all the difference in cultivating a thriving garden. This section delves into the intricate elements that contribute to the functionality and efficiency of such equipment. By exploring the various constituents, one can gain insights into how each piece interacts to enhance performance and ease of use.

Identifying the specific elements of these machines is crucial for maintenance and optimization. Knowledge of these components allows users to troubleshoot issues, ensuring their equipment remains in top working condition. Furthermore, understanding the arrangement and role of each segment fosters a deeper appreciation of how these tools facilitate soil preparation.

For those interested in repairs or upgrades, a comprehensive overview of these essential features is invaluable. Recognizing the significance of each element not only aids in effective handling but also empowers gardeners to make informed decisions about their equipment. Ultimately, this knowledge paves the way for a more productive and enjoyable gardening experience.

Understanding Earthquake Vector Tiller Functionality

This section explores the inner workings of a popular gardening tool designed for soil cultivation. By examining its mechanisms, we can appreciate how various components contribute to its efficiency and effectiveness in tilling soil. Understanding these functions can enhance user experience and maintenance practices.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives the tilling action. |

| Tines | Break up and aerate the soil for better planting conditions. |

| Handle | Provides control and maneuverability during operation. |

| Transmission | Transfers power from the engine to the tines. |

| Chassis | Supports all components and provides stability during use. |

Key Components of Tiller Systems

Understanding the fundamental elements of these agricultural implements is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring efficient operation, aiding users in achieving their cultivation goals effectively.

Main Elements

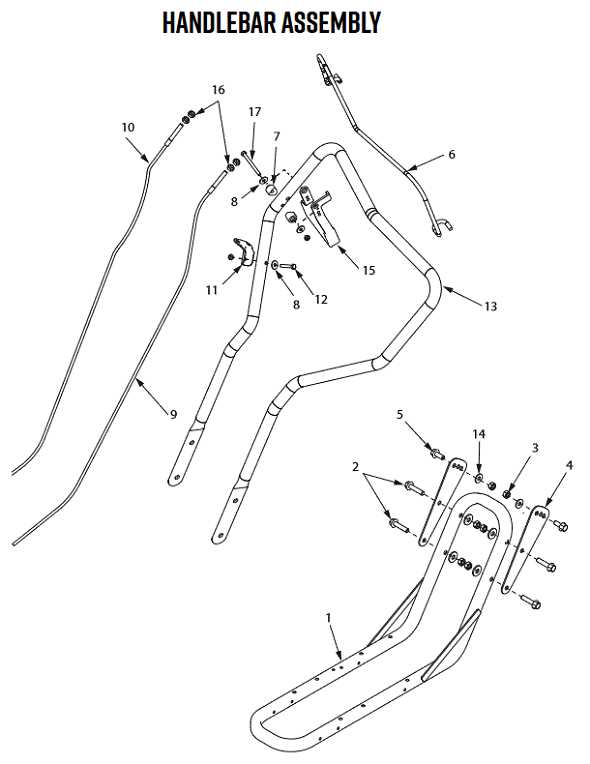

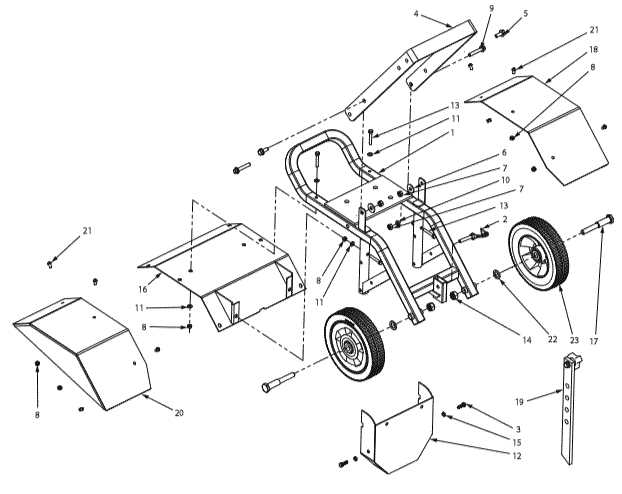

- Frame: The backbone of the system, providing stability and support.

- Engine: The power source that drives the entire mechanism, available in various types for different applications.

