In the world of horticultural equipment, having a clear understanding of the various components and their relationships is essential for effective maintenance and repairs. Knowledge of how each element interacts within the larger system can greatly enhance the longevity and performance of your machinery. By visualizing these connections, operators can troubleshoot issues more efficiently and ensure their equipment runs smoothly.

Illustrative representations of machinery components serve as invaluable tools for enthusiasts and professionals alike. These visual guides provide a comprehensive overview of how each piece fits together, making it easier to identify parts that require attention or replacement. Such resources are especially beneficial when tackling complex repairs or upgrades, where clarity is paramount.

For those seeking to deepen their understanding of their gardening tools, exploring these graphical representations not only demystifies the assembly but also empowers users to take proactive measures in their upkeep. A solid grasp of the underlying structure can lead to more informed decisions, ultimately contributing to the overall efficiency and effectiveness of the equipment.

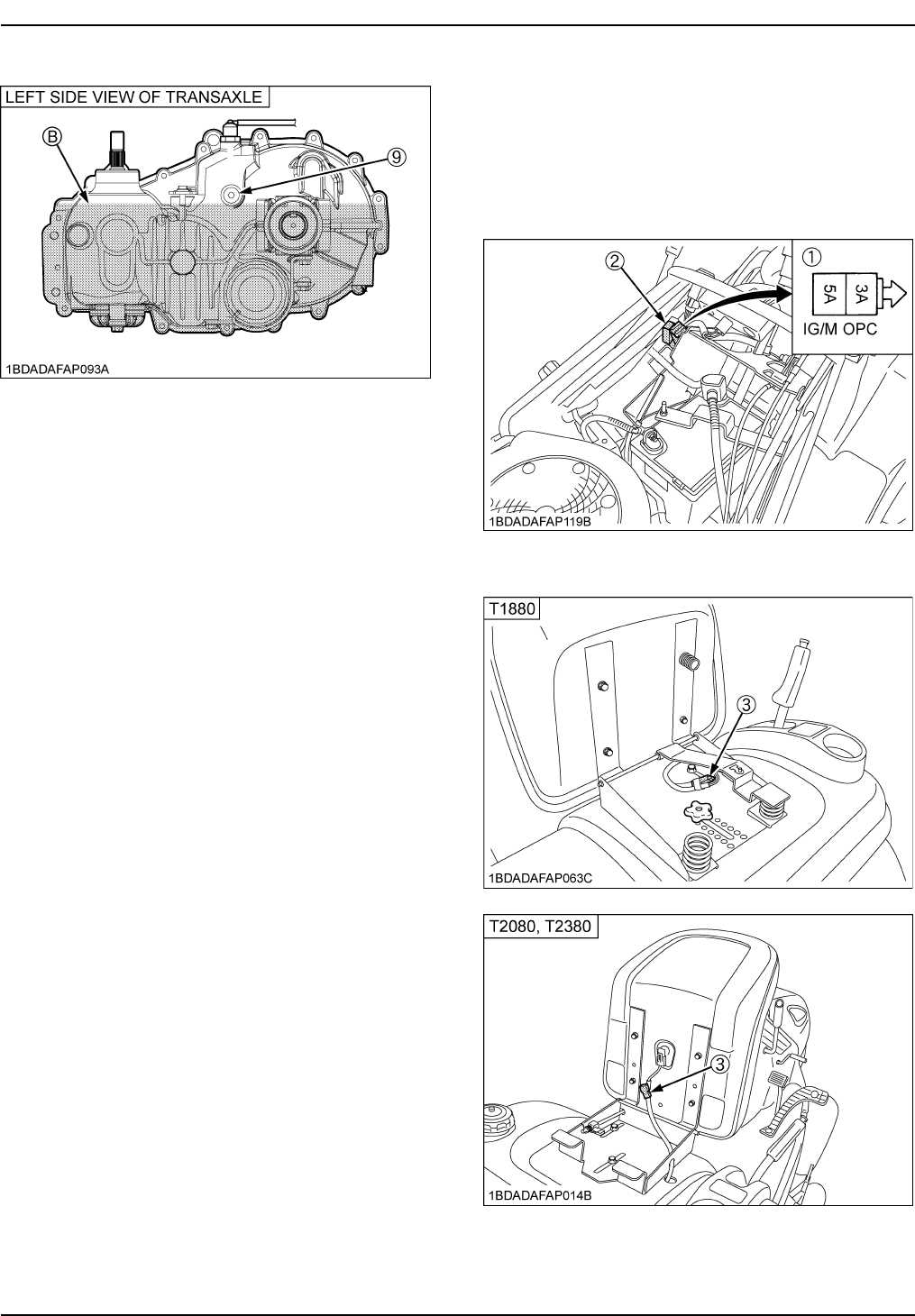

Understanding Kubota T1880 Components

Gaining insight into the various elements of a lawn care machine is essential for optimal performance and maintenance. Each component plays a vital role, contributing to the overall efficiency and functionality of the equipment.

