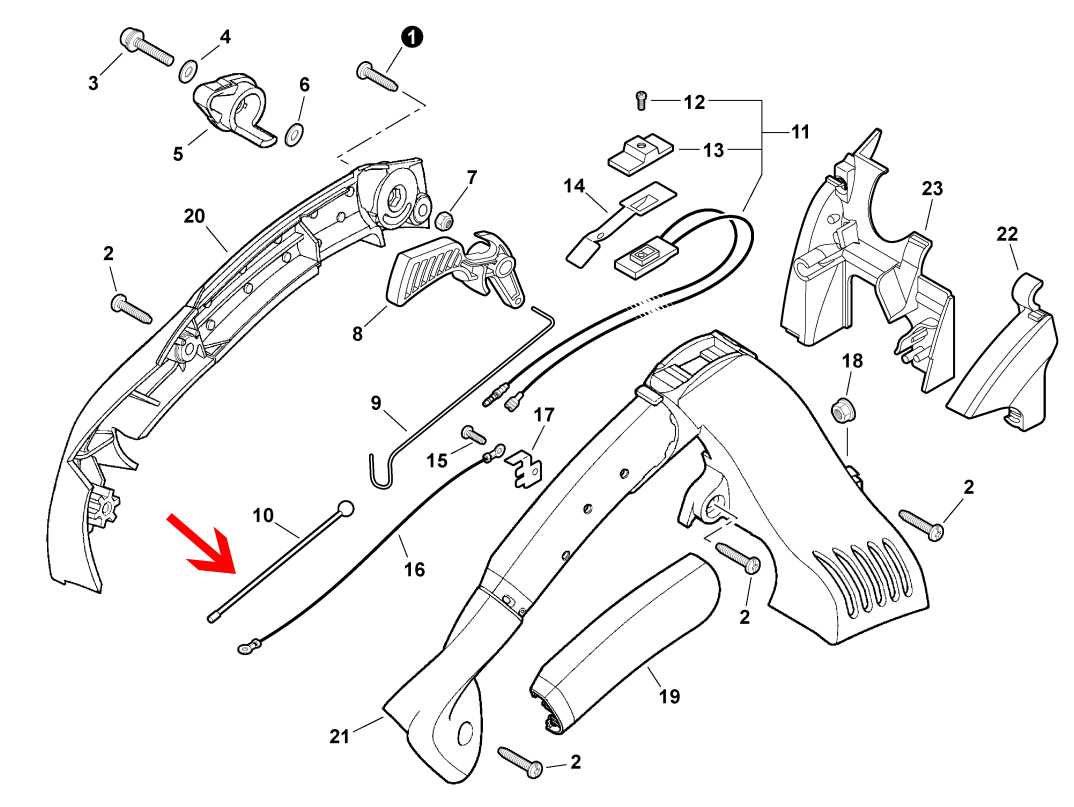

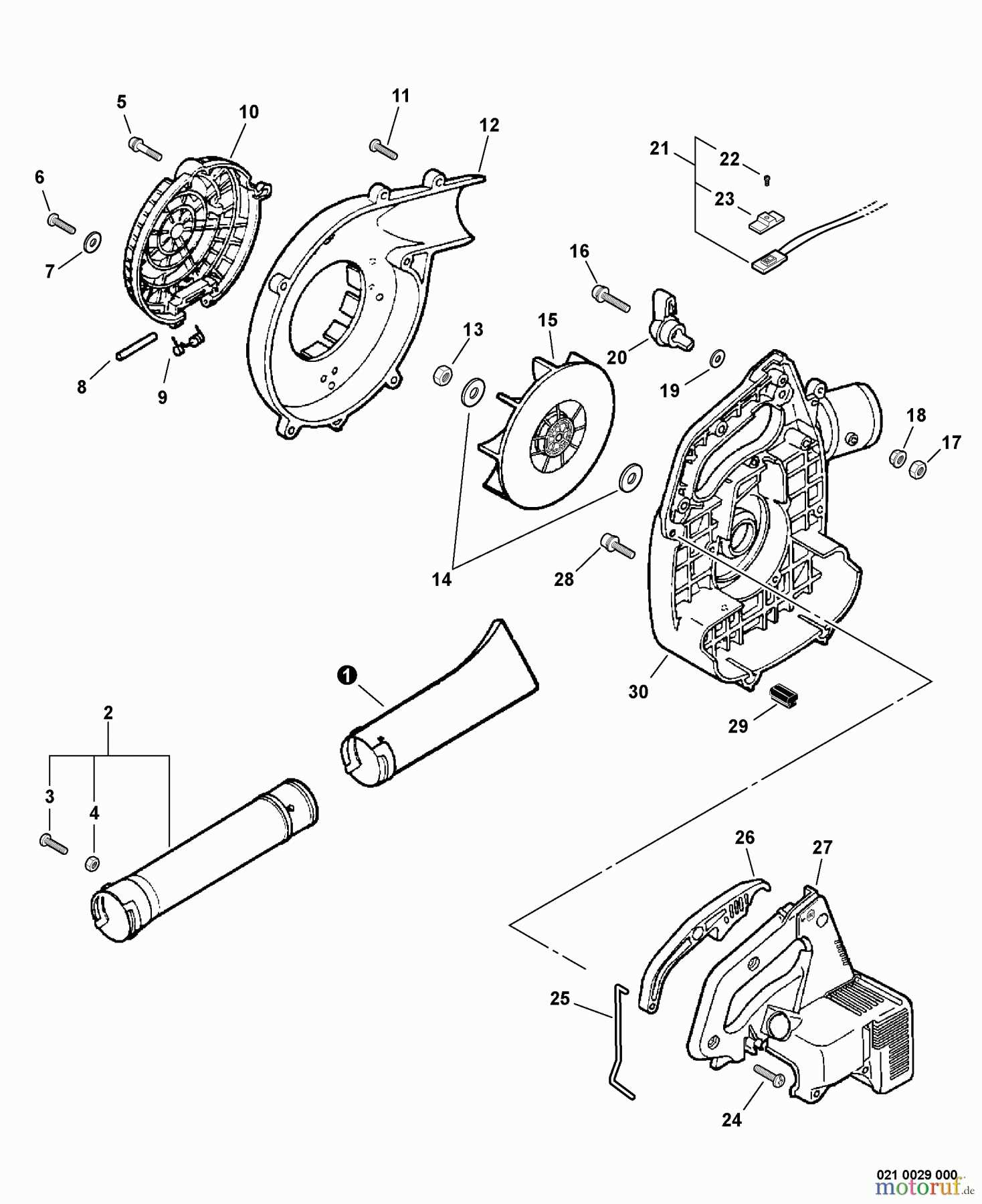

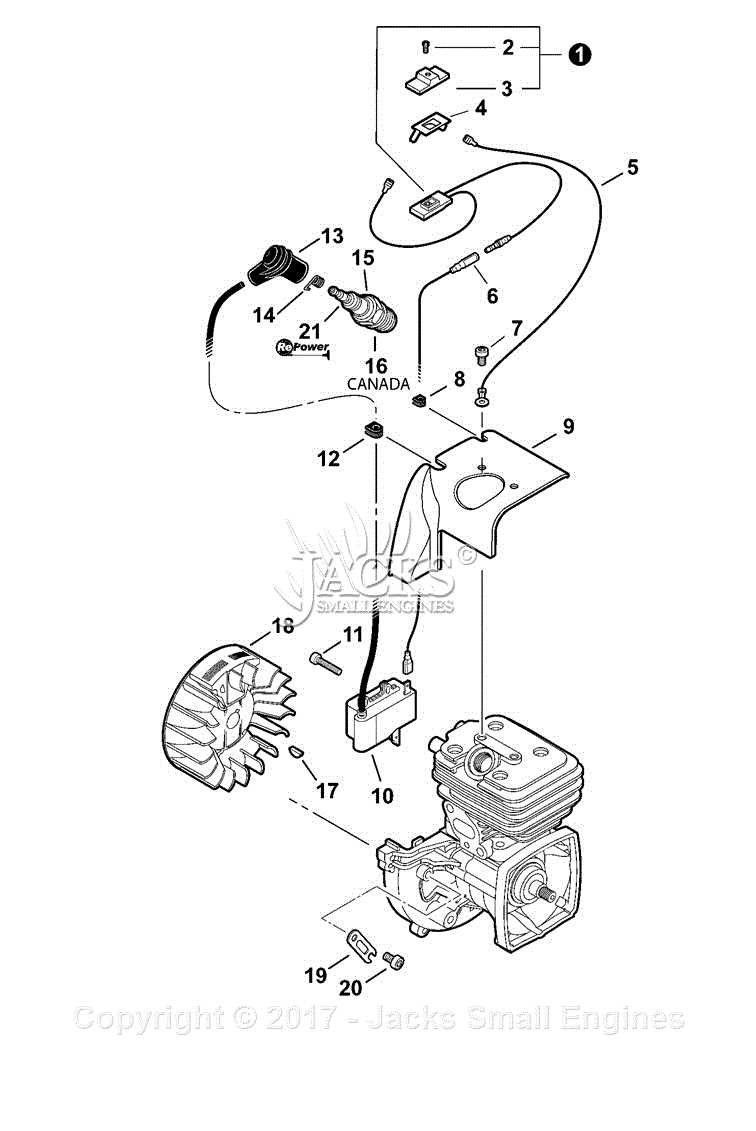

Maintaining outdoor machinery can be a complex task, particularly when it comes to grasping the intricate relationship between its various elements. A clear representation of the components is essential for anyone looking to troubleshoot or enhance performance. Visual aids play a significant role in simplifying this process, allowing users to identify each part’s function and importance.

By analyzing a detailed representation of the unit, individuals can gain valuable insights into the assembly and disassembly of its parts. This knowledge not only fosters a deeper understanding but also empowers users to perform repairs and upgrades with confidence. Engaging with such illustrations can transform the way one approaches maintenance tasks.

Whether you’re an experienced technician or a novice, having access to well-structured visuals can significantly enhance your ability to manage equipment efficiently. As you delve into the specifics of your machinery, you’ll find that familiarity with its individual components leads to greater operational success and longevity.

Understanding Echo PB-250 Components

Grasping the intricacies of a specific machine involves familiarizing oneself with its essential elements. Each component plays a crucial role in the overall functionality and efficiency of the device.