- Handles: Designed for ease of control, allowing the operator to maneuver effortlessly.

Additional Features

- Blades: Essential for soil cultivation, varying in size and shape for different soil types.

- Transmission: Transfers power from the engine to the working components, influencing speed and efficiency.

- Wheels: Facilitate movement across diverse terrains, ensuring stability and traction.

Each of these elements contributes to the overall functionality, making it imperative for users to be familiar with their characteristics and maintenance needs for optimal use.

Importance of Proper Maintenance

Regular upkeep is crucial for ensuring optimal performance and longevity of any machinery. Neglecting maintenance can lead to diminished efficiency, increased wear and tear, and ultimately, costly repairs. Adopting a routine care schedule not only enhances functionality but also promotes safety during operation.

Proactive attention to equipment can prevent unexpected breakdowns. By identifying and addressing minor issues before they escalate, operators can maintain productivity and reduce downtime. Timely inspections and adjustments are essential for preserving the integrity of the machinery.

Moreover, proper care can significantly enhance the overall value of the investment. Well-maintained equipment often retains its resale value and performs better over time, making maintenance not just a necessity, but a smart economic choice.

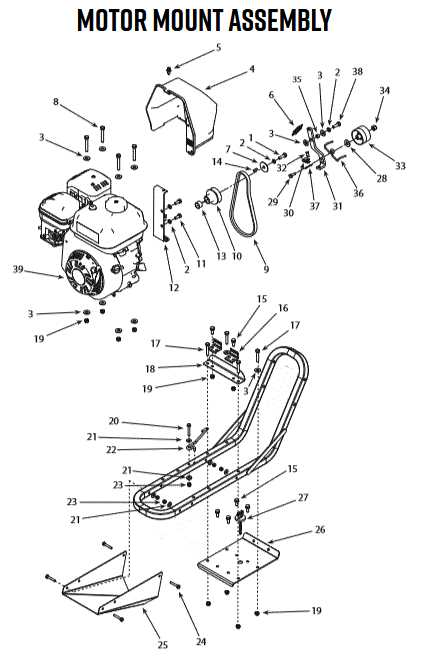

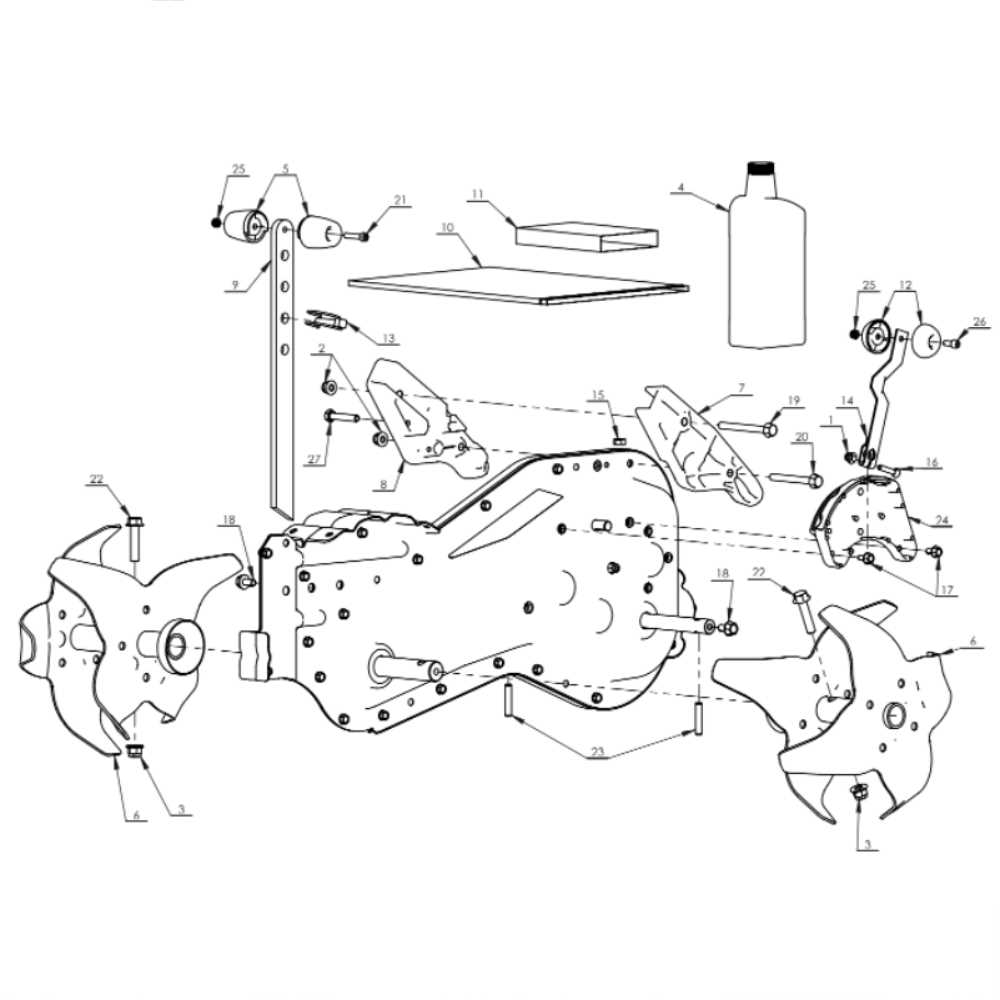

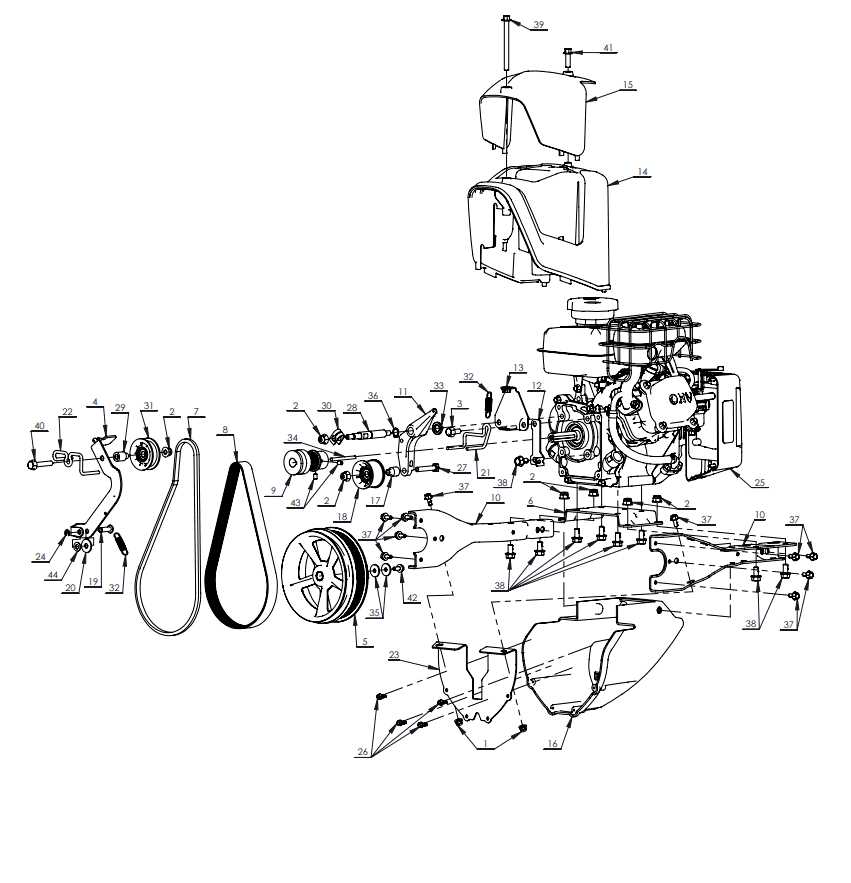

How to Read Tiller Diagrams

Understanding technical illustrations is crucial for efficient maintenance and operation of machinery. These visual representations provide essential information about various components and their interconnections, allowing users to grasp complex systems quickly.

Identifying Key Elements

Begin by familiarizing yourself with the main components depicted in the illustration. Look for labels and legends that explain each symbol and its function. Color coding often indicates different systems, making it easier to differentiate parts.

Interpreting Connections

Next, focus on the lines and arrows that demonstrate how elements interact. Directional arrows usually signify movement or flow, while connecting lines represent physical relationships. Understanding these connections is vital for troubleshooting and repairs.