Key Elements to Consider

- Engine: The heart of the machine, providing necessary power.

- Transmission: Essential for speed control and movement.

- Deck: Influences cutting efficiency and grass handling.

Maintenance and Upkeep

- Regular checks of fluid levels to ensure smooth operation.

- Cleaning air filters to enhance engine performance.

- Inspecting belts and blades for wear and tear.

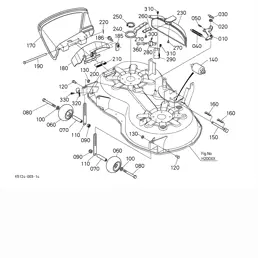

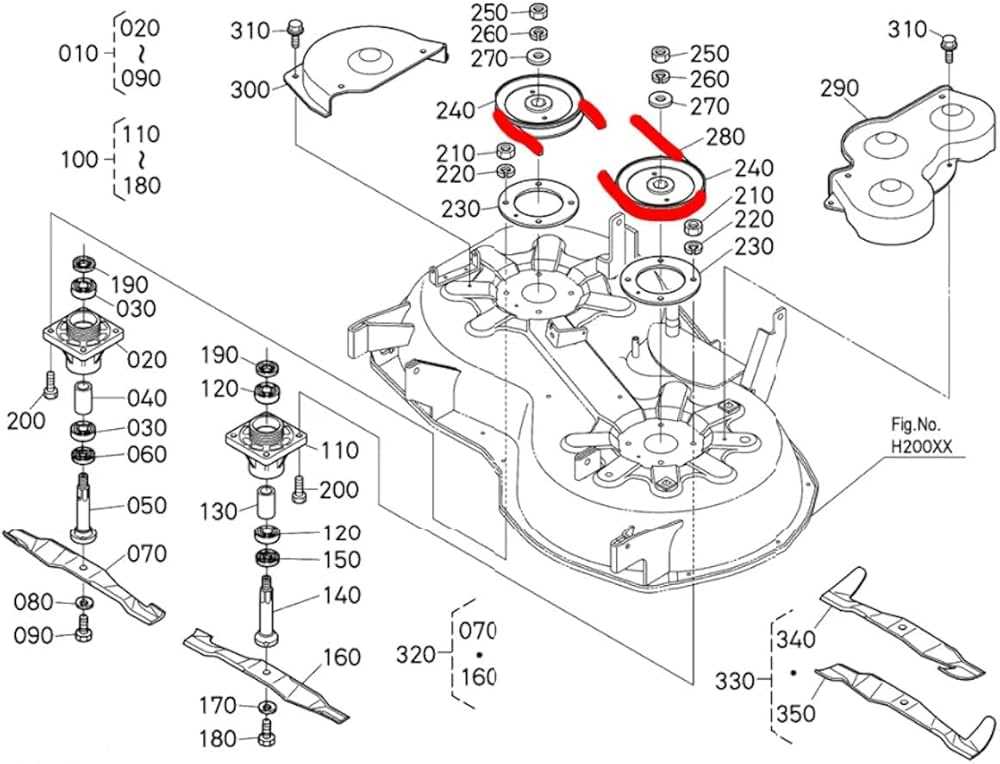

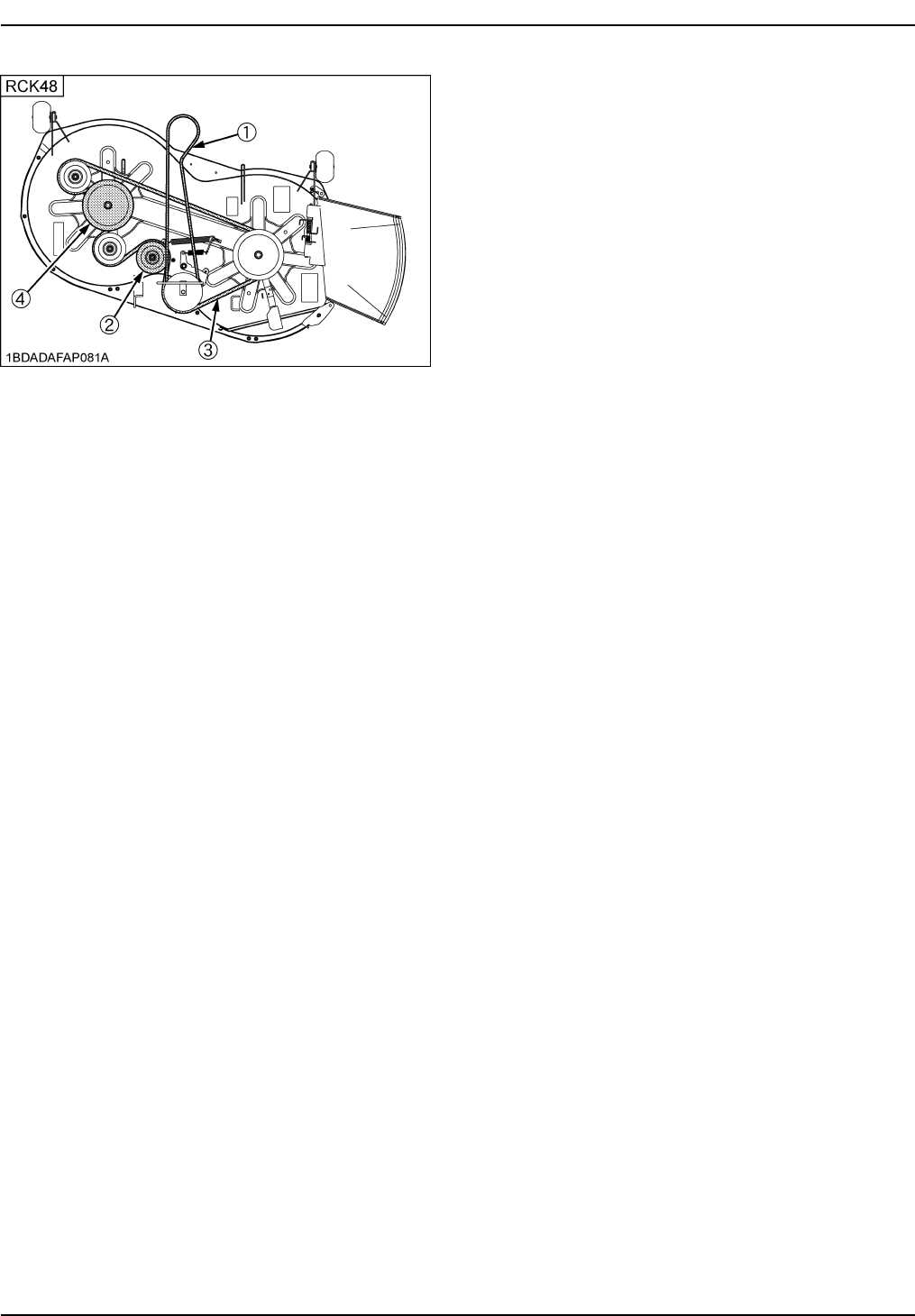

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations play a significant role in simplifying the process of identifying individual elements and their functions. These illustrations not only facilitate troubleshooting but also enhance the overall efficiency of the maintenance workflow.

Here are several key reasons why these visual aids are essential:

- Clarity: Detailed visuals provide a clear overview of the assembly, making it easier to locate specific components.

- Efficiency: With a well-structured representation, technicians can quickly find and replace faulty parts, reducing downtime.

- Accuracy: Illustrations help ensure that the correct components are identified, minimizing the risk of errors during repairs.

- Training: New team members can learn about the machinery more effectively through these visual tools, fostering a better understanding of each part’s role.

- Documentation: Visual references serve as valuable documentation for future repairs and modifications, aiding in consistent maintenance practices.

In summary, utilizing visual references for components enhances the understanding, efficiency, and accuracy of maintenance tasks, ultimately leading to improved machinery performance and longevity.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effectively maintaining and repairing machinery. These visuals provide a detailed overview of components, their arrangement, and connections. By familiarizing yourself with these representations, you can identify parts, locate replacements, and streamline your repair process.