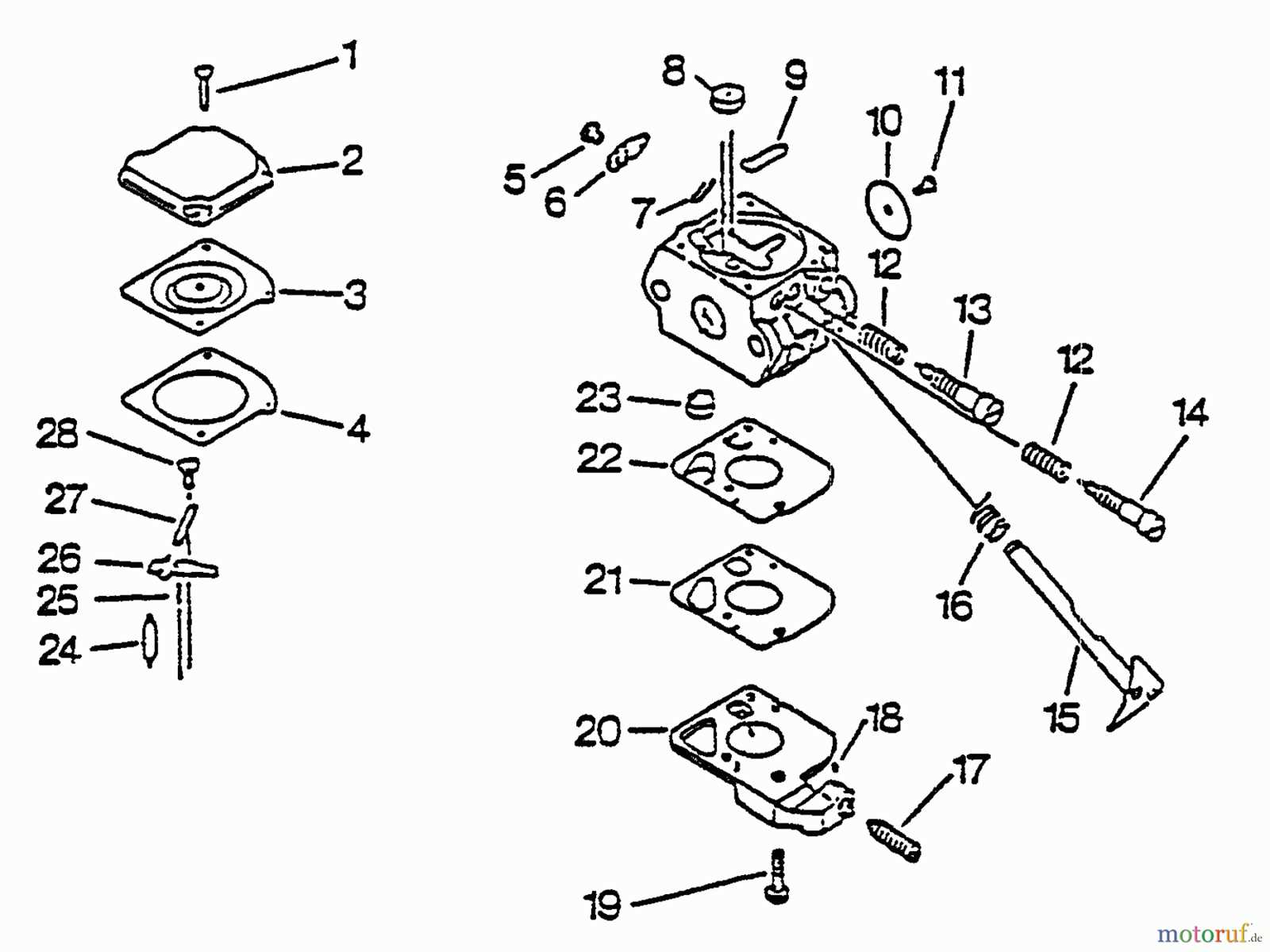

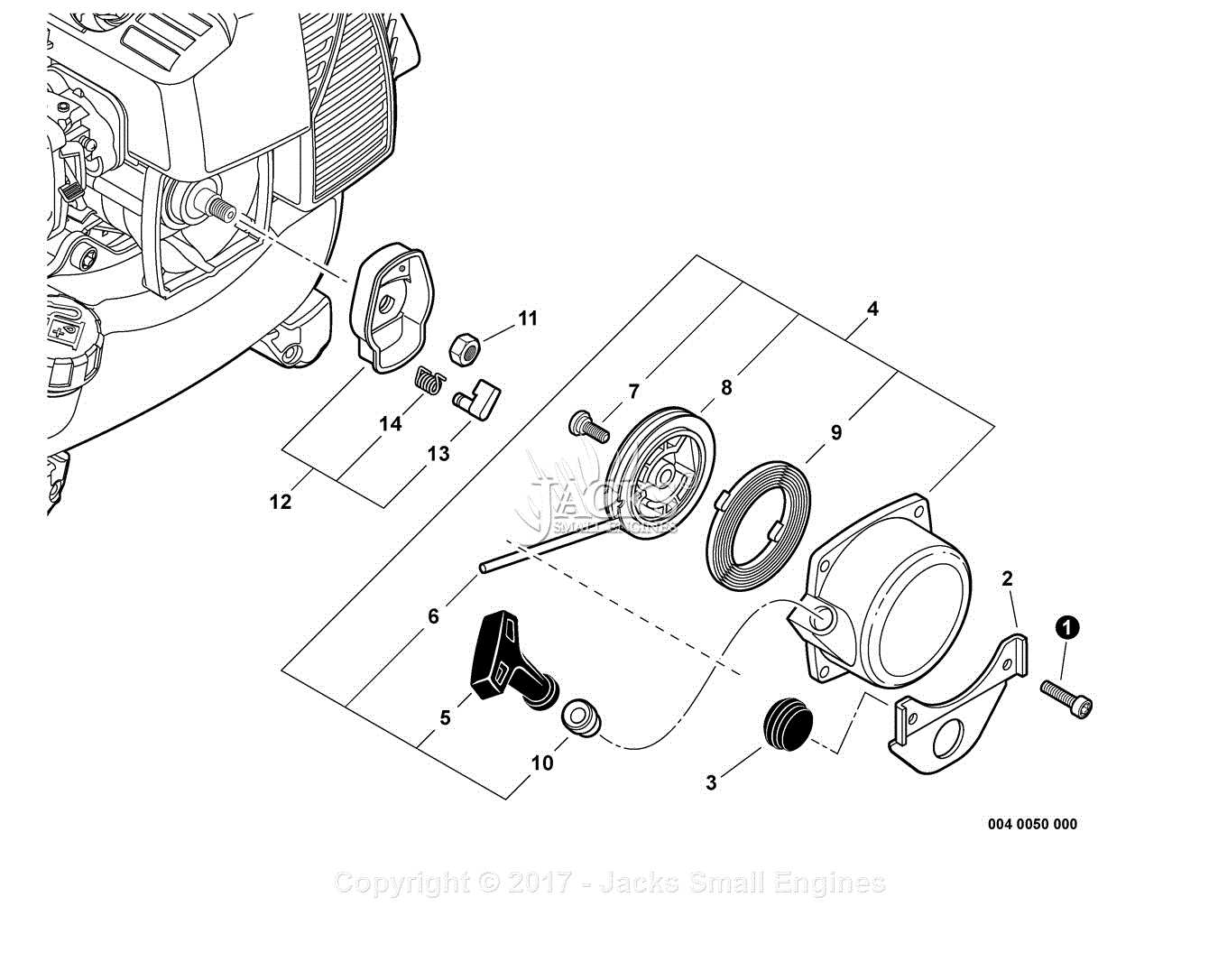

Here are the key categories of components to consider:

- Power System: This includes the engine and associated parts that drive the machine.

- Control Mechanism: Controls allow users to operate and manage the equipment effectively.

- Fuel Delivery: This system ensures the engine receives the right amount of fuel for optimal performance.

- Exhaust System: Essential for expelling gases produced during operation.

- Body and Frame: The structural components that house all the machinery.

Understanding these categories will ultimately aid in maintenance and troubleshooting, ensuring the longevity and efficiency of the equipment.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations serve as invaluable tools, enabling users to identify, locate, and comprehend the functionality of each individual element. This clarity is essential for both novice and experienced technicians, facilitating quicker troubleshooting and informed decision-making.

Moreover, these illustrations enhance the learning process, allowing users to delve deeper into the mechanics of their equipment. With a comprehensive visual guide, individuals can more easily grasp the relationships between various parts, ultimately leading to improved operational knowledge and skill.

Additionally, access to accurate schematics ensures that replacements are correctly sourced and fitted, minimizing downtime and maximizing productivity. In essence, these resources are fundamental for anyone seeking to maintain their equipment in peak condition.

Common Issues with Echo PB-250

This section explores frequent challenges users encounter with a specific model of handheld blower, focusing on performance and maintenance. Identifying these issues can significantly enhance user experience and equipment longevity.

- Starting Problems: Difficulty in initiating the blower is a common complaint, often linked to fuel issues or spark plug malfunction.

- Power Loss: Users may notice a decrease in performance, typically caused by clogged air filters or fuel lines.

- Excessive Vibration: An increase in vibration can indicate worn components or imbalances in the rotor.

- Overheating: Machines may overheat due to inadequate ventilation or prolonged use without breaks.

- Fuel Leaks: Leaks can arise from damaged fuel lines or improperly sealed connections, leading to efficiency loss.

Addressing these issues promptly can lead to improved functionality and extended lifespan of the equipment.

Where to Find Replacement Parts

When seeking components for maintenance or repair, it’s essential to know the best resources available. From authorized dealers to online marketplaces, various options cater to your needs and ensure that you find quality items for your equipment.