Common Issues with Tiller Parts

Understanding the typical challenges that can arise with cultivation equipment is crucial for maintaining optimal performance. Various components can experience wear and tear, leading to operational inefficiencies and potential breakdowns.

One frequent concern is the deterioration of components due to exposure to harsh conditions. Corrosion can weaken metal parts, resulting in failure during use. Regular inspection and maintenance are essential to mitigate this issue.

Another common problem involves the misalignment of mechanisms, which can cause uneven performance. Proper calibration and adjustment can help ensure all elements work harmoniously, enhancing overall functionality.

Lastly, clogs can obstruct the machinery, leading to reduced efficiency and potential damage. Regular cleaning and checks can prevent these interruptions, ensuring smooth operation during cultivation tasks.

Choosing the Right Replacement Parts

Selecting the appropriate components for your machinery is essential for maintaining optimal performance and longevity. Quality and compatibility play a significant role in ensuring that your equipment operates smoothly and efficiently. Understanding the specifications and requirements will help you make informed decisions when sourcing these crucial elements.

Key Considerations

When looking for replacements, several factors should guide your selection process. Firstly, confirm compatibility with your model to avoid any operational issues. Secondly, assess the quality of materials, as this directly impacts durability and performance. Finally, consider reviews and recommendations to gauge the reliability of the components.

Comparison Table

| Factor | Importance | Recommended Action |

|---|---|---|

| Compatibility | High | Verify model specifications |

| Material Quality | High | Choose trusted brands |

| Reviews | Medium | Read user feedback |

Safety Tips for Tiller Operation

Operating agricultural machinery requires careful attention to safety to prevent accidents and injuries. Following proper guidelines ensures not only the operator’s well-being but also the longevity of the equipment and the efficiency of the task at hand.

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety guidelines.

- Wear Appropriate Gear: Use gloves, sturdy shoes, and safety goggles to protect yourself during operation.

- Inspect the Equipment: Before starting, check for any damages or loose components. Ensure all safety features are functioning properly.

- Clear the Area: Remove any obstacles or debris from the work area to prevent accidents.

- Maintain a Safe Distance: Keep bystanders, especially children and pets, at a safe distance while operating the machinery.

Adhering to these recommendations will help create a safer working environment and promote efficient handling of the equipment.

- Be Mindful of Your Surroundings: Stay alert to changing conditions and potential hazards in the environment.

- Start and Stop Safely: Always ensure the machine is completely stopped before making adjustments or repairs.

- Know Emergency Procedures: Familiarize yourself with emergency shutdown procedures in case of an unexpected situation.

By implementing these safety practices, operators can significantly reduce risks and enhance their productivity in agricultural tasks.

Comparing Different Tiller Models

This section aims to explore various cultivator designs, highlighting their unique features and benefits. Understanding these distinctions can aid in selecting the right equipment for specific gardening needs.

Key factors to consider when evaluating models include:

- Power source: gas vs. electric

- Weight and maneuverability

- Working width and depth

- Durability and construction materials

- Ease of maintenance

Below are some popular models compared on essential criteria:

- Model A

- Power: Gas

- Weight: 100 lbs

- Working width: 16 inches

- Model B

- Power: Electric

- Weight: 75 lbs

- Working width: 12 inches

- Model C

- Power: Gas

- Weight: 120 lbs

- Working width: 18 inches

Each model presents its own advantages, making them suitable for different tasks and preferences. Delving into specifications and user reviews can lead to the ultimate choice for your gardening projects.

Enhancing Performance with Upgrades

Improving machinery efficiency can lead to increased productivity and better results. By incorporating advanced components and innovative technologies, users can significantly enhance the overall functionality of their equipment.

Key Benefits of Upgrading

- Increased power output

- Improved fuel efficiency

- Enhanced durability and lifespan

- Better adaptability to various tasks

Popular Upgrade Options

- High-performance engines for greater torque

- Advanced transmission systems for smoother operation

- Ergonomic handles and controls for user comfort

- Innovative attachments for versatility in usage

By strategically selecting upgrades, users can delve into a realm of superior performance, ultimately transforming their experience and results in the field.