When approaching an assembly illustration, consider the following elements:

| Element | Description |

|---|---|

| Legend | A guide that explains symbols used within the illustration, such as lines, arrows, and shaded areas. |

| Component Numbers | Identifiers assigned to each part, which correspond to lists that specify details like part names and specifications. |

| Connection Points | Indications of how components fit together or are connected, often represented by lines or arrows. |

| Views | Different angles or sections of the assembly that provide clarity on how parts interact. |

| Notes | Additional information that may highlight special instructions, warnings, or maintenance tips related to specific components. |

By taking the time to carefully analyze these components, you can enhance your understanding of the assembly, ensuring efficient repairs and proper maintenance.

Common Issues with T1880 Parts

When dealing with the components of outdoor machinery, several common challenges can arise that affect performance and longevity. Understanding these issues is crucial for maintaining optimal function and ensuring efficient operation over time. Many users encounter various difficulties that stem from wear and tear, improper installation, or environmental factors.

Frequent Wear and Tear

One of the primary concerns is the gradual deterioration of certain elements due to regular use. Parts that experience constant friction, such as belts and blades, may require more frequent replacements. Regular inspections can help identify signs of wear early, allowing for timely interventions to prevent more significant problems down the line.

Installation and Alignment Issues

Another prevalent issue involves the incorrect installation of components, which can lead to misalignment and operational inefficiencies. Proper alignment is essential for ensuring that all parts work in harmony, reducing strain and prolonging their lifespan. It is advisable to refer to manufacturer guidelines or seek professional assistance when replacing or adjusting critical components.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a daunting task, yet it is essential for maintaining optimal performance. Fortunately, there are numerous avenues to explore when seeking high-quality replacements. Whether you are looking for specific items or general supplies, understanding your options can streamline the process.

Online Retailers

One of the most convenient methods to locate essential components is through online retailers. Numerous websites specialize in agricultural equipment and offer a wide selection of items at competitive prices. User reviews and detailed descriptions can help guide your purchasing decisions.

Local Dealers and Shops

Visiting local dealerships or specialized shops can also yield excellent results. These establishments often provide personalized service and expert advice, ensuring you find the right fit for your needs. Building relationships with local suppliers can lead to better deals and timely access to necessary items.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires a commitment to regular upkeep and preventive care. By adhering to specific maintenance practices, you can extend the lifespan of your machinery and avoid costly repairs. This section outlines essential strategies to keep your equipment running smoothly for years to come.

First and foremost, regular cleaning is crucial. Debris, dirt, and grass clippings can accumulate and hinder performance. Make it a habit to inspect and clean your machine after each use. Pay particular attention to the engine area, air filters, and any cooling vents.

Secondly, routine checks of fluid levels are vital. This includes oil, fuel, and hydraulic fluids. Keeping these at optimal levels ensures efficient operation and prevents damage. Consider changing the oil at recommended intervals to maintain engine health.

Another important aspect is sharpening and maintaining blades. Dull blades can stress the engine and lead to uneven cuts. Regularly inspect and sharpen them to enhance performance and reduce strain on the equipment.

Lastly, store your machinery properly when not in use. A dry, sheltered space protects it from the elements and reduces the risk of rust and corrosion. Implementing these maintenance practices will contribute significantly to the longevity of your equipment.

Comparing T1880 with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. Understanding these variations can aid in making an informed decision based on individual needs and preferences.

Performance Metrics

When evaluating different machines, performance metrics such as engine power, cutting width, and speed are crucial. The discussed model boasts a robust engine that often outperforms its rivals, delivering an ultimate mowing experience. Its efficiency in tackling various terrains sets it apart, providing users with both power and precision.

Features and Usability

Innovative features play a significant role in usability. While some models offer basic functionalities, the one in focus includes advanced options like ergonomic controls and enhanced maneuverability. These characteristics not only improve user comfort but also ensure that tasks are completed efficiently and effectively, giving it an edge over competitors.

Upgrades and Modifications Available

Enhancing performance and functionality is essential for maximizing the potential of your equipment. Various upgrades and modifications can significantly improve efficiency, durability, and overall user experience.

- Engine enhancements for increased power and torque

- Transmission upgrades for smoother operation

- Improved suspension systems for better stability

- Aftermarket attachments for added versatility

- Custom seating options for enhanced comfort

Each modification can be tailored to suit specific needs, allowing users to delve into the ultimate setup for their unique applications.