Authorized Dealers

Visiting an official retailer guarantees authentic replacements that meet the manufacturer’s standards. These dealers often have knowledgeable staff who can assist you in identifying the correct components for your machinery.

Online Marketplaces

The internet offers a vast selection of suppliers, making it easy to browse and compare products. Popular e-commerce platforms provide user reviews, which can guide you in selecting reliable options while ensuring competitive pricing.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment efficiently and effectively. By following the outlined procedures, you can diagnose issues, replace faulty components, and ensure optimal performance. Each step is designed to guide you through the repair process with clarity and precision.

Preparation

- Gather all necessary tools: screwdrivers, wrenches, and replacement components.

- Find a clean, well-lit workspace to facilitate your repair.

- Review the manufacturer’s manual for specific details on your model.

Repair Process

- Begin by disconnecting the power source to prevent any accidents.

- Carefully remove the outer casing to access internal parts.

- Identify the malfunctioning component by visually inspecting for wear or damage.

- Replace the faulty part with a new one, ensuring a secure fit.

- Reassemble the casing, making sure all screws are tightened properly.

- Reconnect the power and test the equipment to verify successful repair.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan of your equipment. Implementing proper care practices can significantly enhance performance and reduce the likelihood of breakdowns. By following a systematic approach, you can ensure that your tools remain efficient and reliable for years to come.

| Tip | Description |

|---|---|

| Clean After Use | Remove debris and dirt to prevent clogging and corrosion. |

| Inspect Regularly | Check for wear and tear; replace any damaged components promptly. |

| Lubricate Moving Parts | Use appropriate lubricants to ensure smooth operation. |

| Store Properly | Keep in a dry, safe location to avoid environmental damage. |

| Follow Manufacturer Guidelines | Adhere to recommended maintenance schedules for optimal performance. |

Identifying Parts by Model Number

Understanding the significance of model numbers is crucial for accurately recognizing components of any equipment. Each identifier serves as a unique key, enabling users to pinpoint specific elements and ensure compatibility. By leveraging these numerical codes, individuals can streamline the process of finding and replacing necessary items, enhancing overall functionality.

Begin by locating the model number, typically found on the equipment itself, often near the engine or on a label. This number provides essential information about the specifications and design, making it easier to reference in manuals or online resources. Researching the model number in trusted databases or retailers can yield detailed descriptions of each component, including their respective roles and compatibility with various models.

Finally, cross-referencing the model number with manufacturer documentation or online platforms can reveal insights into part availability and installation procedures. This meticulous approach not only saves time but also ensures that replacements are executed seamlessly, maintaining the equipment’s performance and longevity.

Tools Needed for Repairs

When it comes to maintaining and fixing equipment, having the right instruments is crucial for efficiency and effectiveness. A well-prepared toolkit not only simplifies the process but also enhances the overall quality of the repair work. Understanding which tools are essential can save time and effort.

Essential Instruments

Basic tools like screwdrivers, wrenches, and pliers form the foundation of any repair endeavor. Precision tools, such as torque wrenches and specialty bits, may also be necessary for more intricate tasks. Ensuring you have the correct size and type for each job will streamline the entire procedure.

Safety Equipment

Alongside standard instruments, protective gear is paramount. Gloves, goggles, and face shields protect against potential hazards, allowing you to work confidently. Investing in safety equipment is as important as having the right tools, ensuring that every repair is performed without risk of injury.

Frequently Asked Questions About Repairs

When it comes to maintenance and restoration of outdoor equipment, many users have common inquiries regarding the processes and best practices. Understanding these questions can significantly enhance your repair experience and ensure the longevity of your tools.

What are the most common issues faced during repairs?

Users frequently encounter problems such as wear and tear on components, fuel system malfunctions, and ignition troubles. Addressing these issues promptly can prevent further damage and improve overall performance.

How can I identify the right components for replacement?

To ensure proper replacements, consult the user manual for your device, which often includes detailed information on specifications. Additionally, using manufacturer resources or trusted online platforms can help you pinpoint the exact parts needed. Investing time in research will lead to the ultimate success of your repairs.